AC motor

An AC motor, lamination technology, applied in the magnetic circuit static parts, magnetic circuit shape/style/structure and other directions, can solve the problems of stator winding temperature rise, hidden danger of motor safety, large space occupation, etc., to improve thermal conductivity , the effect of reducing weight and volume, avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

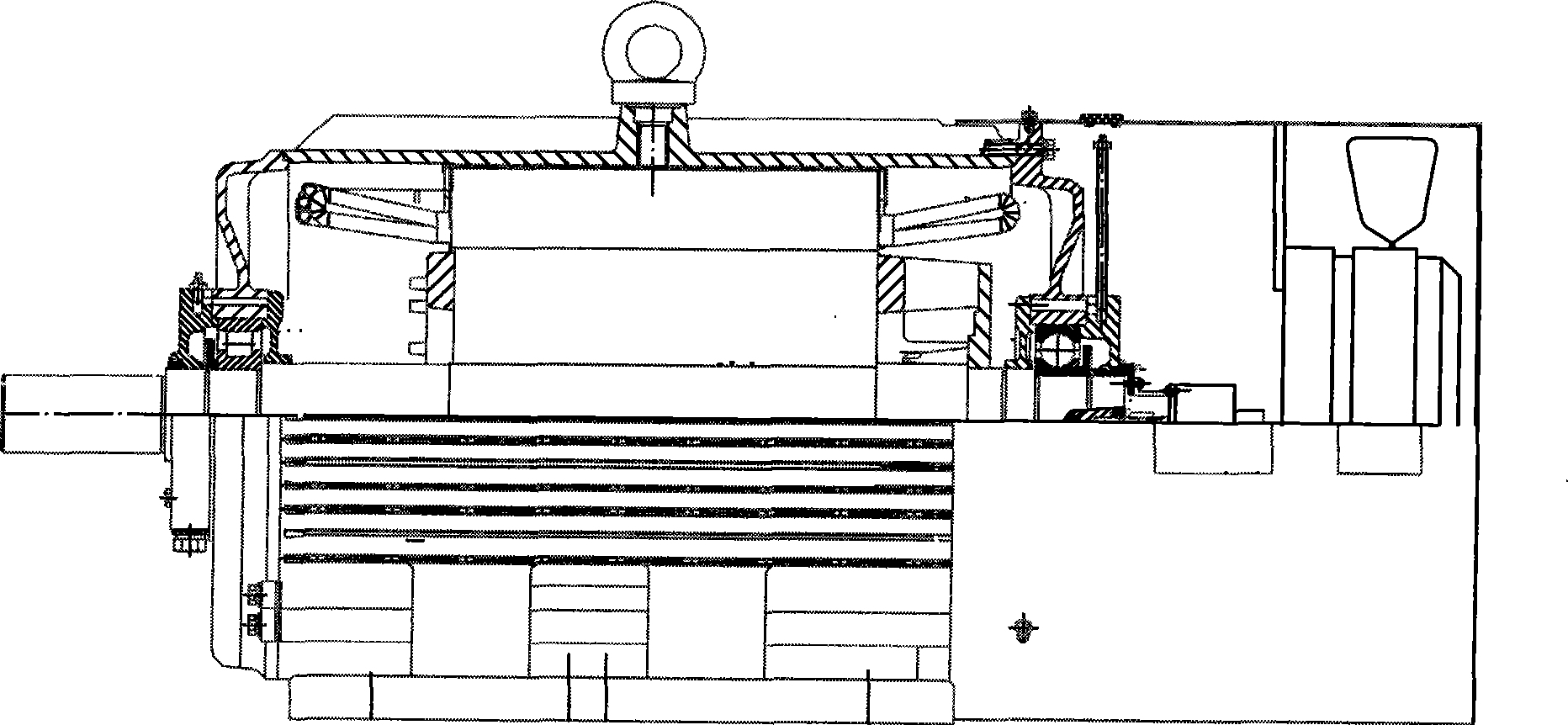

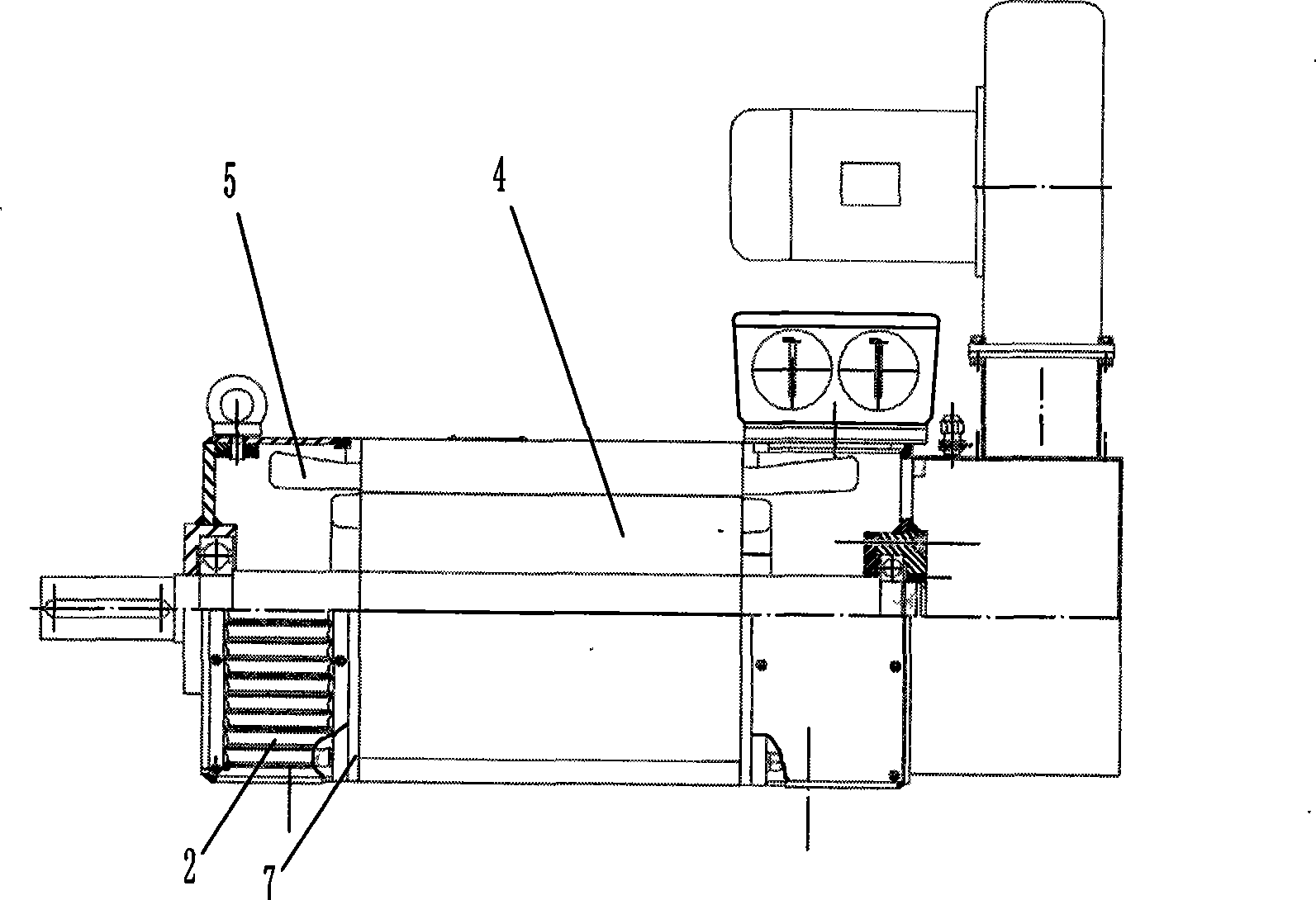

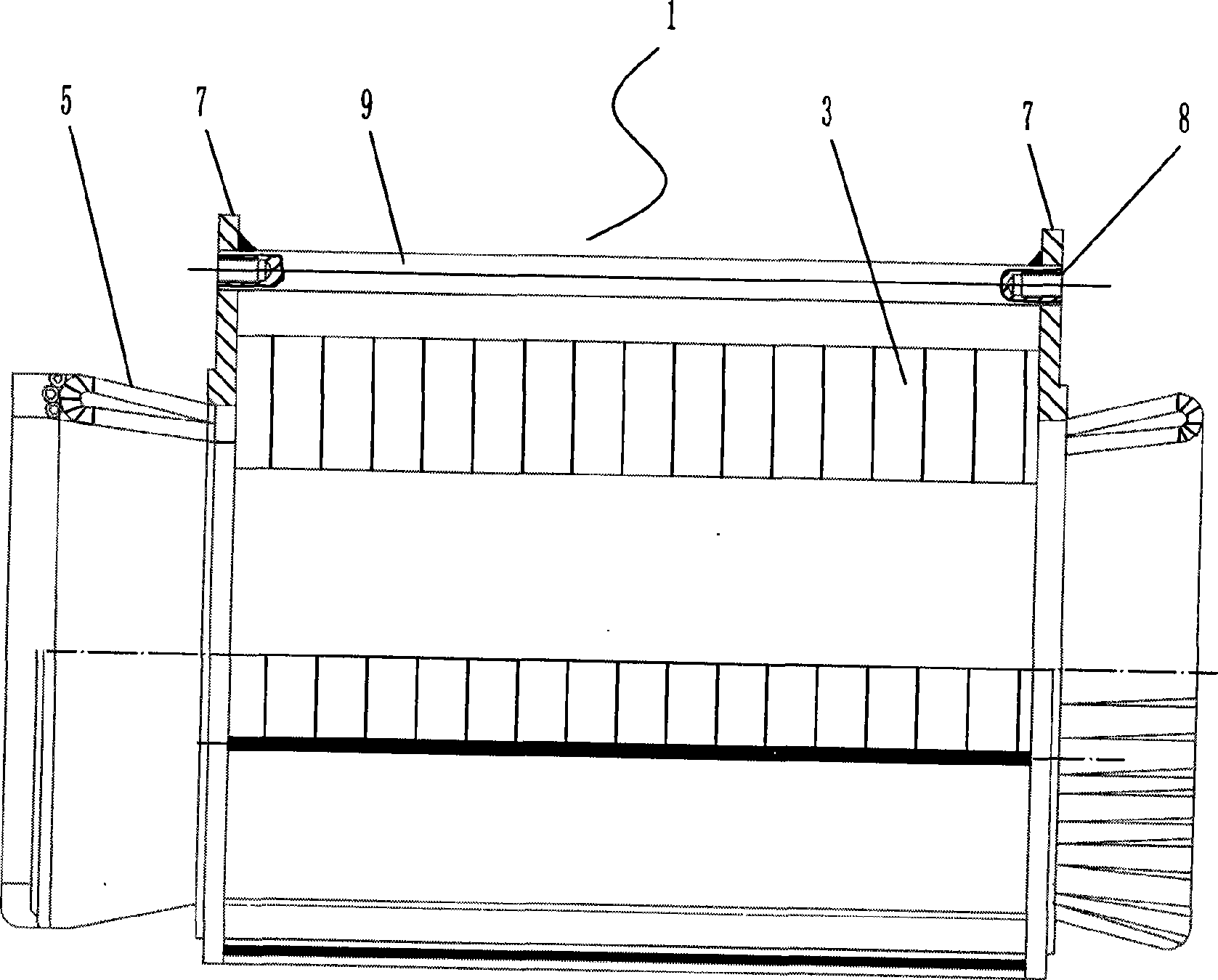

[0013] refer to Figure 2-4 , an AC motor, including a rotor, a stator 1, and an end cover 2. The stator is composed of a stator core 4 and a winding 5 formed by laminations 3. The laminations are square, and the corresponding four corners are concave. The square open slot structure 6, the two ends of the stator core are provided with a pressure frame 7, the pressure frame is provided with a groove 8 corresponding to the opening slot position of the lamination, and the opening slot and the corresponding groove are arranged There are tendons 9, which are fixedly connected to the laminations and the pressure frame; the positions of the adjacent open grooves of the laminations are separated into several closed ventilation holes 11 by curved heat dissipation ribs 10, and the ventilation holes of adjacent laminations The position correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com