Direct-energization heating desorption regeneration device and method of radon-absorption active carbon

An activated carbon and desorption technology, applied in separation methods, filter regeneration, chemical instruments and methods, etc., can solve the problems of inability to adapt to the requirements of rapid regeneration of activated carbon, long regeneration time, slow temperature rise, etc., and achieves easy automation and rapid cooling. , the effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

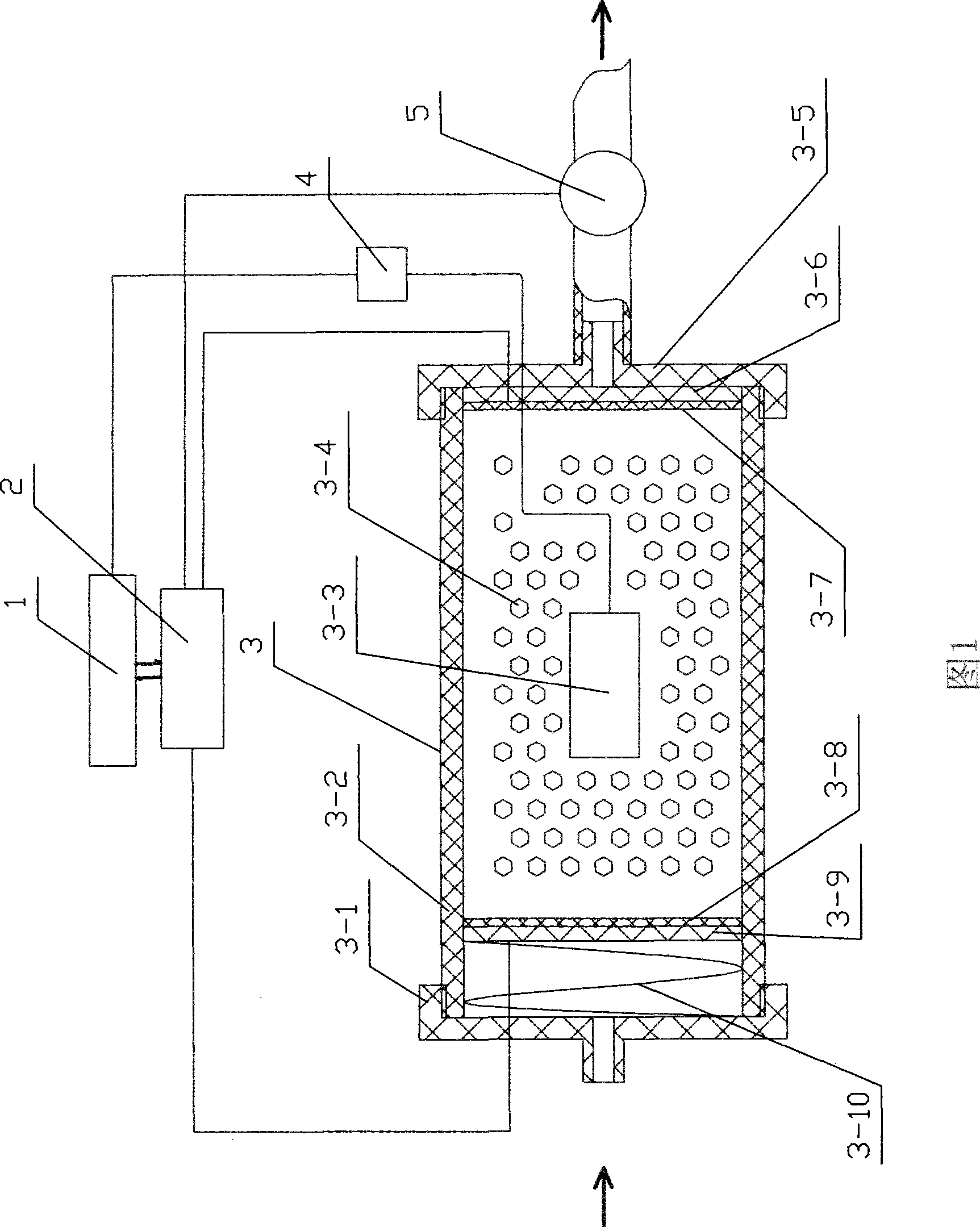

[0015] A method for directly energizing, heating, desorbing and regenerating radon-absorbing activated carbon. First, power is applied to both ends of the activated carbon tube 3, and the temperature of the activated carbon 3-4 is measured through the temperature measuring meter 4. When the activated carbon 3-4 in the activated carbon tube 3 reaches 150-250°C Finally, keep for 3 to 5 minutes, then open the air pump 4 to pump air for 5 to 15 minutes, so that the desorbed radon will be taken out of the activated carbon tube 3 by fresh air. The above operation processes are all automatically controlled by the controller 1 .

[0016] A radon-absorbing active carbon direct heating desorption regeneration device, which is composed of a controller 1, a power supply 2, an activated carbon tube 3, a temperature gauge 4 and an air pump 5. Wherein, the activated carbon tube 3 consists of a cylindrical shell 3-2 with two ends open, end caps 3-1, 3-5 located at the two open ends of the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com