Pipe junction cutting sleeve suitable for high temperature condition

A technology for pipe joints and conditions, which is applied in the direction of non-detachable pipe connections, pipes/pipe joints/fittings, pipe connection arrangements, etc., can solve the problems of rubber O-rings that are not resistant to high temperatures, unsatisfactory sealing methods, and lack of elasticity. To achieve the effect of ensuring the sealing effect, solving the problem of high temperature sealing, and compact structure

Active Publication Date: 2010-12-01

NANJING TECH UNIV +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The rubber O-ring with good elasticity is not resistant to high temperature, and the high temperature resistant sealing material such as graphite lacks elasticity, so this sealing method is not ideal

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Login to View More

Abstract

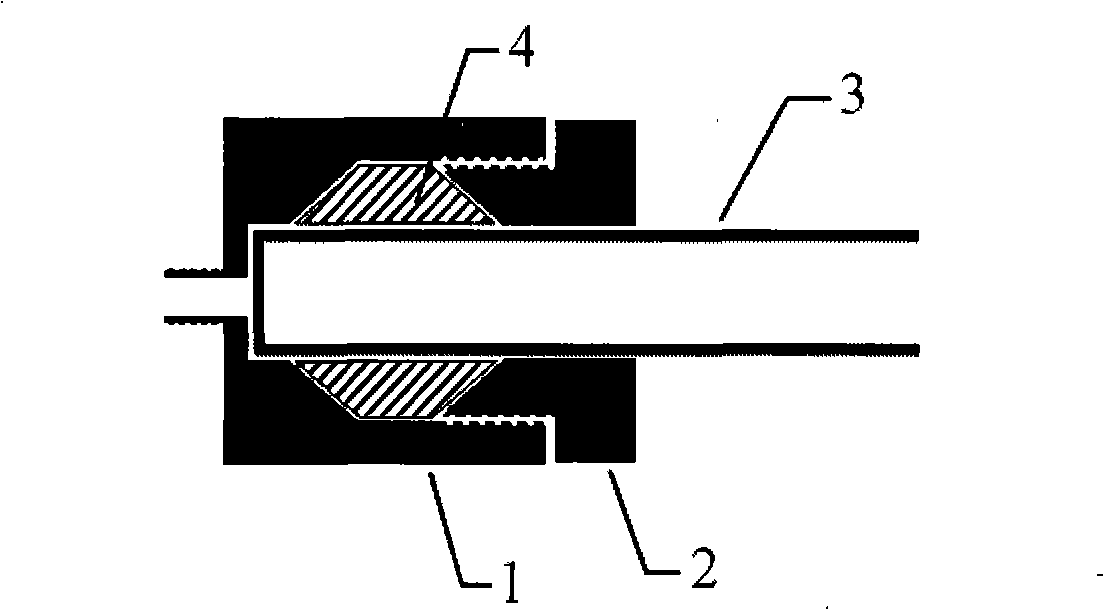

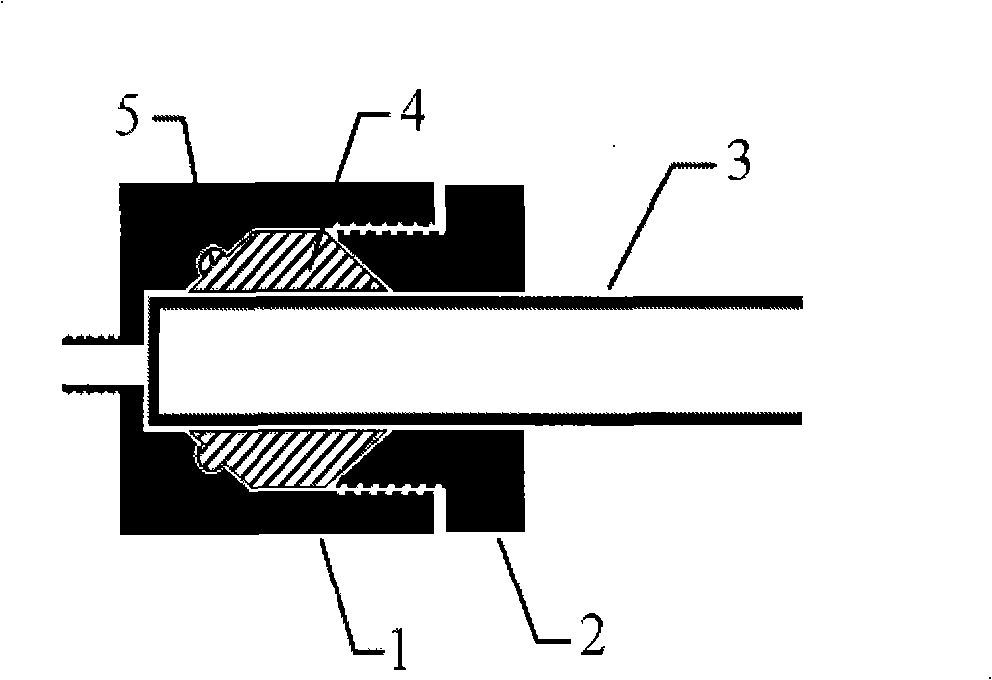

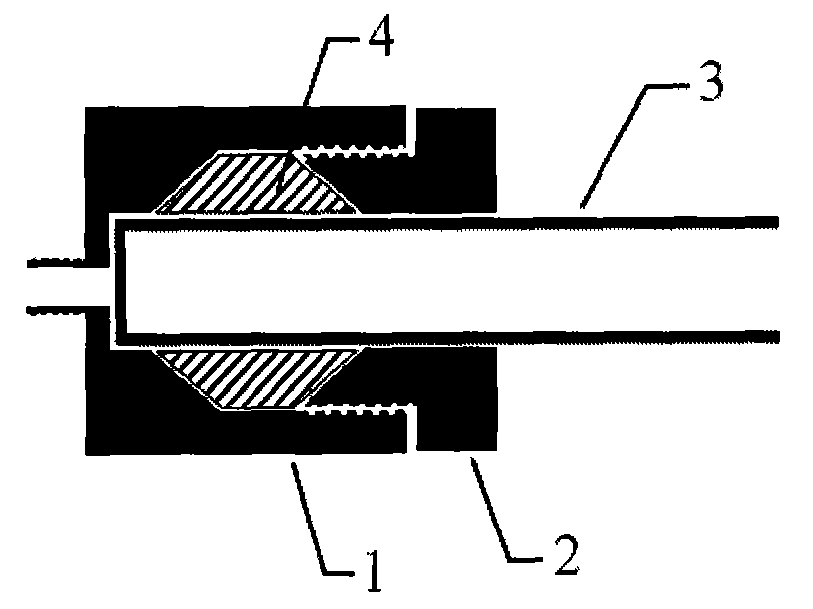

The invention relates to a pipe joint sleeve suitable for high temperature, comprising a screw cap, a screw bolt, a graphite pad as a sealing material, wherein, an inclined surface exists in the interfaces of the screw cap and graphite pad or the screw bolt and the graphite pad, thus not only prolonging the length of two sealing surfaces between the graphite pad and screw cap, and the graphite pad and work pipe fitting, but also partly transforming the extrusion pressure between the screw cap and screw bolt to the pressure from the graphite pad to the work pipe fitting so as to ensure the sealing effect and connecting strength. The sleeve is especially suitable for high-temperature seal and connection of the brittle material pipe fitting.

Description

A pipe joint ferrule suitable for high temperature conditions Technical field: The invention relates to a pipe joint ferrule suitable for high temperature conditions, especially suitable for the connection between ceramic pipe fittings and metal pipelines. Background technique: Ceramic materials have excellent chemical stability and high temperature stability, but their biggest disadvantage is that they are easily brittle. There are usually three methods for connecting ceramic pipes to metal pipelines: welding, bonding and mechanical connection. The welding method can achieve a good seal and has a certain strength, but the properties of metal and ceramics are very different, and a special welding process must be used. There are many metal-ceramic welding methods reported in the literature [Ye Dameng, Xiong Weihao, Xu Huaan. Research status and prospects of metal-ceramic and metal welding technology. Materials Herald, 2006, 20(8): 72~75.], such as melting Welding, brazing...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F16L13/013F16L49/06

Inventor 黄彦胡小娟陈卫东

Owner NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com