Engine oil sump

An engine oil and oil pan technology, which is applied in the direction of engine components, machines/engines, and engine lubrication, can solve problems such as increased manufacturing difficulty and cost, complex engine structure, and large oil pressure loss, saving power and reducing The space occupied, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

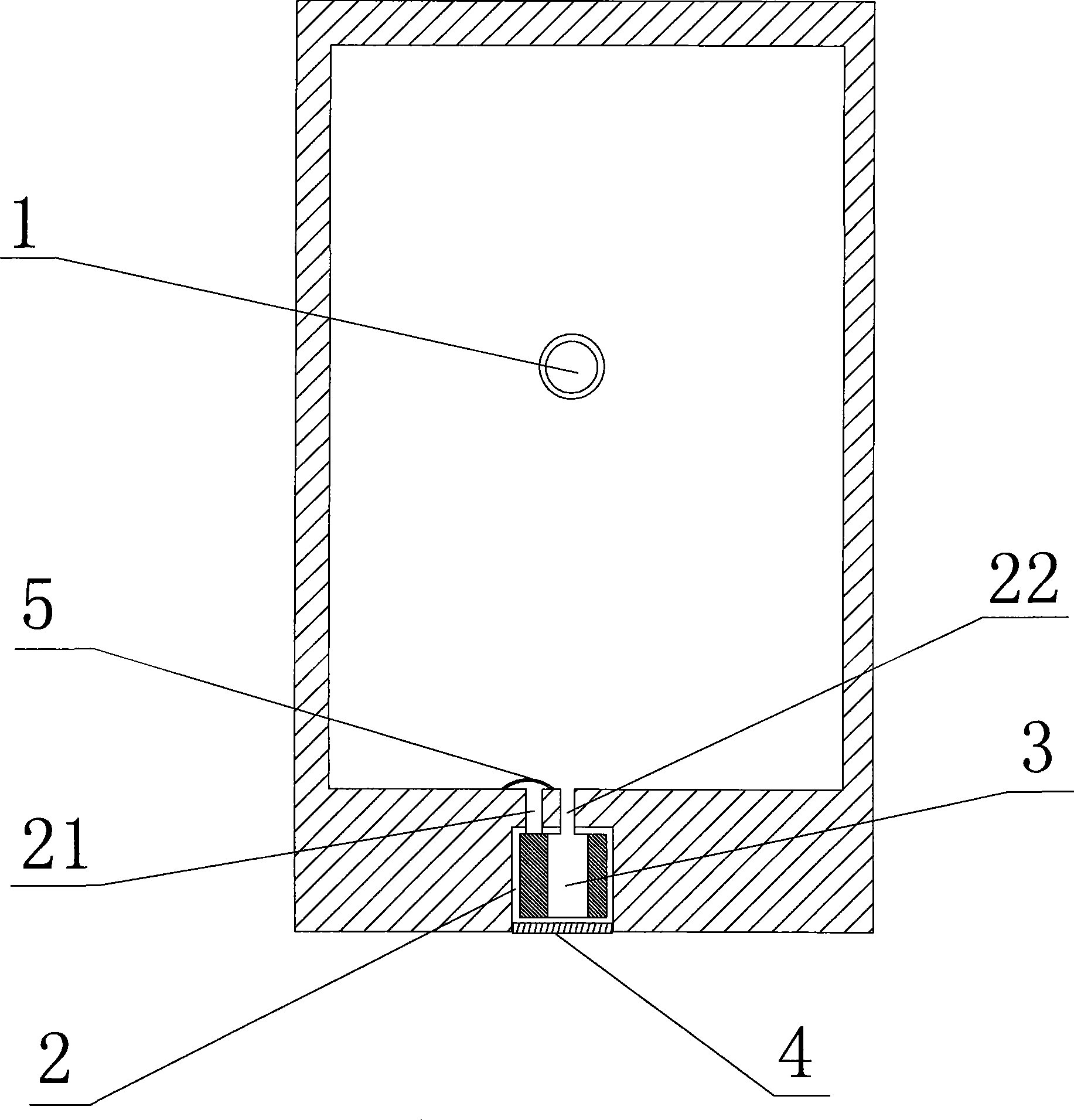

Embodiment 1

[0020] The bottom of the engine oil pan in this embodiment is provided with an oil drain plug 1, and the side wall is provided with an accommodating hole 2 that can accommodate the oil filter element 3, and the end of the accommodating hole 2 facing the inside of the oil pan is provided with an oil plug. The oil passage inlet 21 and the oil passage outlet 22, the other end is threaded to install the oil filter cover 4, the oil filter element 3 is installed inside the accommodation hole 2, and the oil passage inlet 21 of the accommodation hole 2 is equipped with a filter screen 5.

[0021] The engine oil passage of this embodiment is arranged like this: After the engine oil enters the oil pan from the oil passage of the cylinder body, it passes through the oil passage of the oil pan, the oil filter, the oil pump and the cylinder body frame in turn, and finally returns to the cylinder body Oil passage, the length of the oil passage of the whole engine is greatly shortened compar...

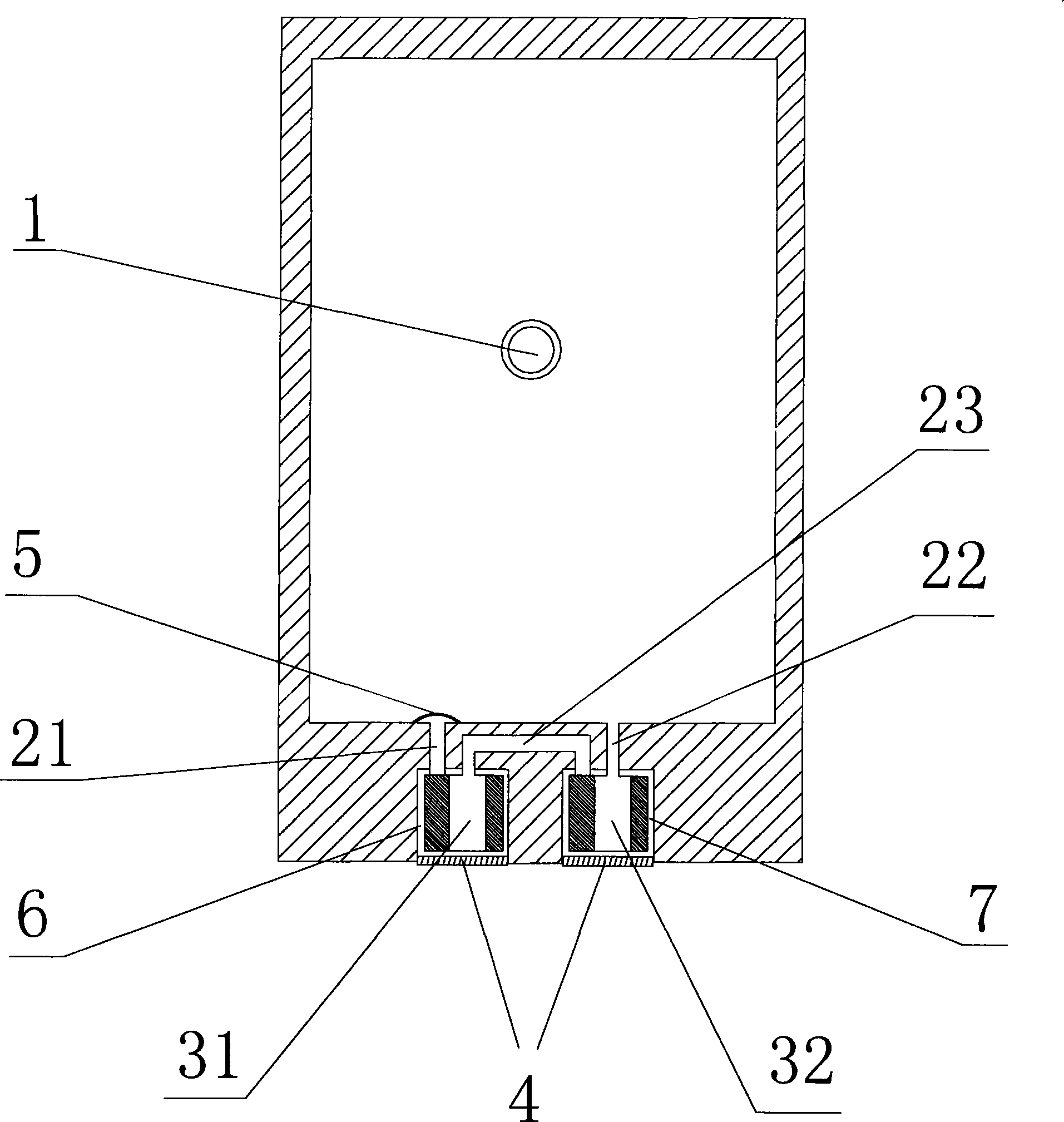

Embodiment 2

[0023] The bottom of the engine oil pan in this embodiment is provided with an oil drain screw plug 1, and the side wall is provided with two accommodating holes 6, 7 that can accommodate the oil primary filter element 31 and the engine oil fine filter element 32. The accommodating hole 6 has an oil inlet 21 at one end facing the oil pan, the accommodating hole 7 has an oil outlet 22 at one end facing the oil pan, and the other ends of the accommodating holes 6 and 7 are threaded. Install the oil filter cover 4, install the primary oil filter element 31 and the fine oil filter element 32 inside the two accommodation holes 6 and 7 respectively, and there is an oil passage between the two accommodation holes 6 and 7 23 are connected, and filter screen 5 is installed at oil inlet 21 places.

[0024] The engine oil passage of this embodiment is arranged like this: After the engine oil enters the oil pan from the oil passage of the cylinder body, it passes through the oil pan, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com