Electric spindle based on gullet-free motor

An electro-spindle, no cogging technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of increasing the mechanical loss and temperature rise of the motor, increasing the overall weight of the motor, and increasing the vibration of the electro-spindle, and reducing the speed of the spindle. Vibration, reduction of overall weight and moment of inertia, reduction of machining errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

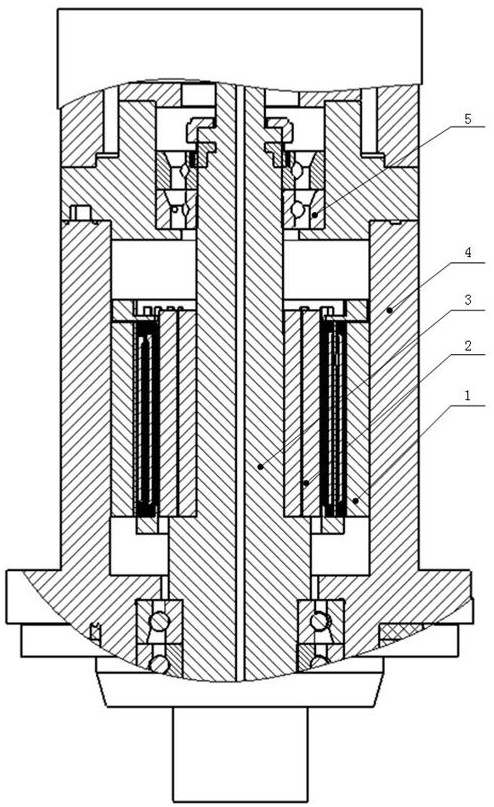

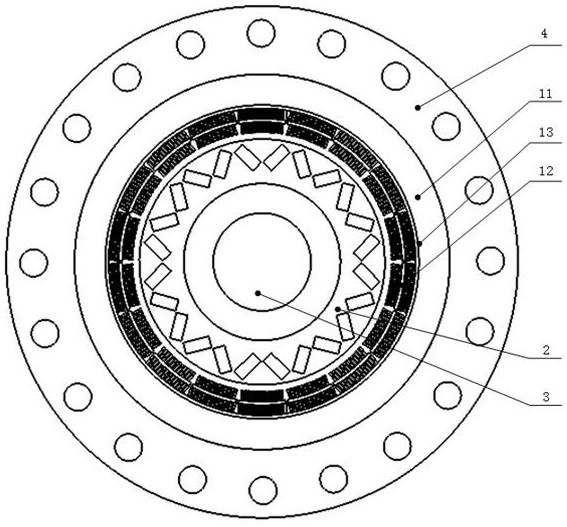

[0026] combine Figure 1 to Figure 3 As shown, an electric spindle based on a slotless motor of the present invention includes a stator 1 , a rotor 2 , a main shaft 3 , a sleeve 4 and a bearing 5 . Stator 1 , rotor 2 , and main shaft 3 are arranged coaxially inside sleeve 4 in sequence from outside to inside, and main shaft 3 is supported by bearing 5 and can rotate under the interaction of stator 1 and rotor 2 .

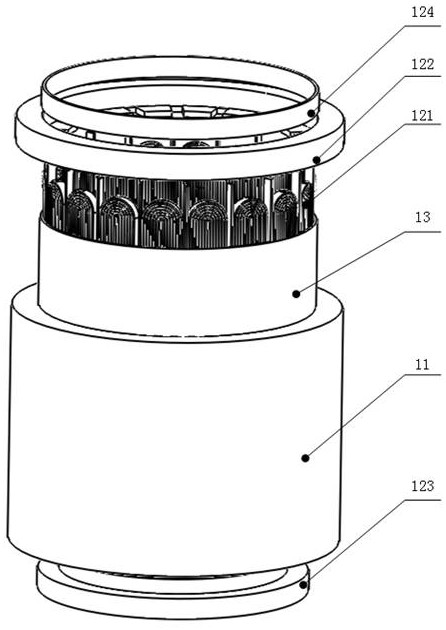

[0027] The stator 1 comprises a stator yoke 11, a stator winding 12 and a yoke insulating layer 13, the inner surface of the stator yoke 11 is provided with a yoke insulating layer 13, the stator winding 13 is installed on the inside of the stator yoke 11, and is connected with the yoke The insulating layer 13 is bonded together. The stator yoke is made of magnetically permeable or non-magnetically permeable material. When it is made of magnetically conductive material, it constitutes a non-cogging rotating machine, and when it is made of non-magnetically conducti...

Embodiment 2

[0033] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the stator 1 of this embodiment does not include a stator yoke 11, but only consists of stator windings 12, such as Figure 9 As shown, the stator winding 12 is directly installed on the inner side of the sleeve 4. In order to ensure insulation, a sleeve insulating layer 41 is arranged on the inner surface of the sleeve 4. After the stator winding 12 is installed on the inner side of the sleeve 4, it is connected with the sleeve insulating layer 41 phase fit, in order to further increase the insulation and rigidity, it can also be potted with heat-conducting and insulating curing glue. The sleeve 4 is provided with an external cooling channel 42, which can cool the main shaft as a whole after passing through the cooling liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com