Stereo air exhaust loop and plasma processing apparatus

A plasma and exhaust ring technology, applied in the direction of plasma, electrical components, gaseous chemical plating, etc., can solve the problems of small conduction area, scattered plasma distribution, poor gas fluidity, etc., and achieve the best conduction area big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

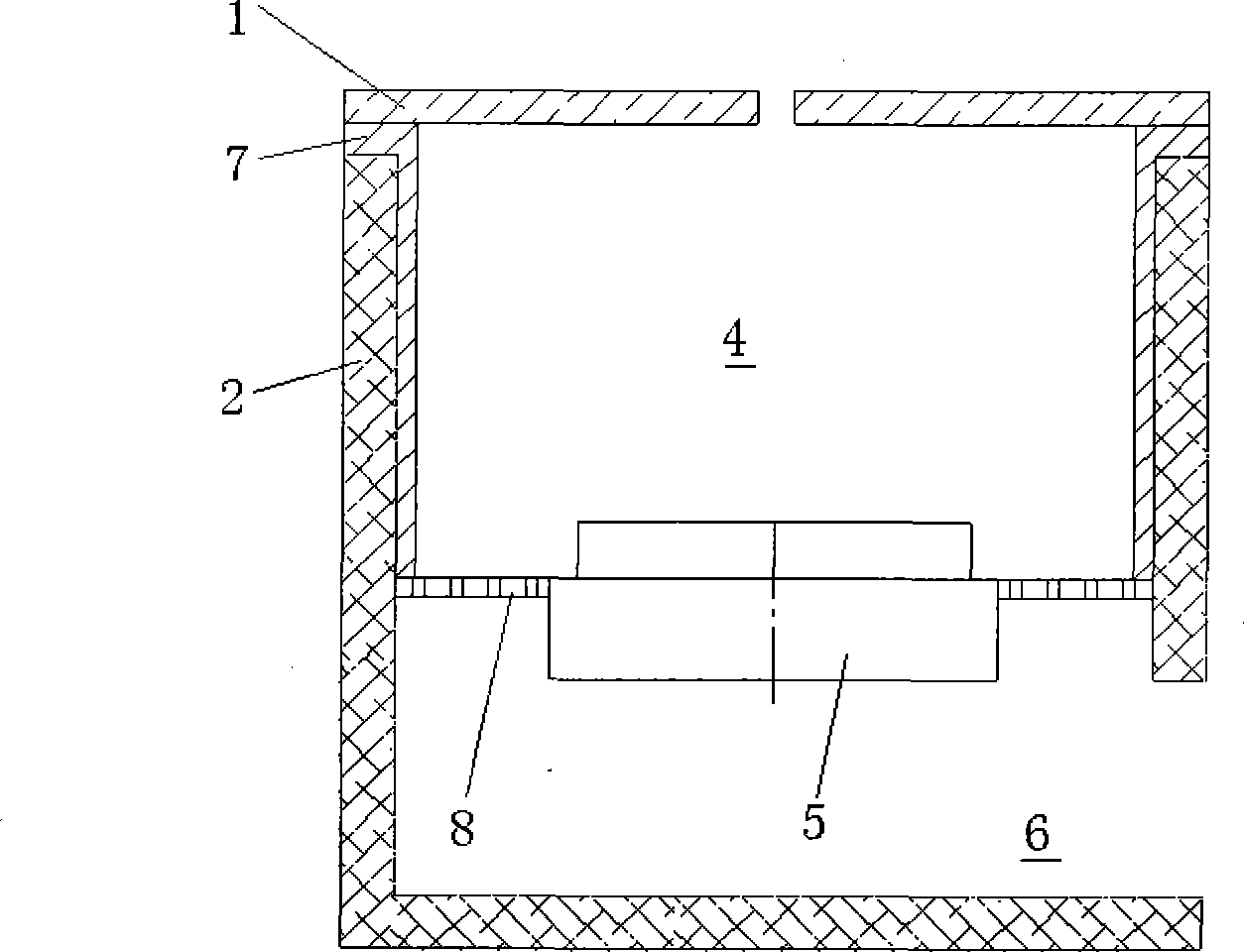

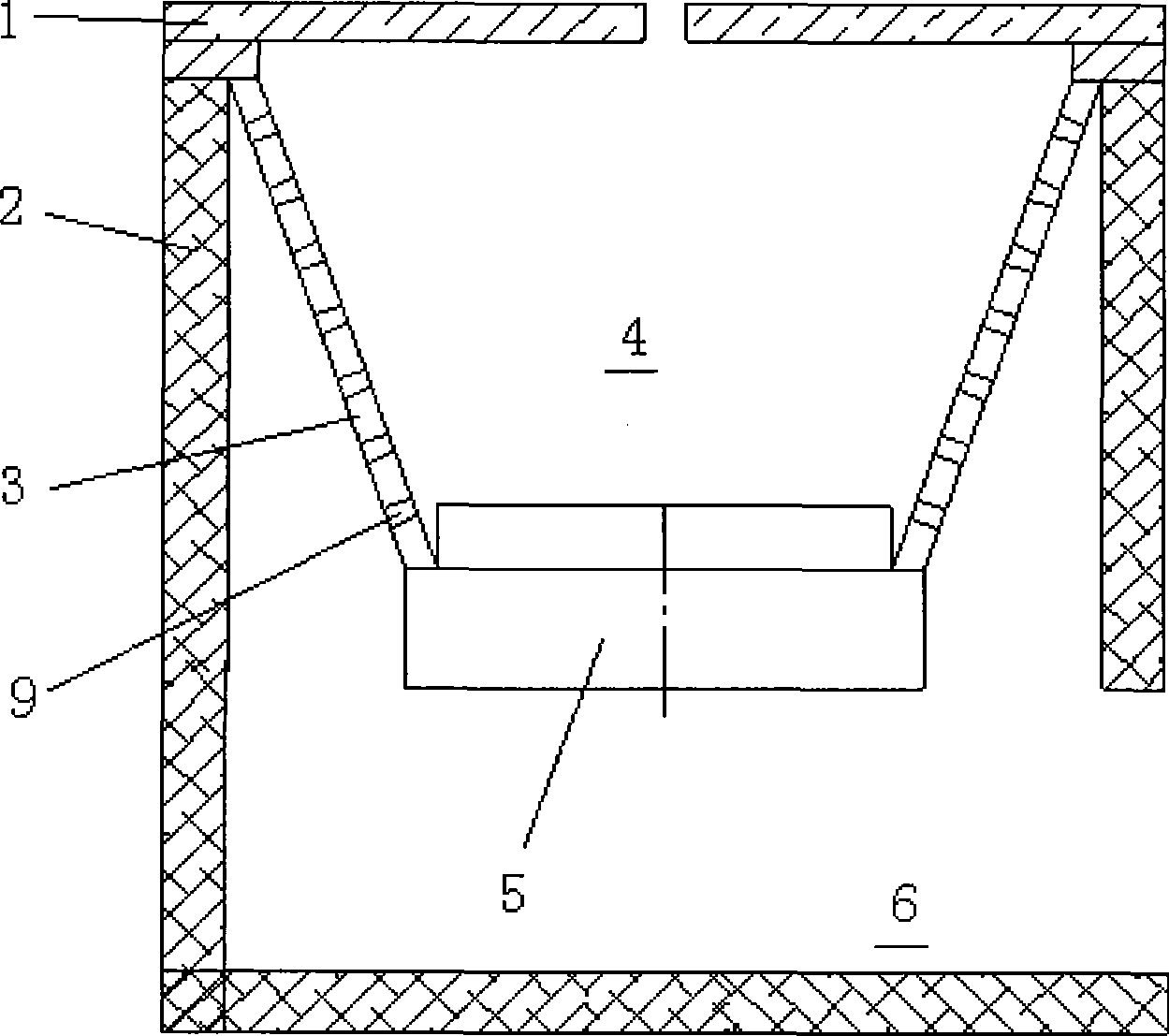

[0016] Stereo exhaust ring and plasma processing device of the present invention, its preferred specific embodiment is as figure 2 As shown, the three-dimensional exhaust ring includes a body 3, which is a cylindrical structure, and a plurality of through holes 9 are opened on the wall of the cylindrical structure. The body 3 is a cylindrical structure in the shape of a truncated cone.

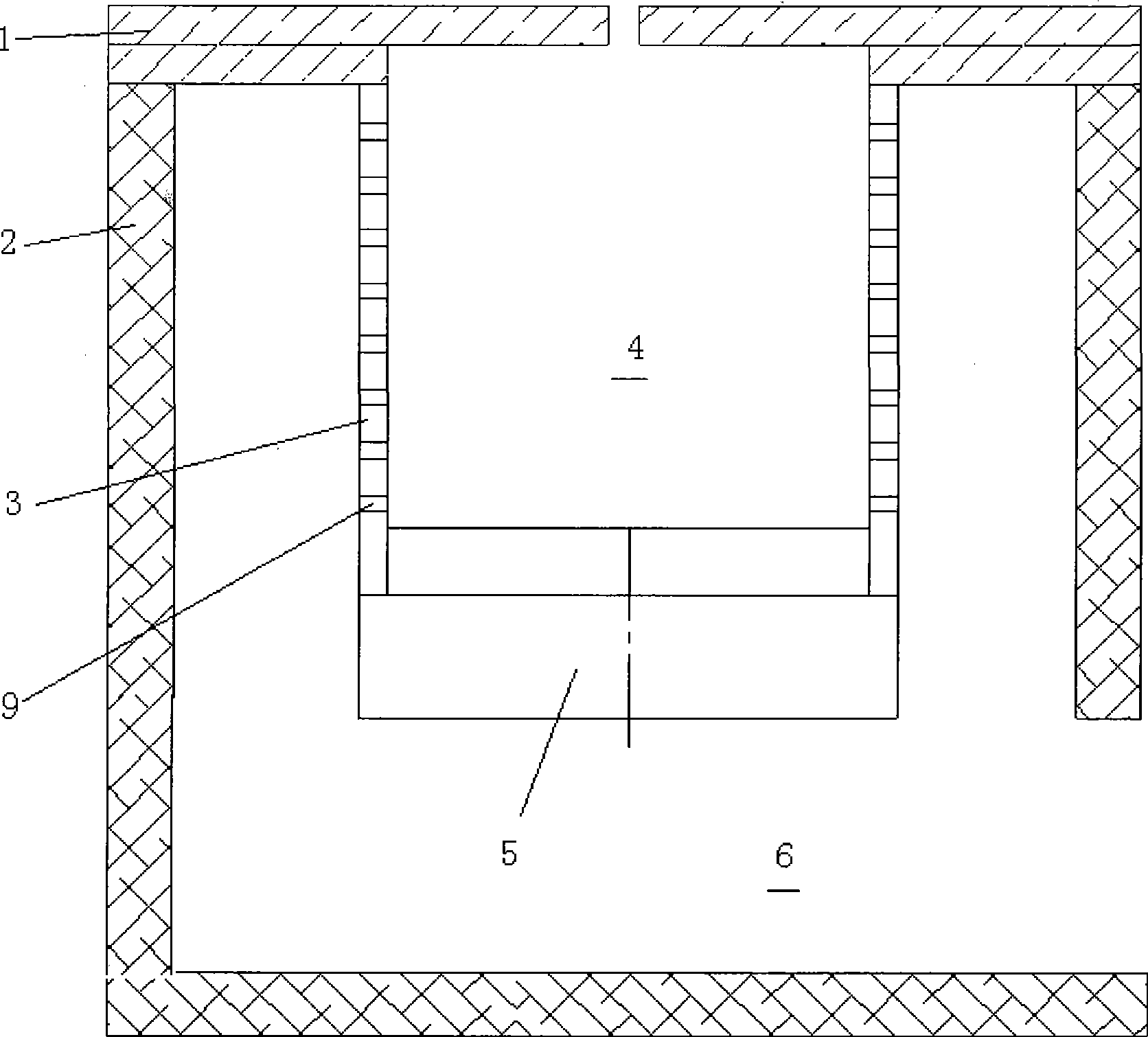

[0017] Preferred specific embodiment two such as image 3 As shown, the body 3 is a cylindrical tubular structure.

[0018] The body 3 can also be an arc-shaped cylindrical structure, for example, the wall of the cylindrical structure adopts a curved surface or an arc surface, or other forms of three-dimensional structure.

[0019] The cross-section of the through hole 9 can be circular, elliptical, oblong, triangular or trapezoidal, and can also be polygonal or elongated.

[0020] The longitudinal section of the through hole 9 can be rectangular, trapezoidal, funnel-shaped, etc.

[0021]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com