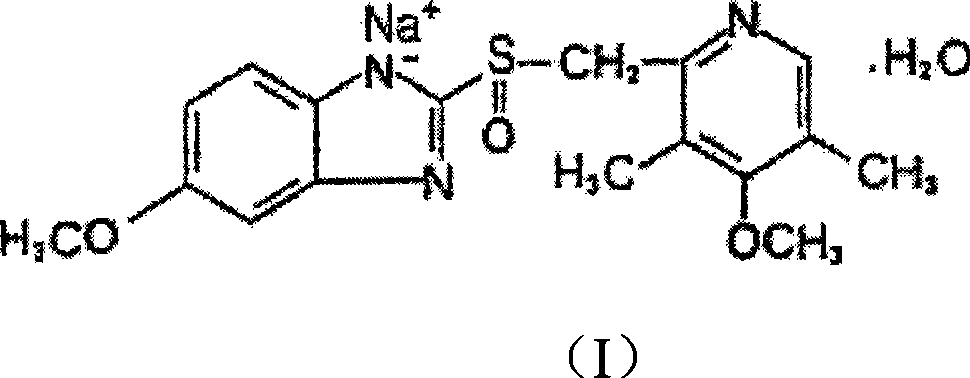

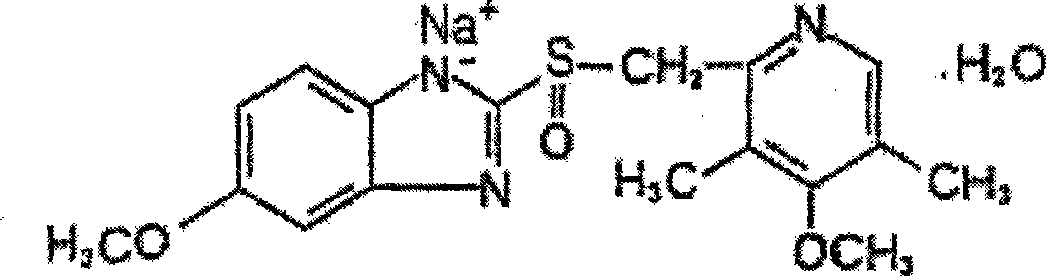

Omeprazole sodium compound and preparation thereof

A technology for omeprazole sodium and compound, which is applied in the field of preparation method of omeprazole sodium compound, can solve the problems such as influence on clinical application, poor purity of omeprazole sodium, decreased stability of preparation of omeprazole sodium and the like , to achieve the effect of improving clinical drug effect, high yield and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 100g of omeprazole sodium in 1000ml of water, add 2M sodium bisulfate solution, adjust the pH value to 6.8, stir to precipitate insoluble matter, filter, wash with 200ml of purified water, then add 220ml of dichloromethane to the resulting solid to make it Dissolve, add to the column filled with D101 macroporous resin to pass through, then elute the column with chloroform, collect the eluate, adjust the pH value to 10.5 with 5M sodium bicarbonate solution, precipitate solid, centrifuge, wash with 200ml ethanol , dried under vacuum at 40° C. for 6 hours to obtain 91.7 g of refined omeprazole sodium, with a yield of 91.7% and a purity of 99.9%.

Embodiment 2

[0022] Dissolve 100g of omeprazole sodium in 800ml of water, add 5M potassium hydrogen tartrate solution, adjust the pH value to 6.6, stir to precipitate insoluble matter, filter, wash with 230ml of purified water, then add 350ml of ethanol to the resulting solid to dissolve it, Add the column filled with AB-8 macroporous resin to pass through, then elute the column with chloroform, collect the eluate, adjust the pH value to 9.7 with 2M potassium bicarbonate solution, precipitate solid, centrifuge, wash with 200ml ethanol , dried under vacuum at 35°C for 10 hours to obtain 92.2 g of refined omeprazole sodium, with a yield of 92.2% and a purity of 99.9%.

Embodiment 3

[0024] Dissolve 100g of omeprazole sodium in 1200ml of water, add 1M disodium hydrogen phosphate solution, adjust the pH value to 6.5, stir to precipitate insoluble matter, filter, wash with 200ml of purified water, and then add 270ml of methanol to the obtained solid to dissolve it , add the column filled with D101 macroporous resin to pass through, then elute the column with chloroform, collect the eluate, adjust the pH value to 10.0 with 5M sodium bicarbonate solution, separate out the solid, centrifuge, wash with 300ml ethanol, Vacuum drying at 40°C for 8 hours gave 90.1 g of refined omeprazole sodium with a yield of 90.1% and a purity of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com