Coupling structure and coupling method for coupling piping of air contitioner

A technology for connecting structures and air conditioners, applied in air conditioning systems, sealing surface connections, pipes/pipe joints/fittings, etc., can solve the problems of refrigerant leakage, corrosion, poor air tightness, etc. Durability, leak prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, the coupling structure of the connecting pipes for an air conditioner according to a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

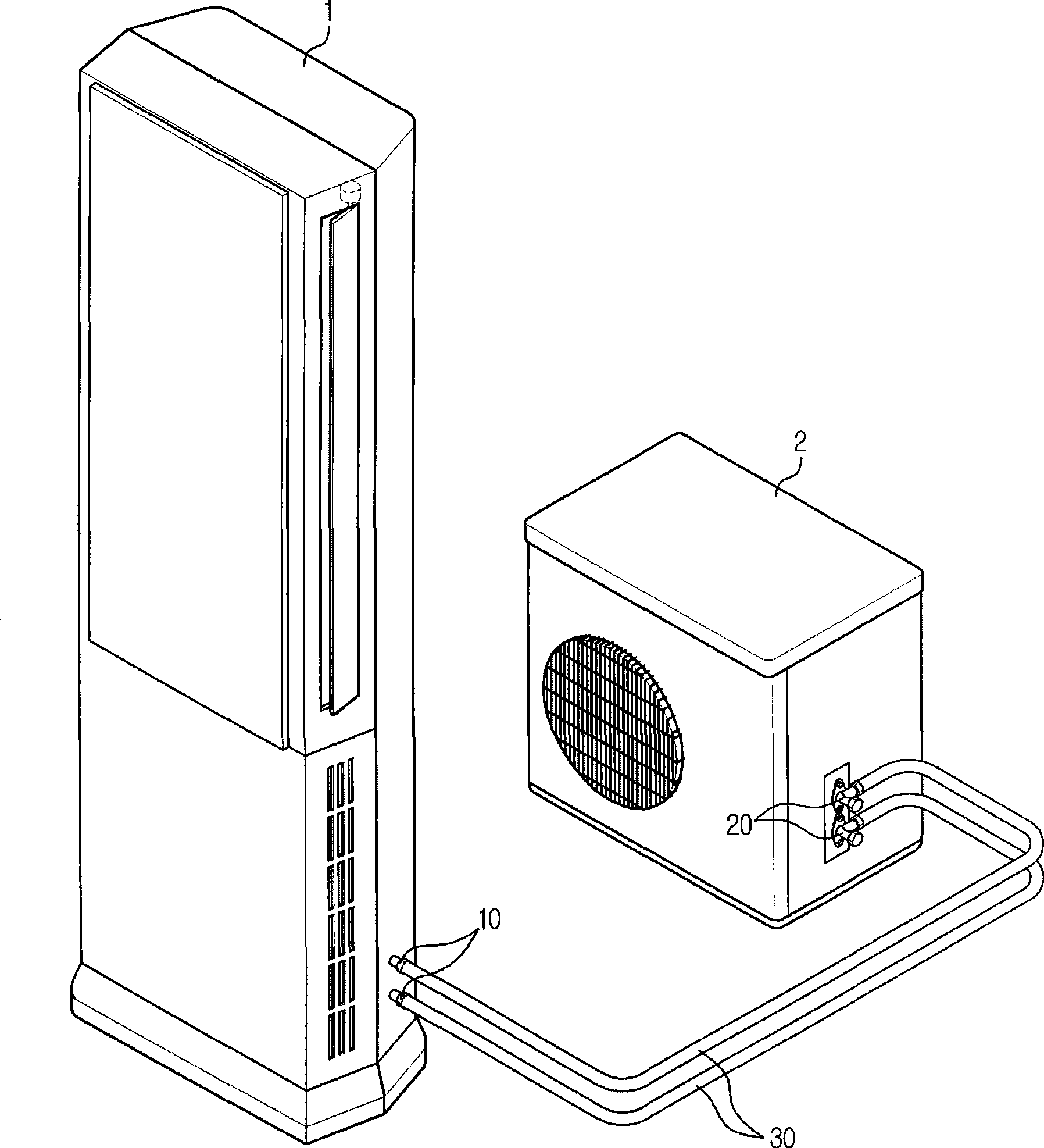

[0040] figure 1 It is a perspective view of the air conditioner provided by the present invention.

[0041] Such as figure 1 As shown, the air conditioner provided by the present invention includes: an indoor unit 1 arranged in a room where air needs to be conditioned; an outdoor unit 2 arranged outside the air conditioning space; a connecting pipe 30 connecting the outdoor unit 2 and the indoor unit 1 to Used to circulate the refrigerant between the indoor unit 1 and the outdoor unit 2.

[0042] Although not shown in the figure, the indoor unit 1 includes: a heat exchanger; and an exhaust fan providing exhaust force for supplying heat-exchanged air into the room. The outdoor unit 2 includes a compressor, a capillary tube, a heat exchanger and an exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com