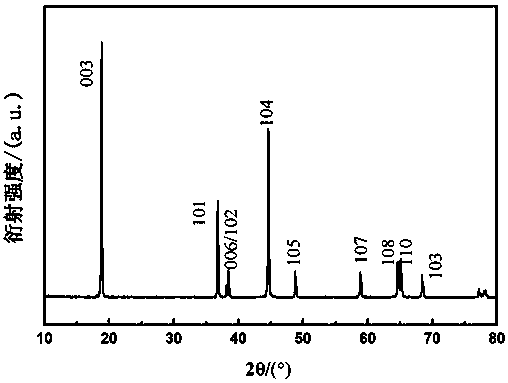

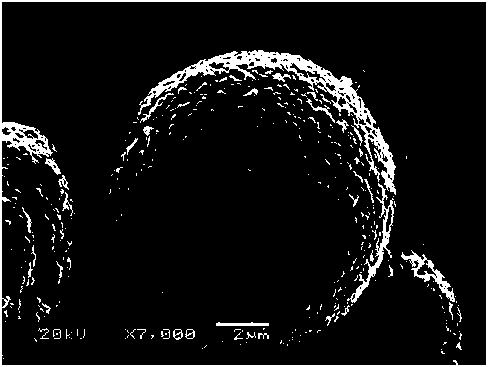

Preparation method of N-doped mesoporous carbon-coated ternary cathode material of lithium ion battery

A nitrogen-doped mesoporous carbon and lithium-ion battery technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as poor electrical conductivity and uneven coating layer, so as to improve electronic conductivity and cycle performance , The effect of improving the magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0040] Preparation method of high-capacity ternary cathode material for lithium ion battery:

[0041] 2.203g (52.5mmol) LiOH·H 2 O and 4.589g (50mmol) Ni 0.8 co 0.15 Al 0.05 (OH) 2 Grinding and mixing, in an oxygen atmosphere with a purity ≥ 99.9%, first raise the temperature to 550°C at a rate of 5°C / min, calcinate for 4 hours, then raise the temperature to 750°C at a rate of 5°C / min, calcinate for 15 hours, and cool naturally to room temperature , LiNi, a high-capacity ternary cathode material for lithium-ion batteries 0.8 co 0.15 Al 0.05 o 2 .

reference example 2

[0043] Preparation method of high-capacity ternary cathode material for lithium ion battery:

[0044] 1.507g (20.4mmol) Li 2 CO 3 and 3.67g (40mmol) Ni 0.6 co 0.2 mn 0.2 (OH) 2 Grinding and mixing, in an oxygen atmosphere with a purity ≥ 99.9%, first raise the temperature to 480°C at a rate of 5°C / min, calcinate for 5h, then raise the temperature to 800°C at a rate of 5°C / min, calcinate for 12h, and cool naturally to room temperature , LiNi, a high-capacity ternary cathode material for lithium-ion batteries 0.6 co 0.2 mn 0.2 o 2 .

reference example 3

[0046] Preparation method of high-capacity ternary cathode material for lithium ion battery:

[0047] 1.983g (47.25mmol) LiOH·H 2 O and 4.130 g (45 mmol) Ni 0.8 co 0.1 mn 0.1 (OH) 2 Carry out grinding and mixing, in the air atmosphere, first raise the temperature to 480°C at a rate of 4°C / min, calcinate for 4h, then raise the temperature at a rate of 4°C / min to 750°C, calcinate for 10h, and naturally cool to room temperature to obtain a lithium-ion battery High-capacity ternary cathode material LiNi 0.8 co 0.1 mn 0.1 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com