Patents

Literature

109results about How to "Suitable for large industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

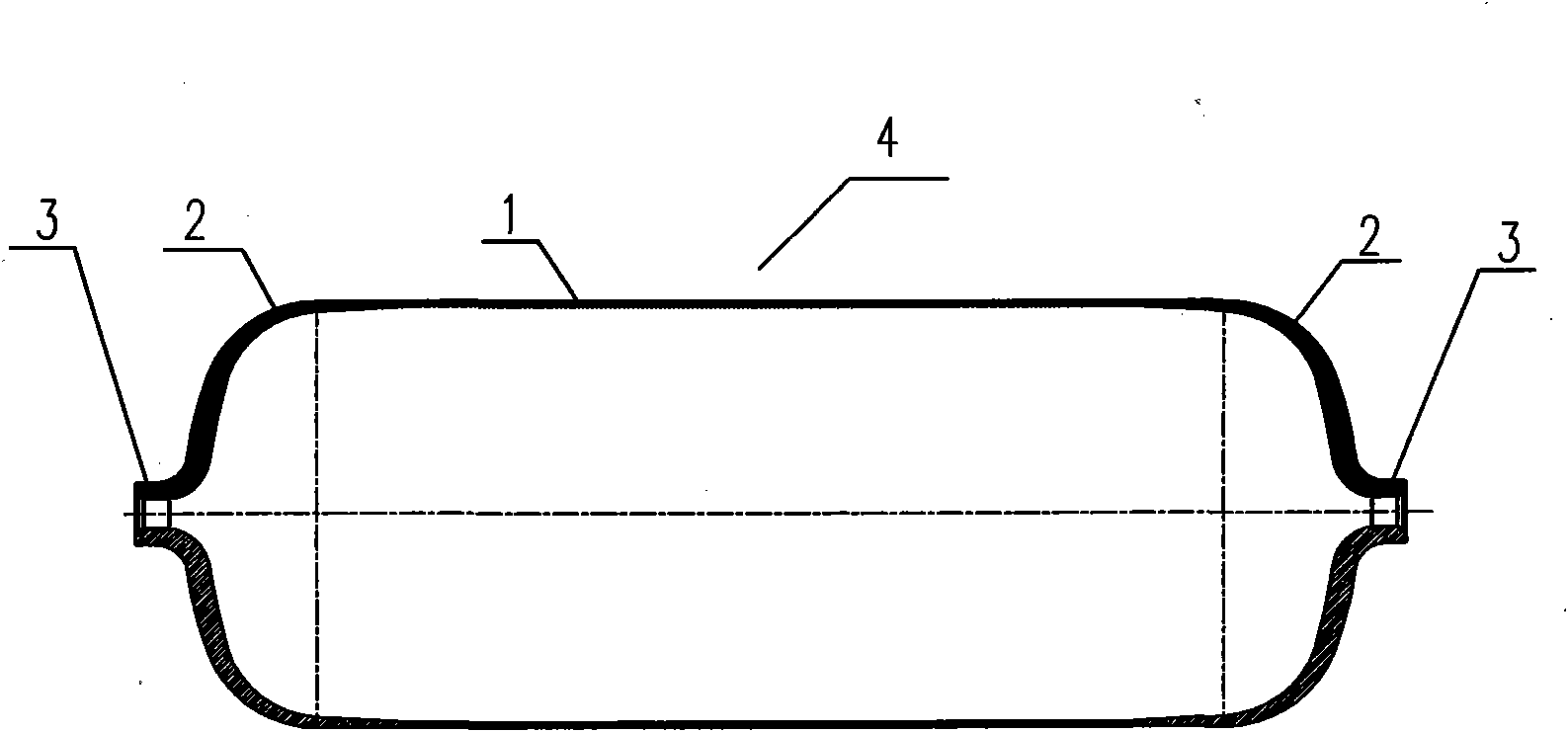

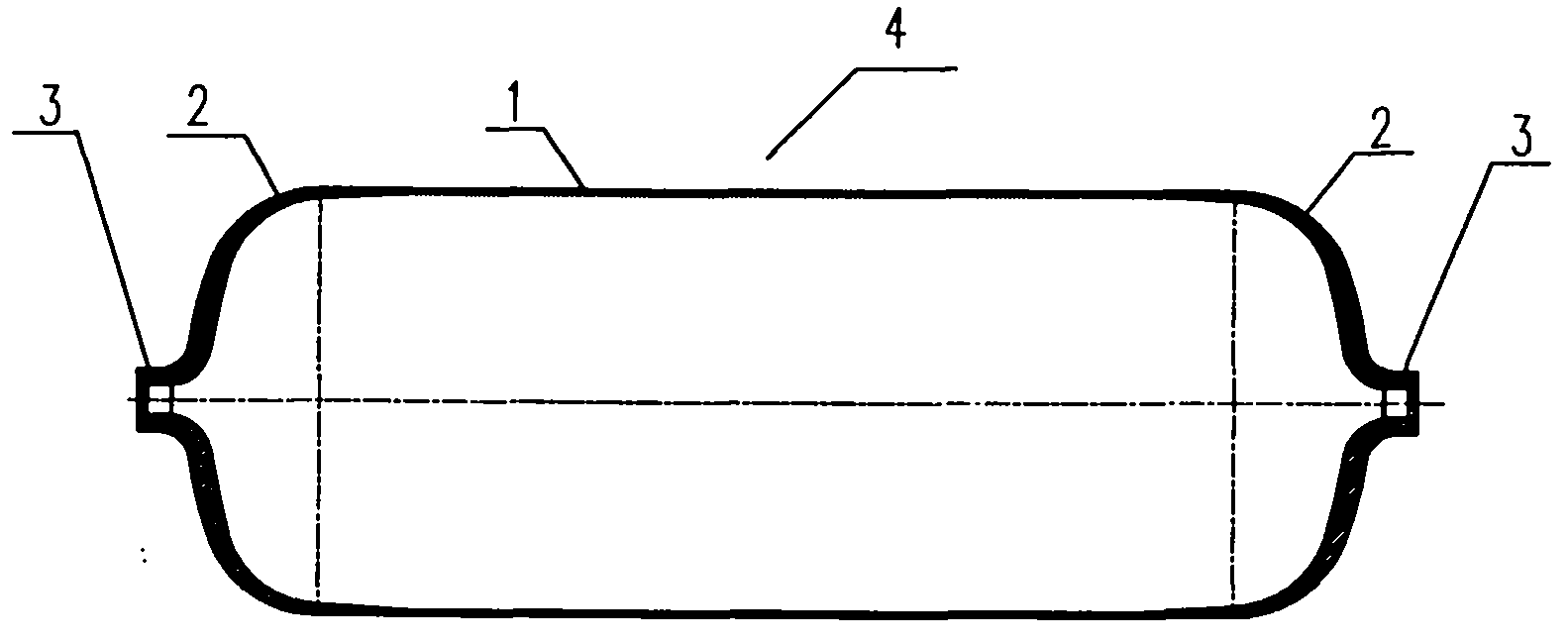

Method for manufacturing aluminum liner of vehicular composite cylinder

The invention discloses a method for manufacturing an aluminum liner of a vehicular composite cylinder, which is used for manufacturing the aluminum liner of the vehicular composite cylinder. The aluminum liner consists of a thin-walled cylinder body of the aluminum liner, an end enclosure gradually thickening part and an opening part. The aluminum liner is manufactured by adopting a method of reducing the wall thickness of a thick-wall aluminum pipe by over 60 percent by one time of rotary pressing by a 450 strong spinning reduction machine, forming the end enclosure part and the opening part by using a 412 spinning necking machine, and machining the connecting threads on the opening part after solution ageing heat treatment. The aluminum liner of the vehicular composite cylinder has the advantages of high quality, large diameter, thin wall thickness, small weight capacity ratio (weight / capacity), high geometric dimensioning accuracy, high quality of inner and outer surfaces and the like, and has the excellent application and market prospects.

Owner:BEIJING TIANHAI IND

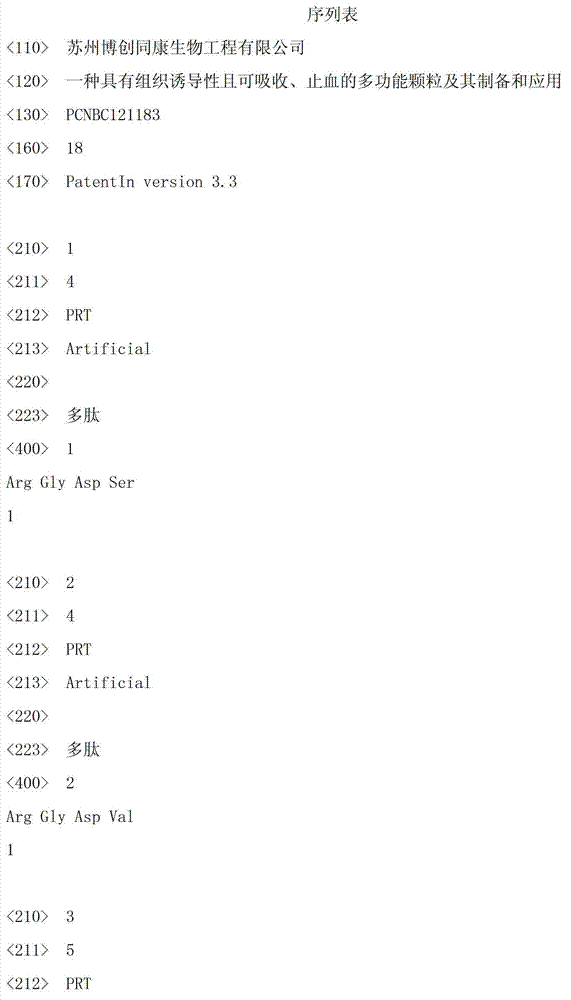

Absorbable and hemostatic multifunctional particle with tissue induction and preparation and application of multifunctional particle

ActiveCN102772821AGood hemostasisImprove liquid absorption performanceAbsorbent padsBandagesHyaluronic acidPharmaceutical Excipient

The invention relates to a multifunctional particle used for stopping human body wounds bleeding, filling, absorbing fluid, preventing adhesion and inducing tissue regeneration and repair. The absorbable particle with multiple functions of stopping bleeding, filling, absorbing the fluid, preventing the adhesion and inducing the tissue regeneration and repair comprises the following raw materials in weight percentage: 30-98.95 percent of polyanionic substance, 1-70 percent of cationic substance and / or polycationic substance, 0.05-2 percent of hyaluronic acid and / or functional factor polypeptide and 0-68.95 percent of pharmaceutical excipient. The particle is 0.01-1.0mm in particle size, and the particle is irregular in shape. The absorbable particle material with the multiple functions of stopping bleeding, filling, absorbing the fluid, preventing the adhesion and inducing the tissue regeneration and repair can be used for stopping the human body wounds bleeding, filling, absorbing fluid, preventing the adhesion and inducing the tissue regeneration and repair and is especially suitable for the wounds and defective tissues during minimally invasive surgery.

Owner:SUZHOU BOCHUANG TONGKANG PHARM TECH CO LTD

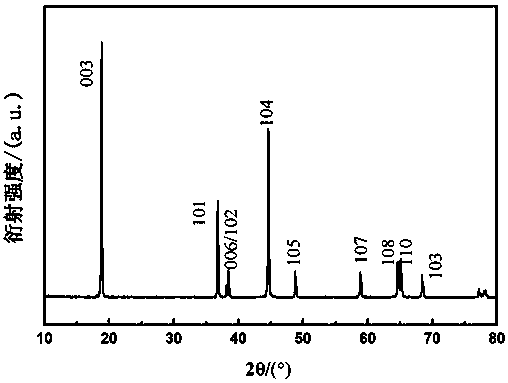

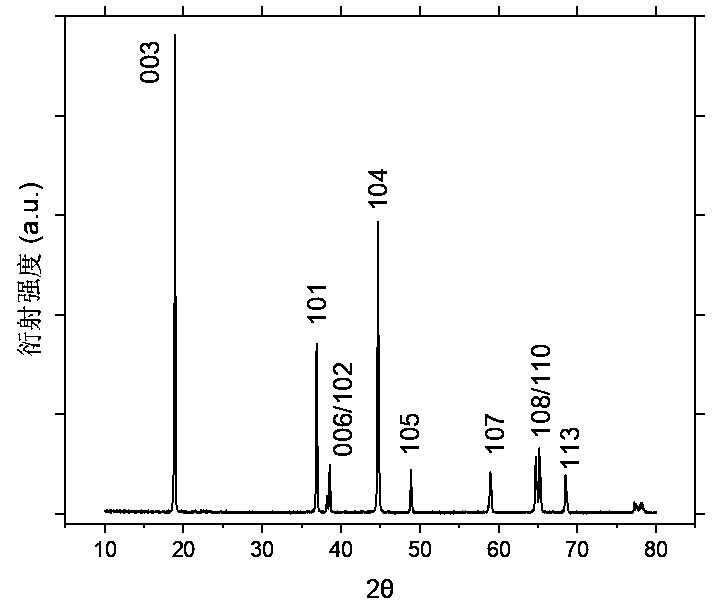

Preparation method of N-doped mesoporous carbon-coated ternary cathode material of lithium ion battery

ActiveCN107732220AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSodium-ion batteryLithium-ion battery

The invention provides a preparation method of an N-doped mesoporous carbon-coated ternary cathode material of a lithium ion battery. The preparation method comprises the following steps: (1) performing ultrasonic dispersion on a ternary cathode material into water, adding a phenylamine monomer, performing ultrasonic dispersion and adding acid solution, so as to obtain precursor solution; (2) adding ammonium persulfate solution into the precursor solution, heating and stirring the mixture, washing and settling twice or more than twice after centrifugal separation and performing vacuum drying,so as to obtain a polyaniline-coated ternary cathode material of the lithium ion battery; (3) placing the polyaniline-coated ternary cathode material into a tube furnace, calcining the polyaniline-coated ternary cathode material in an inert atmosphere, and naturally cooling to room temperature, so as to obtain the N-doped mesoporous carbon-coated ternary cathode material. The particle size of theN-doped mesoporous carbon-coated ternary cathode material of the lithium ion battery, which is obtained by the method, is 5-15mum, and an N-doped mesoporous carbon-coated layer is uniform and is 3-20nm in thickness; the N-doped mesoporous carbon-coated ternary cathode material is assembled into the battery and has comparatively good cycling stability and large rate discharge performance. The method is low in cost and simple in process, therefore, the method is suitable for large-scale industrial production.

Owner:CENT SOUTH UNIV

Continuous extraction method of pectin, tannin and pigment from persimmon exocarp

InactiveCN101381420ARich sourcesSimple extraction methodOrganic chemistryNatural dyesUltrafiltrationTannin

The invention discloses a continuous extraction method for pectin, tannin and pigment in a persimmon pericarp, which comprises the following steps: a. after the persimmon pericarp is pretreated, the pretreated persimmon pericarp is extracted by water at a temperature which is more than or equal to 70 DEG C and is less than 100 DEG C to obtain an extract and pulp stock; b. the extract is filtered by an ultrafiltration membrane with a cutoff molecular weight of between 10000 and 30000, the trapped part is a pectin liquid, a filtrate is absorbed and separated by a macroporous resin to obtain the tannin; and c. the pulp stock obtained in step a is extracted by acetone at a temperature of between 60 and 70 DEG C, and an extraction liquid is filtered, distilled and dried to obtain the pigment. The method has rich sources of raw materials, is simple, and is more suitable for large-scale industrial production; a used reagent has lower price, small toxicity, and strong maneuverability, and is easy to amplify the technology, and the cost is lower than extraction cost of corresponding products at present. A product extracted by the method is safe and nontoxic, and has simple and reasonable production technology.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

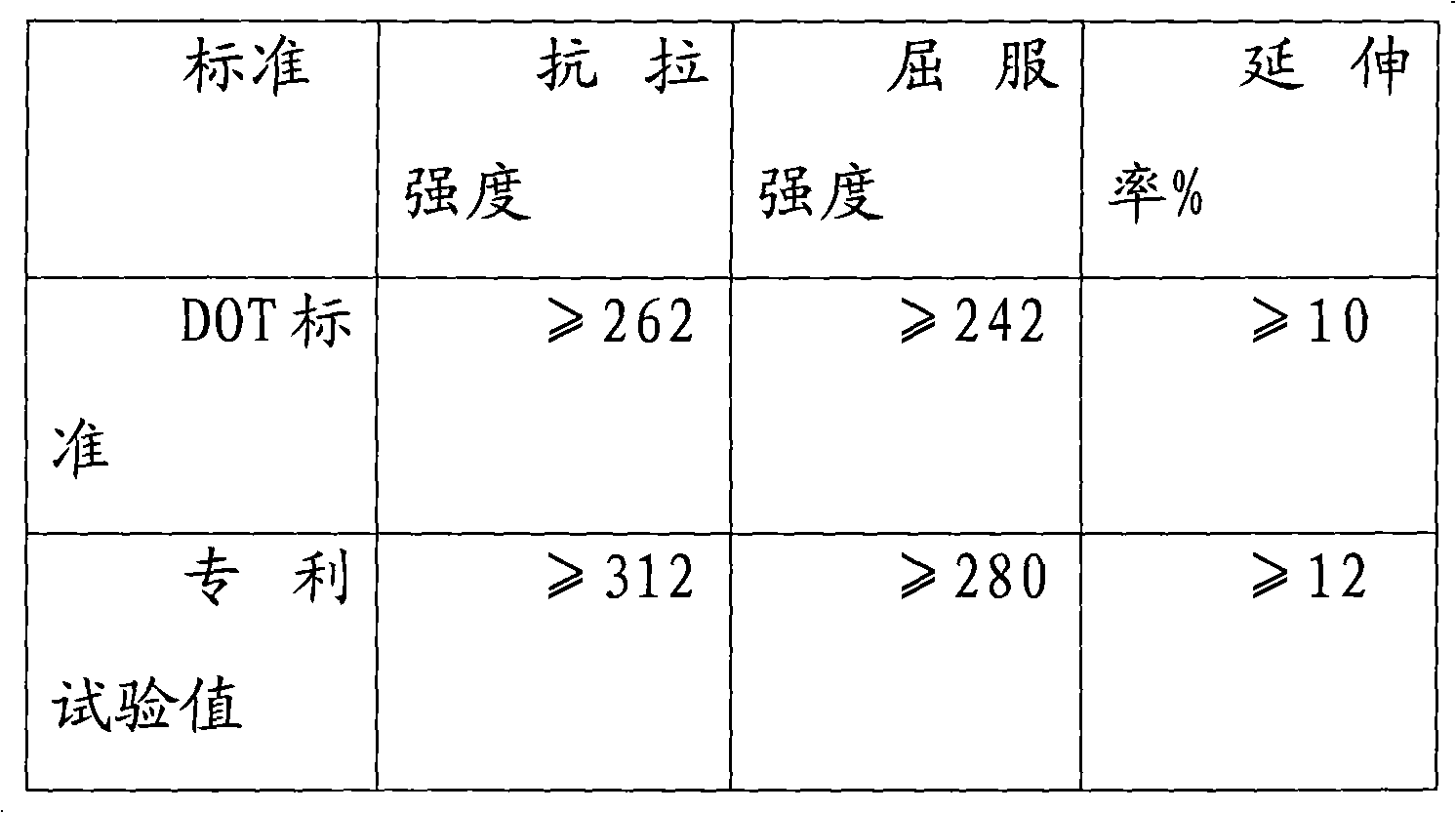

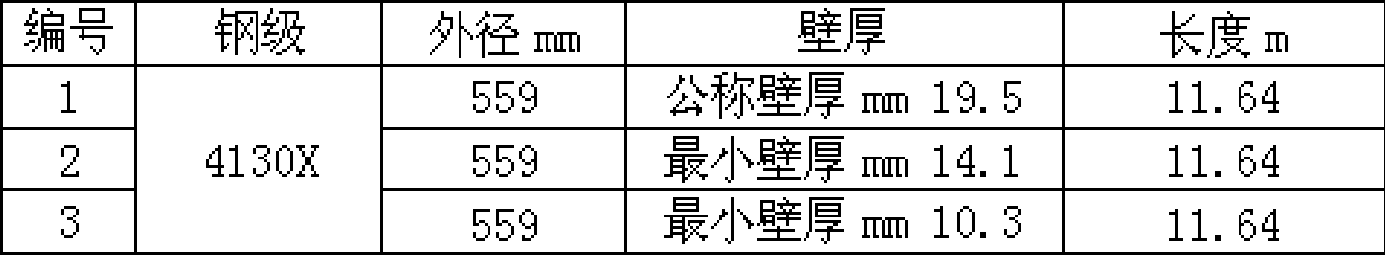

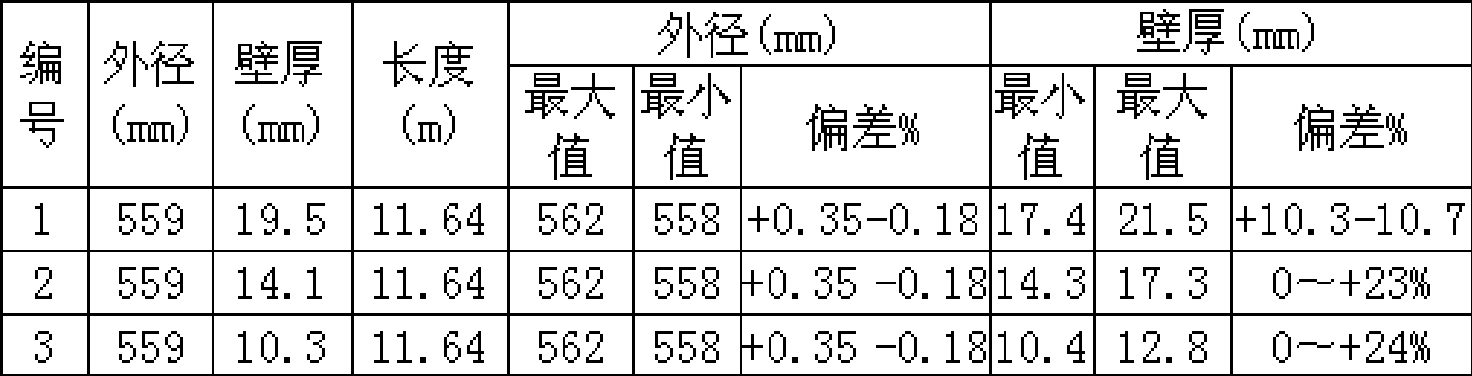

Method for producing seamless steel pipe for producing gas cylinder with heavy caliber for hauled vehicle

ActiveCN101439350ASimple processLow costRoll mill control devicesFurnace typesSuperficial massLarge aperture

The invention relates to a method for manufacturing a seamless steel pipe of a large-aperture high pressure cylinder for producing a trailer and belongs to the field of manufacturing a seamless steel pipe. The invention mainly solves the technical problem of satisfying the physical dimension precision and the quality requirements on internal and external surfaces of the seamless steel pipe of the large-aperture high pressure cylinder for the trailer at low cost. The invention adopts the technical proposal that after being perforated, a heavy-section round wave steel ingot is formed by being rolled by a step rolled mill and then drawn by a drawing aperture enlarging machine set; the tolerance of the wall thickness of a pipe blank rolled by the step rolled mill is S-8<10> percent and the extreme deviation is less than or equal to 2.5 mm; when the drawing pipe expander set is expanded and manufactured, the aperture enlargement ratio is controlled to be less than 25 percent when the pipe blank is heated each time; the aperture enlargement and the wall reduction are conducted for at most 4 times; the aperture enlargement magnitude of each time is not larger than 45 mm; and the expanding and manufacturing temperature is larger than 780 DEG C at the last expanding and manufacturing.

Owner:攀钢集团成都钢铁有限责任公司

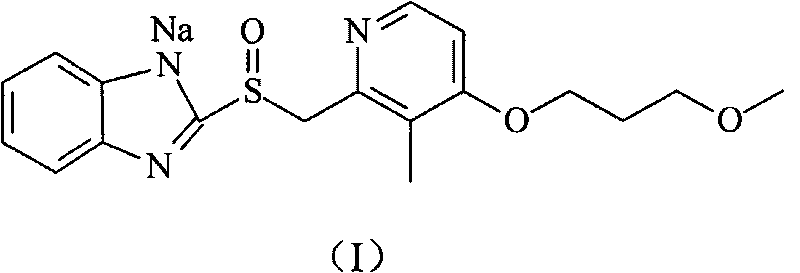

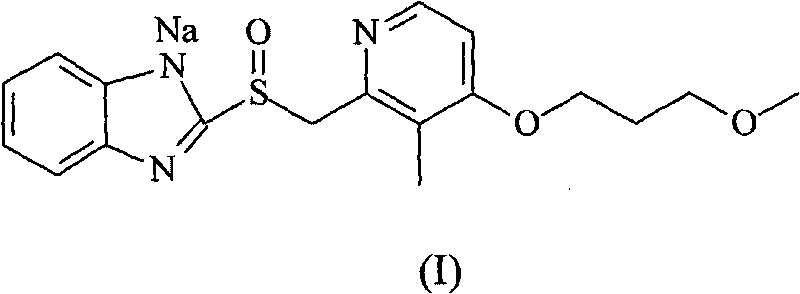

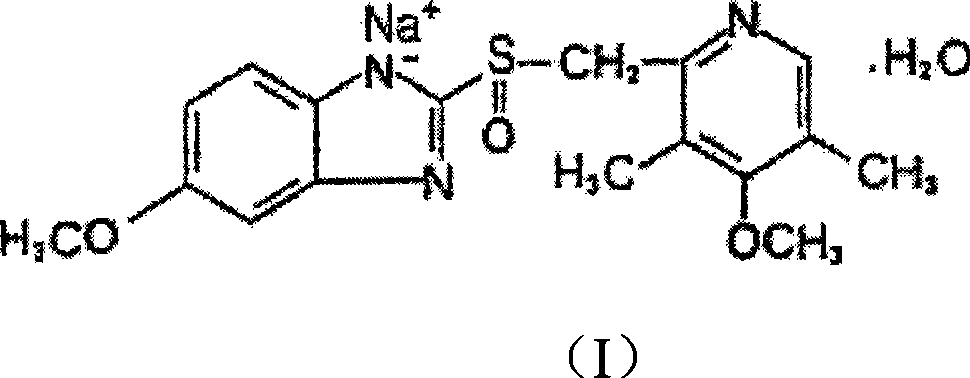

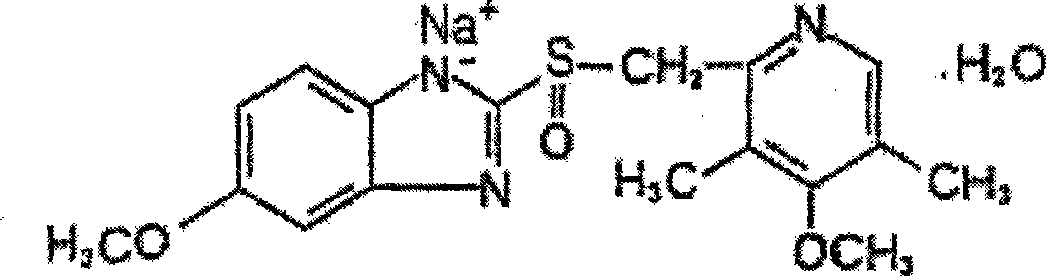

High-purity sodium rabeprazole compound

InactiveCN101704811AOvercome purityOvercome the disadvantages of difficult purificationOrganic chemistryOrganic solventRabeprazole

The invention relates to a high-purity sodium rabeprazole compound, belonging to the technical field of medicine. The method includes the following steps: dissolving crude sodium rabeprazole synthesized by the reaction of rabeprazole and sodium hydroxide in water, adjusting pH value to be faintly acid to neutral by using solid acid salt, and collecting precipitated solid; after dissolving the solid with organic solvent, conducting elution and purification by using eluting agent through macroporous adsorption resin, and collecting eluent; and adjusting the pH value of the eluent to be alkaline, and collecting the precipitated solid to obtain the pure sodium rabeprazole.

Owner:HAINAN MEILAN SMITH KLINE PHARMA

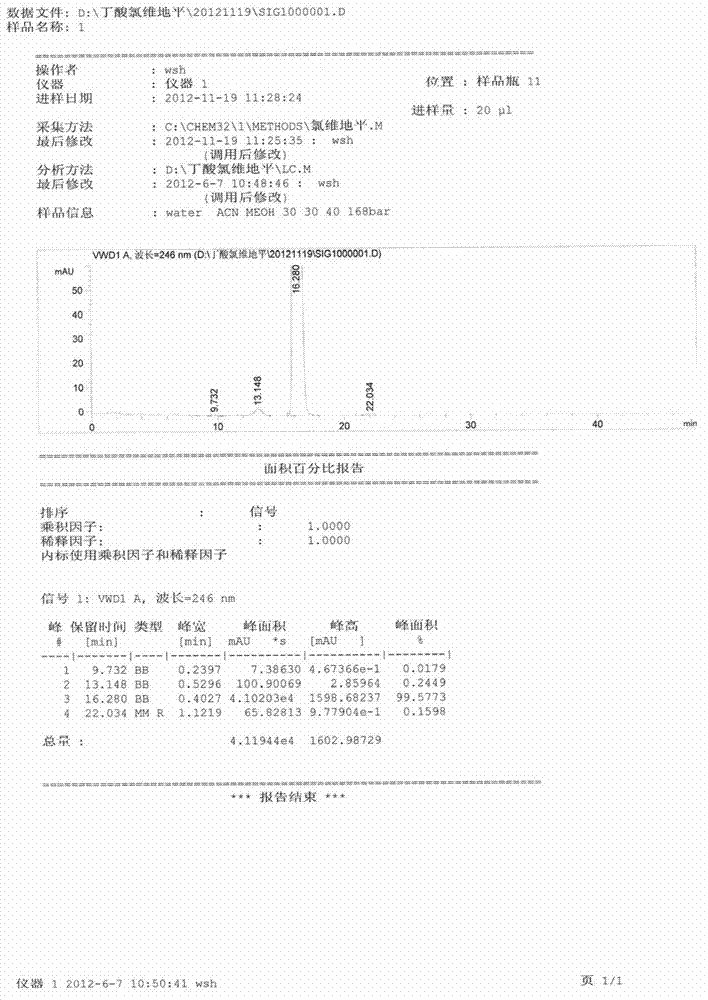

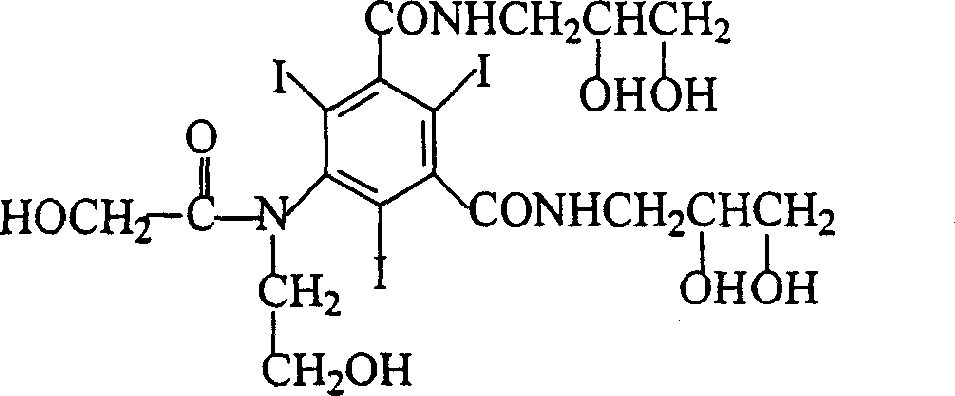

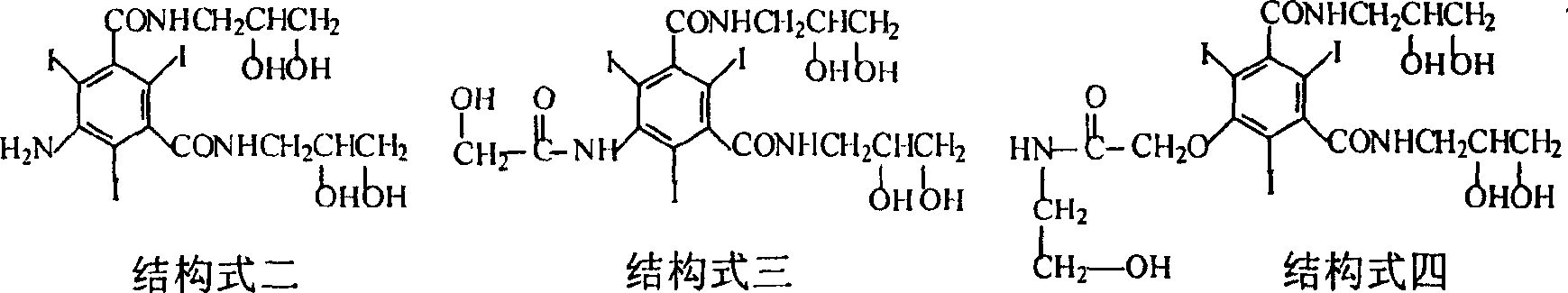

Preparation method of ioversol

InactiveCN1477093AAvoid decompositionMild reaction conditionsOrganic compound preparationCarboxylic acid amides preparationAlkyl transferX-ray

The present invention relates to a preparation method of X-ray contrast agent ioversol. The method adopts 5-chloroacetamino-N,N'-bis(2,3- dihydroxypropyl)-2,4,6-triodo-1,3-phthalamine and chloroethanol to make them implement alkylation reaction in the presence of inorganic alkali to obtain reaction liquor, said reaction liquor has no need of separation, and the anhydrous sodium acetate can be directly added to make reaction.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

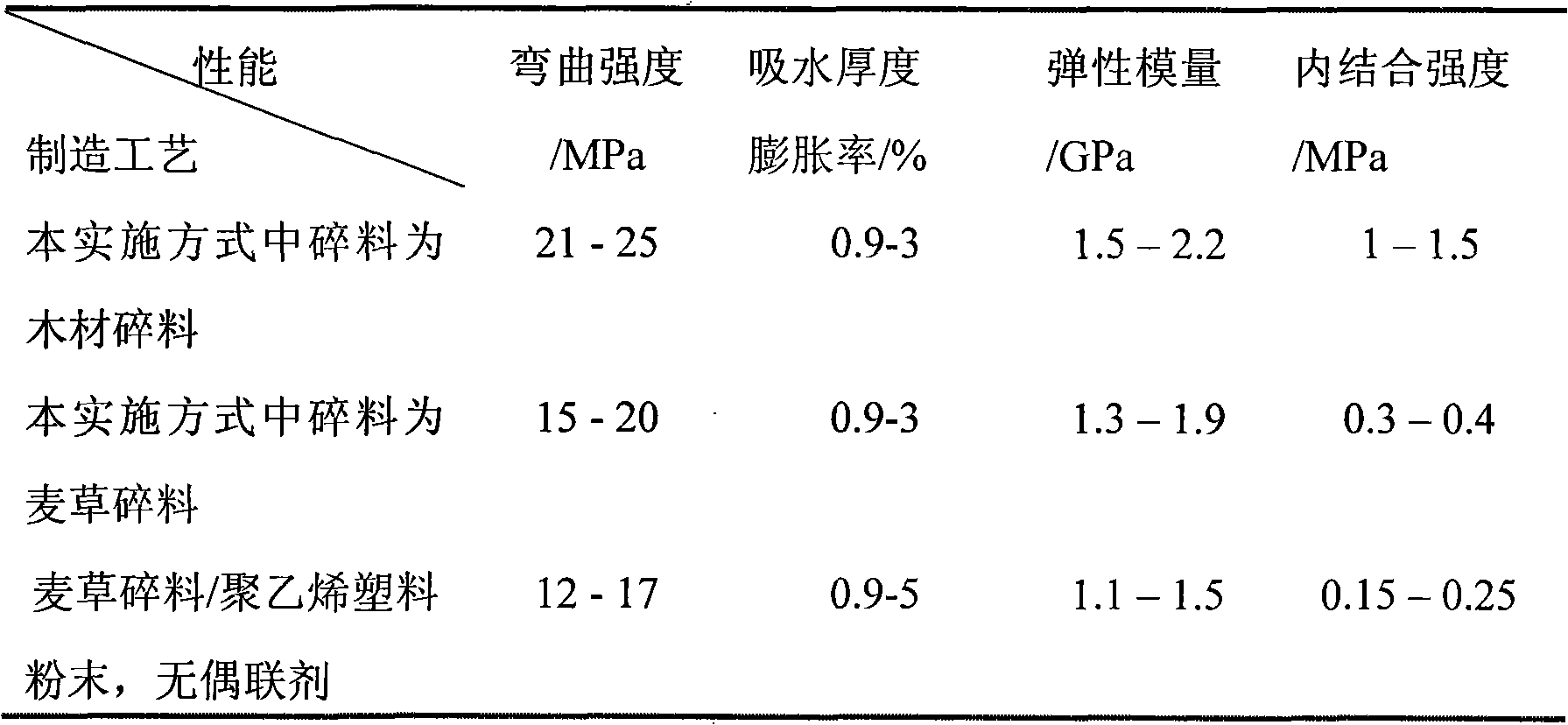

Heat pressing production method of polyethylene fiber-plant fibre compound material

InactiveCN101323130AShorten heating timeEasy to melt and transfer heatFlat articlesDomestic articlesFlexural strengthPlastic compounding

A heat pressing method for polyethylene plant fiber composite material relates to a method for manufacturing plant fiber material. The invention solves the problems that only fibril can be applied, plant format is narrower, straw is liable to thermolysis and charring and the mechanical properties of plant manufactured by pre-heat pressing are poor in the production of WPC in the manner of extraction. The method of the invention has the steps that: PE plastic fiber is mixed with crushed plant aggregates to obtain mixture that is paved into a plate base; the plate base is pre heated under a pressure of 1 to 3 MPa and at a temperature of 170 to 190 CEG D; the plate base is kept under a pressure of 4 to 6 MPa for 8 to 15mins; and at last, the plate base is cooled to 70 to 80 CEG D under a pressure of 3 to 6 MPa; and after pressure relief, the plank is obtained. The flexural strength of the plank manufactured in the method of the invention is 20 MPa. The invention adopts the polyethylene in fiber configuration and the crushed aggregates of the plant and the fiber is evenly mixed and has high productivity. In addition, the crushed aggregates of the plant and the fiber can be prevented from being deteriorated and darkened due to high temperature.

Owner:NORTHEAST FORESTRY UNIVERSITY

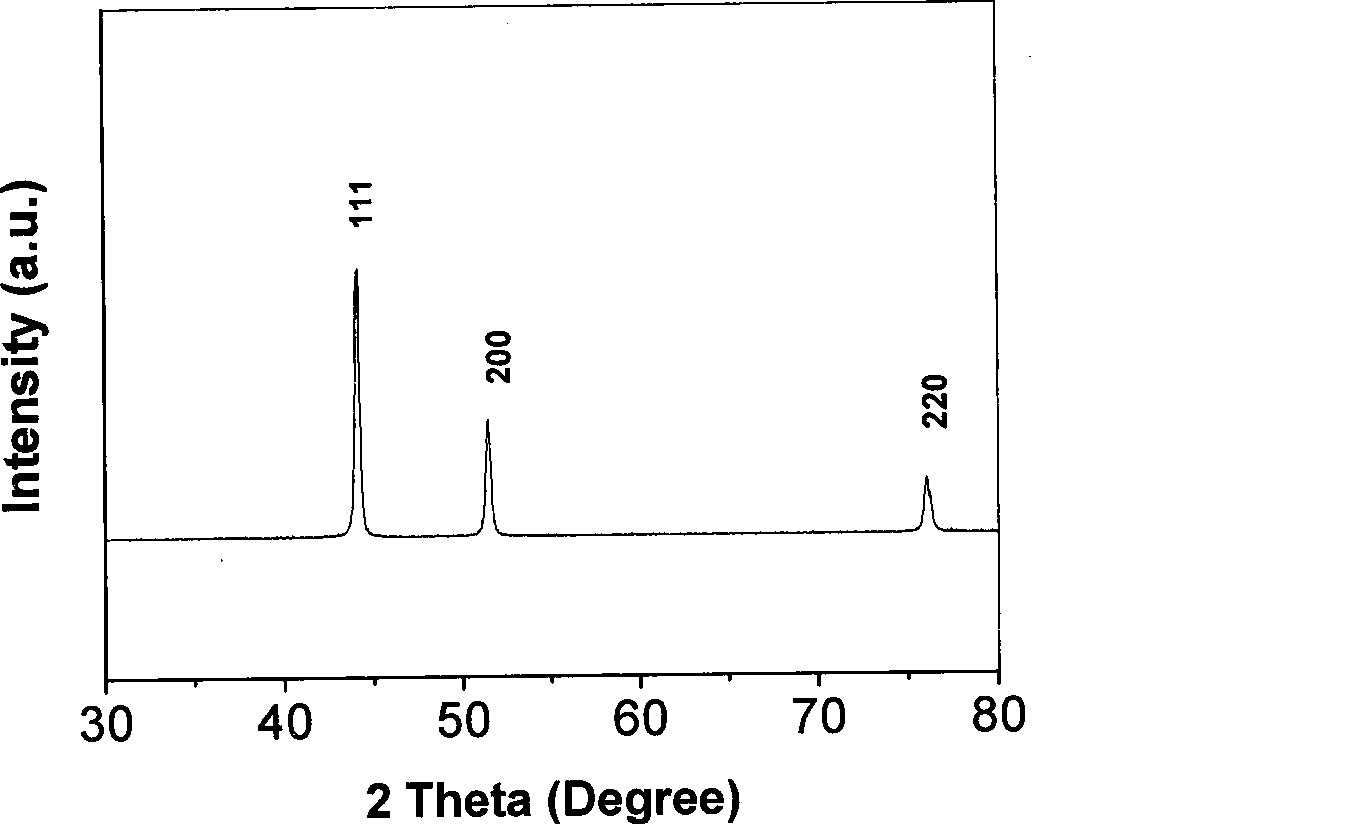

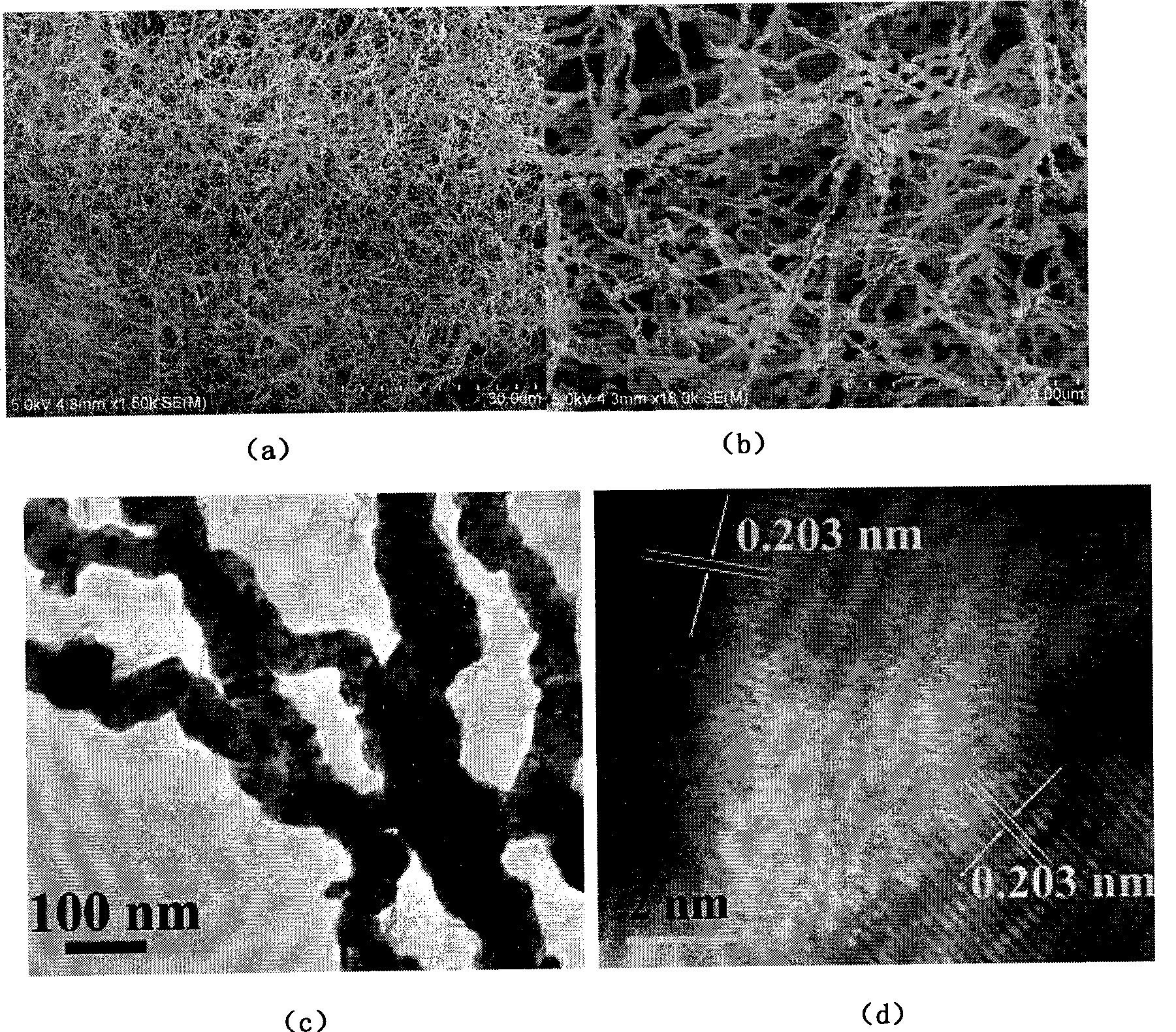

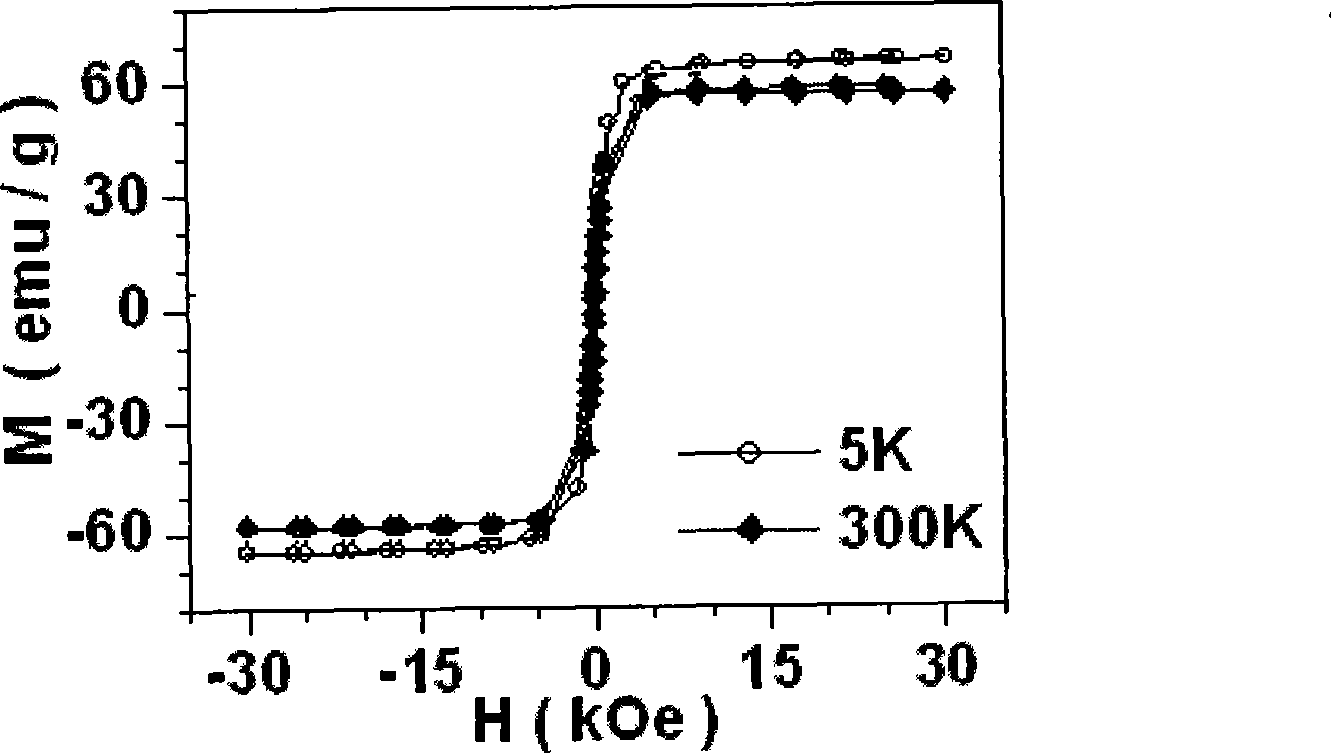

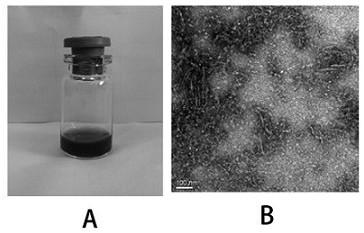

Method for preparing metallic nickel nano-wire

The invention discloses a method for preparing metal nickel nano wires, which comprises the following steps: firstly, dissolving a metal nickel salt and polyvinylpyrrolidone into ethylene glycol according to the mass ratio of 1:0.5-1:20; secondly, adding hydrazine hydrate and 5-15 ml ethanol according to the fact that the mol ratio of the hydrazine hydrate to the metal nickel salt is 0.3-1.9:1; and thirdly, performing heating reaction for 3 to 48 hours until black deposit is generated in a solution, washing and drying the black deposit, and obtaining the black powder metal nickel nano wires, wherein the metal nickel salt is any one of nickel acetate, nickel sulfate, nickel chlorite and nickel nitrate, and the molar concentration of the metal nickel salt in the ethylene glycol is between 0.001 and 0.1 mol / L. The prepared metal nickel nano wires are continuous and compact and have good crystal formation and higher slenderness ratio.

Owner:JIANGSU UNIV OF SCI & TECH

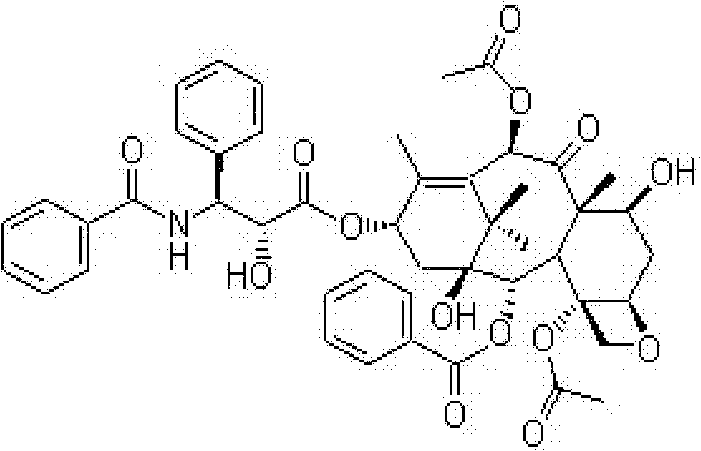

Method for extracting taxol simply, conveniently and efficiently

ActiveCN102363612AHigh extraction rateContent was not affectedOrganic chemistryBulk chemical productionOrganic solventAlcohol

The invention relates to a method for extracting taxol simply, conveniently and efficiently and belongs to a method for extracting taxol. The method comprises: crushing a taxus chinensis dry medicinal material into coarse powder, removing fat soluble impurities by a supercritical CO2 extraction process, and adding cellulase into medicinal residue for hydrolysis; and filtering, drying the medicinal residue, leaching in ethanol, filtering, recovering ethanol under reduced pressure till the residue gives off no alcohol smell, washing the residual with water, discarding washing solution, drying and obtaining taxol by chromatography. The method improves the extraction rate of taxol, uses a small volume of water, avoids using an organic solvent in a solvent extraction method, reduces column loading pressure and is more suitable for mass industrial production.

Owner:赵华

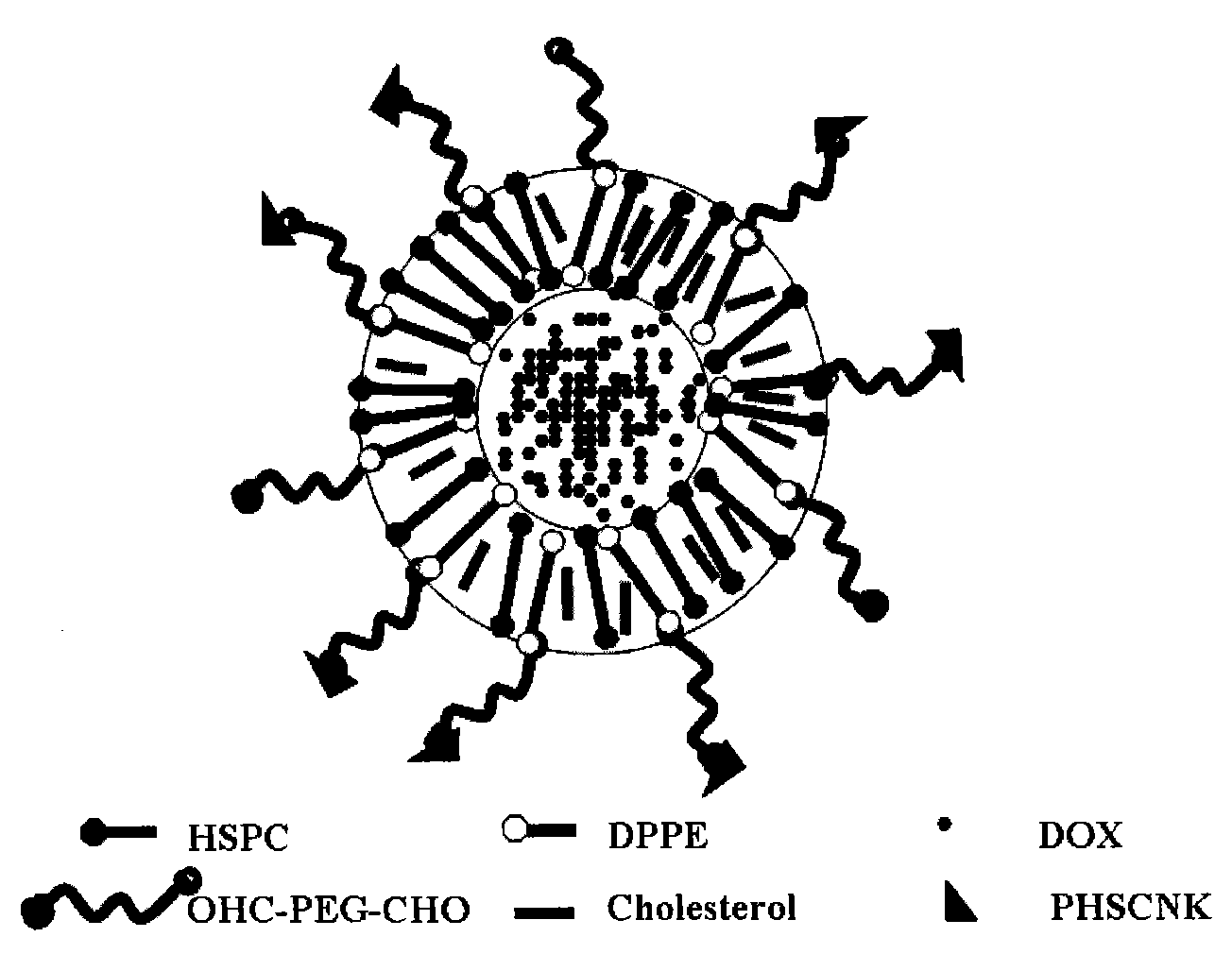

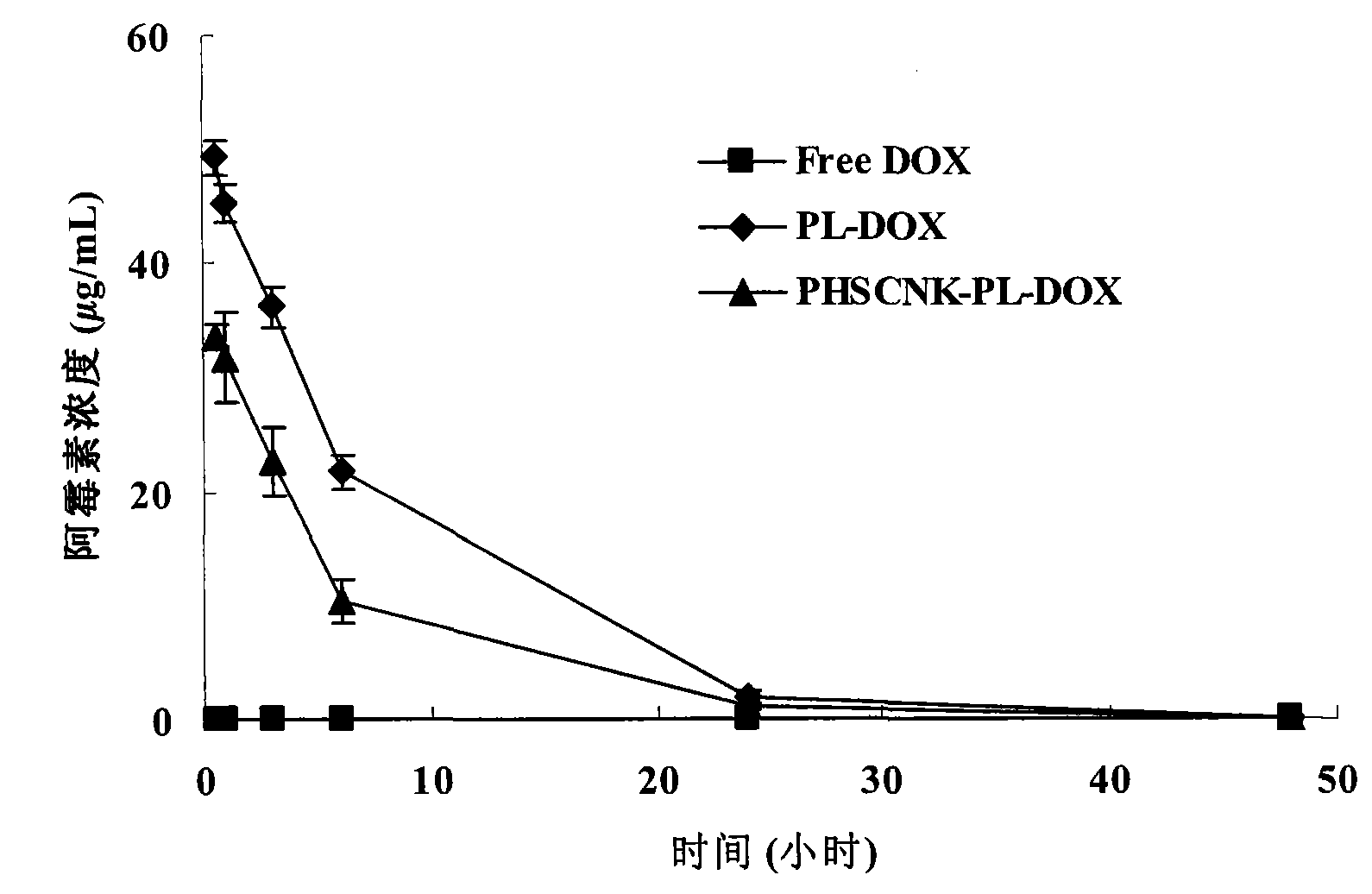

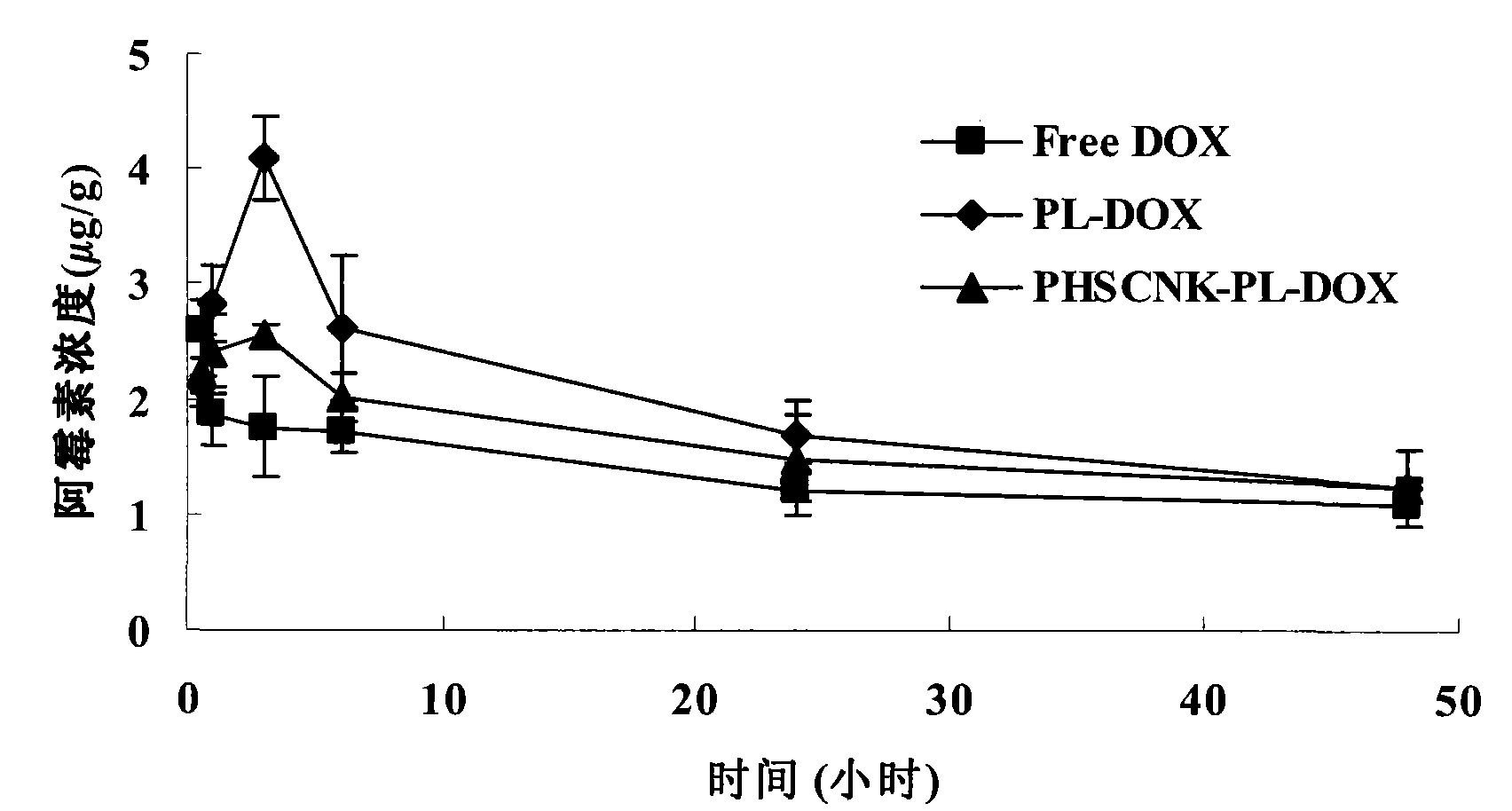

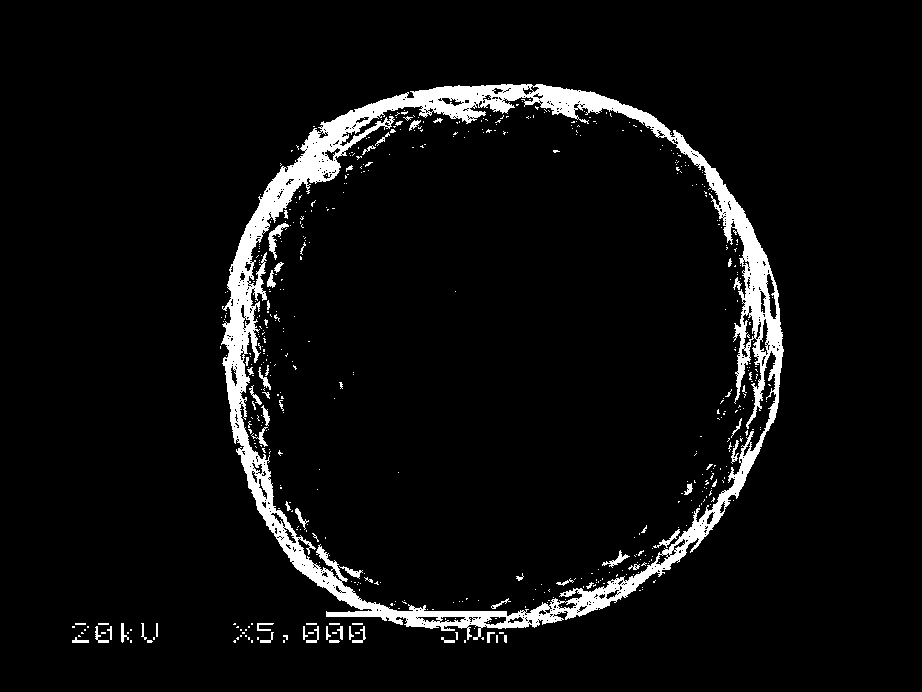

Tumor dual target liposome mediated by integrin and preparation method thereof

InactiveCN101653416AImprove therapeutic indexGrowth inhibitionMacromolecular non-active ingredientsAntineoplastic agentsPolyethylene glycolDisintegrin

The invention provides a tumor dual target liposome mediated by integrin and a preparation method thereof. The composition of the invention comprises the components of an antitumor medicament, polypeptide with tumor new vessel target function and tumor cell target function, polyethylene glycol and derivates thereof and a vector for preparing liposome medicaments.

Owner:PEKING UNIV

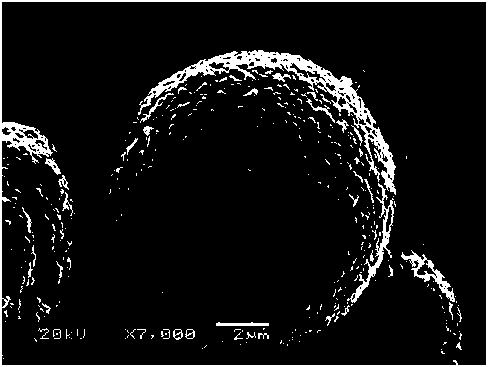

Lithium zirconium phosphate fast ionic conductor coated lithium nickel cobalt aluminate positive electrode material and preparation method thereof

ActiveCN109192956AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsElectrical conductorMaterials science

The invention relates to a lithium zirconium phosphate fast ionic conductor coat lithium nickel cobalt aluminate positive electrode material and a preparation method thereof, wherein that mass of thelithium zirconium phosphate fast ionic conductor is 0. 1-10wt%, and the lithium zirconium phosphate fast ionic conductor form a coating layer with a thickness of 5-30nm and is coated on the lithium nickel cobalt aluminate. The positive electrode material is spherical particles with a particle diameter of 5 to 15 mum. The preparation method comprises the following steps: (1) preparing a solution containing phosphorus source and zirconium source, adding zirconium source solution into an organic solvent or water, adding phosphorus source solution, stirring, adding lithium nickel cobalt aluminate,heating and stirring, slowly evaporating and drying, and placing the obtained powder in an oven for drying; (2) placing the powder obtained in the step (1) in a tubular furnace for low-temperature rapid sintering. The positive electrode material of the invention has good cycle stability and rate discharge performance; as that method of the invention can effectively reduce the problem of low circulation stability of the surface residual lithium and ternary materials dure conventional coating, the process cost is low, the process is simple, and the method is suitable for large-scale industrialproduction.

Owner:CENT SOUTH UNIV

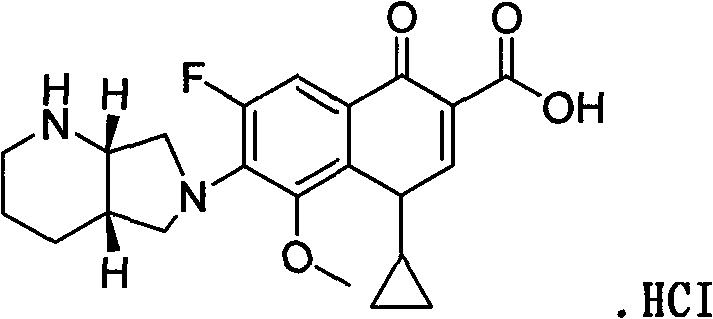

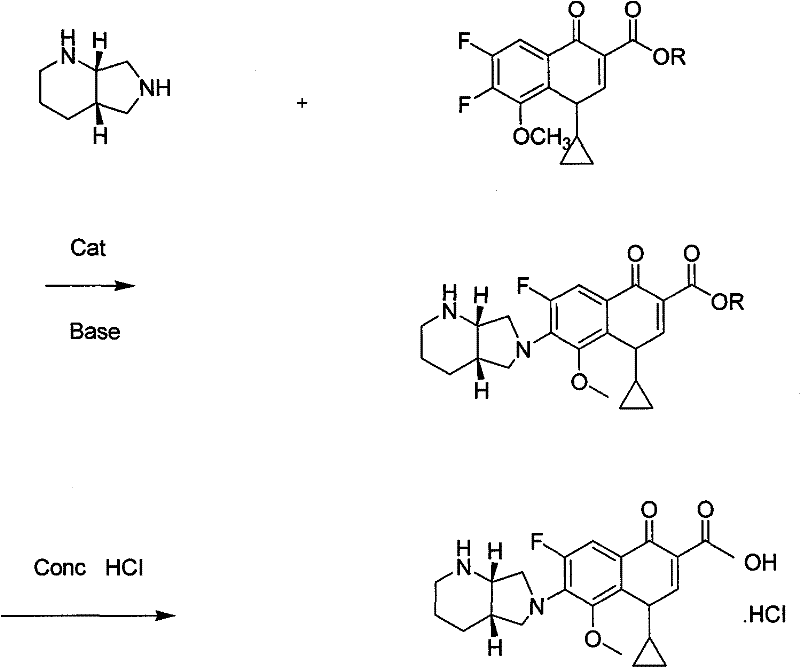

Preparing method of moxifloxacin or slat thereof

A preparing method of moxifloxacin or slat thereof includes that: 1-cyclopropyl-6,7-difluoro-8-methoxyl-4-oxo-1,4-dihydro-3-quinoline carboxylic acid ester and S,2-2,8-diazabicyclo(4.3.0) nonane are used as raw materials, catalysts are added into the raw materials for condensation reaction in mild condition, and before separation, condensation product moxifloxacin ester can be directly added with hydrolysis of ester group for separation to obtain moxifloxacin or slat thereof. By adopting the method, product purity is high, yield is high, the process is simple and can be controlled easily, and product manufacture cost is low. The preparing method is suitable for large-scale industrial production.

Owner:苏州中科天马肽工程中心有限公司 +1

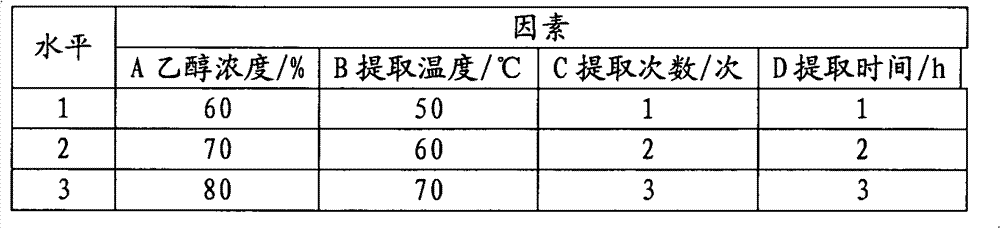

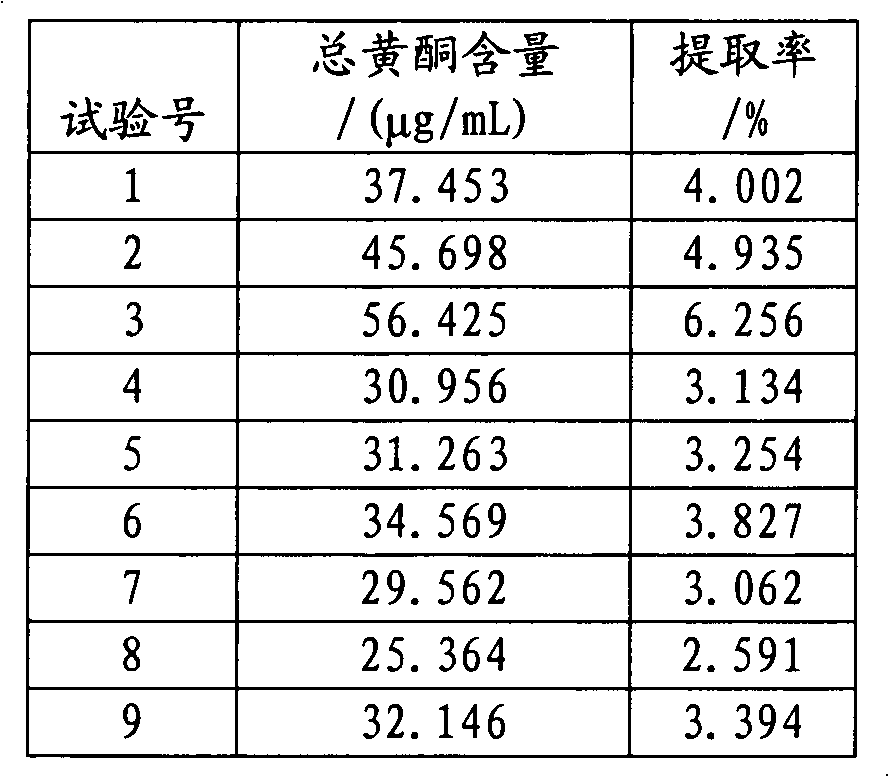

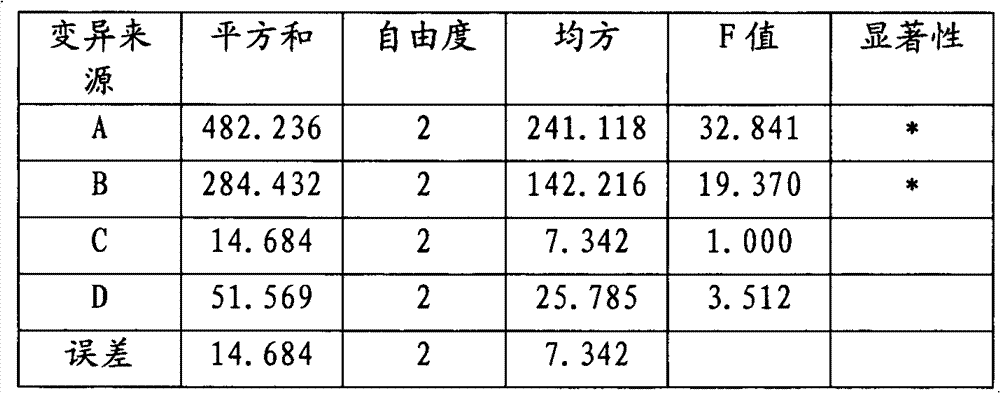

Wild chrysanthemum extraction process and measuring method for total flavonoids in wild chrysanthemums

InactiveCN102961427ABest extraction processLow costAntibacterial agentsMetabolism disorderDesorptionFiltration

The invention relates to the technical field of extraction of Chinese traditional medicines and particularly relates to a wild chrysanthemum extraction process and a measuring method for total flavonoids in wild chrysanthemums. The wild chrysanthemum extraction process sequentially comprises the following steps of: ethanol extraction, first concentration and filtration, resin adsorption, second concentration, spray drying and the like to obtain a wild chrysanthemum extract. The wild chrysanthemum extraction process and the measuring method for the total flavonoids in the wild chrysanthemums, provided by the invention, have the advantages that the ethanol heating reflux extraction is carried out on the wild chrysanthemums by using an orthogonal experiment method, the wild chrysanthemum extract is not reacted with chrysanthemum components, the total flavonoid component of the wild chrysanthemums can be dissolved to the maximum extent, and therefore, the optimal extraction process is obtained. The extraction ratio of the total flavonoids in the wild chrysanthemums is up to 6.23%, and the content of the total flavonoids is up to 9.5%. The wild chrysanthemums are low in raw material cost and suitable for large-scale industrial production, and therefore, the extraction development for the flavonoids in the chrysanthemums has higher practical significance. Macroporous resin has the characteristics of high adsorbing capacity and high desorption ratio is adopted.

Owner:安徽老炊食品有限公司

Method for preparing lyophobic silicon dioxide for VOC (Volatile Organic Compound) adsorption

The invention discloses a method for preparing lyophobic silicon dioxide for VOC (Volatile Organic Compound) adsorption. The method comprises the following steps: (1) mixing nitric acid, deionized water and absolute ethyl alcohol in a container so as to obtain a mixed liquid; (2) mixing a silicon dioxide source, the absolute ethyl alcohol and the deionized water so as to obtain another mixed liquid, adding a composite coupling agent, and uniformly stirring; (3) pouring the solution obtained in the step (2) into the mixed liquid obtained in the step (1), keeping the pH value of the solution within 2-6, and stirring for several hours; (4) sealing the container, and aging for 2 hours; (5) performing suction filtration on gel which is subjected to surface modification and is interchanged with a solvent, washing, and leaving to stand at normal temperature; and (6) drying the washed gel, and performing airflow superfine crushing, thereby obtaining a finished product. By adopting the method for preparing the lyophobic silicon dioxide for VOC adsorption, the lyophobic silicon dioxide is capable of adsorbing different types of VOC molecules, and not only is the environment protected, but also the cost is low.

Owner:德清美联新材料科技有限公司

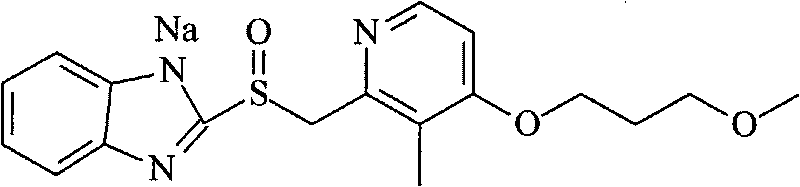

Omeprazole sodium compound and preparation thereof

InactiveCN101412710AImprove stabilityImprove clinical efficacyOrganic chemistryDigestive systemOmeprazole SodiumOrganic solvent

The invention relates to an omeprazole sodium compound and a method for preparing the same. The method comprises the following steps: dissolving an omeprazole sodium crude product in water, adding solution of a solid acid salt into the mixture, collecting the precipitated solid, dissolving the solid by using an organic solvent, eluting and purifying the mixture by an eluant through macroporous resin, collecting the eluate, adding an alkaline solution into the eluate to regulate the pH value to be alkaline, collecting the precipitated solid, and performing vacuum drying on the solid after washing to obtain the refined product of the omeprazole sodium. The purity of the omeprazole sodium prepared by the method is more than 99.8 percent, thus the purity and the preparation stability of the omeprazole sodium product are greatly improved.

Owner:HAINAN LINGKANG PHARMA CO LTD

Unsaturated polyester-bonded and glass fiber-reinforced beam and implementation method thereof

InactiveCN101725216AHigh mechanical strengthImprove creep resistanceWood working apparatusGirdersGlass fiberPolyester

The invention discloses an unsaturated polyester-bonded and glass fiber-reinforced beam and an implementation method thereof, belonging to the manufacturing field of building structure materials. The glass fiber-reinforced beam mainly consists of glulam beam and glass fiber cloth, and glass fiber cloth is bonded at the partial bottom of the beam by unsaturated polyester so that the beam is reinforced. The preparation method of the glass fiber-reinforced beam realizes the preparation of the glulam beam and the partial reinforcement of the glass fiber cloth through a series of processes of preparing materials, processing, finger jointing, cold pressing, pretreating, post treating and the like. The glass fiber-reinforced beam solves the problems that the structure is difficult to reinforce due to the blockage of connection positions and wood composites have poor performance caused by the quality defects of wood in the mode of partial reinforcement, simultaneously utilizes the unsaturated polyester to bond the glass fibers for reinforcement to save the cost of an adhesive, and can bond multi-layer glass fiber cloth to reach high reinforcement strength.

Owner:NORTHEAST FORESTRY UNIVERSITY

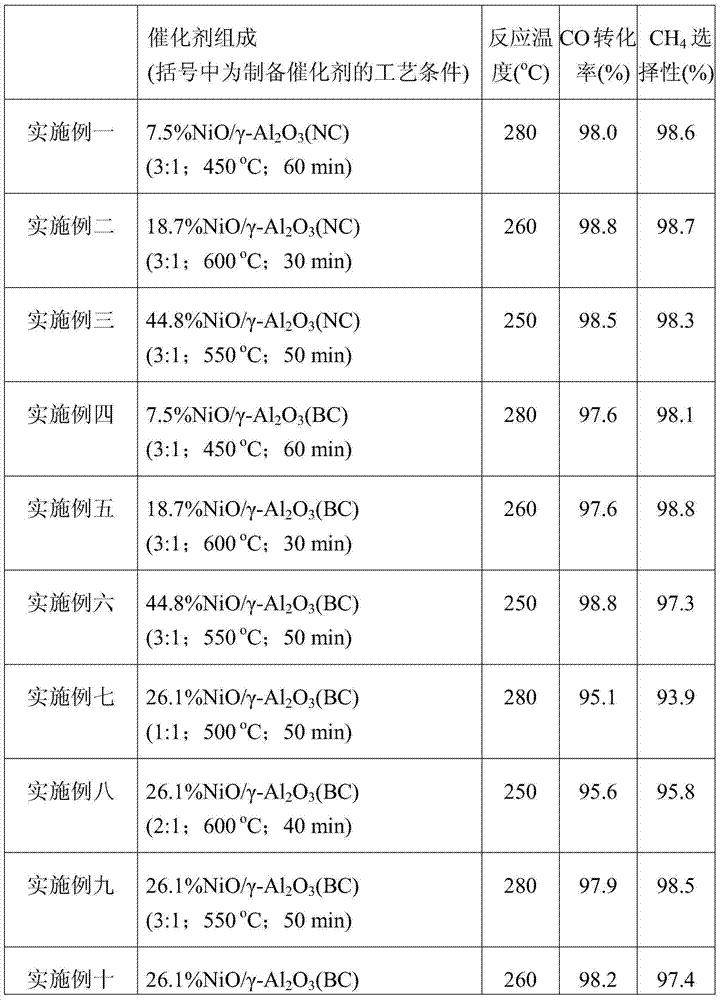

Method for preparing methanation catalyst by adopting urea combustion method

InactiveCN103537288AEasy to operateShort processHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsMuffle furnaceChemistry

The invention relates to a method for preparing a methanation catalyst by adopting a urea combustion method. The method for preparing the methanation catalyst comprises the following steps: firstly mixing a catalyst active component precursor, an auxiliary M precursor and a catalyst carrier precursor; simultaneously adding a combustion agent and a dispersing agent, carrying out ball grinding for 20-60 minutes by adopting a planet ball grinding mill, and uniformly mixing; then transferring the material which is fully ball-ground and uniformly mixed into a crucible or quartz boat, directly placing the crucible or quartz boat into a constant-temperature muffle furnace at a preset temperature of 300-600 DEG C, and carrying out a combustion reaction for 30-60 minutes, thus obtaining the methanation catalyst. According to the method for preparing the methanation catalyst, aluminium nitrate or pseudo-boehmite is taken as a carrier raw material, nickel nitrate is taken as a main active component raw material, nitrates of other metals are taken as auxiliary raw materials, ethyl alcohol is taken as the dispersing agent, urea is taken as the combustion agent, and the method for preparing the methanation catalyst has the biggest advantages of simple operation process, short preparation time and no waste water discharge, and is especially applicable to industrial mass production.

Owner:HUANENG CLEAN ENERGY RES INST +1

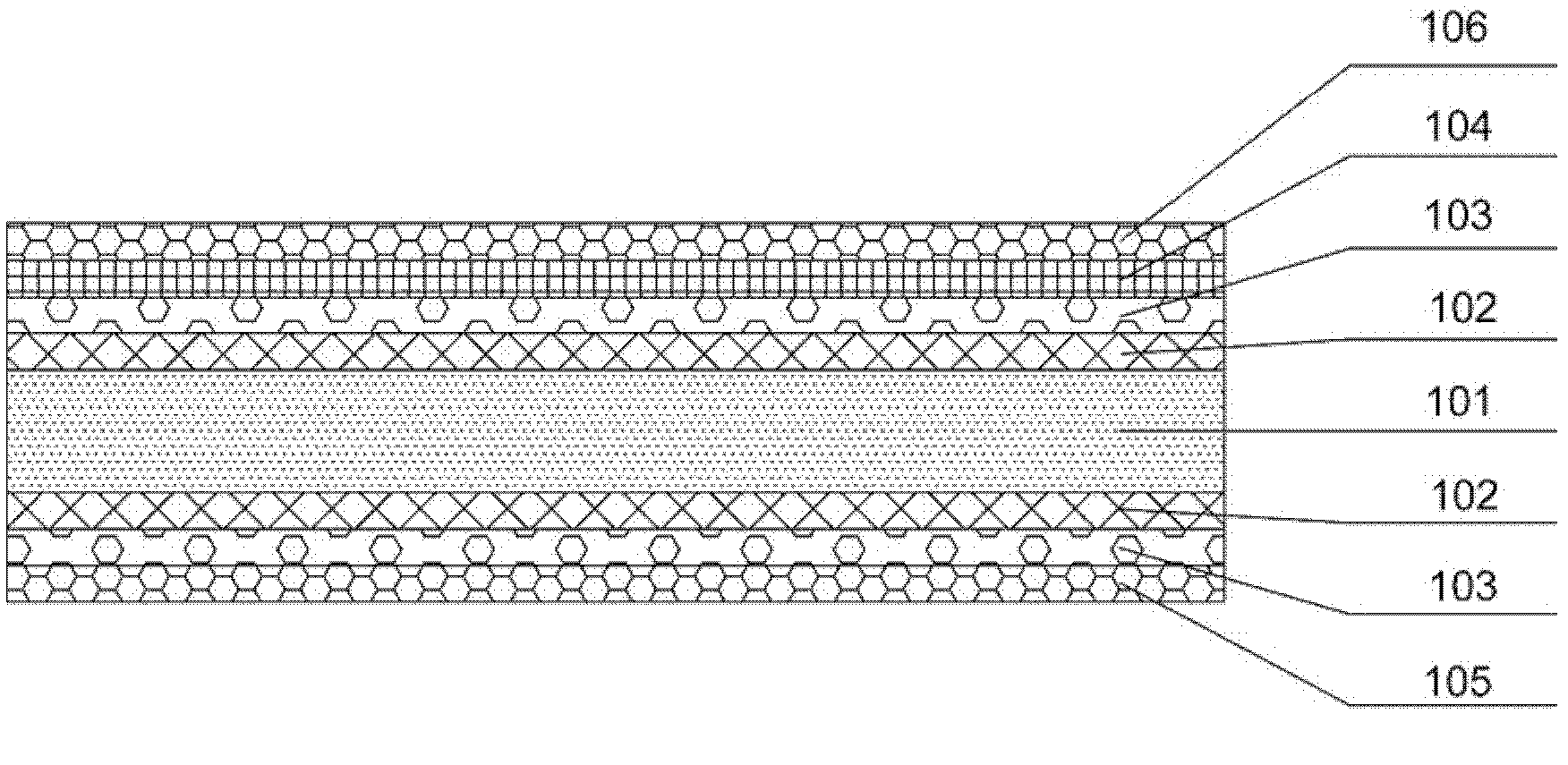

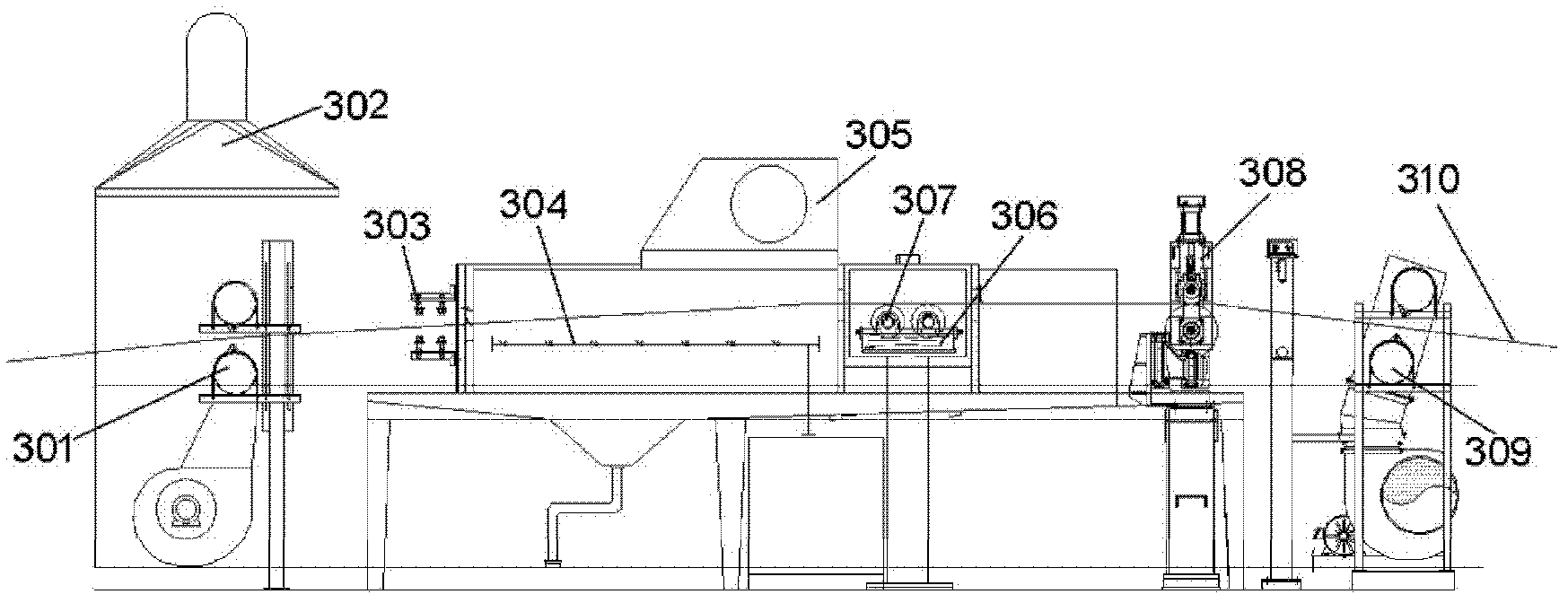

Cleansing color coated steel plate for purification and preparation method thereof

InactiveCN102275353AImprove adhesionImprove surface propertiesSynthetic resin layered productsMetal layered productsEnvironmental resistanceCoated surface

The present invention relates to the technical field of materials, in particular to a cleansing color-coated steel sheet for purification and a preparation method thereof. The cleansing color-coated steel sheet for purification comprises: a smooth galvanized substrate (101); The chemical conversion layer (103), the primer layer (104), and the top paint layer (106) are sequentially upward from the surface, and the chemical conversion layer (103) and the back paint layer are sequentially downward from the lower surface of the substrate (101) (105). The present invention greatly improves the adhesion of the coating by improving the structure and process of the color-coated steel plate, and obtains a clean color-coated plate with a delicate and smooth outer coating surface. Compared with the existing color-coated steel plate, its The advantages are: good surface characteristics, bending processing performance, easy cleaning and resistance to repeated scrubbing, non-toxic and environmentally friendly, and the preparation method of the present invention is simple and effective, with less equipment investment and low cost, and is very suitable for large industrial production.

Owner:SUZHOU YANGTZE NEW MATERIALS CO LTD

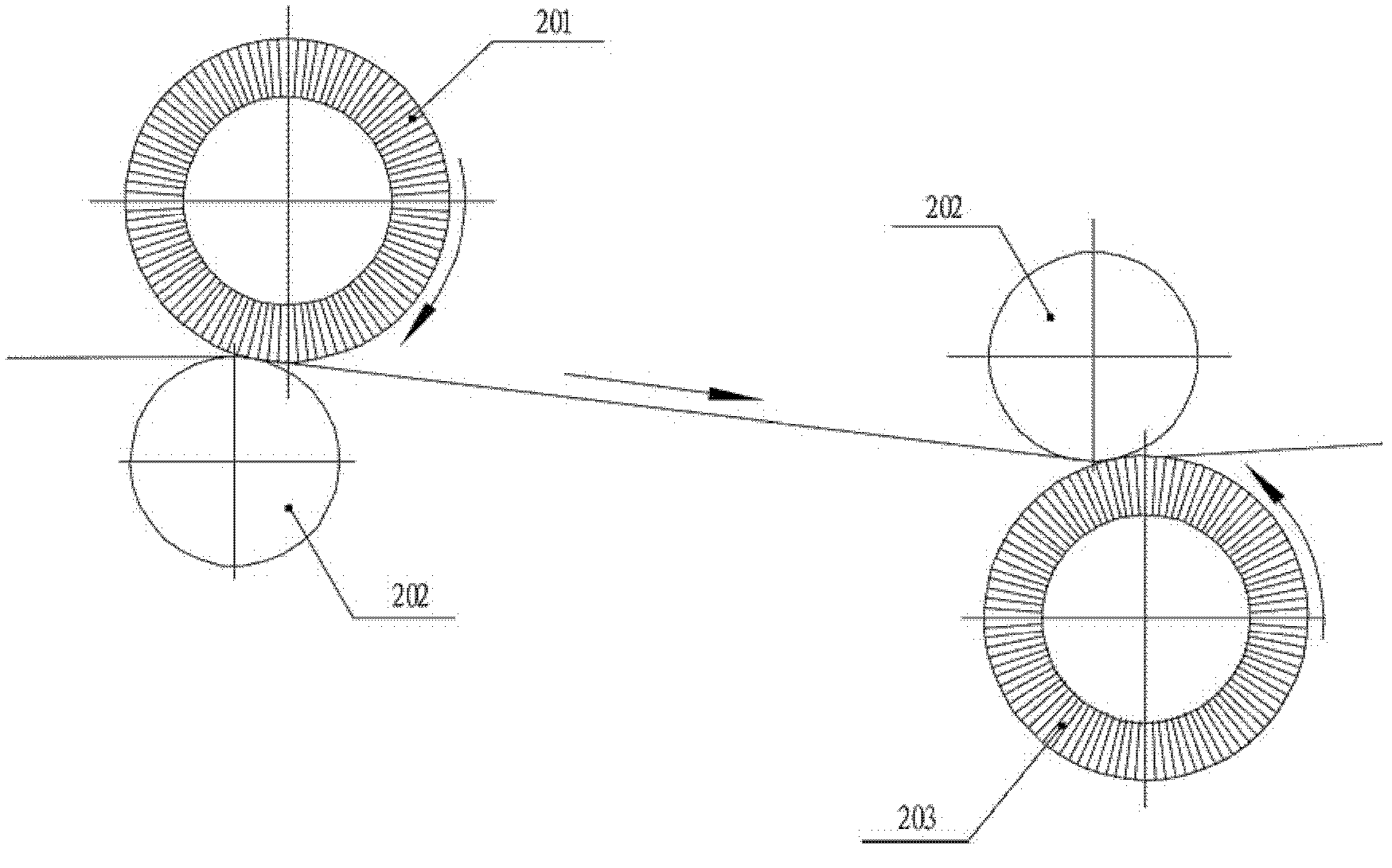

Carbon fiber reinforced wood composite material and preparation method thereof

InactiveCN101670599AHigh mechanical strengthImprove creep resistanceWood veneer joiningWood layered productsFiberCarbon fiber reinforced composite

The invention discloses a carbon fiber reinforced wood composite material and a preparation method thereof, belonging to the field of building structural plates production. The carbon fiber reinforcedwood composite material mainly consists of wood composite material and carbon fiber cloth. The reinforcement is achieved by partially sticking the carbon fiber cloth on the bottom of the wood composite material. The preparation method realizes the preparation of the wood composite material and the partial reinforcement of the carbon fiber cloth by a series of processes such as stock processing, end part gluing, end pressing, plane gluing, cold rolling, post-processing and the like. The method utilizes the carbon fiber to partially reinforce the wood composite material, thereby not only improving the mechanical strength and creep resistance of the wood composite material, but also reducing the variability of the wood composite material and meanwhile avoiding the problem of high cost causedby the massive use of the carbon fiber. The invention realizes simple preparation process and convenient operation and is suitable for large-scale industrial production.

Owner:NORTHEAST FORESTRY UNIVERSITY

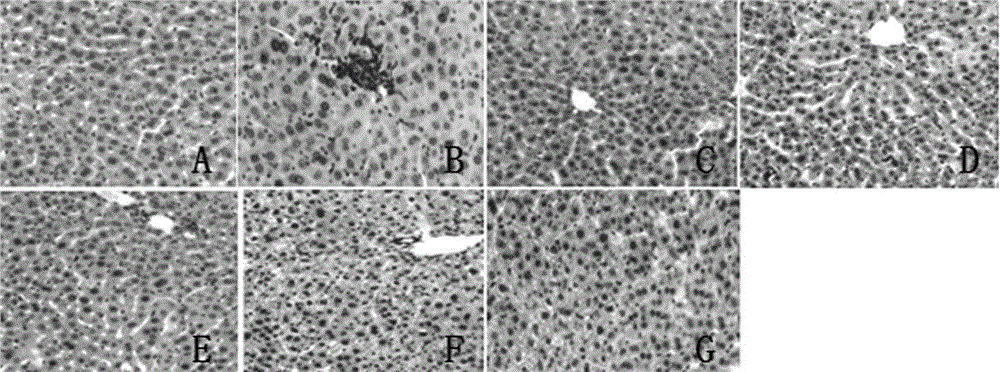

Health care product with function of protecting alcoholic liver injury

ActiveCN104667175APromote alcohol metabolismEffective fastDigestive systemPlant ingredientsSide effectSchisandra chinensis

The invention provides a health care product with a function of protecting alcoholic liver injury. The health care product is prepared from the following traditional Chinese medicines in parts by weight: 3-15 parts of roots of kudzu vines, 3-12 parts of Chinese wolfberries, 3-10 parts of turmeric and 2-6 parts of schisandra chinensis. The health care product with the function of protecting alcoholic liver injury provided by the invention can be used for accelerating ethanolic metabolism and protecting liver injury caused by excessive drinking in an auxiliary manner, further has a certain protective effect on chemical liver injury and can be used for preventing and treating liver injury caused by various reasons. The health care product is a liver protective agent which is quick in effect taking, low in cost and small in side effect. The composition provided by the invention is safe and easily available, can be taken for a long time, and is simple in preparation process and suitable for industrial production on a large scale.

Owner:LIAONING UNIV OF TRADITIONAL CHINESE MEDICINE

Preparation of high-purity animals cartilaginous collagen polypeptides

InactiveCN101253924AHigh quality hydrolyzedSimple processAnimal proteins working-upCartilage collagenLipid formation

The invention relates to a technological method for preparing collagen polypeptide from raw material of collagen powder by value-raised deep-processing technology, wherein the collagen powder is obtained by extracting chondroitin sulfate from animal cartilage; in particular to a method for preparing highly purified animal cartilage collagen polypeptide in the filed of natural material extraction technology. The method includes the following steps: first, animal cartilage collagen powder is prepared into aqueous solution, after clarification, the aqueous solution is stirred in organic solvent, stood, and extracted to remove lipid components and peculiar smells; second, salt is eluted from lower solution by the sephadex column chromatography filtering method, the eluent is collected, and then heated to 40-55 DEG C, macerozyme is selected to cut pacemaker enzyme under the condition that the collagen powder is stirred, and the eluent is stirred, decolored, filtered, concentrated and dried to obtain the hydrolytic collagen polypeptide. The method has the advantages of simple technological process, easily obtained raw material, high production efficiency, high product quality, good taste, low cost and good chemical properties and is suitable for large-scale industrial production.

Owner:QINGDAO BETTER BIO TECH

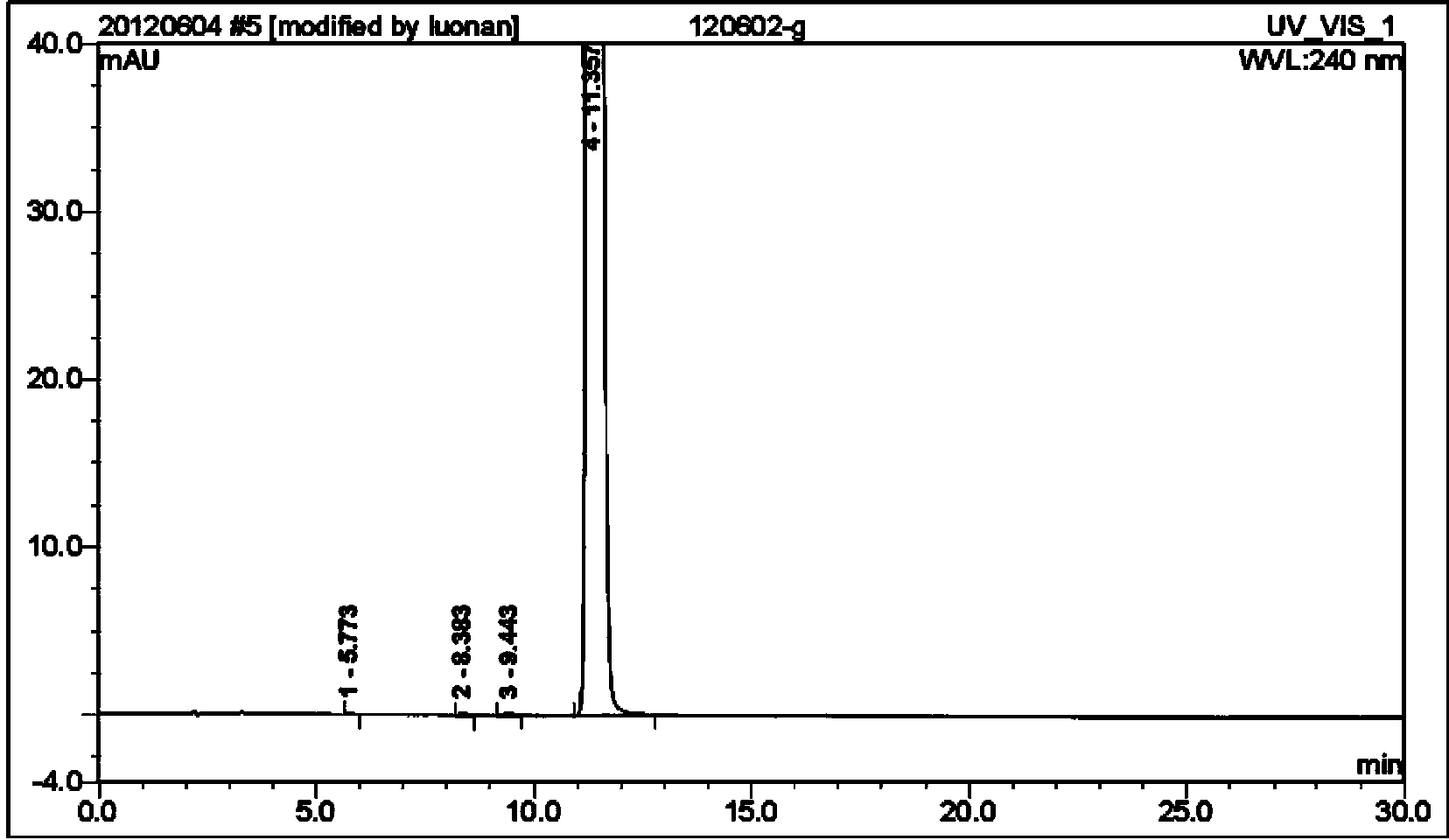

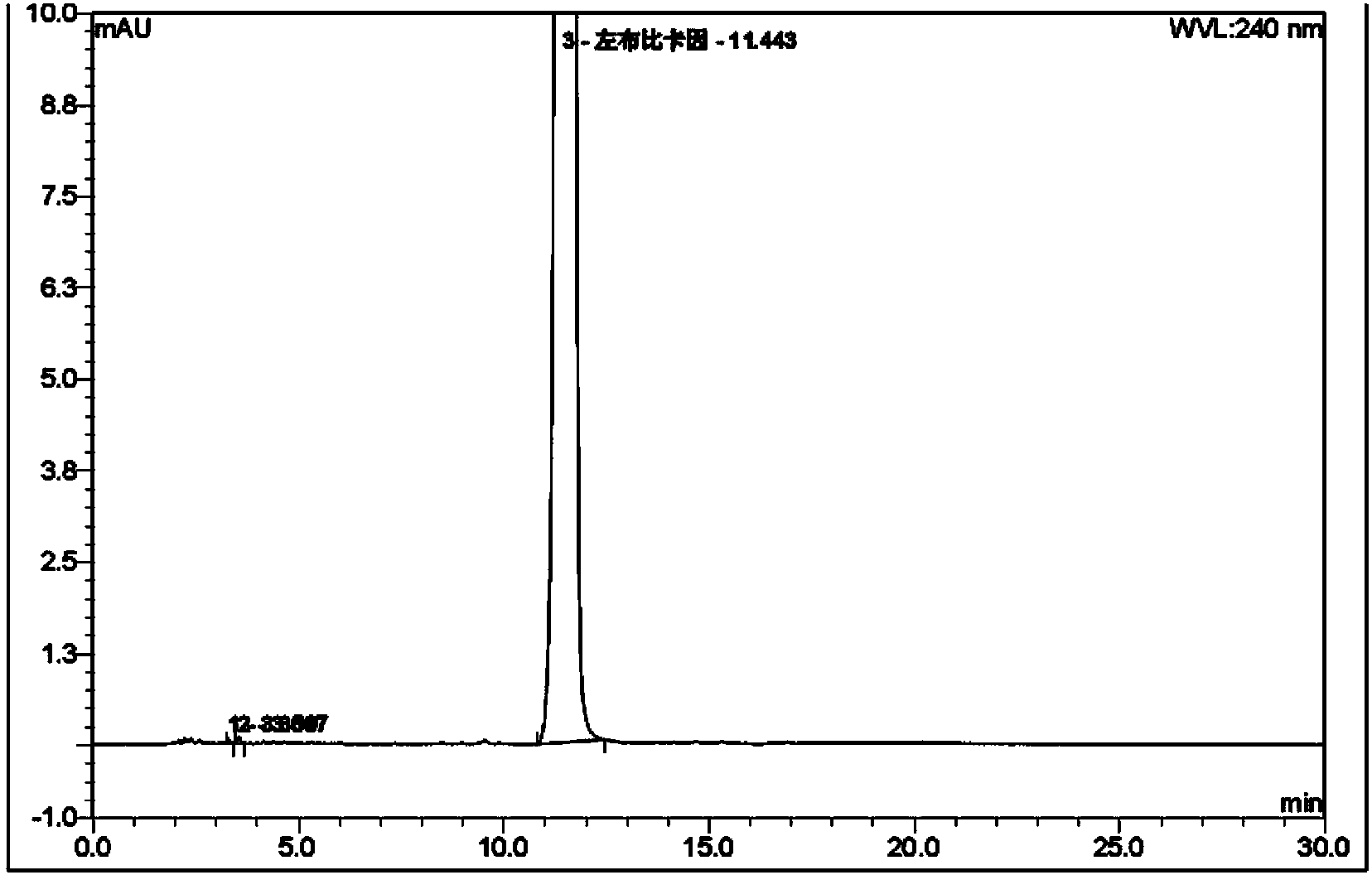

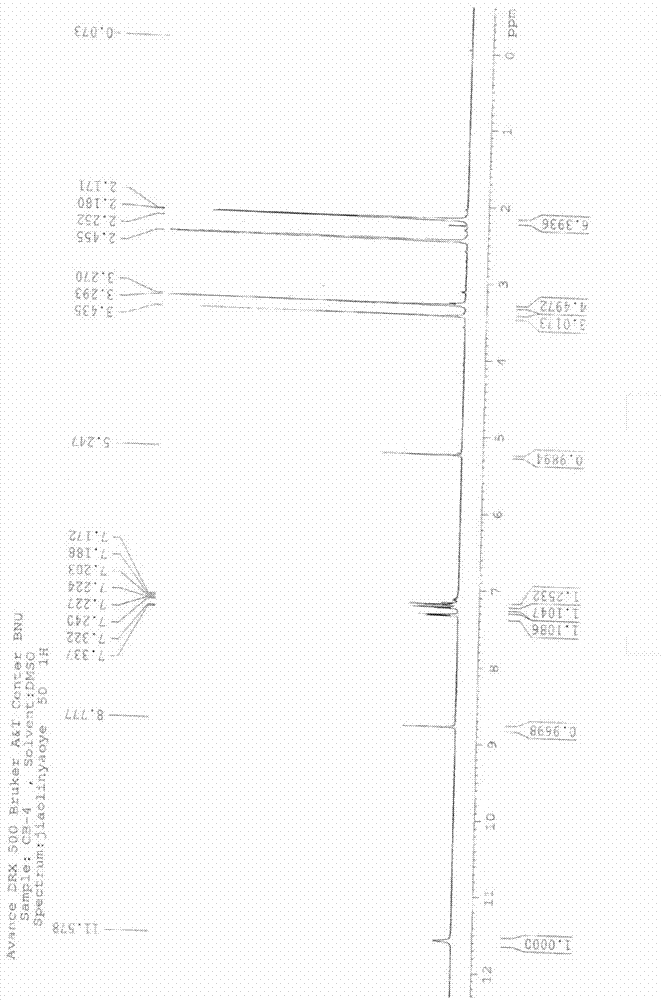

Method for purifying N-(2',6'-xylyl)-2-piperidinecarboxamide type local anesthetic

The invention discloses a method for purifying a high-purity N-(2',6'-xylyl)-2-piperidinecarboxamide type local anesthetic. The method comprises the following steps: adding N-(2',6'-xylyl)-2-piperidinecarboxamide type compound bases into a mixed solvent to release most impurities, grinding by using a colloid grinder, filtering, and replacing a small quantity of impurities through using a salifying and emulsifying method to obtain a refined product of which the particle size is smaller than 2 microns. The method is simple to operate and good in repeatability, the purity of the product reaches 99.98%, the final yield reaches 74%, and the particle size coefficient of the product is smaller than 2 microns, so that the method is suitable for large industrial production, has good economic benefits and can significantly improve the production efficiency.

Owner:YICHANG HUMANWELL PHARMA

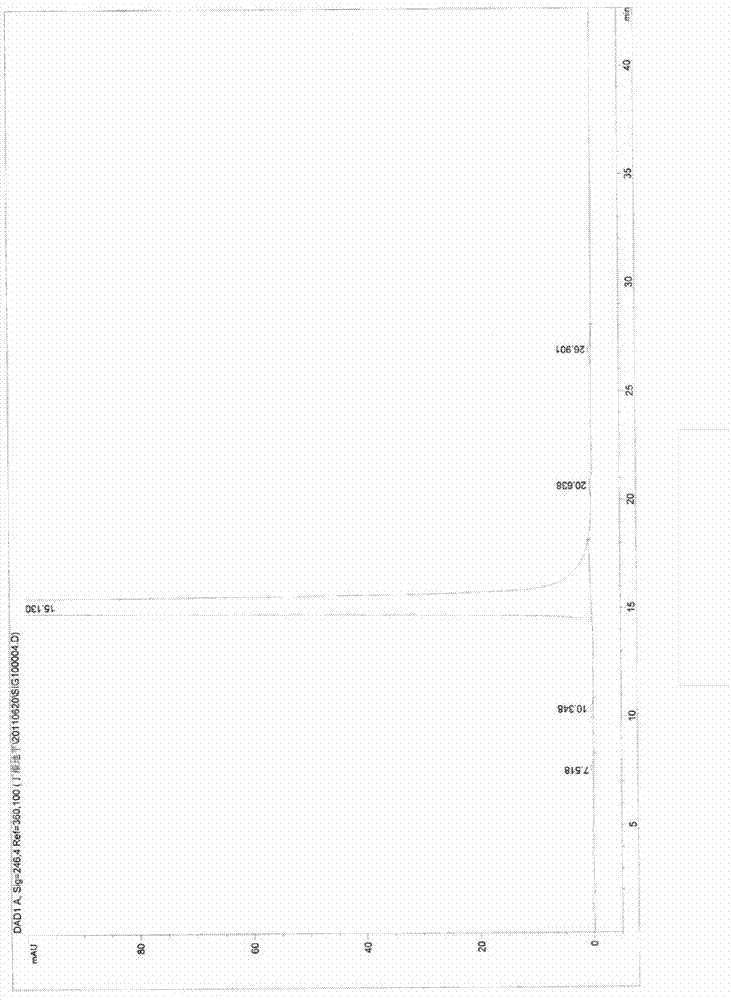

Purification method of clevidipine butyrate intermediate

The invention discloses a purification method of 4-(2,3-dichlorophenyl)-2,6-dimethyl-1,4-dihydropyridine-3-methyl carboxylate-5-carboxylic acid as an import intermediate for synthesizing clevidipine butyrate. The purification method comprises the following steps of: reacting the 4-(2,3-dichlorophenyl)-2,6-dimethyl-1,4-dihydropyridine-3-methyl carboxylate-5-carboxylic acid with alkali to generate alkali metal salt; separating out the alkali metal salt from a solvent to achieve the impurity removal purpose; acidifying the alkali metal salt, and then reacting with n-butyric acid chloroformate to prepare the clevidipine butyrate. The purification method disclosed by the invention obtains high-purity high-yield monocarboxylic acid by effectively removing dicarboxylic acid impurities contained in the monocarboxylic acid intermediate through operation steps which are easy to operate and can obviously reduce the content of principal impurities contained in the clevidipine butyrate by adopting the prepared high-purity monocarboxylic acid intermediate, simplify the purification procedure of the clevidipine butyrate and increase the total yield.

Owner:BEIJING JIALIN PHARM INC

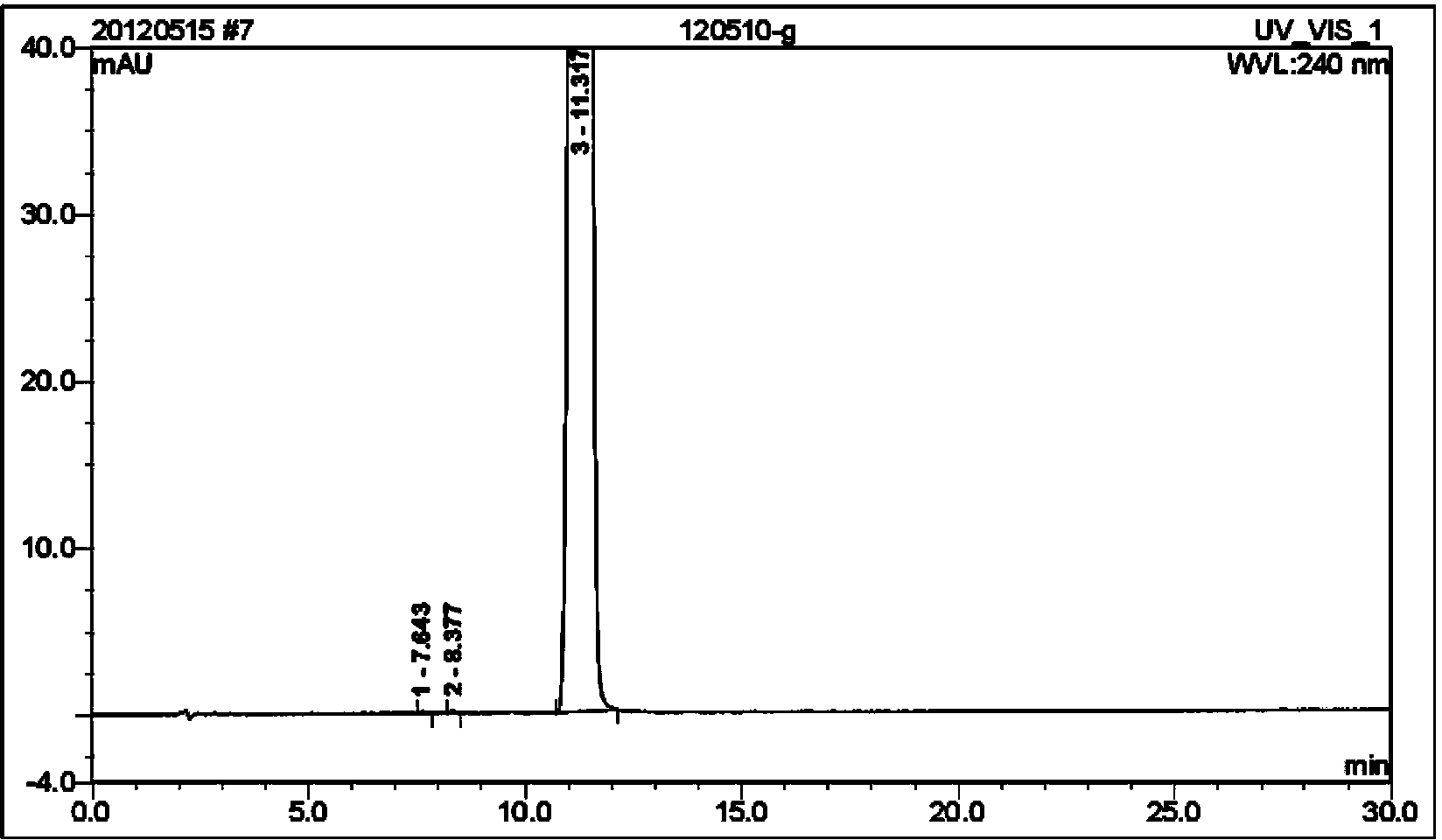

Method for purifying ioversol

InactiveCN1483723AIncrease dosageIncrease contentCarboxylic acid amide separation/purificationPurification methodsAlcohol

The present invention relates to a purification method of X-ray non-ionic contrast agent ioversol. Said invention adopts the solvent recrystallization method to make the ioversol crude product undergo the process of recrystallization at twice, and its used recrystallization solvent includes: normal butyl alcohol, 2-methyl cellosolve and isopropanol mixed solvent and 2-methyl cellosolve and normal butyl alcohol mixed solvent. After having being recrystallized the content of the ioversol can be up to above 99.0%.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

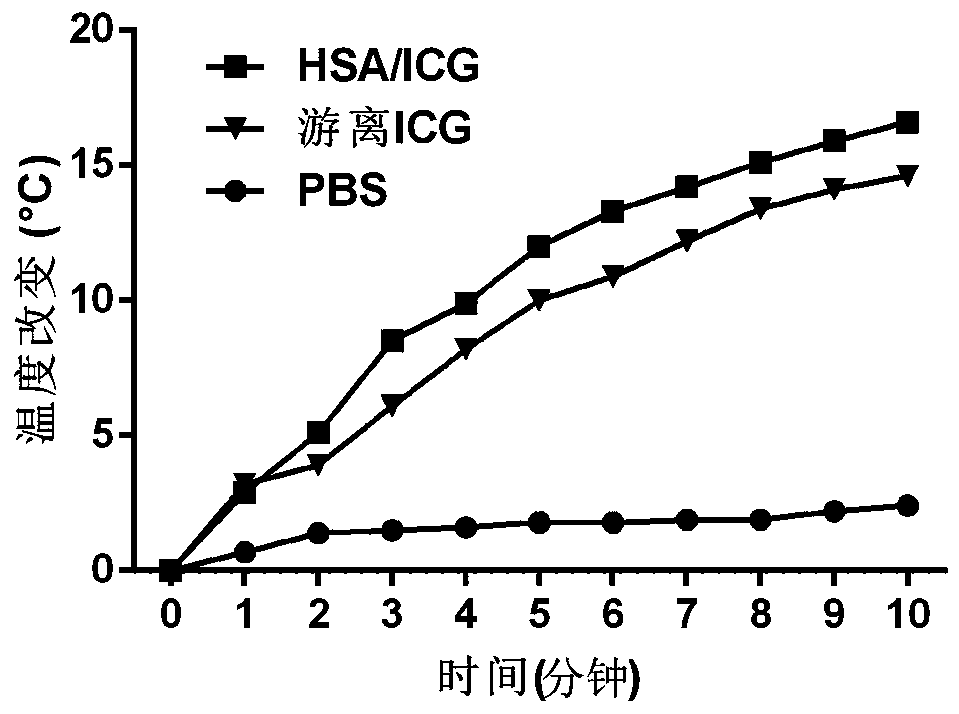

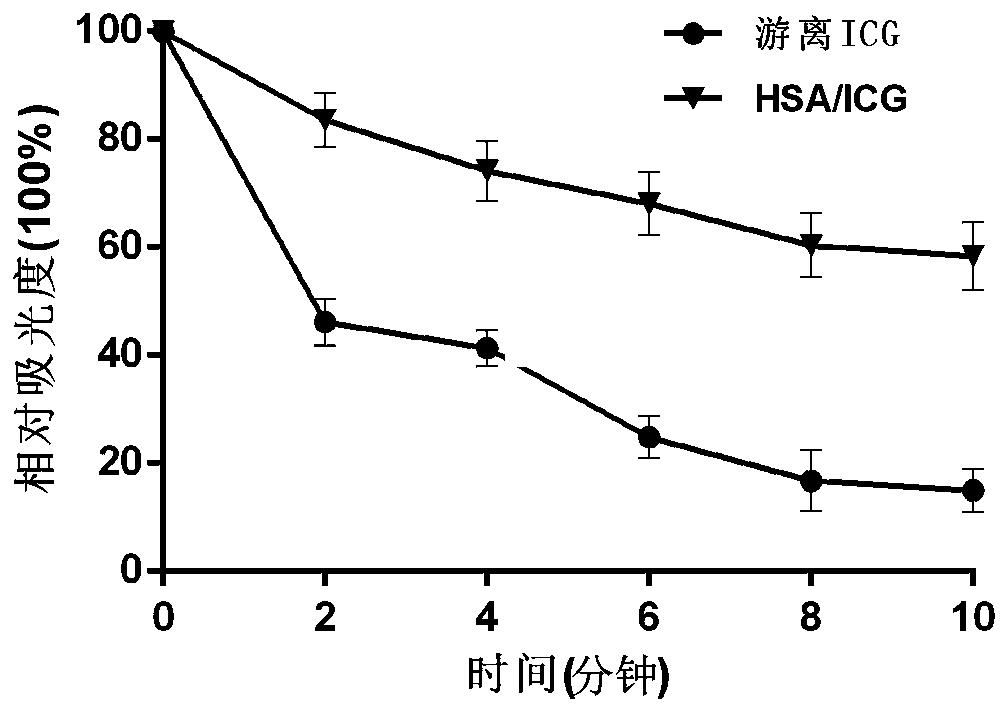

Albumin-binding indocyanine green anti-tumor photo-thermal preparation and preparation method thereof

ActiveCN111135296ANon-immunogenicBiodegradableEnergy modified materialsPharmaceutical non-active ingredientsTumor targetingActive agent

The invention provides an indocyanine green albumin conjugate preparation and a preparation method thereof. An injection mainly contains indocyanine green, albumin and a surfactant. The preparation prepared by the method has tumor targeting, significantly improves drug efficacy and reduces toxicity, and has good biocompatibility, and good stability; and a preparation process is simple, and suitable for industrialized mass production, and has broad application prospects.

Owner:SICHUAN UNIV

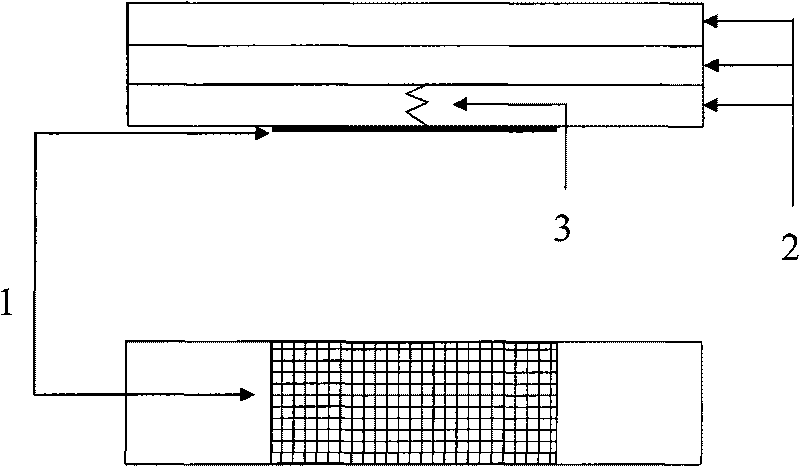

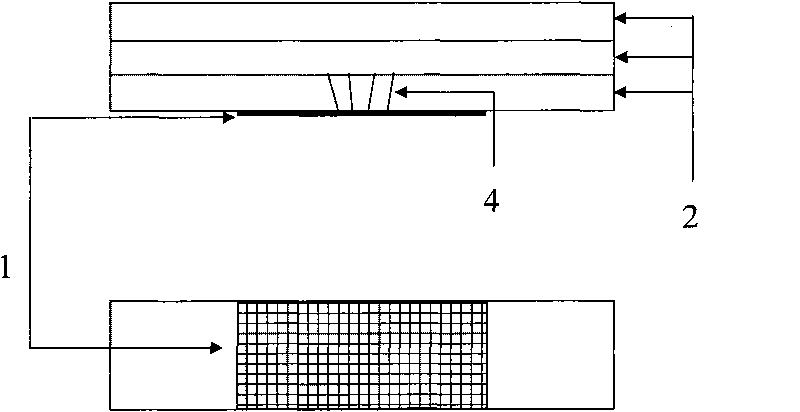

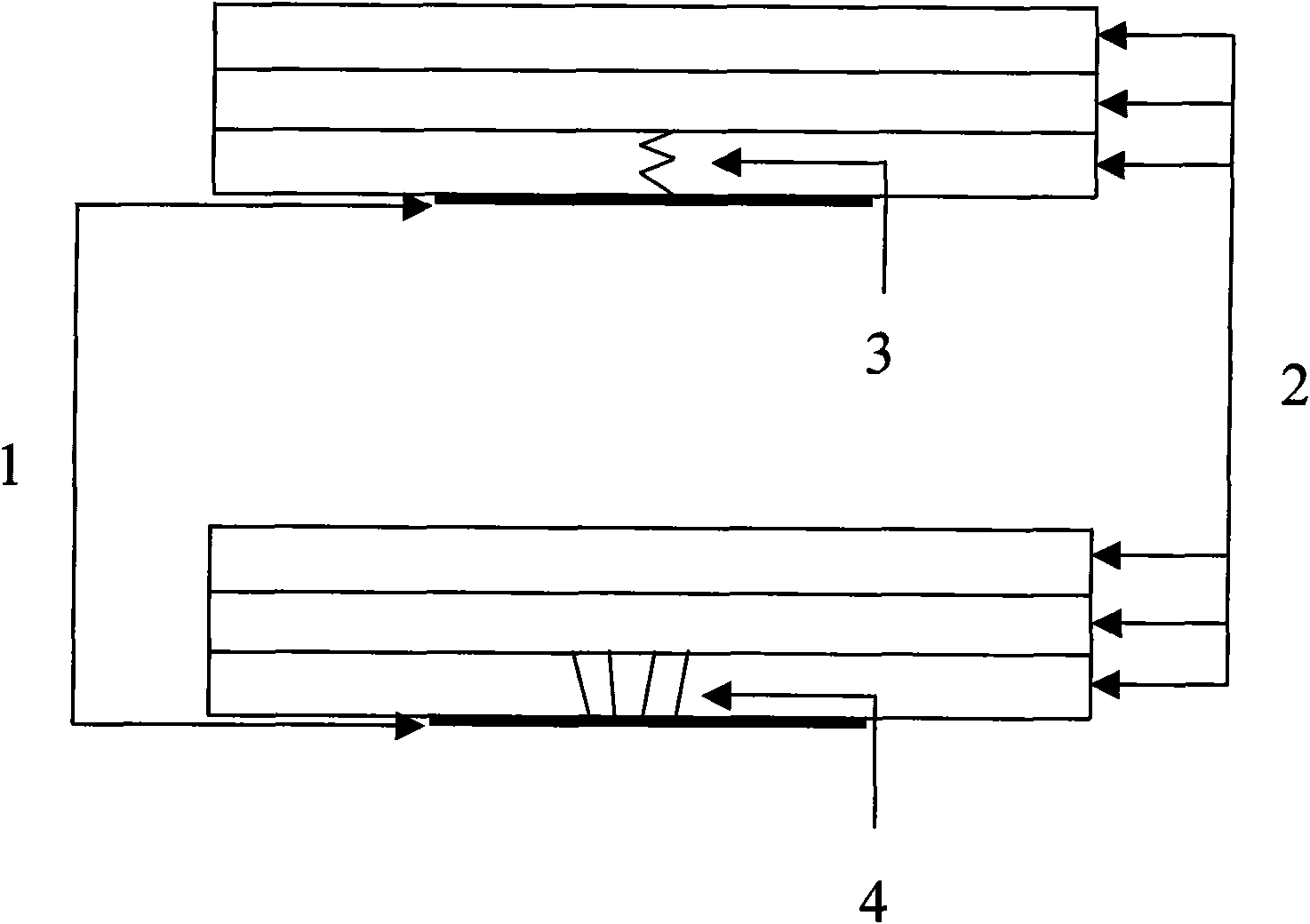

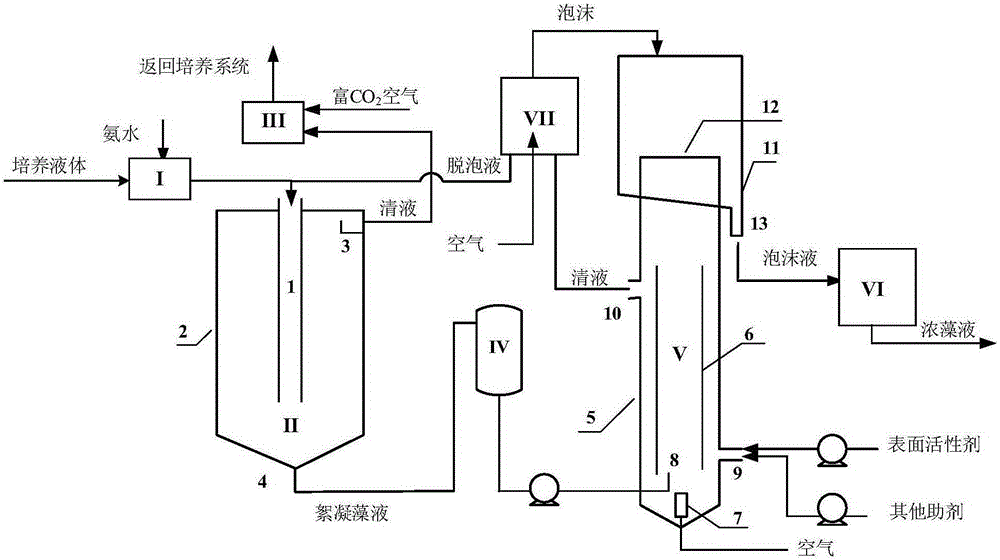

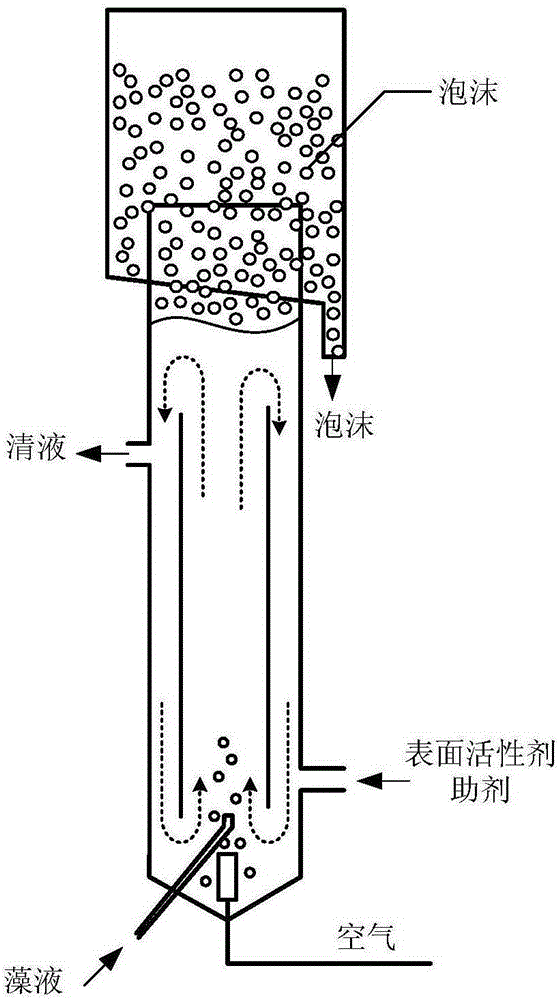

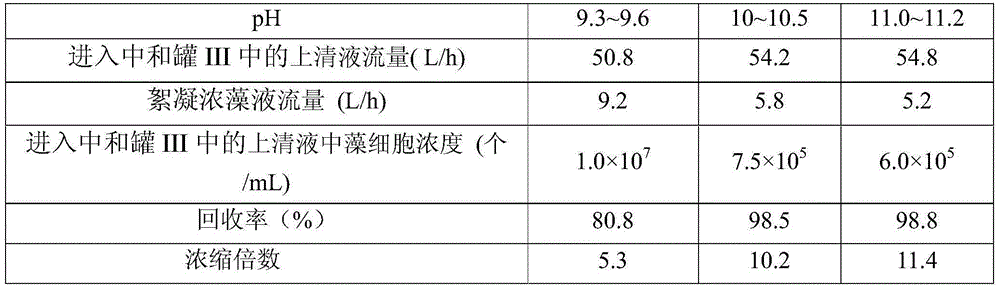

Method for harvesting microalgae through alkalescence flocculation-foam separation and separation device

ActiveCN105176826AReduce volumeReduce accumulationBioreactor/fermenter combinationsBiological substance pretreatmentsFlocculationConcentration ratio

The invention discloses a method for harvesting microalgae through alkalescence flocculation-foam separation and a separation device. The method comprises the following steps: 1) adjusting the pH value of an algae liquid; 2) performing flocculating settling on the algae liquid in a settling pond after pH adjustment, thereby obtaining a flocculated algae liquid and supernate; and 3) introducing air into a foam separation tower which is filled with the flocculated algae liquid, a surfactant and a separation additive so as to enrich microalgae to foams, and collecting the foams, thereby obtaining the microalgae. The separation device comprises the settling pond and a circulation foam tower, wherein the flocculated algae liquid outlet in the settling pond is connected with an algae liquid inlet of the circulation foam tower through a middle storage tank. The circulation foam tower consists of a foam section and a rising section, and a circulation section is divided into a rising area and a settling area by using a guide cylinder, so that gas-liquid-solid contact mass transfer can be improved, and the separation efficiency can be improved. The method is high in recycling rate and concentration ratio, can operate continuously, is short in separation time and is applicable to large-scale industrial production, high in production capacity and relatively low in cost, and meanwhile circulation of water can be achieved.

Owner:TSINGHUA UNIV

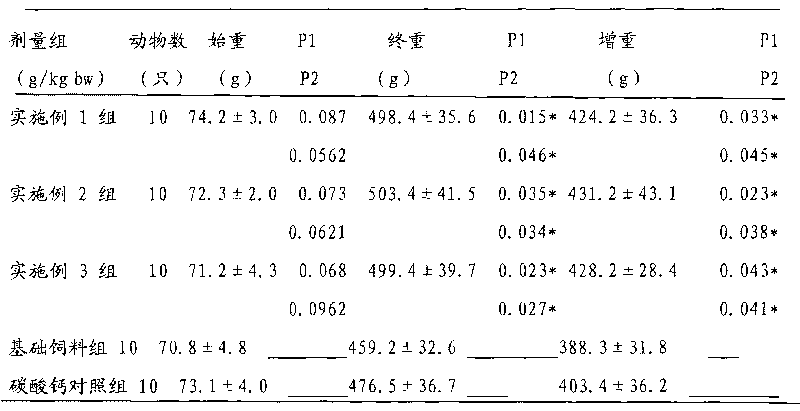

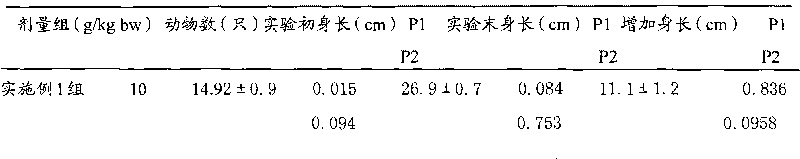

Heath product for increasing bone density and preparation method thereof

The invention discloses a health product for increasing bone density, which consists of cattle bone meal, chondroitin sulfate and vitamin D3. Preferably, mass percentages of the components of the cattle bone meal, the chondroitin sulfate and the vitamin D3 by weight are: 74 to 75 percent, 24 to 25 percent and 0.1 to 1 percent respectively. The invention also provides a method for preparing the health product. Animal tests prove that after a rat orally takes the health product for three months, the final weight and the added weight of the rate are both higher than those of a basal feed group and a calcium carbonate control group, and the differences are statistically meaningful; the apparent absorption rate of calcium of the health product is higher than that of the calcium carbonate control group; and the dry weight of the thigh bone and the density at the distal end of the thigh bone of the health product group are obviously higher those of the basal feed group and the calcium carbonate control group. The health product of the invention has the advantages of good calcium supplying effect, high absorption rate, obvious increase of the bone density and wide application prospect.

Owner:吉林省长春皓月清真肉业股份有限公司

Cooling equipment used in metallurgy field

InactiveCN105420462AImprove cooling effectQuality improvementDrying machines with progressive movementsCleaning using toolsCooling effectMaterial resources

The invention provides cooling equipment used in the metallurgy field. The cooling equipment comprises a machine frame, a conveying belt and a cooling and cleaning assembly. The cooling and cleaning assembly comprises a cleaning tank, the tank is provided with a cleaning device, cooling spraying water pipes and a water drainage pipeline, and windows are arranged on two opposite lateral walls of the tank in the direction of the conveying belt and provided with curtains. A weight sensor is arranged at the bottom of the window at the inlet side of the tank and used for sensing a metallurgy part entering the tank. The cooling spraying water pipes comprise the upper spraying water pipe located on the upper portion of the tank and the lower spraying water pipe located on the lower portion of the tank and are communicated with a cold water tank located on one side of the machine frame respectively. The cooling equipment is good in cooling effect, high in processing efficiency, good in effect and suitable for large industry production, and reduces manpower and material resources.

Owner:TIANJIN DASHUO NEW MATERIAL TECH CO LTD

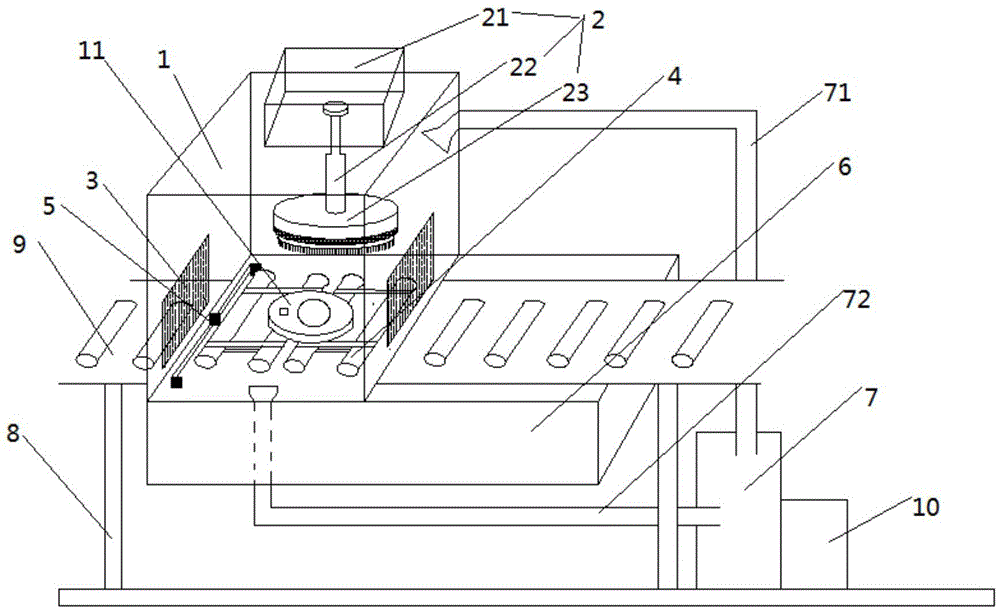

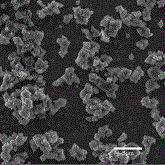

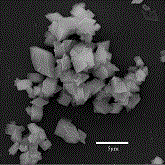

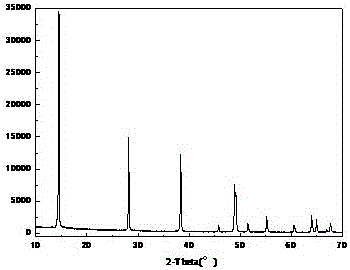

Technology for preparing boehmite microcrystal powder only through adjusting pressure

The invention discloses a technology for preparing boehmite microcrystal powder only through adjusting the pressure, and belongs to the field of ceramic materials. The boehmite microcrystal powder is prepared from industrial alumina trihydrate with large original crystal (D50 = about 13 [mu]m) and low price by using a high-pressure hydrothermal kettle only through adjusting the pressure in the kettle, and products with superior other performances can be prepared from the boehmite microcrystal powder. The technology concretely comprises the following steps: pulpifying the industrial alumina trihydrate with distilled water, pouring the obtained slurry into the high-pressure hydrothermal kettle with a stirring function, stirring and heating the slurry, only adjusting the pressure in the kettle to prepare a boehmite slurry, carrying out air cooling on the obtained slurry to room temperature, carrying out repeated suction filtration and washing with distilled water until the pH value of obtained filtrate is 7, and drying the filtrate to obtain the boehmite microcrystasl powder with small granularity (D50 = about 3.5 [mu]m), uniform distribution and rhombic block-shaped profile.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com