Garlic combined harvester harvesting-platform

A technology of combine harvester and harvesting table, which is applied in the direction of excavator harvester, harvester, top removal machine, etc., can solve the problems of uncertain distance, inconsistent length of seedling cutting, and freedom of garlic fruit shaking, etc. Harvest quality, outstanding substantive characteristics, and the effect of good application and promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

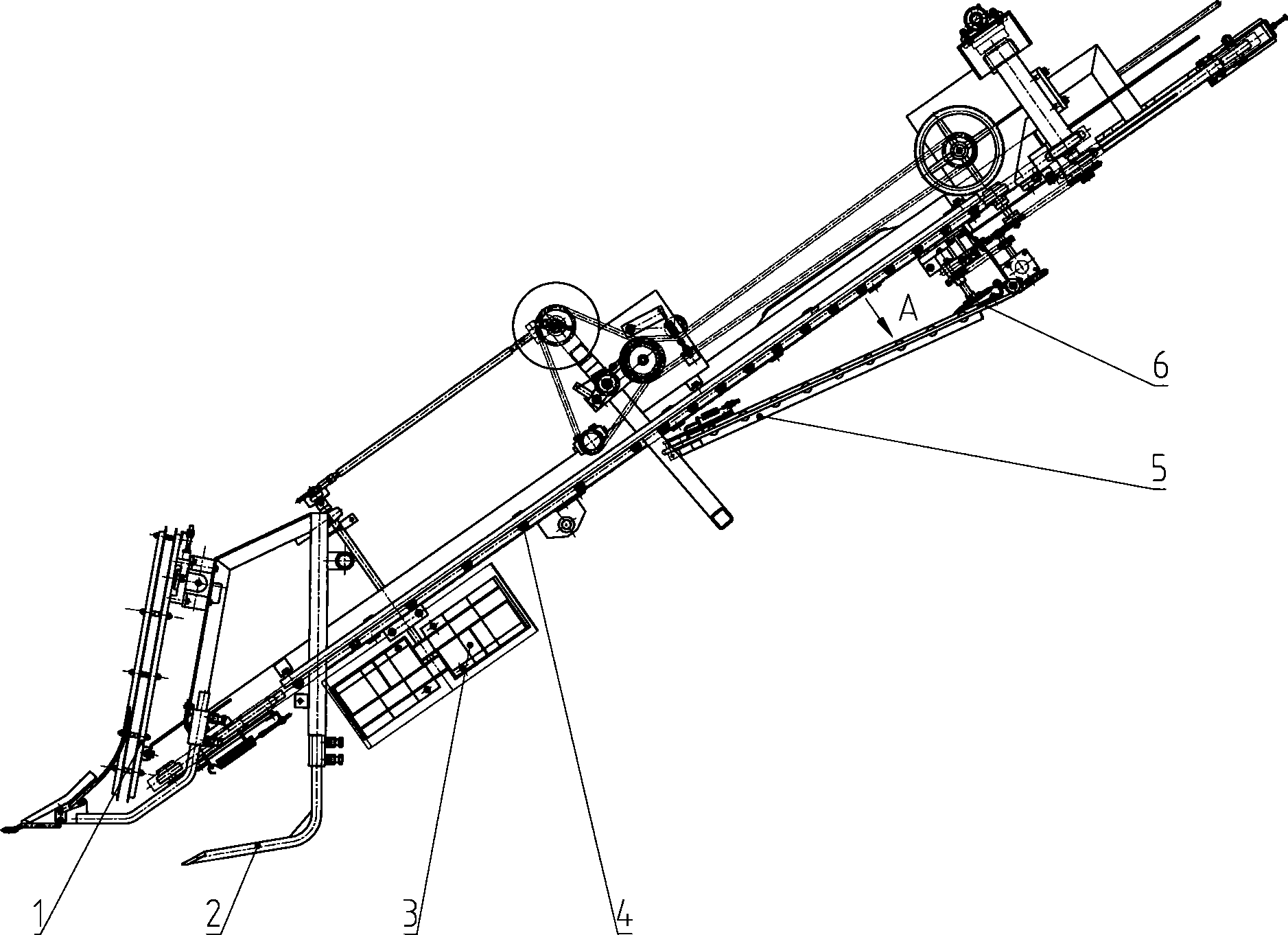

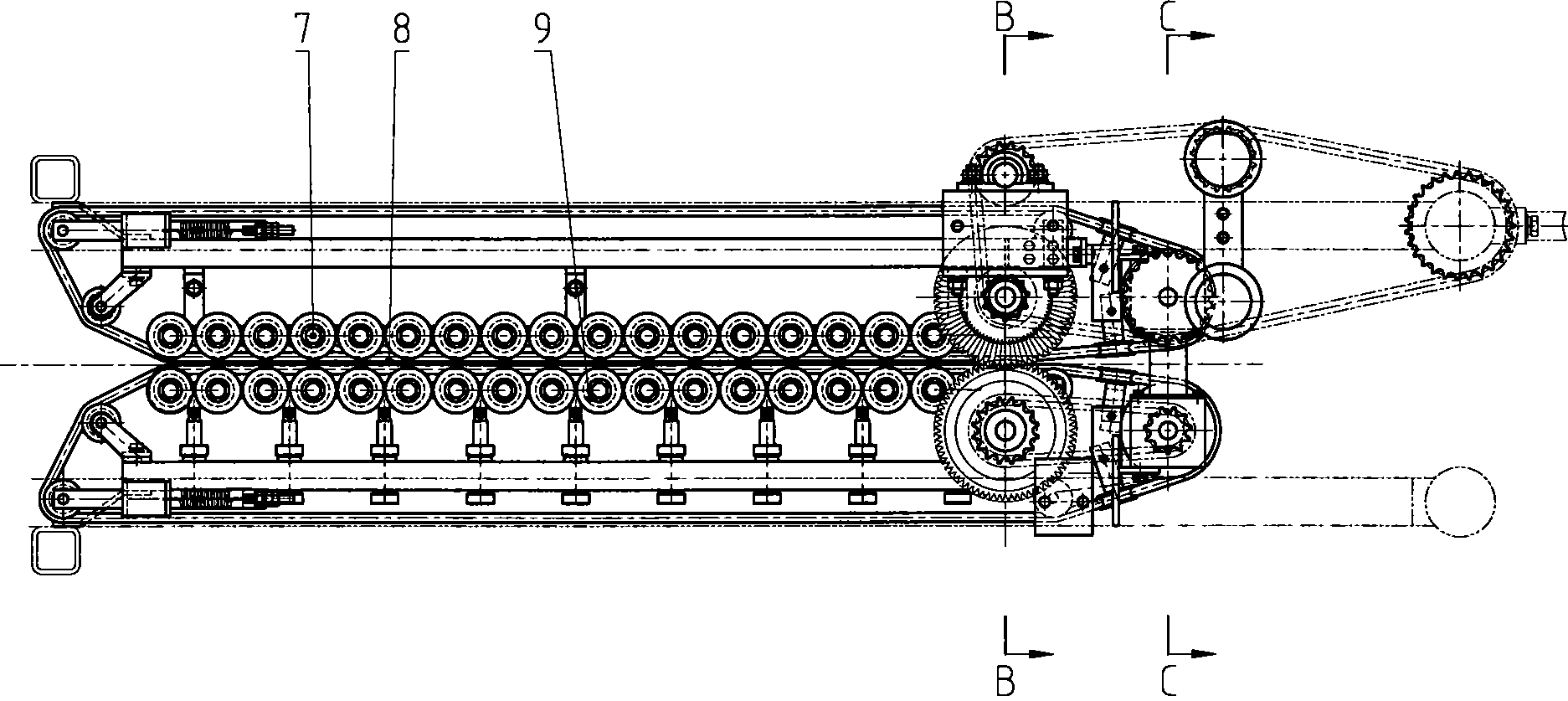

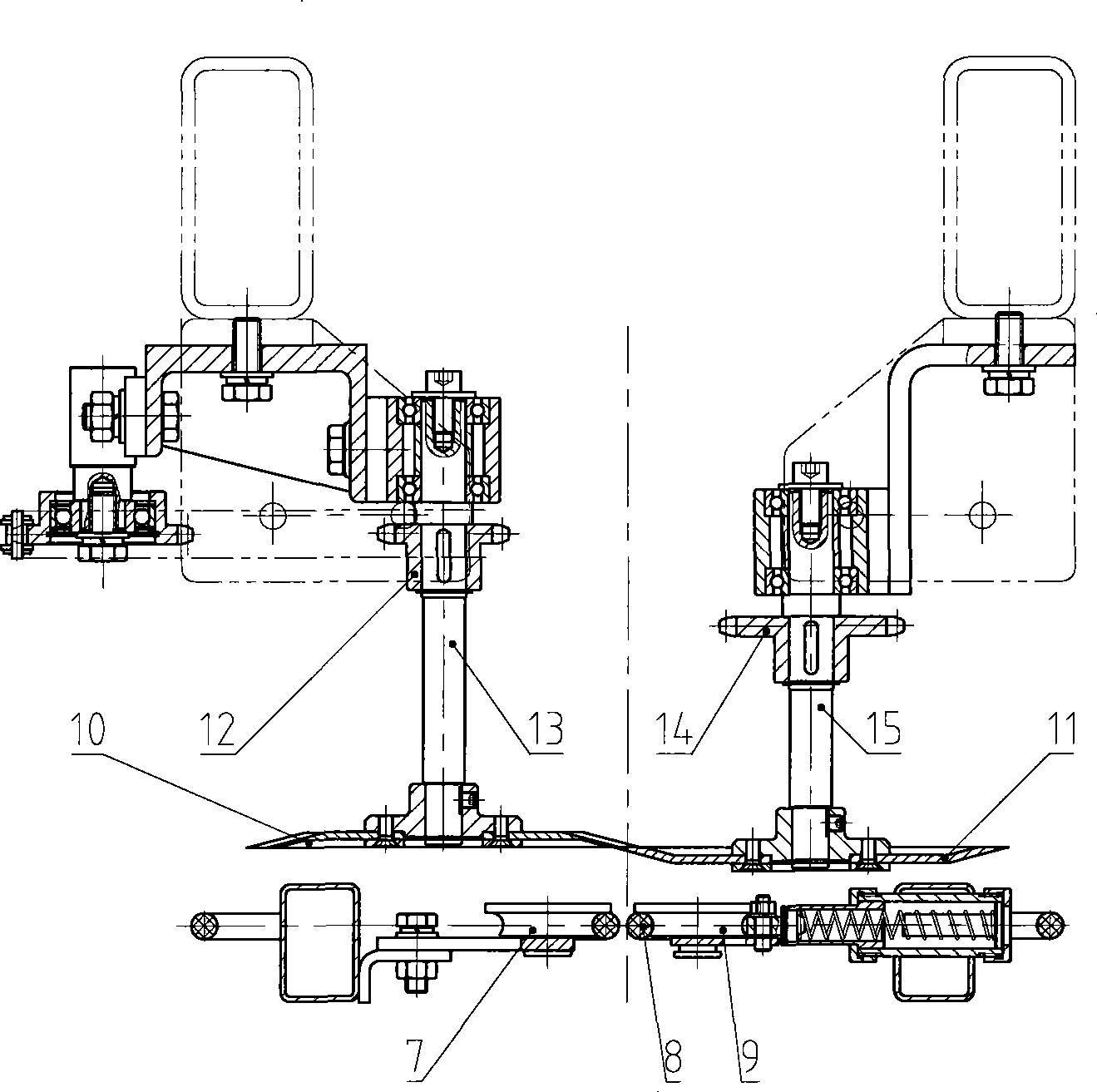

[0013] Such as Figure 1~2 As shown, the harvesting platform of the garlic combine harvester of the present embodiment consists of a seedling supporting mechanism 1, a digging shovel 2, a soil removal mechanism 3, a disc cutter separation mechanism 6, a clamping chain conveying mechanism 4 and a belt clamping conveying mechanism 5 etc., the belt clamping conveying mechanism 5 is installed below the clamping chain conveying mechanism 4 and is inclined downward. The belt clamping conveying mechanism 5 is made up of two belt transmissions arranged side by side, one group of fixed pressing wheels 7 is installed on one belt transmission, and one group of elastic pressing wheels 9 is installed on the other belt transmission. From image 3 It can be seen that at the lower end of the belt clamping conveying mechanism 5, the fixed pressing wheel 7 and the elastic pressing wheel 9 and the conveying belt 8 are below the disc cutter separating mechanism 6, and the disc cutter separating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com