Optical glass, prefabricated part for precise compression molding and optical element

A technology of optical glass and prefabricated parts, applied in glass pressing, glass molding, glass manufacturing equipment, etc., can solve problems such as low temperature softening and stability difficulties, glass transition temperature rise, glass stability deterioration, etc., to achieve realization High-efficiency production, extended life, and lower temperature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

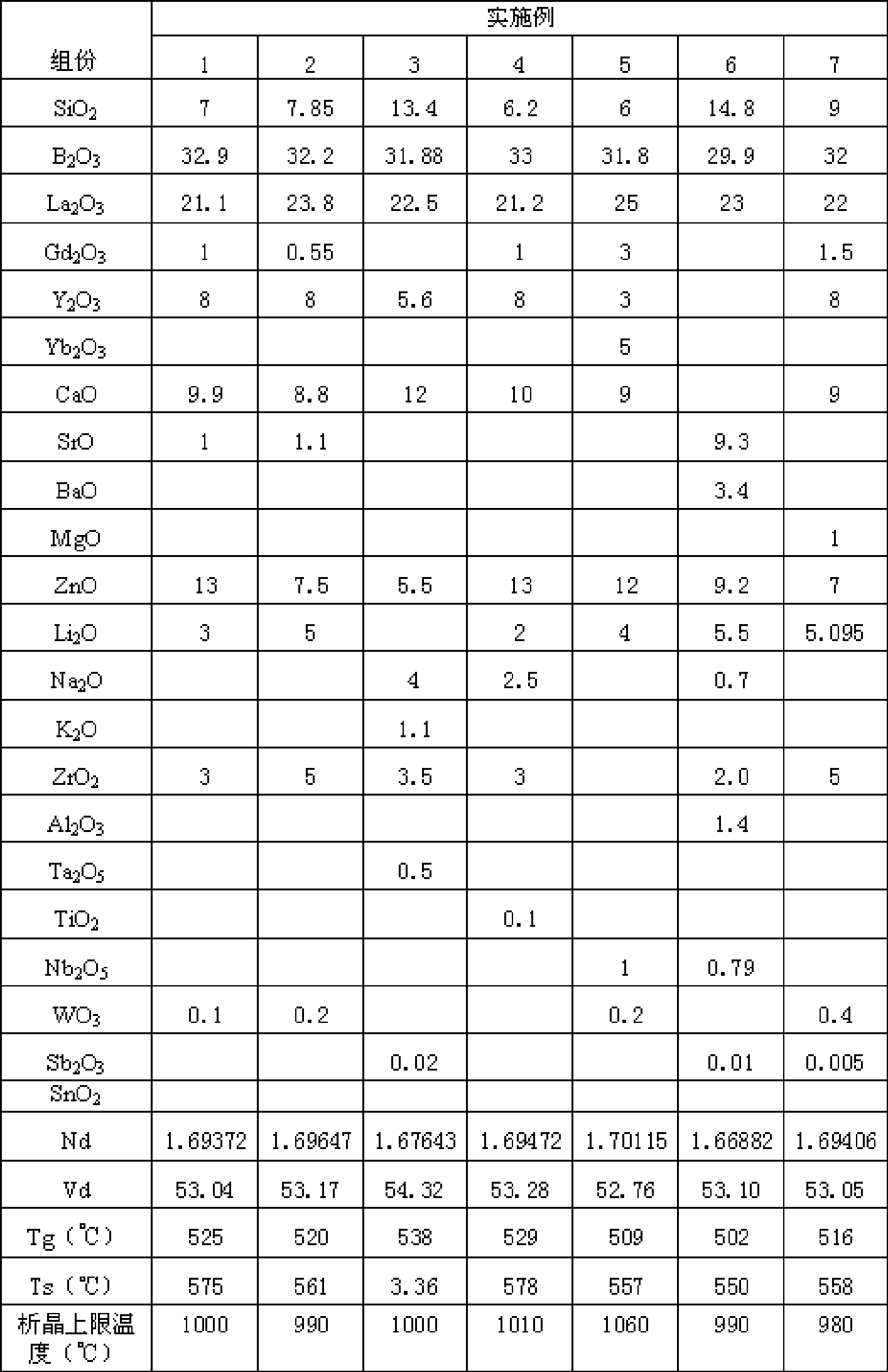

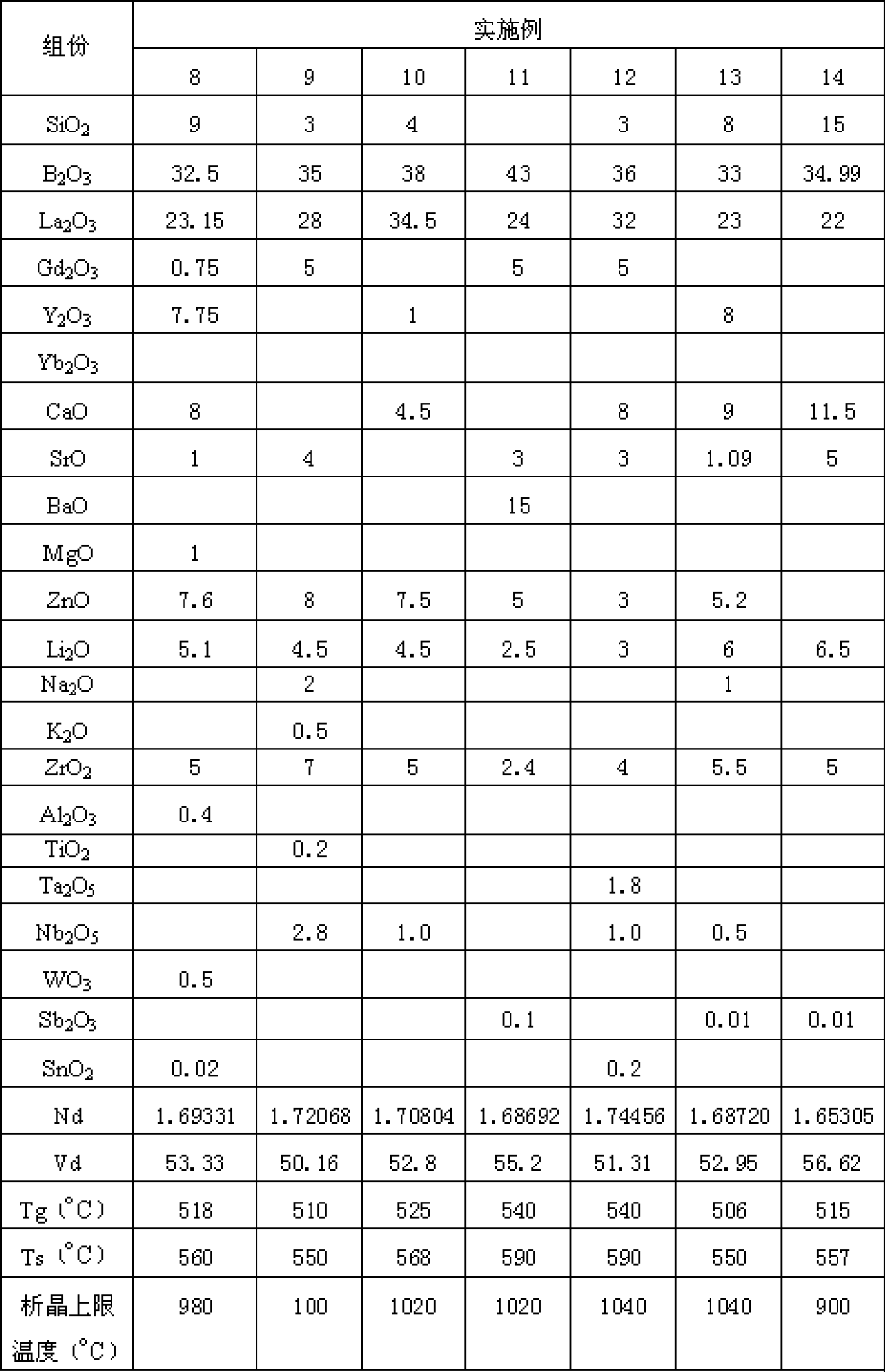

[0014]The reasons for limiting the composition ranges constituting the optical glass of the present invention as described above are as follows. Components are expressed in % by weight of the oxide standard.

[0015] SiO 2 The optical glass of the present invention is very effective in increasing the molding viscosity of the glass, improving devitrification resistance, and chemical stability, but if the amount is too large, Tg increases and meltability deteriorates. Therefore, its content is 0-15%, preferably 6-12%, more preferably 7-10%.

[0016] B 2 o 3 Oxide is an indispensable component as a glass former. However, if the amount is too small, the devitrification resistance will be insufficient, and if the amount is too large, the refractive index of the glass will decrease and the chemical stability will deteriorate. Therefore, its content is 28-43%, preferably 28-35%, more preferably 29-34%.

[0017] La 2 o 3 Effective for increasing the refractive index of glass a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com