Method for overcoming magnetic declination of permanent magnet and device thereof

A magnetic declination and permanent magnet technology, applied in permanent magnets, inductors/transformers/magnet manufacturing, electrical components, etc., can solve the problems of not considering the magnetic declination of permanent magnet materials, and cannot meet the high-precision AC servo motor, etc., to achieve Satisfy the effect of high-precision motor and eliminate cogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

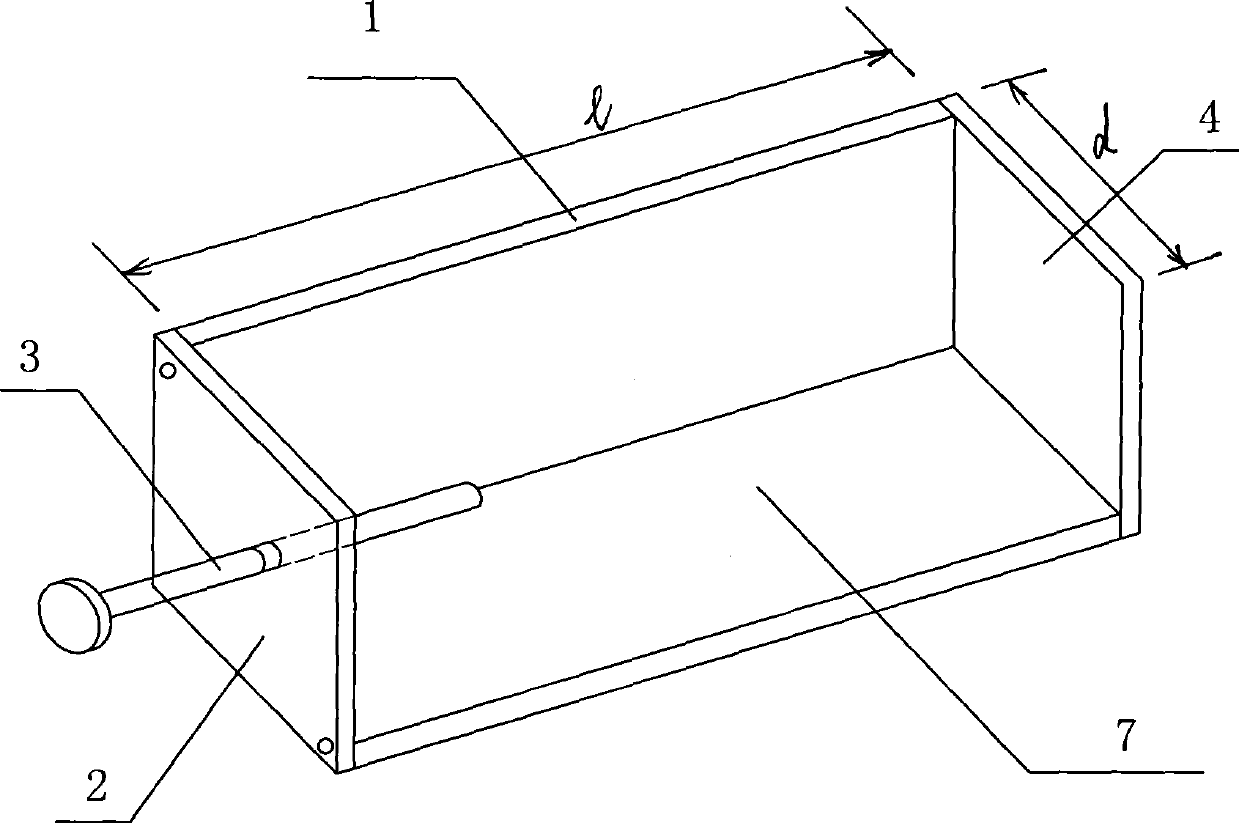

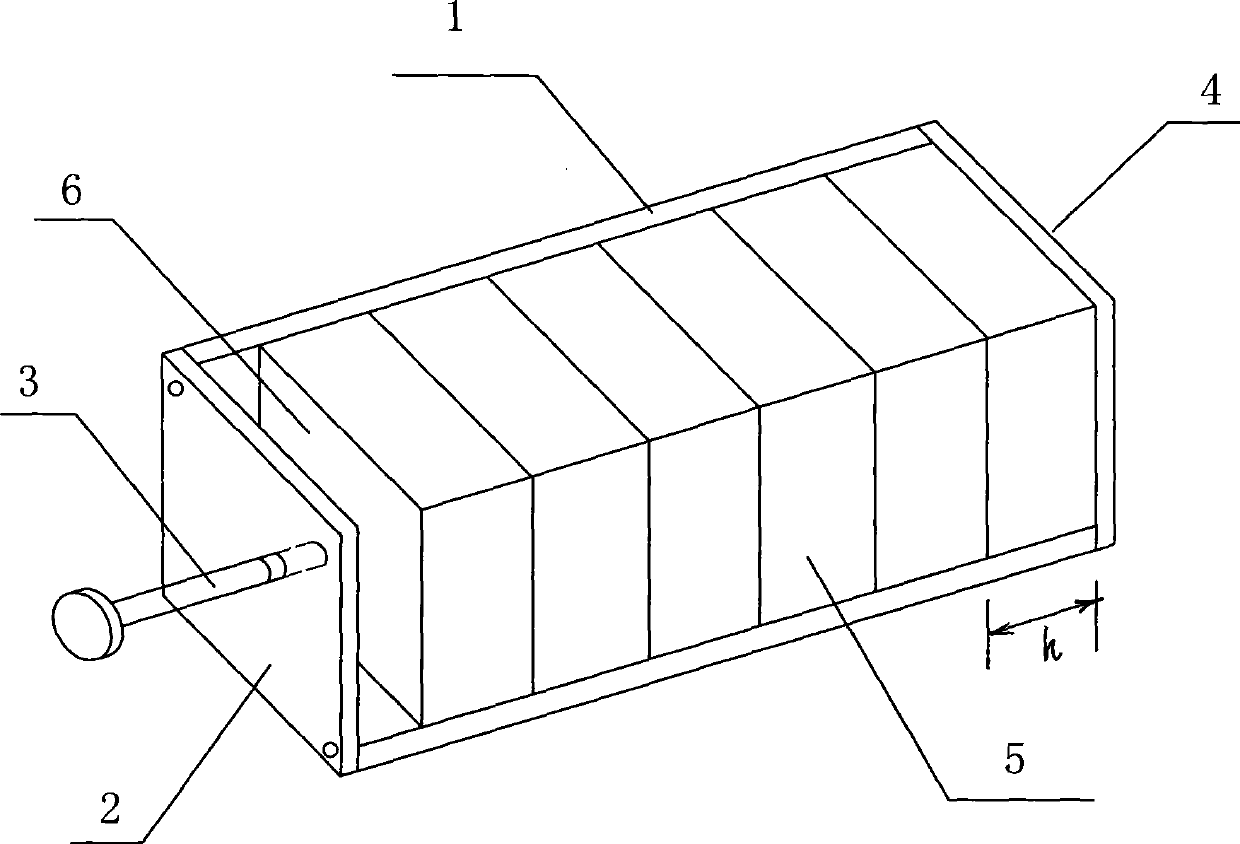

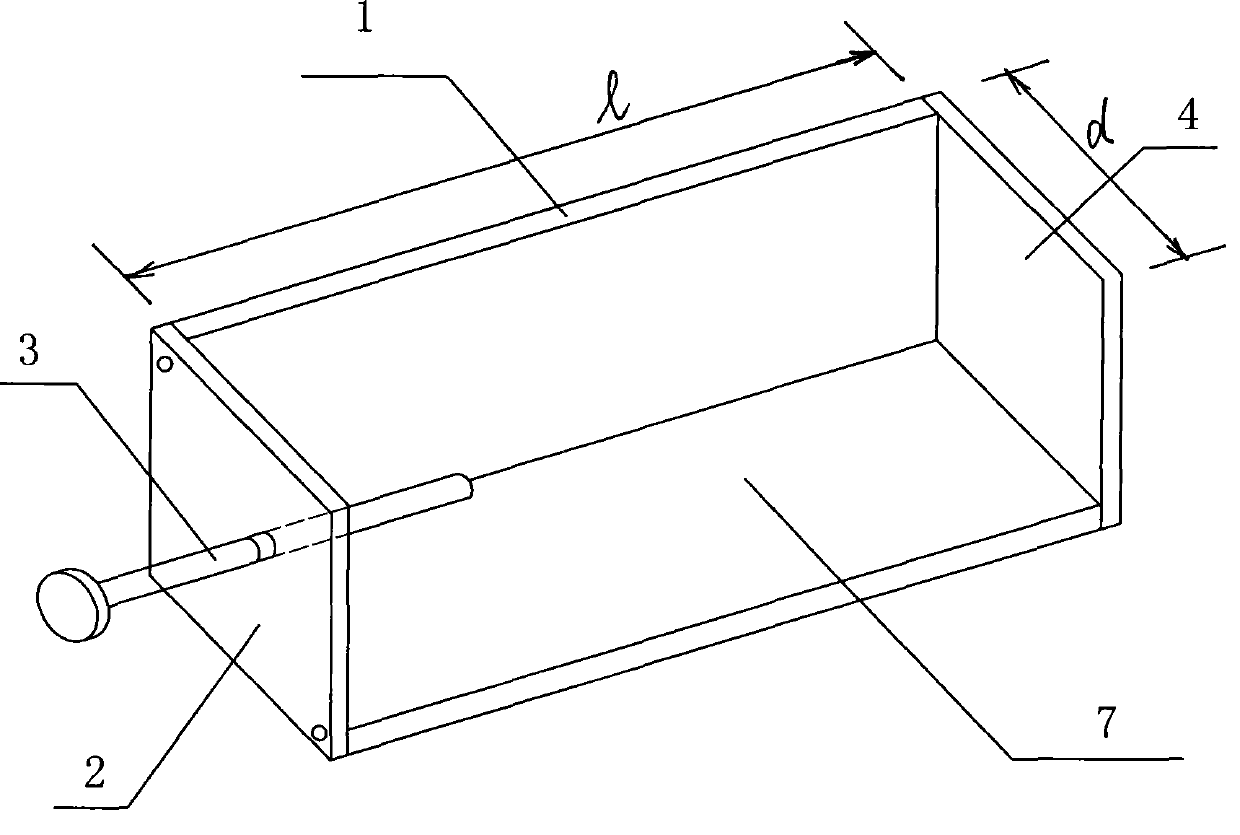

[0019] Embodiment 1: the method for overcoming the magnetic declination of the permanent magnet of the present embodiment comprises the following steps:

[0020] a. First judge the magnetic field orientation of the magnetic material sintered after dry pressing magnetic field orientation forming, and determine the two magnetic field orientation surfaces of the magnetic material;

[0021] b. Carry out mechanical processing on the two magnetic field orientation planes, make the magnetic field orientation planes perpendicular to the magnetic force lines of the magnetic field orientation, and strive to keep consistent with the original dry pressure magnetic field;

[0022] c. Based on the two machined magnetic field orientation surfaces, firstly machine two adjacent surfaces of the remaining four surfaces of the magnetic material to ensure that the relative angular scale is reached; The other two adjacent faces are machined to ensure that the relative angular scale is achieved;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com