High-temperature high-pressure pressure-reducing valve

A high-temperature, high-pressure, pressure-reducing valve technology, which is applied in the direction of lifting valves, valve details, safety valves, etc., to avoid alternating stress, increase the range of pressure reduction, and improve safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

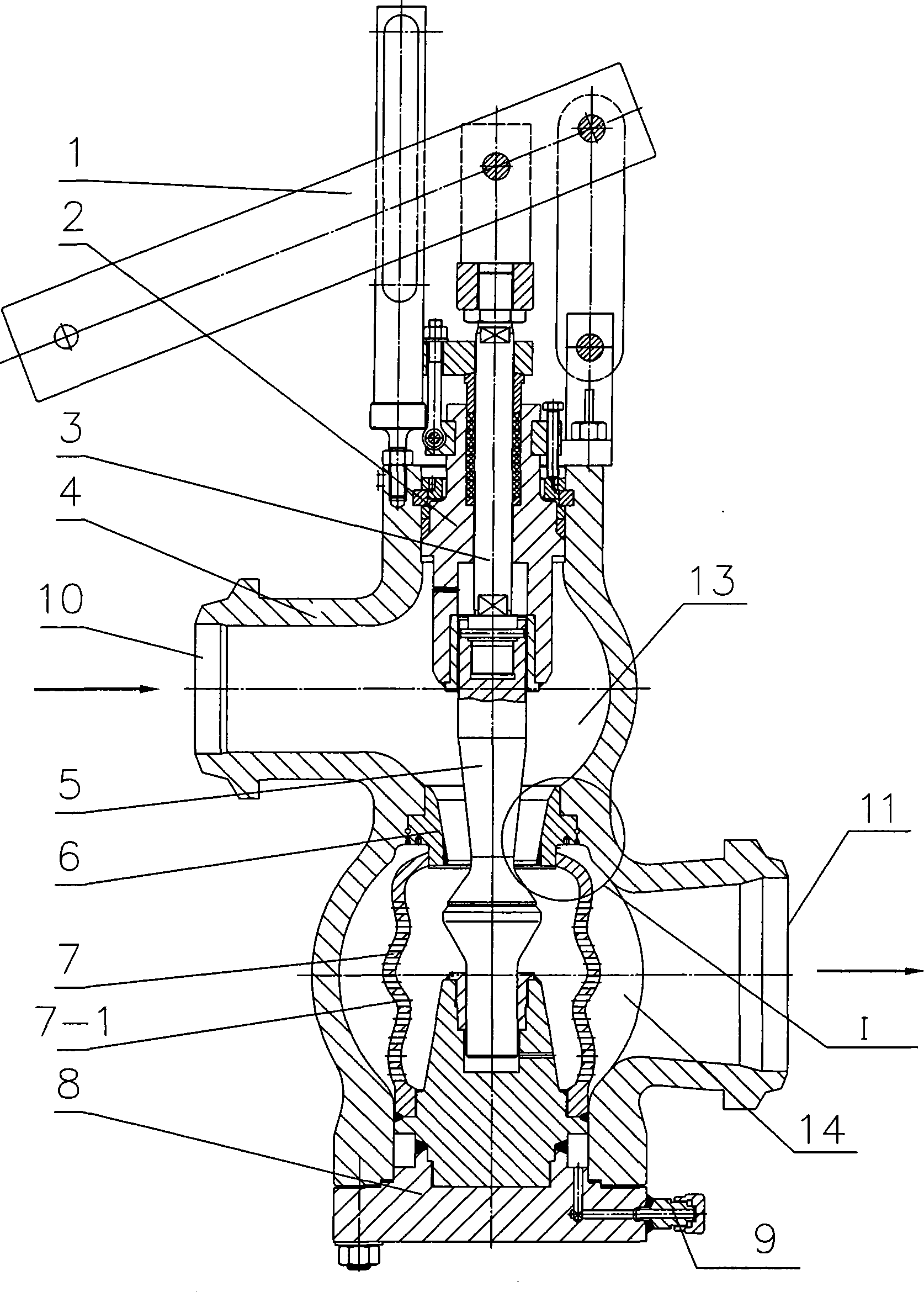

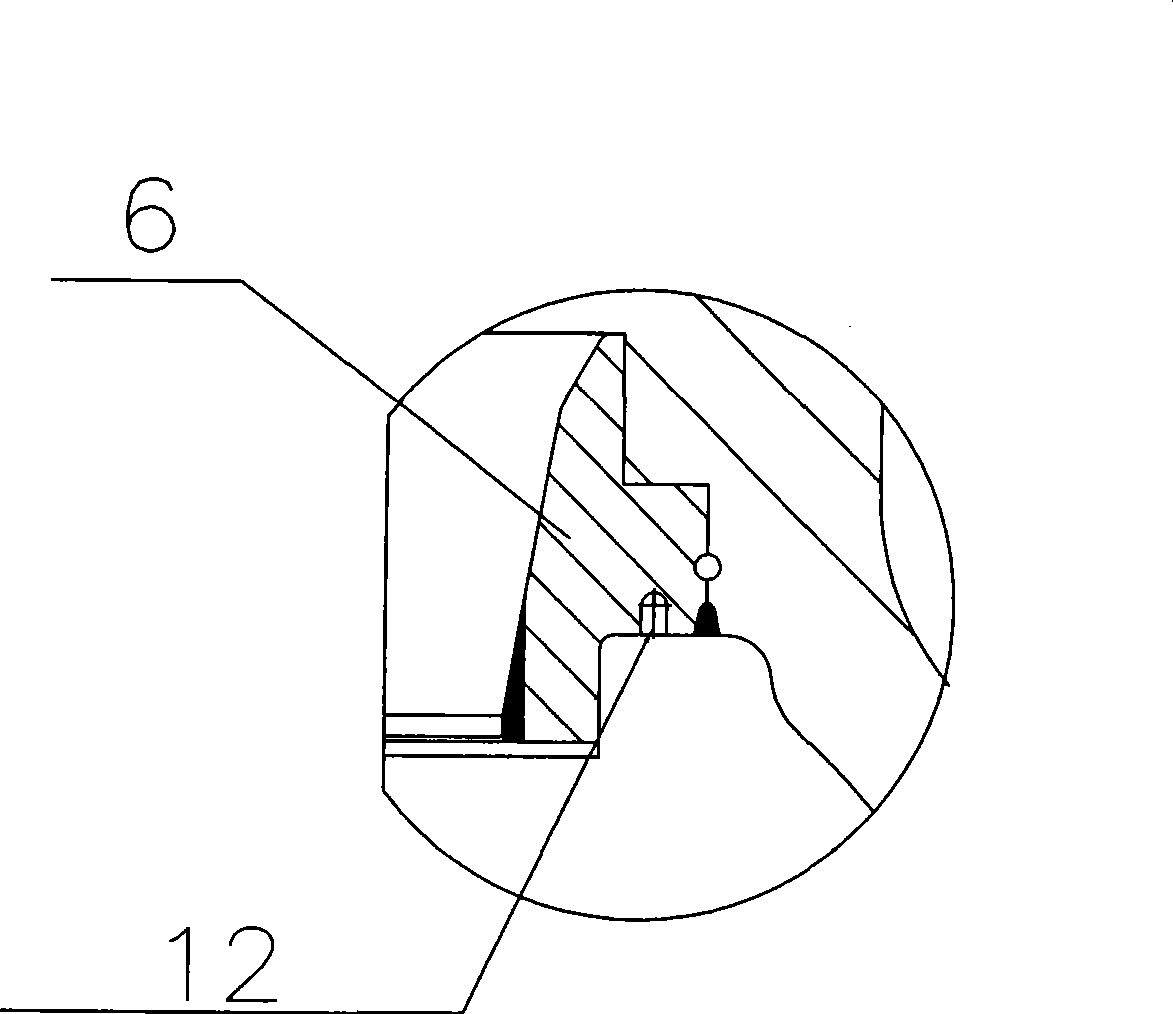

[0015] Such as Figure 1-2 As shown, this high temperature and high pressure pressure reducing valve is mainly composed of a lever 1, an upper bonnet 2, a valve stem 3, a valve body 4, a valve seat 6 and a lower bonnet 8, and the top of the valve body 4 is in phase with the upper bonnet 2 Connection, the bottom of the valve body 4 is equipped with a lower valve cover 8. The lower valve cover 8 is provided with a water trap 9, which avoids the impact of water hammer in various working conditions. The valve body 4 is a double-spherical structure, the upper small sphere is a high-pressure air intake chamber 13, the lower large sphere is a low-pressure air chamber 14, the high-pressure air intake chamber 13 is connected to the inlet 10, and the low-pressure air chamber 14 is connected to the outlet 11 Pass, the outlet 11 channel area is larger than the inlet 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com