Non-stator iron core brushless DC motor

A DC motor without a stator technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit rotating parts, etc., can solve the problems of stator core loss and other problems, achieve no core loss, facilitate heat dissipation, and eliminate the effect of stator core loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

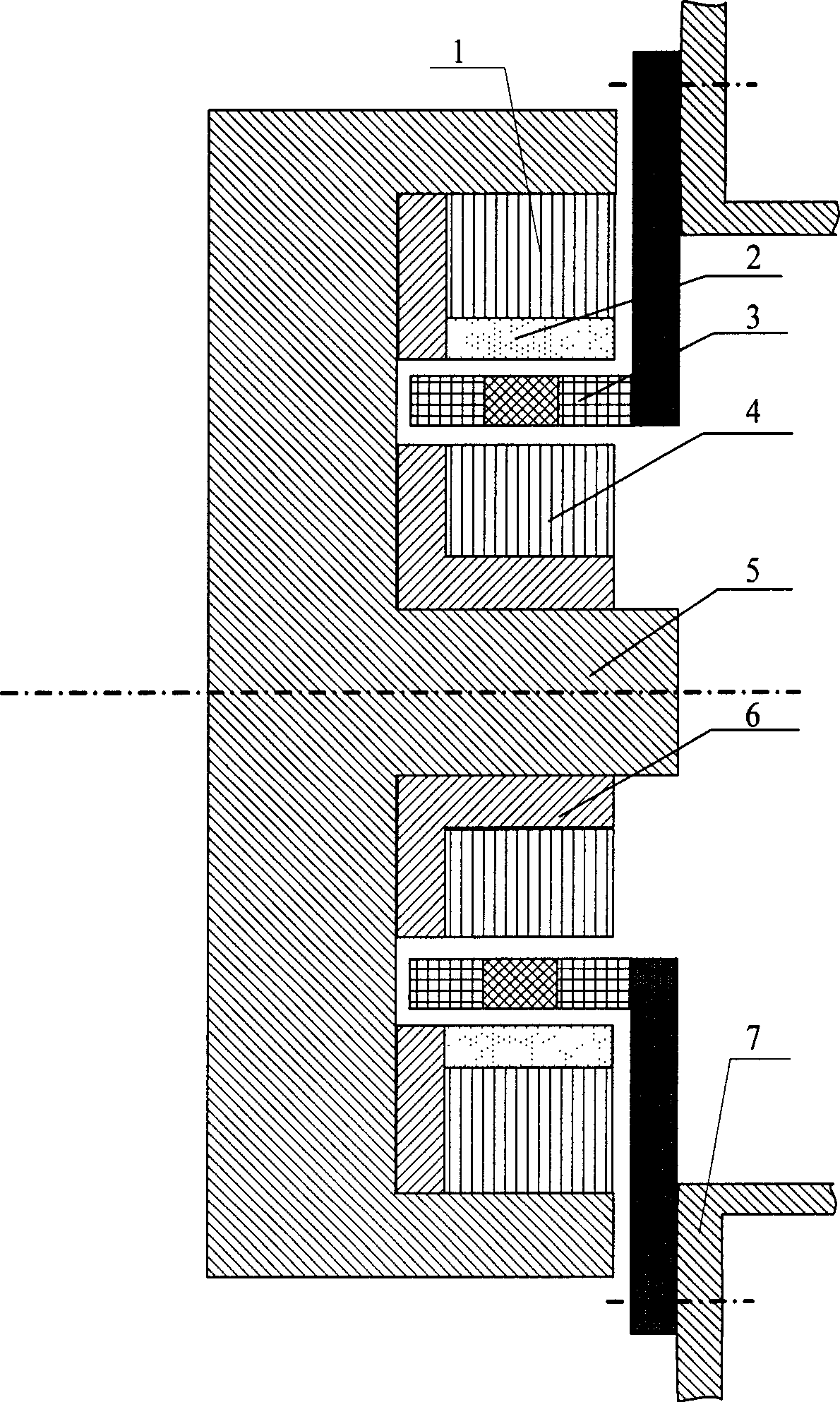

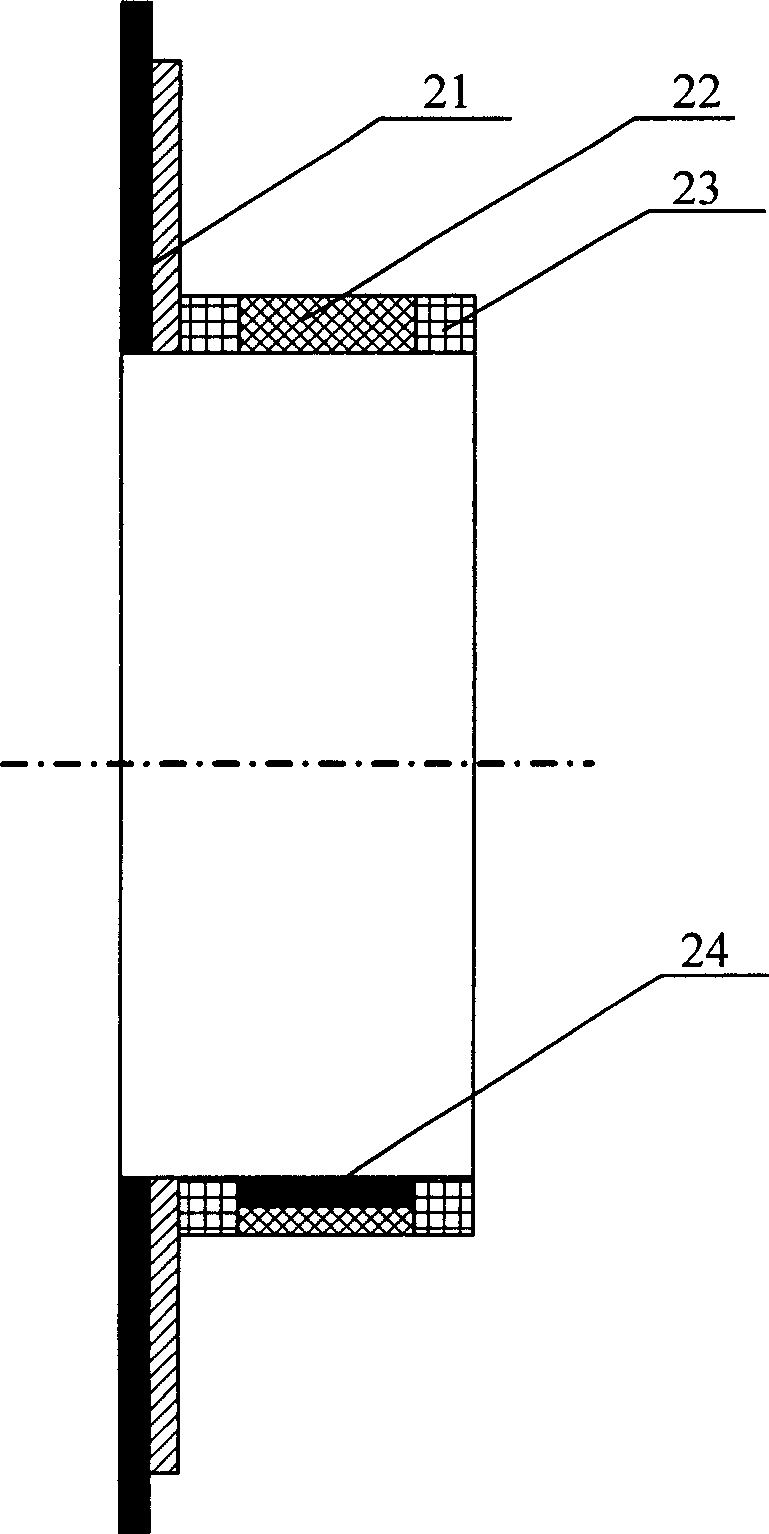

[0009] like figure 1 As shown, the present invention is composed of an outer rotor core 1, a permanent magnet 2, a hollow cup winding 3, an inner rotor core 4 and a rotor shaft 5, and both the outer rotor core 1 and the inner rotor core 4 are fixedly connected to the rotor shaft 5, so that the outer The rotor core 1 and the inner rotor core 4 rotate together with the rotor shaft 5. The permanent magnet 2 can be installed on the inner rotor core 4 or on the outer rotor core 1. Considering that the rotor will generate a huge centrifugal force when rotating at high speed, generally Place the permanent magnet 2 on the outer rotor core 1, the permanent magnet 2 is made of rare earth permanent magnet materials such as cobalt, ferrite, neodymium iron boron, etc., the magnetic flux generated by the permanent magnet 2 passes through the outer rotor core 1 and the inner rotor core 4 and The air gap between them forms a closed circuit, and the hollow cup winding 2 is fixed on the skeleto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com