Method for producing seamless steel pipe for producing gas cylinder with heavy caliber for hauled vehicle

A technology for high-pressure gas cylinders and seamless steel pipes, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve problems such as difficult production, and achieve the effects of low cost, simple process and large output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

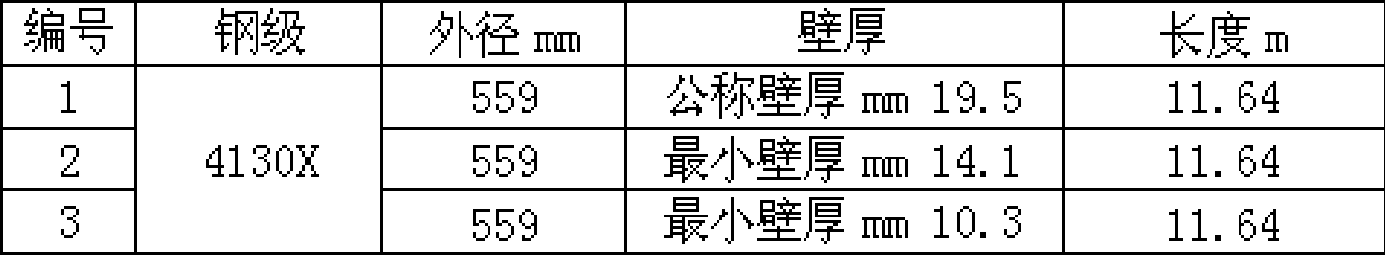

[0031] 1. The steel pipe specifications and steel types required to be prepared,

[0032] The types of steel pipes prepared according to the embodiment of the present invention are required, and the specific indexes are shown in Table 1.

[0033] Table 1

[0034]

[0035] Note: The steel grade is 4130 in the ASTM A519 standard.

[0036] Nominal Wall Thickness: Designated for design, this use is distinguished from actual wall thickness, which may fluctuate above and below the nominal.

[0037] Minimum Wall Thickness: Specifies the minimum wall thickness used for design, this usage is to be distinguished from the actual wall thickness, which may fluctuate above the minimum wall thickness.

[0038] Usually users can order in one of the two forms of nominal wall thickness or minimum wall thickness.

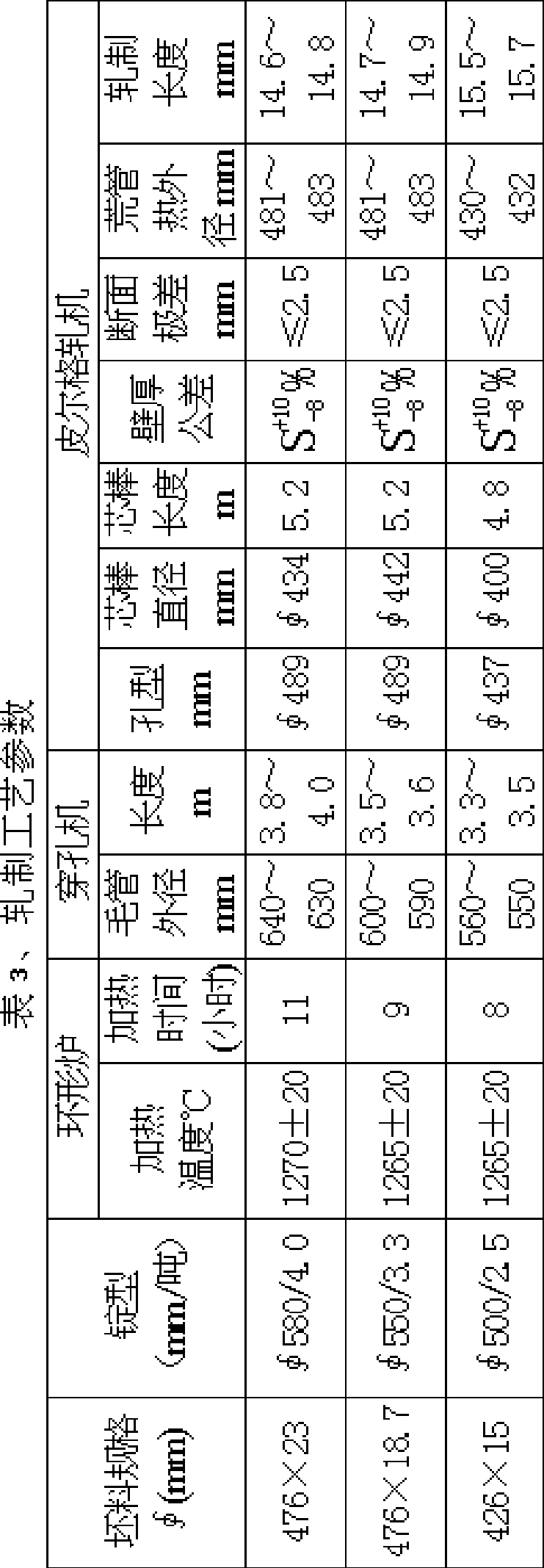

[0039] 2. Production process:

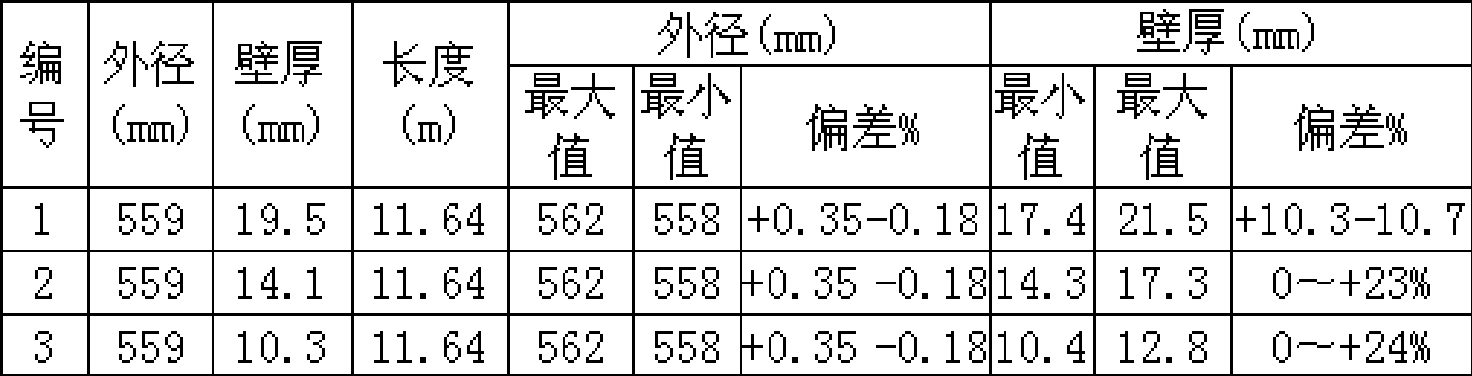

[0040] (1) Large-section round corrugated steel ingot smelted by LF refining furnace + VD vacuum treatment; see Table 2.

[0041] Table 2

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com