Composite self-adhering water-proof coiled material

A technology of self-adhesive waterproof membrane and waterproof layer, which is applied to building thermal insulation materials, roofs using flexible materials, building components, etc. Convenience, improved tear resistance, easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

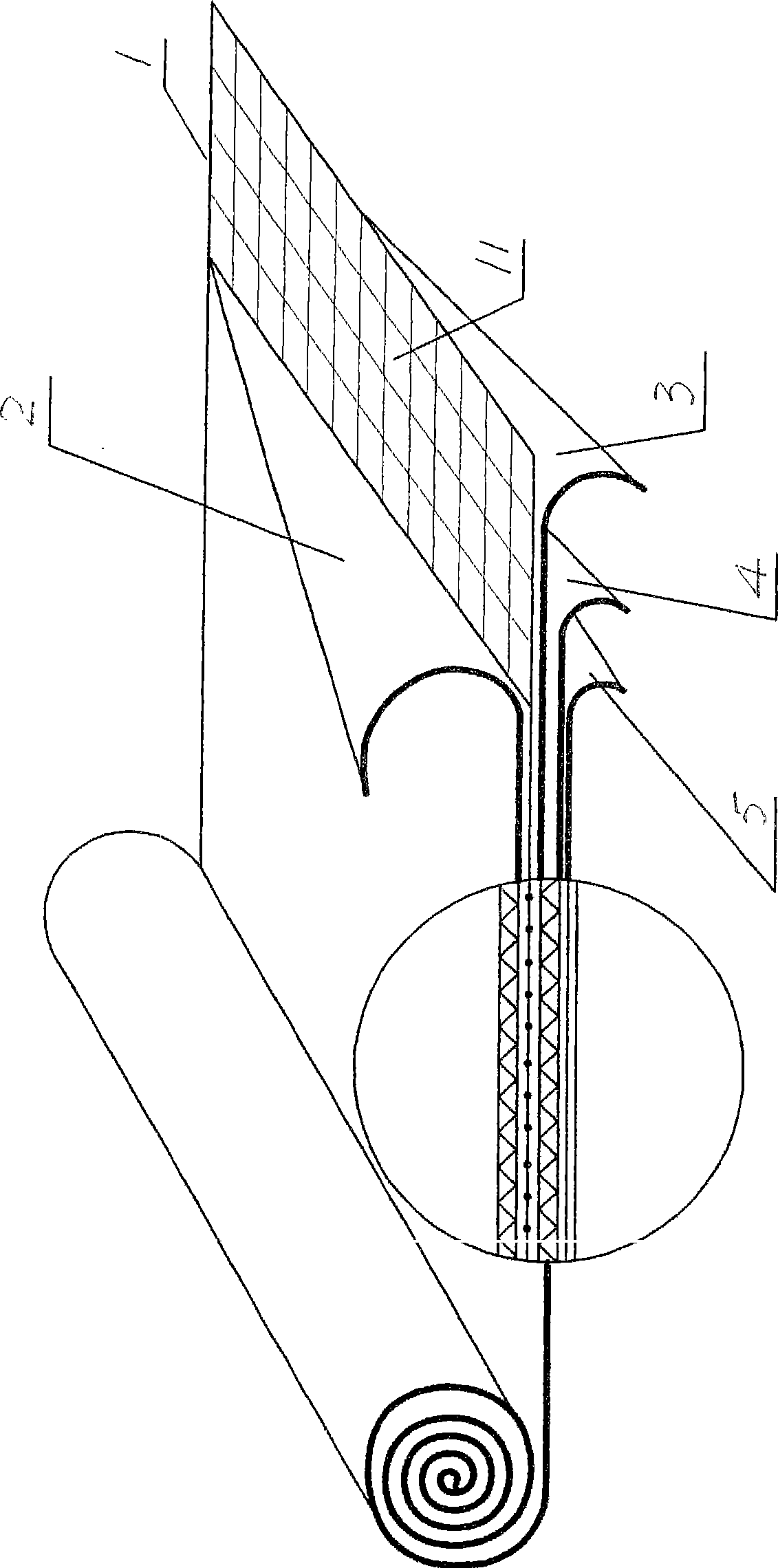

[0021] Referring to the accompanying drawings, a cloth with a mesh 11 and a material made of glass fiber is used as the reinforcing layer 1, wherein the size of the mesh 11 is 20 mesh. Taking the position shown in the current drawings as an example (the same below), the side surface of the reinforcement layer 1 facing upward is the first waterproof layer 2, and the side surface of the reinforcement layer 1 facing downward (ie, the back) is the second waterproof layer 2. Waterproof layer 3. In this embodiment, the thickness of the first waterproof layer 2 is equal to the thickness of the second waterproof layer 3, and the first waterproof layer 2, the reinforcement layer 1 and the second waterproof layer 3 are combined into one body through the rolling process. The reinforcement layer 1 has a structure with mesh holes 11, therefore, the surfaces facing each other of the first and second waterproof layers 2, 3, that is, the surfaces on one side facing the reinforcement layer 1 r...

Embodiment 2

[0024] The figure is omitted, only the size of the mesh 11 is changed to 10 meshes, the thickness of the first waterproof layer 2 is larger than the thickness of the second waterproof layer 3, and the self-adhesive layer 4 is combined on the surface of the first waterproof layer 2, combined with the self-adhesive The isolation layer 5 on the surface of the layer 4 is changed to a release film, and the rest are the same as the description of the embodiment 1.

Embodiment 3

[0026] The diagram is omitted, only the material of the reinforcing layer 1 is changed to polyester fiber mesh cloth, the size of the mesh 11 is 16 mesh, the thickness of the first waterproof layer 2 is larger than that of the second waterproof layer 3, and the rest are the same as in Example 1 description of.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap