Axial-flow fan and fan blade of centrifugal fan

A technology of axial flow fan and centrifugal fan, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as deposition, reduce pressure difference, and improve power consumption and noise quality, and the effect of eliminating the backflow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

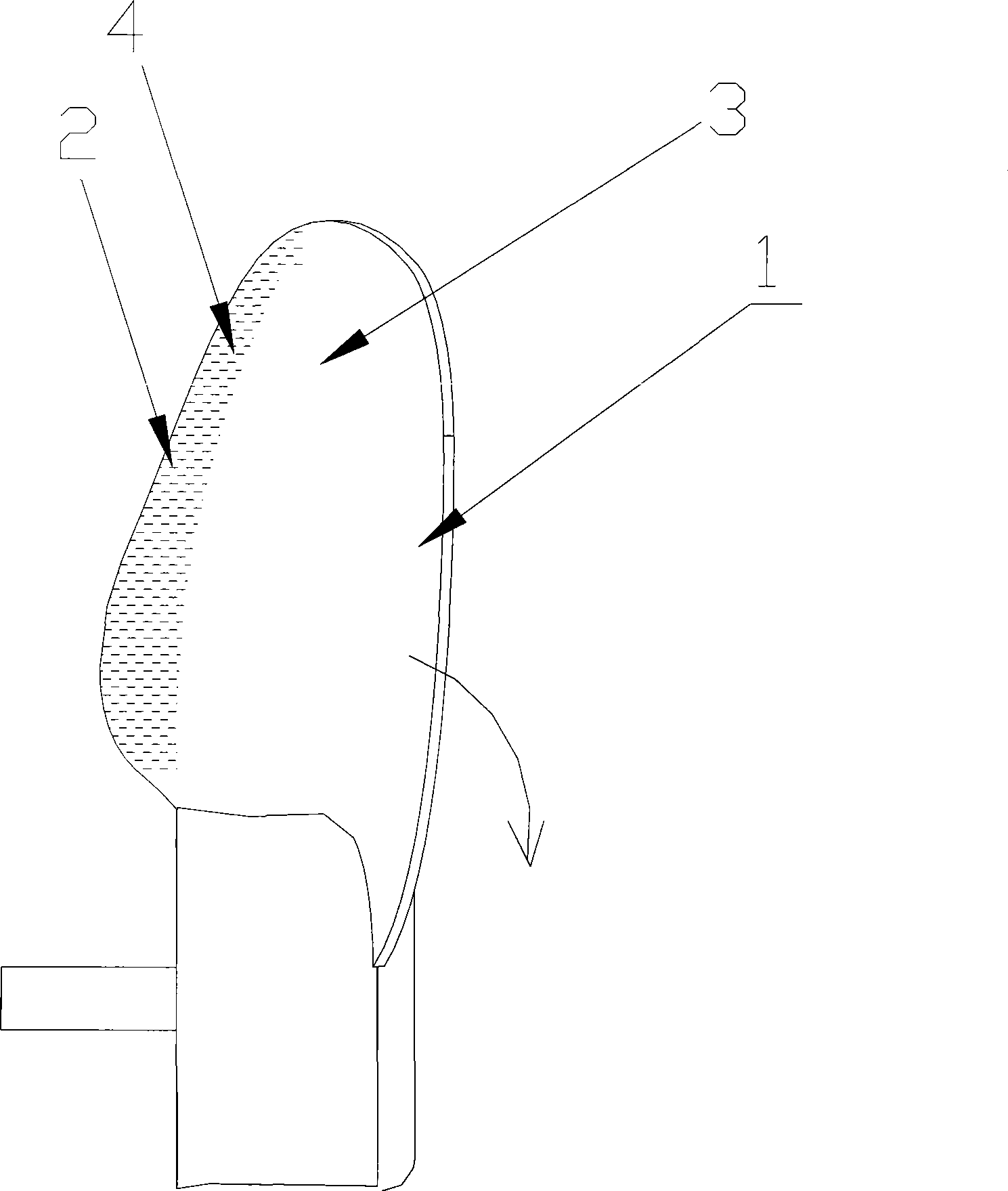

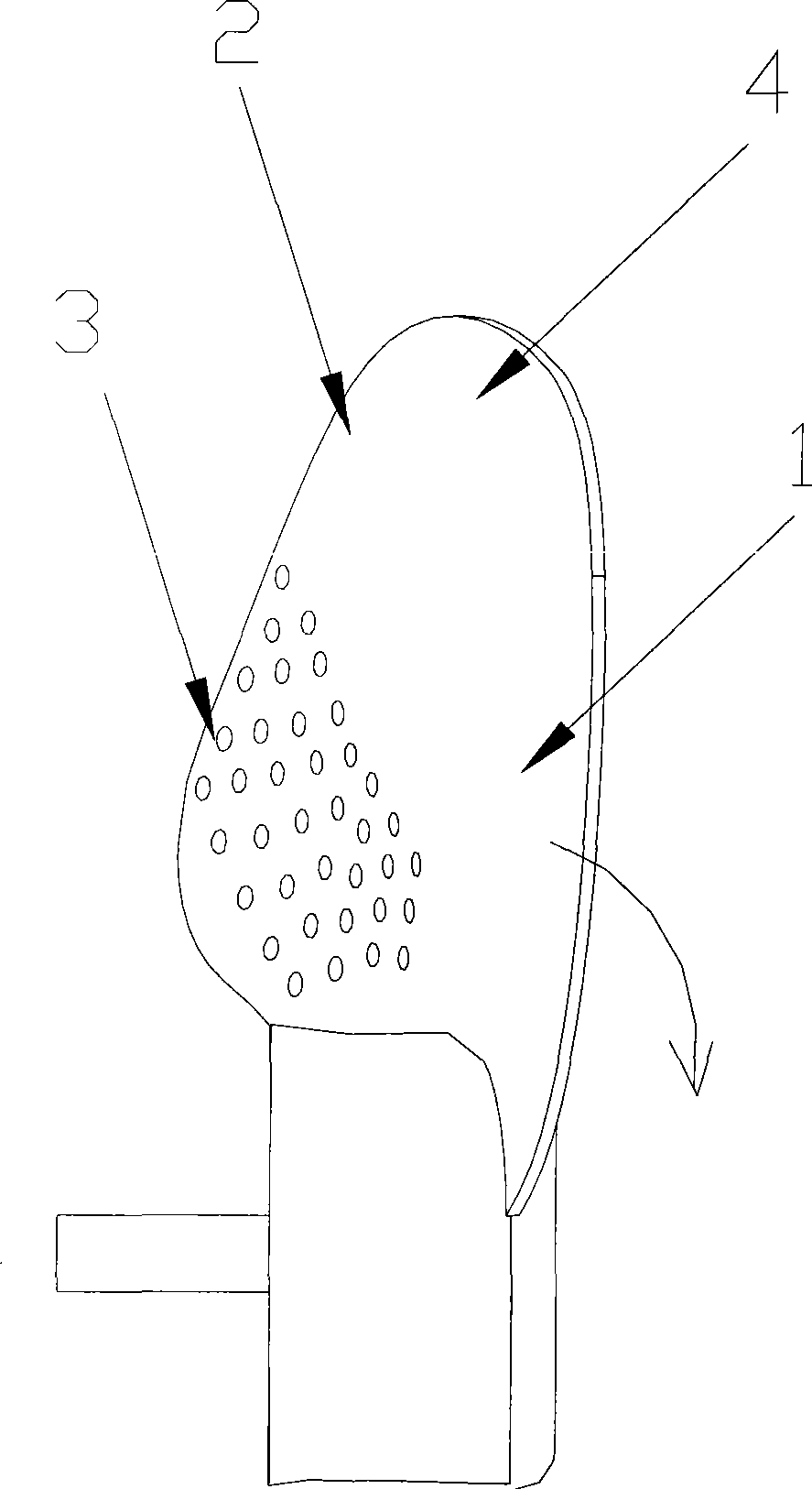

[0024] Embodiment 1: as figure 2 , image 3 As shown, the axial flow fan blade of the present invention includes a front edge portion 1 in the direction of air inflow and a rear edge portion 2 in the direction of air outflow. The rear edge portion 2 is provided with several pressure balance holes 3 . Several pressure balance holes 3 may be circular holes, non-circular holes, straight through holes, straight blind holes, oblique through holes or oblique blind holes. The distribution of several pressure balance holes 3 constitutes a hole network to regulate the pressure on both sides of the fan blade. The diameter range of the pressure balance hole 3 is 0.1mm-100mm.

[0025] It has been proved by experiments that there are several pressure balance holes 3 on the trailing edge 2, which play the role of self-balancing pressure, reduce the pressure difference between the front and back of the fan blade, and eliminate the boundary layer airflow separation zone of the trailing edg...

Embodiment 2

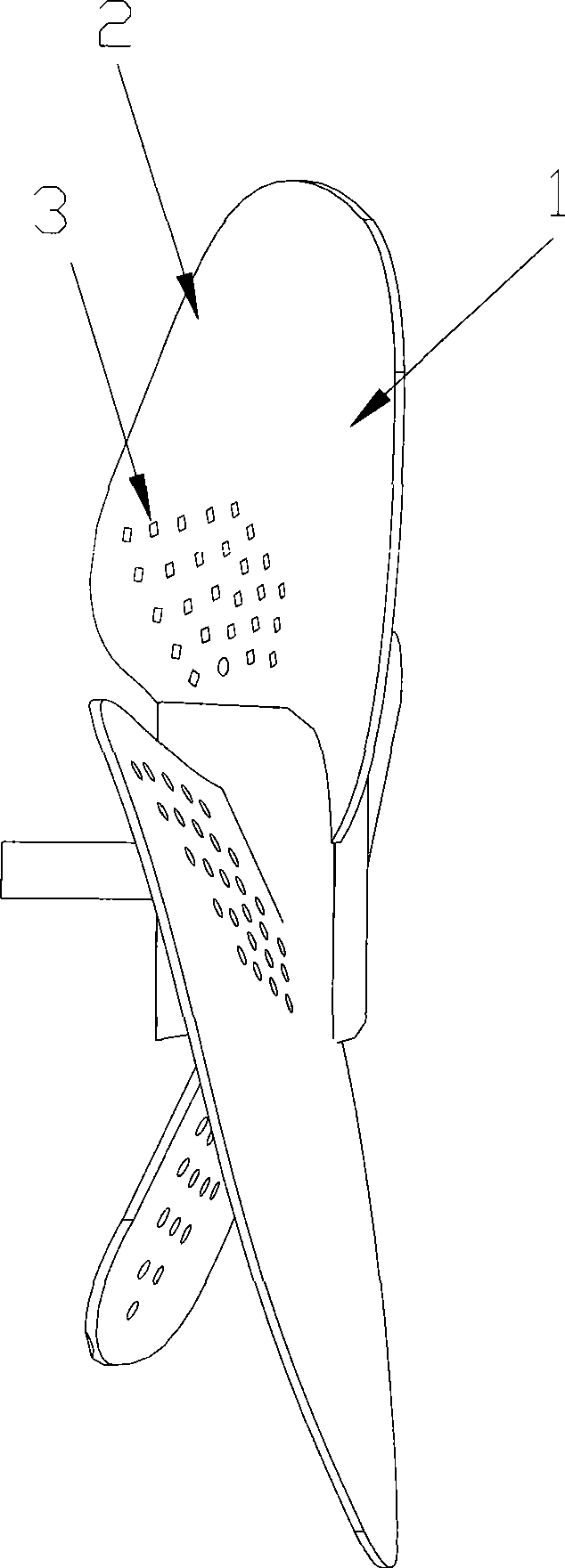

[0026] Embodiment 2: as Figure 4 , Figure 5 As shown, the centrifugal fan blade of the present invention includes a front edge portion 1 in the air inflow direction and a rear edge portion 2 in the air outflow direction, and several pressure balance holes 3 are opened on the rear edge portion 2 . Several pressure balance holes 3 may be circular holes, non-circular holes, straight through holes, straight blind holes, oblique through holes or oblique blind holes. The distribution of several pressure balance holes 3 constitutes a hole network to regulate the pressure on both sides of the fan blade. The diameter range of the pressure balance hole 3 is 0.1mm-100mm.

[0027] It has been proved by experiments that there are several pressure balance holes 3 on the trailing edge 2, which play the role of self-balancing pressure, reduce the pressure difference between the front and back of the fan blade, and eliminate the boundary layer airflow separation zone of the trailing edge 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com