Close-coupled Selective Catalytic Reduction (SCR) system

An SCR catalyst, compact technology, applied in exhaust gas treatment, mechanical equipment, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

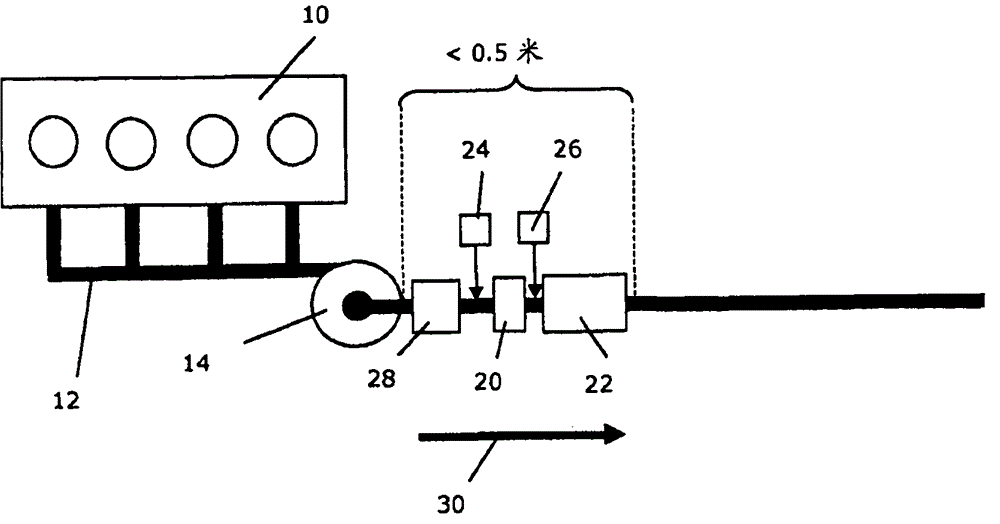

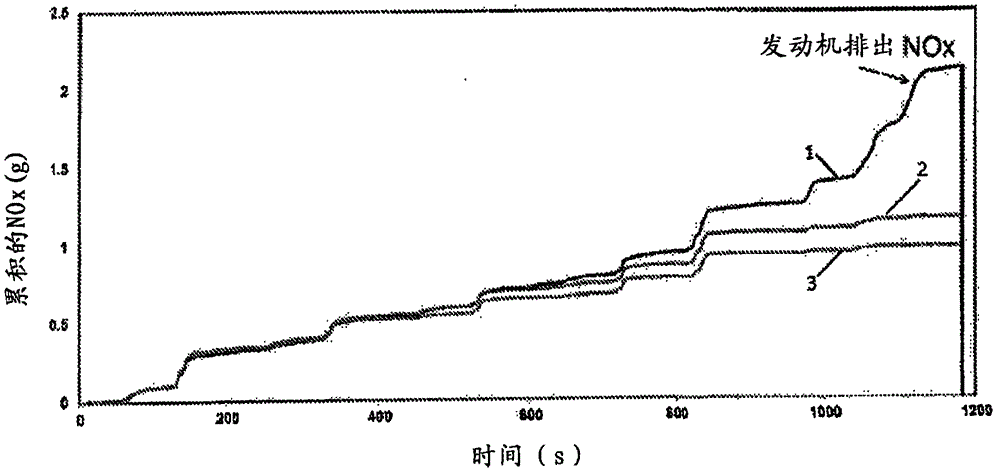

[0046] At engine start, the total NO of the system according to the invention x Conversion versus total NO for systems including only SCR wall flow filters x conversion rates for comparison. The SCR wall flow filter comprises an inert silicon carbide substrate with a porosity of 52% and an average pore size of 20 microns. The wall flow filter has a volume of 2.5L. The compact monolith has a volume of 0.625 L. The compact monolith and SCR wall flow filters were aged at 800°C for 16 hours prior to testing. Both systems were tested in the vehicle's 1.9L engine, subjected to test conditions associated with the MVEG drive cycle, with urea injected as a reducing agent at 180°C. The resulting NO of the two systems x Emissions and controls plotted against time.

[0047] NO provided by the present invention x conversion potential in figure 2 is shown in , which shows the NO x The overall output is reduced. Here, line 1 represents.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com