Electrode for a discharge lamp and a method for producing such an electrode

A technology for discharge lamps and high-pressure discharge lamps, which is applied in the field of electrodes, can solve problems such as troublesome manufacturing and bonding, troublesome connection, and start-up of discharge lamps, and achieve the effect of simplifying manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

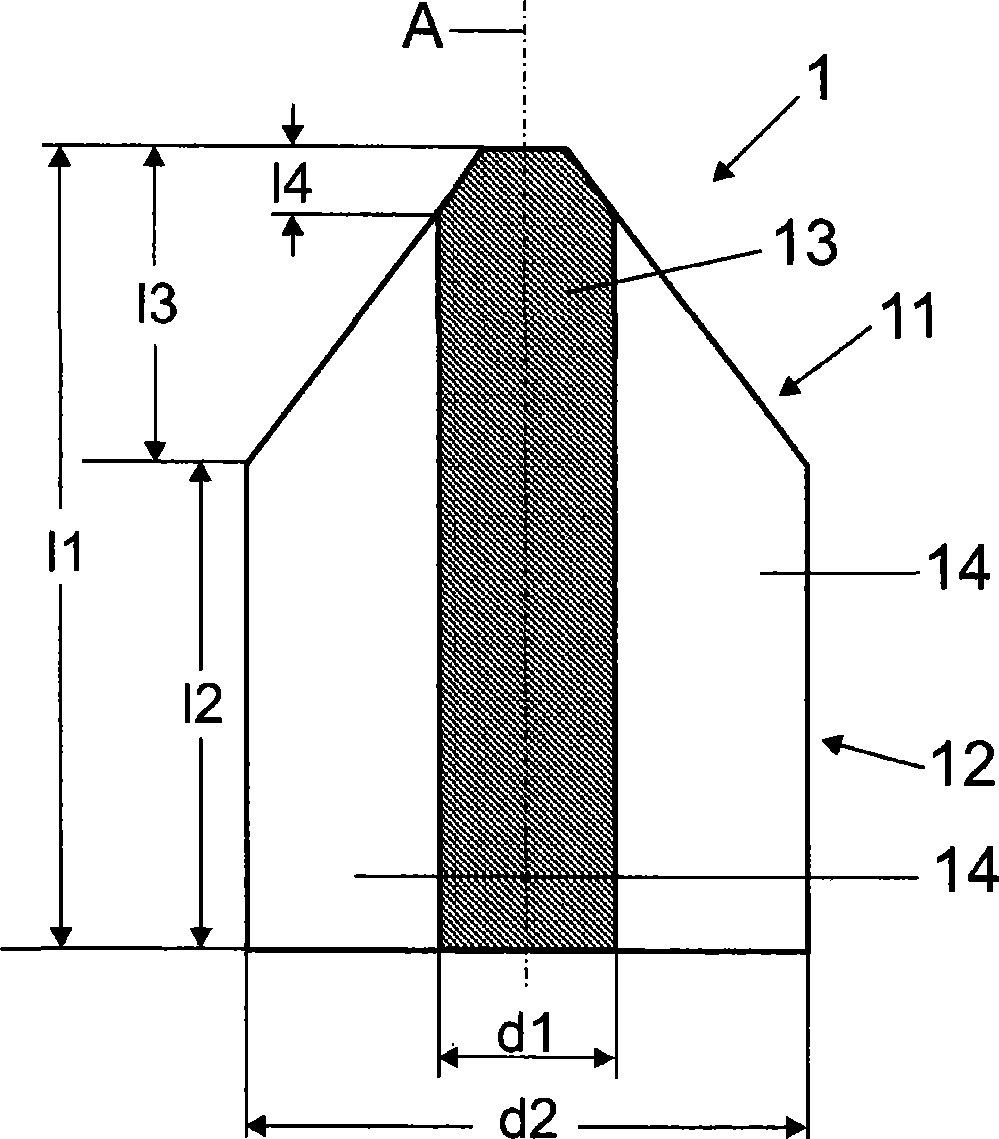

[0027] figure 2 A schematic sectional view through an electrode embodied as cathode 1 is shown. Cathode 1 includes a tip 11 , which in the exemplary embodiment is conically shaped. The tip 11 transitions into a cylindrical rod 12. In the longitudinal direction of the cathode 1 and thus in the direction of the longitudinal axis A, the cathode 1 has a length 11 consisting of the length 12 of the cylindrical rod 12 and the length 13 of the tip 11 . The configurations shown are exemplary only and may vary in length relationship as well as in shape.

[0028] as from figure 2 As can be seen in the illustration, the cathode 1 comprises a core 13 which, in the exemplary embodiment, is arranged concentrically and centrally in the cathode 1 and is thus constructed substantially rotationally symmetrically about the longitudinal axis A. In this exemplary embodiment, the core 13 extends over the entire length of the cathode 1 , the core being formed by the first material region and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com