Patents

Literature

36results about How to "High thermal energy conversion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

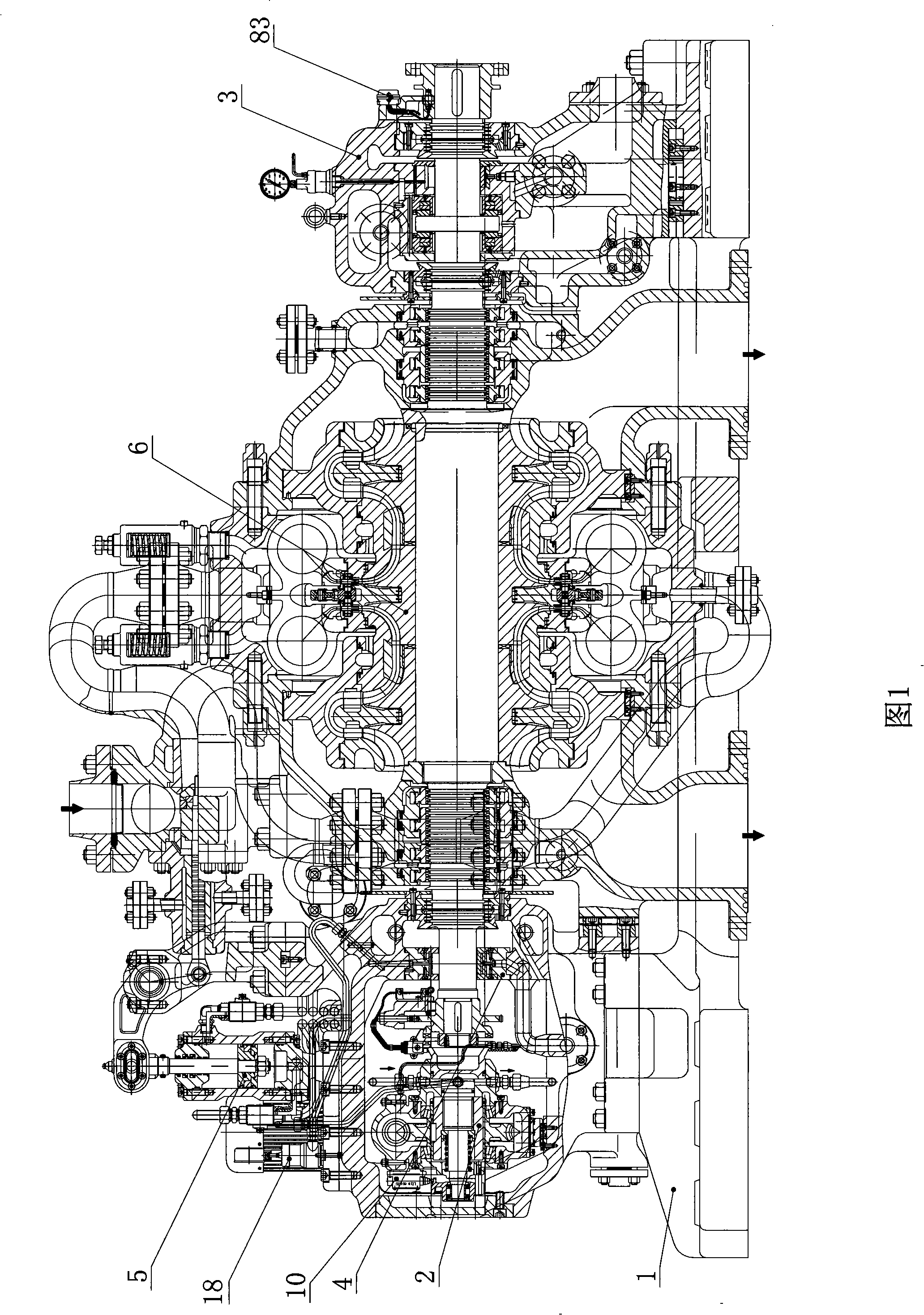

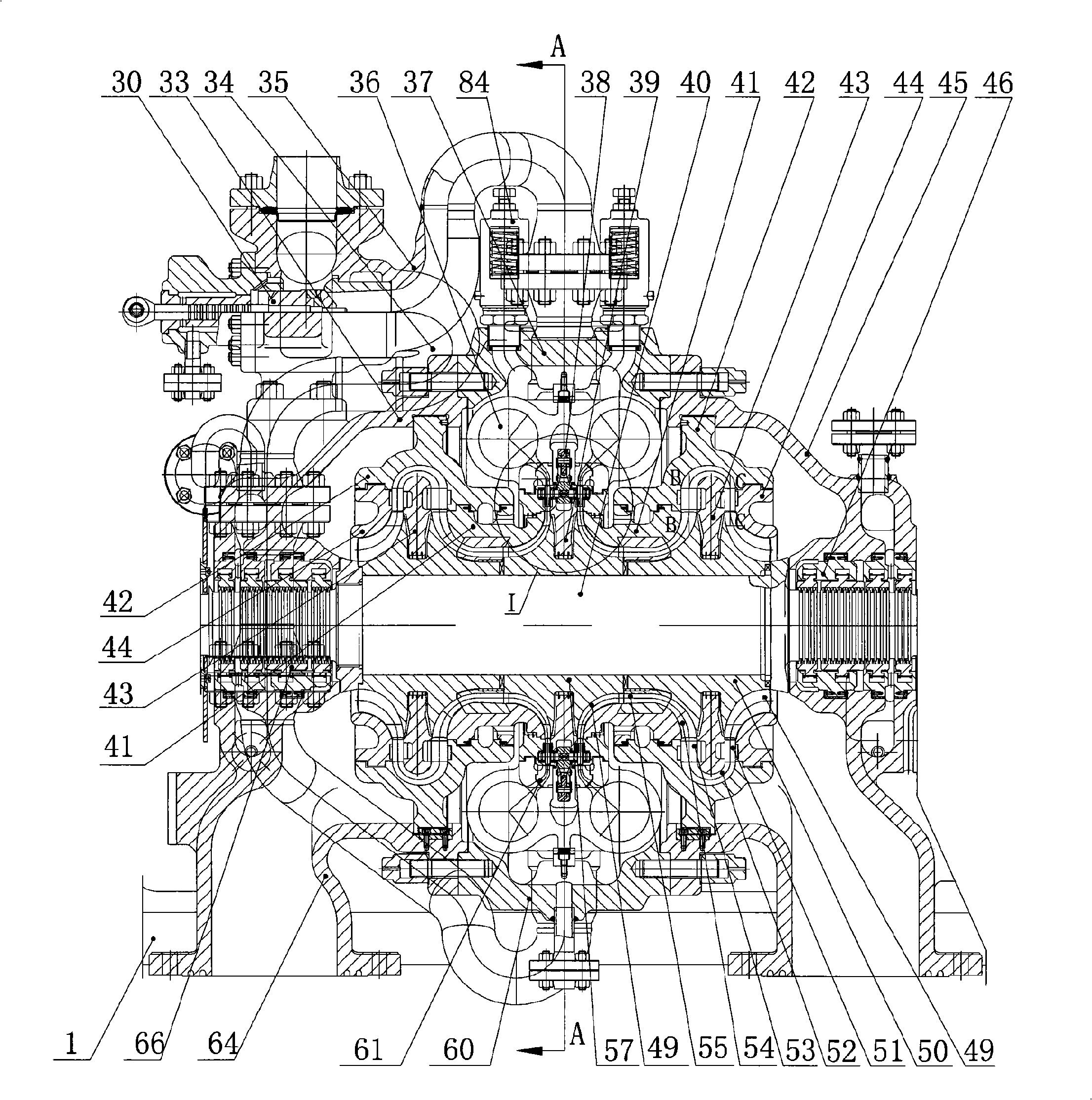

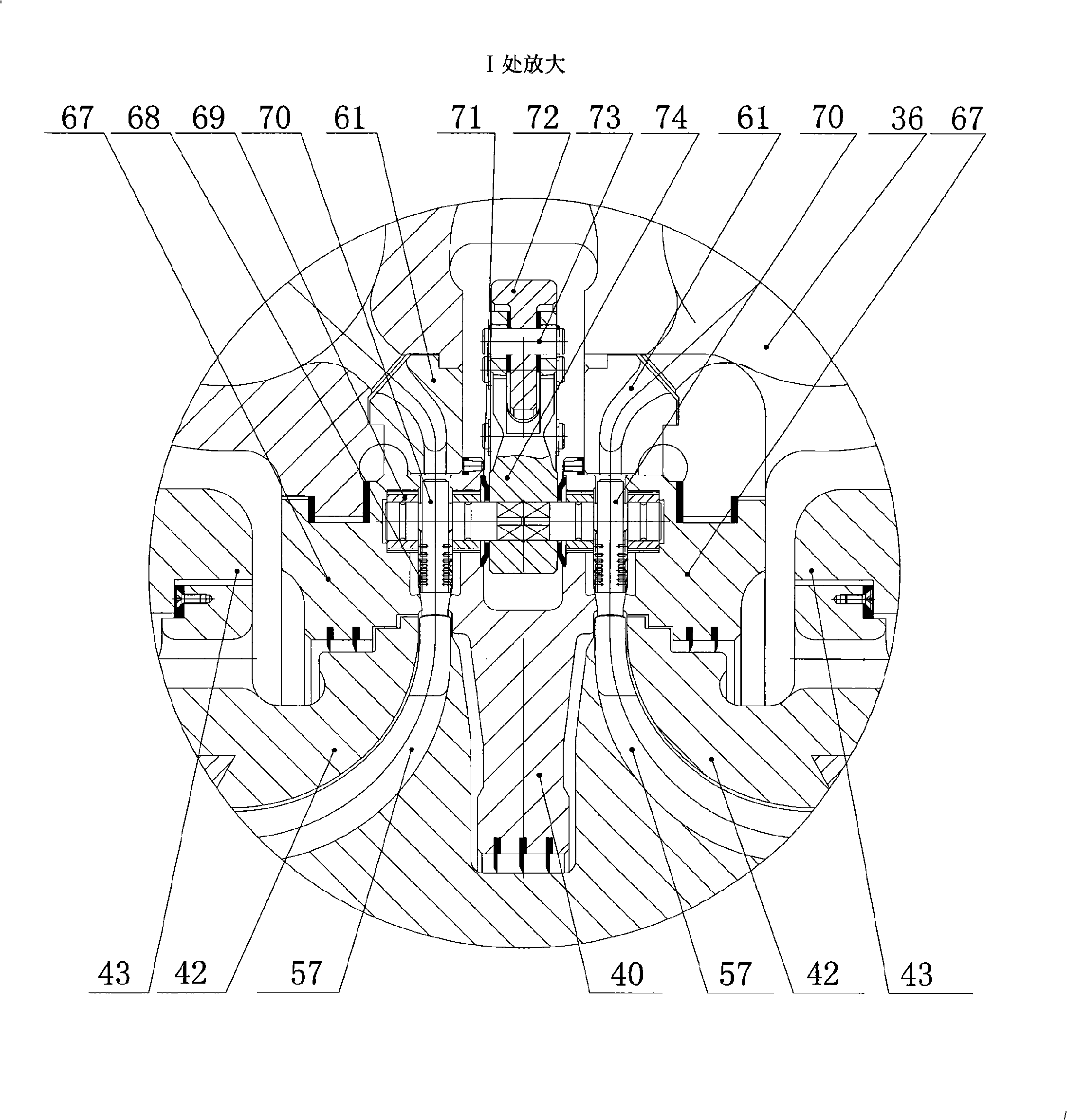

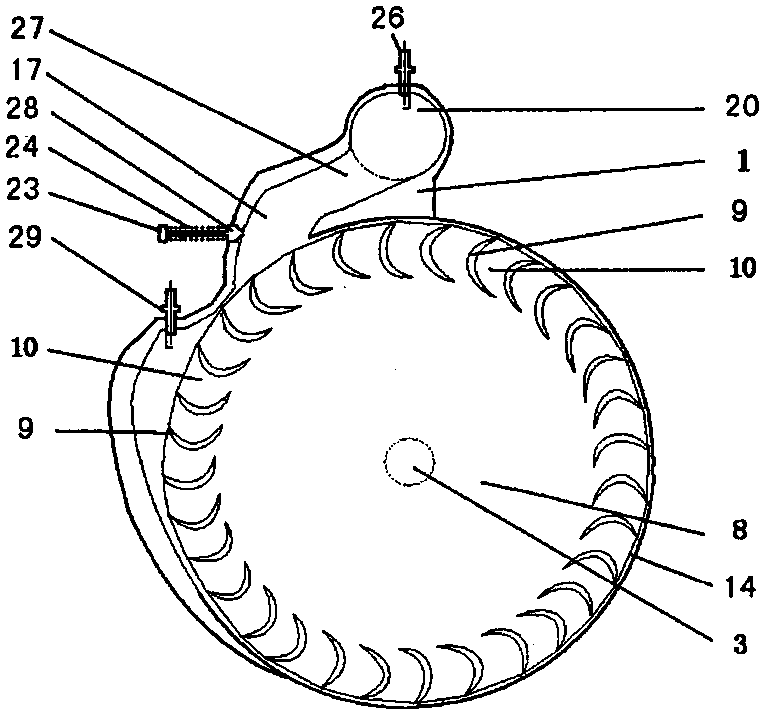

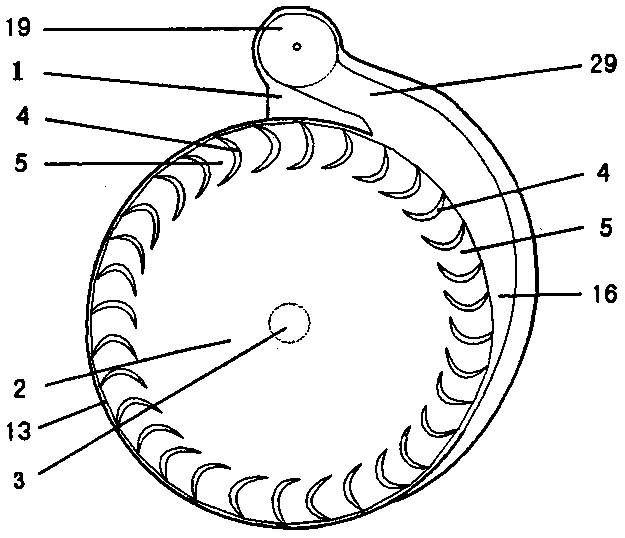

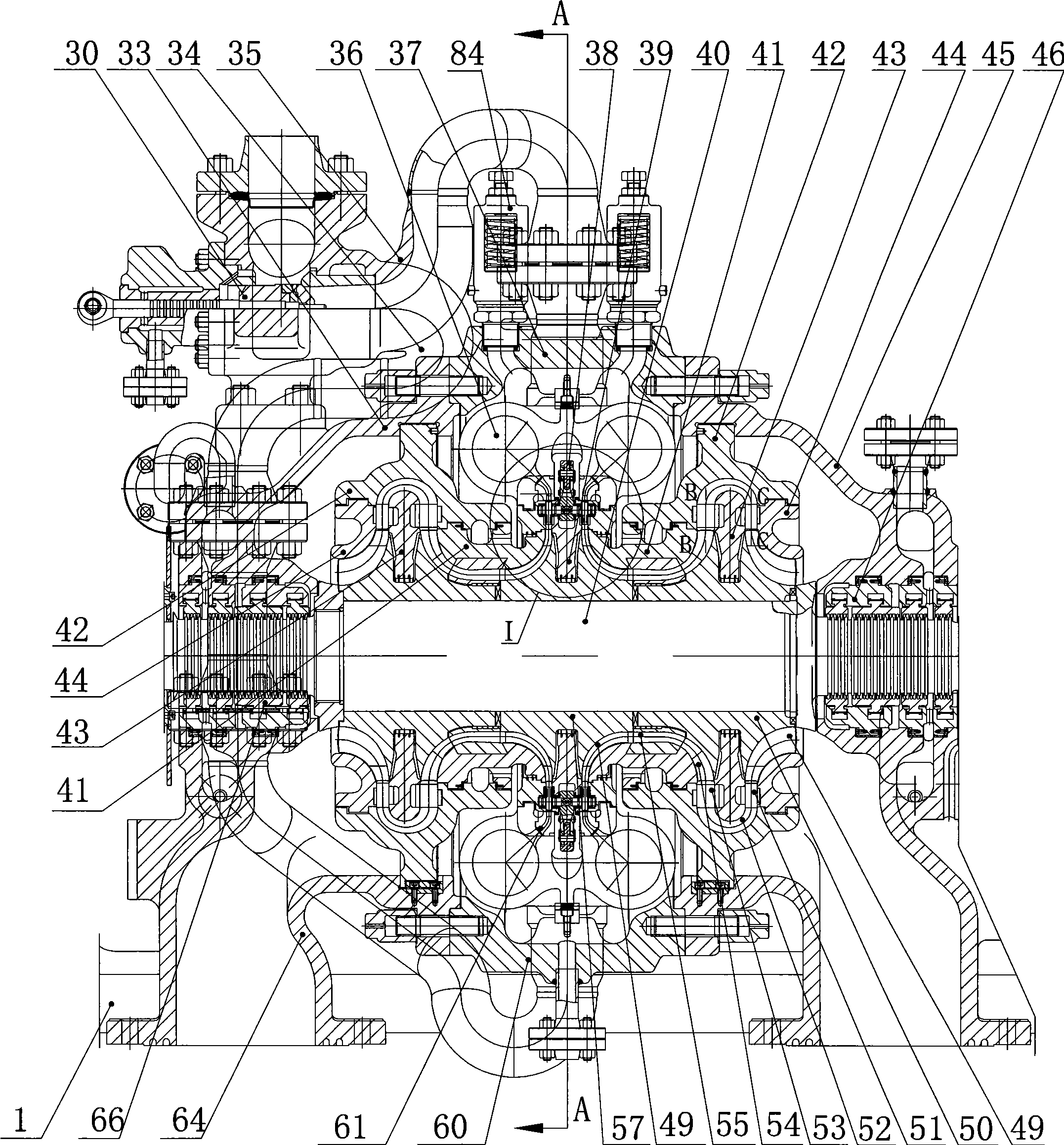

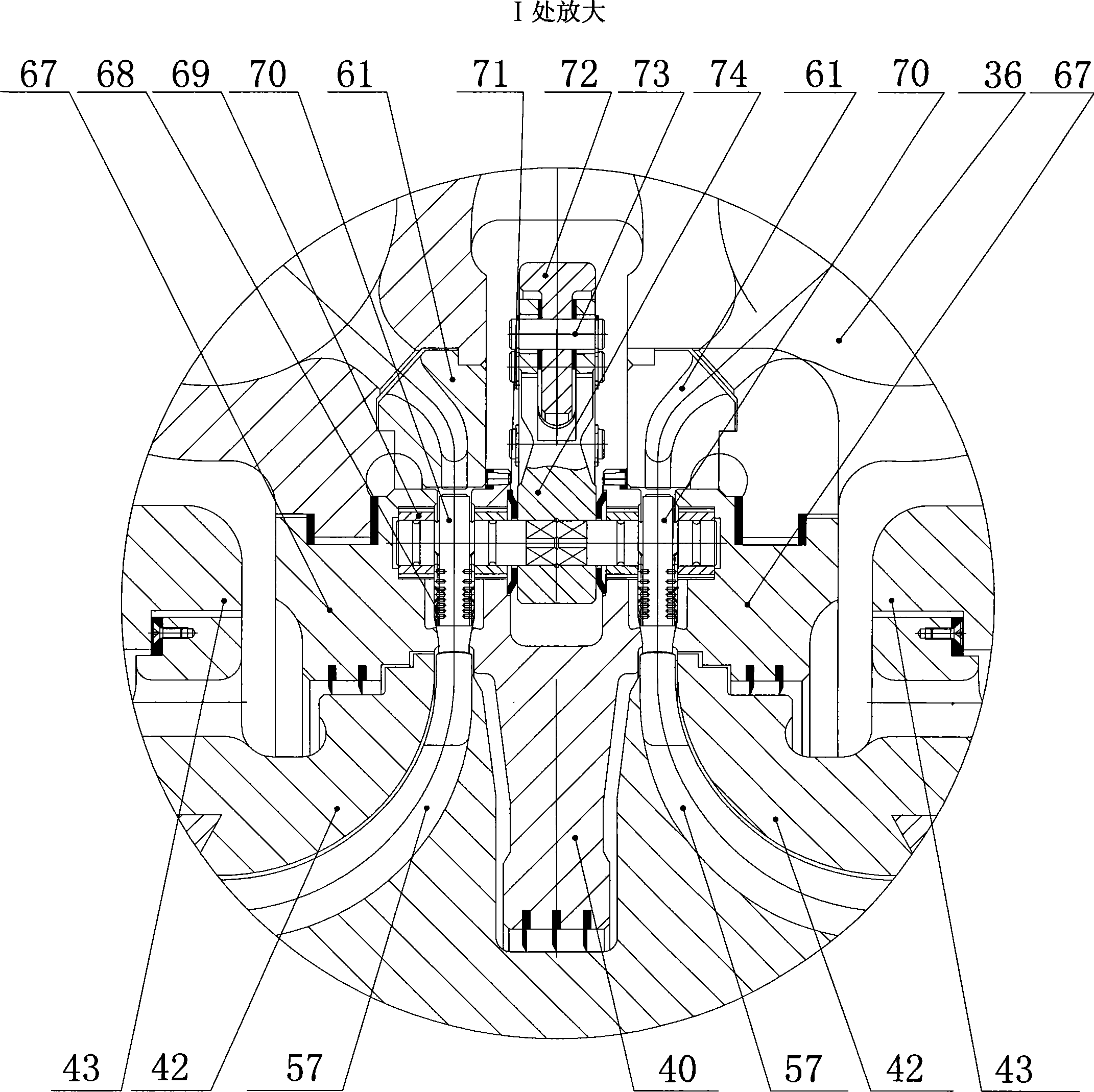

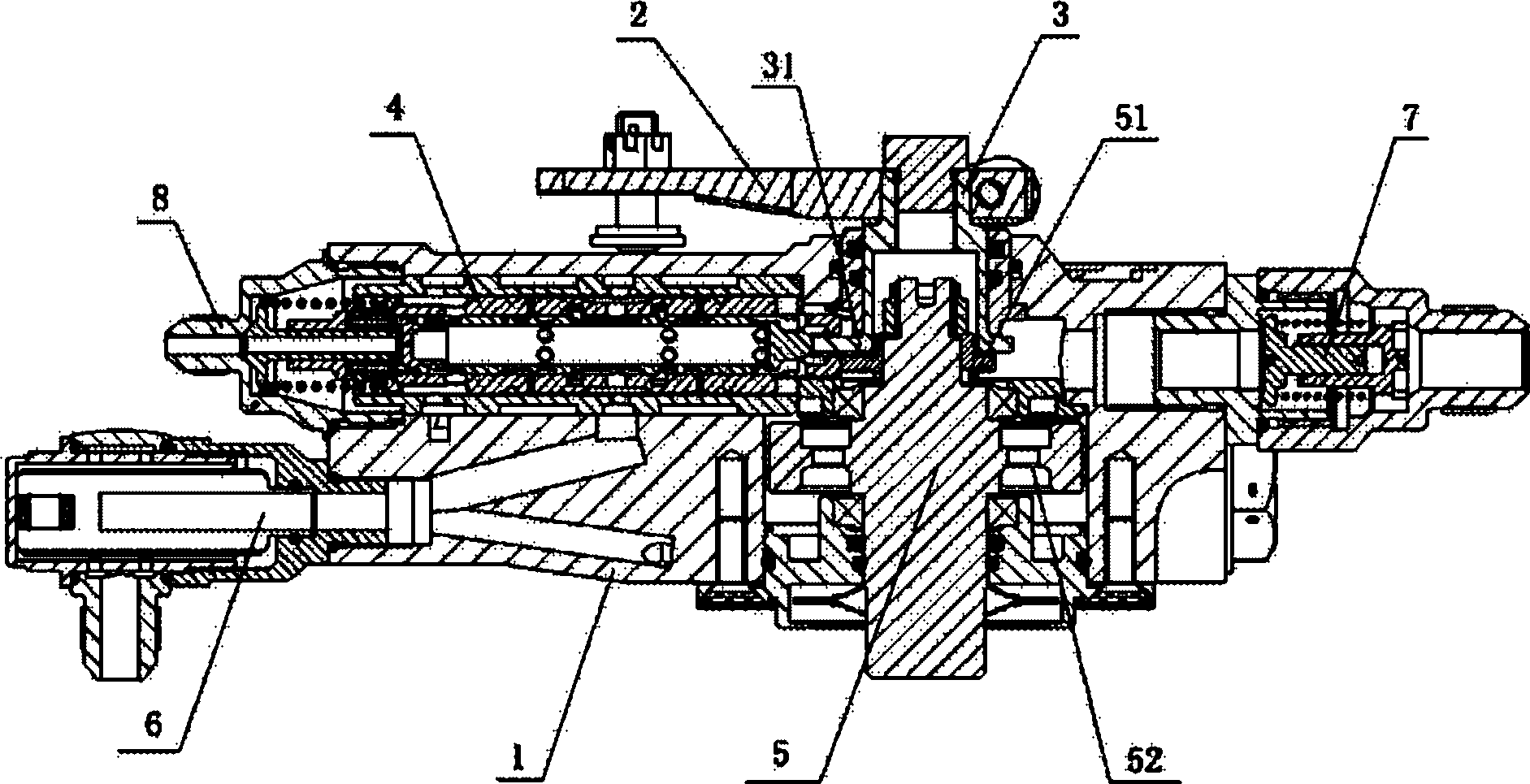

Radial double-flow turbine

The invention relates to a steam turbine, in particular to a radial direction double flow type steam turbine which can effectively reduce axial force and use steam flow energy as much as possible. Double rows of centripetal integral impellers are arranged at the center of a live spindle, centrifugal integral impellers are arranged at two sides. The integral impellers do work when steam flow carries out centripetal movement to push the spindle to rotate, and do work again in the centrifugal stage to push the spindle to rotate after the angular transformation, and enter the next circulation. The structure can counteract the generated axial force, reduce the structure, use the centrifugal energy, and improve the efficiency.

Owner:程建平 +1

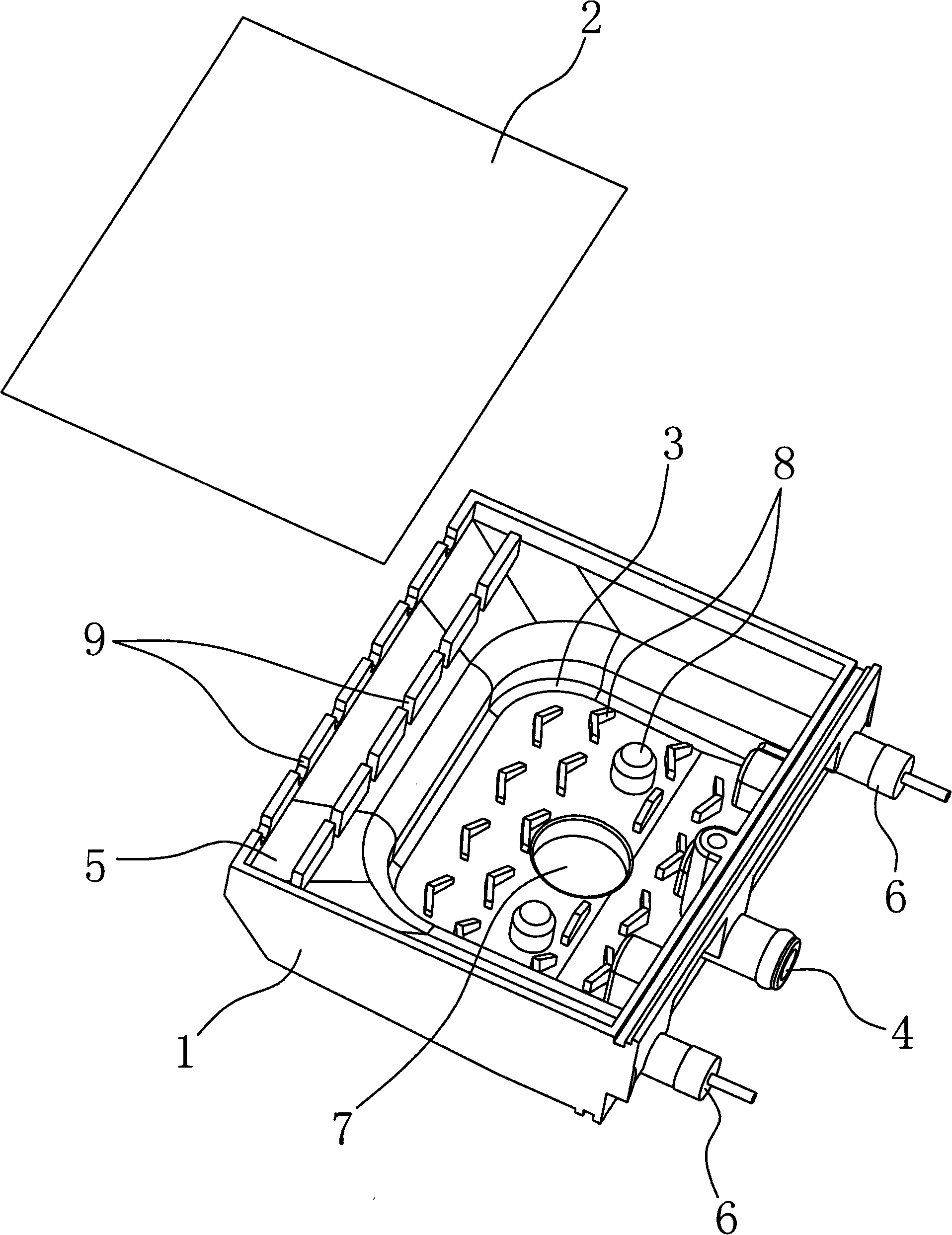

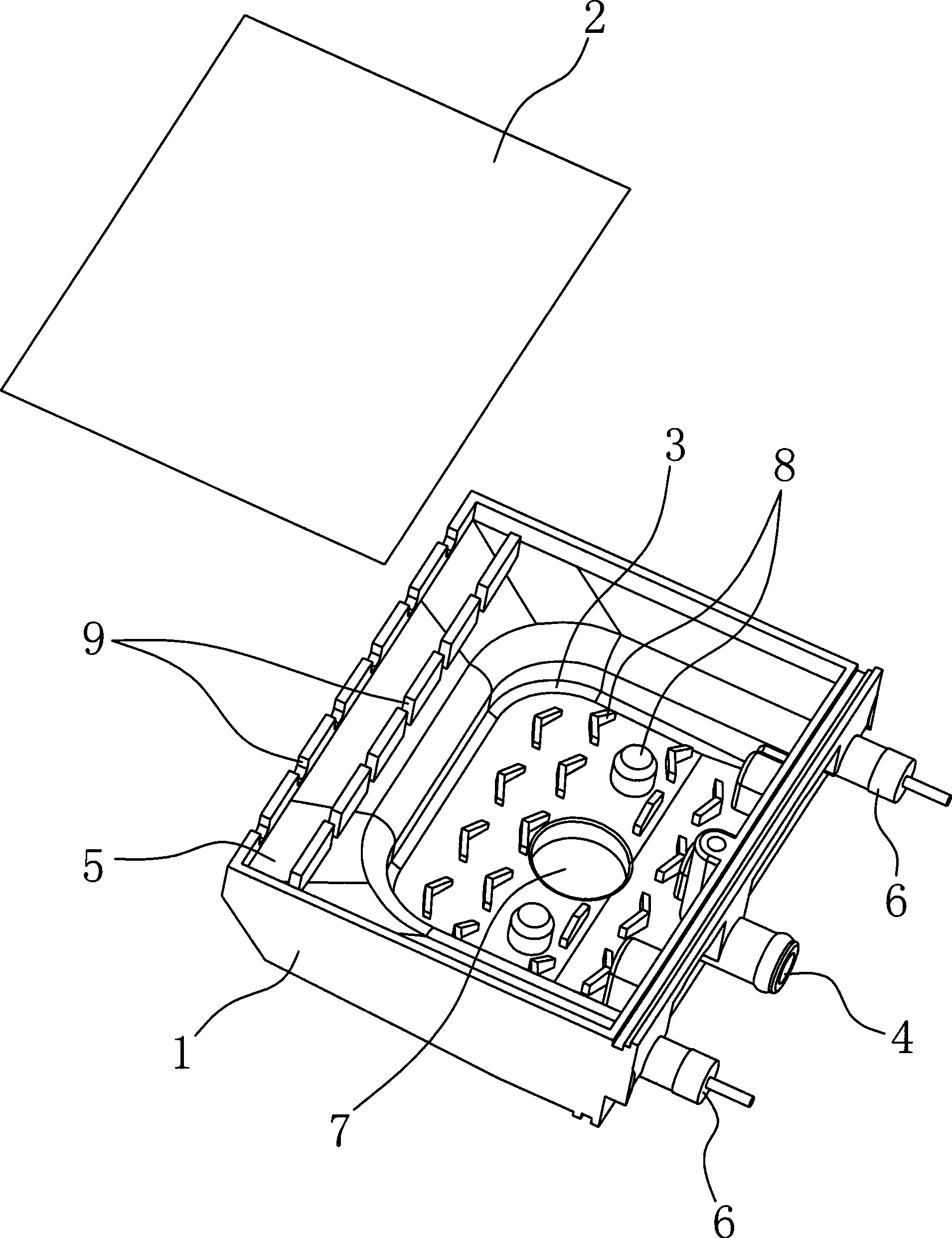

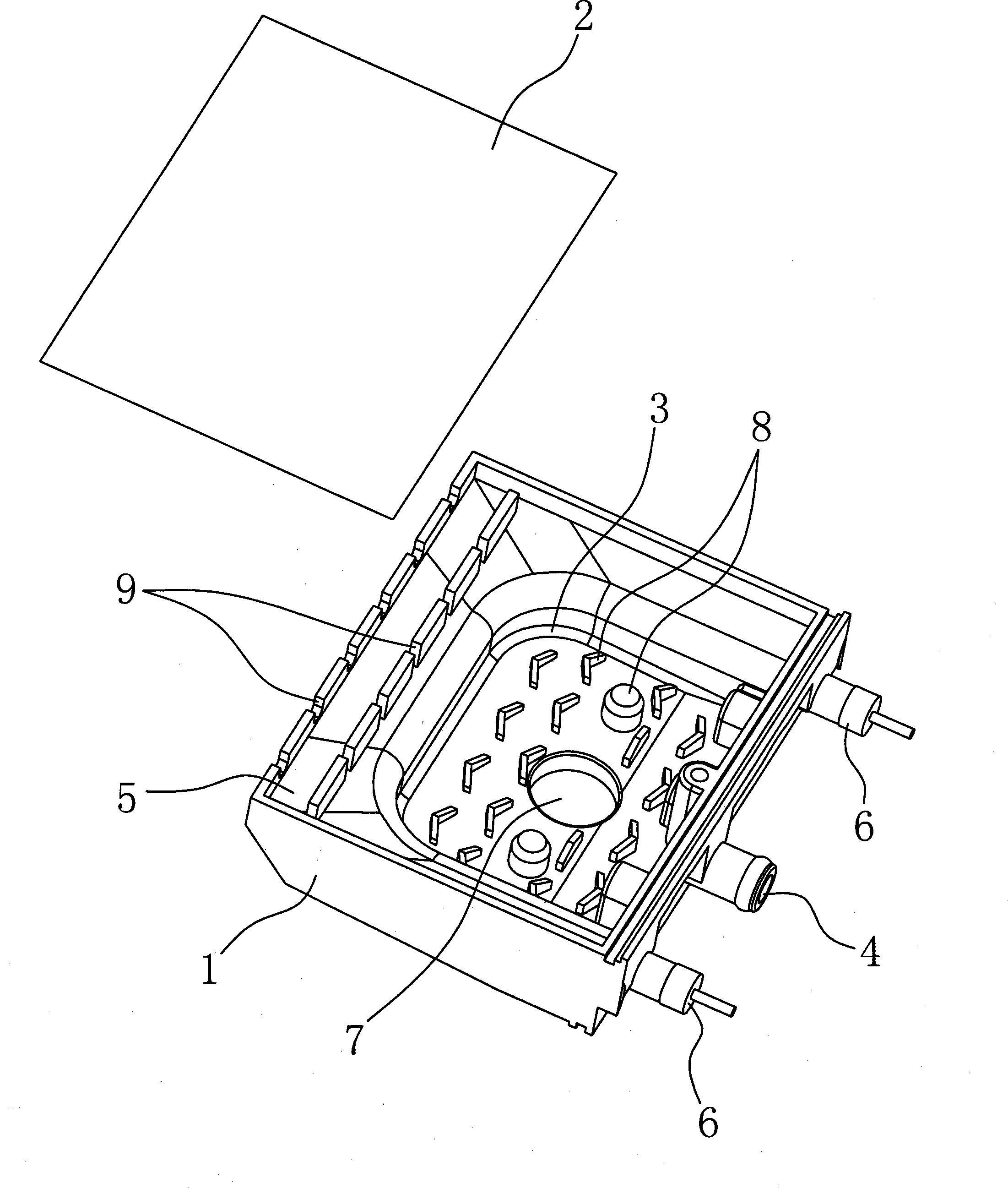

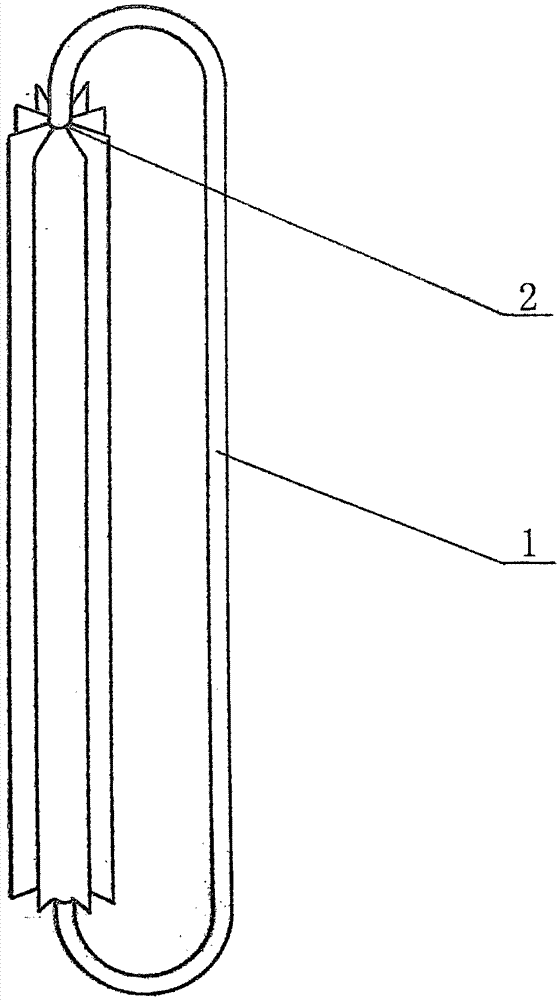

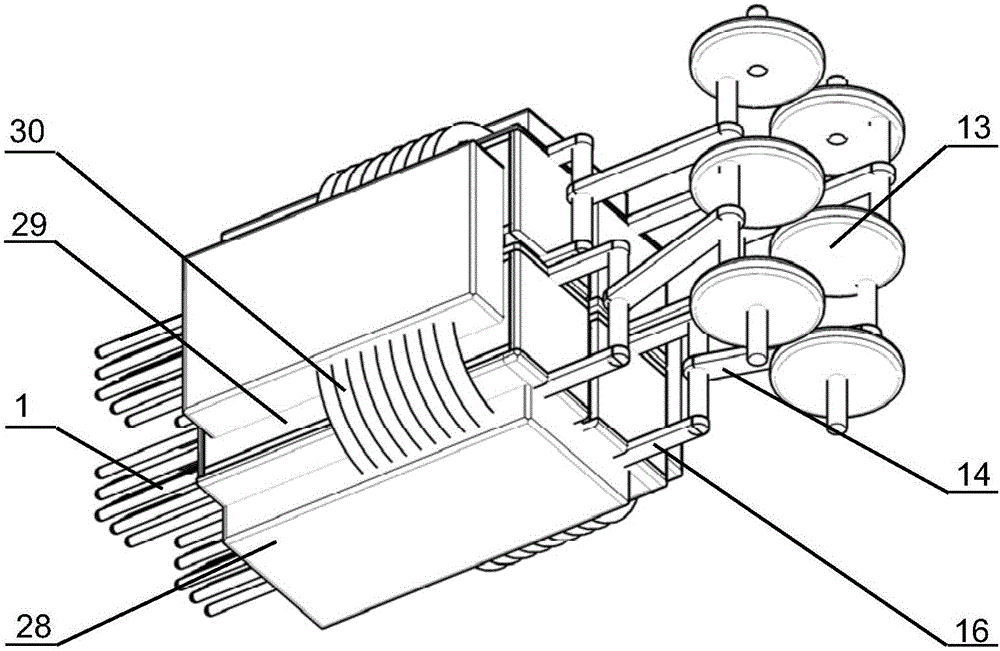

High-temperature steam generation apparatus

InactiveCN101358727AReduce energy consumptionIncrease profitSteam generation heating methodsEngineeringSteam generation

The present invention relates to the technical field of the steam generation device, in particular relates to a high-temperature steam generation device that is used for the devices heating and cooking different foods, which comprises a high-temperature steam generator and an upper cover, wherein, the main body of the high-temperature steam generator is provided with a heating cavity; both ends of the heating cavity are communicated with a water inlet and a steam outlet, which are arranged on the main body; a heating pipe is arranged inside the main body of the high-temperature steam generator and the upper cover covers on the main body of the high-temperature steam generator; the heating pipe inside the high-temperature steam generation device is in a U shape; a plurality of projection elements that are arranged inside the heating cavity increase the contact area between the heating cavity of the water, so that the water can be better contacted with the heating cavity, so as to rapidly produce the steam; moreover, the heat energy conversion efficiency is high; in addition, the upper cover prevents the steam and the heat from leaking; the produced steam is exhausted from the steam outlet, so that the steam is easy to be collected, and the steam utilization rate is high. The high-temperature steam generation device has simple and compact structure, and occupies less space, and is safe and reliable to be operated, and has high heat efficiency, and saves energy and protects the environment.

Owner:GUANGDONG LUBY ELECTRONICS

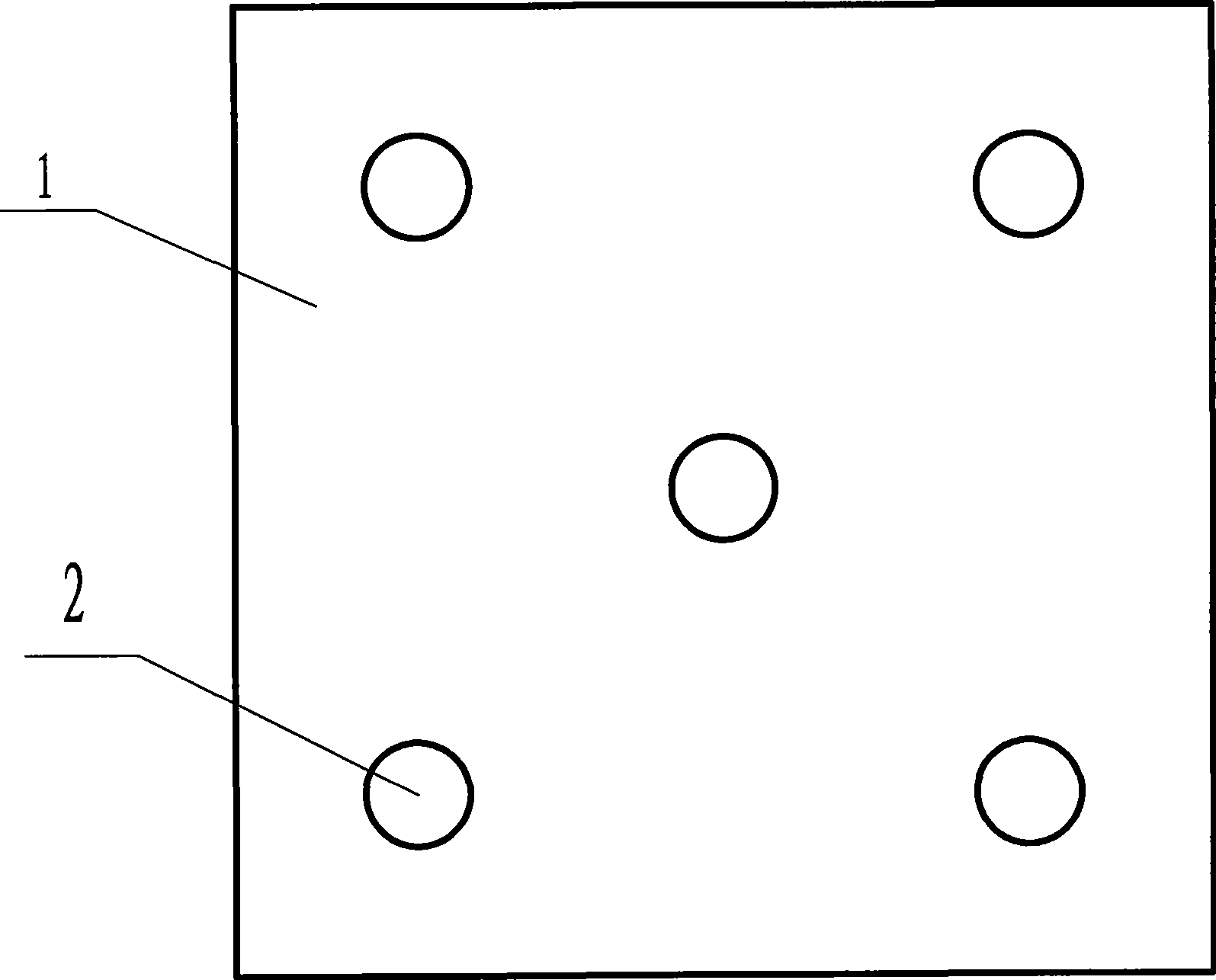

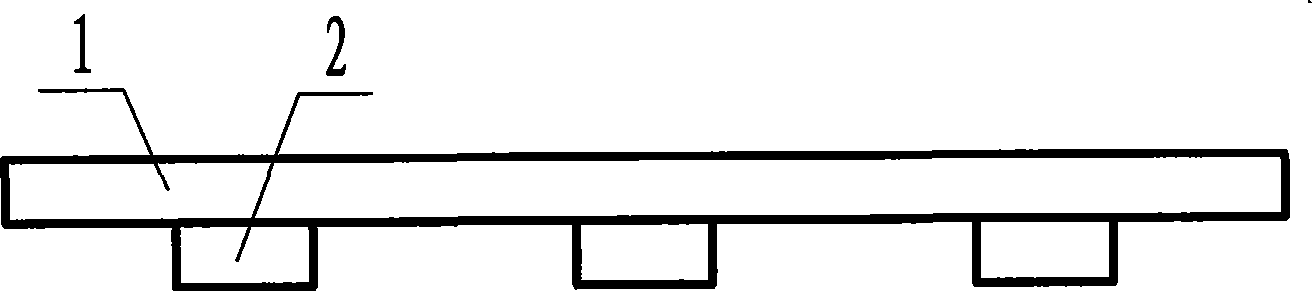

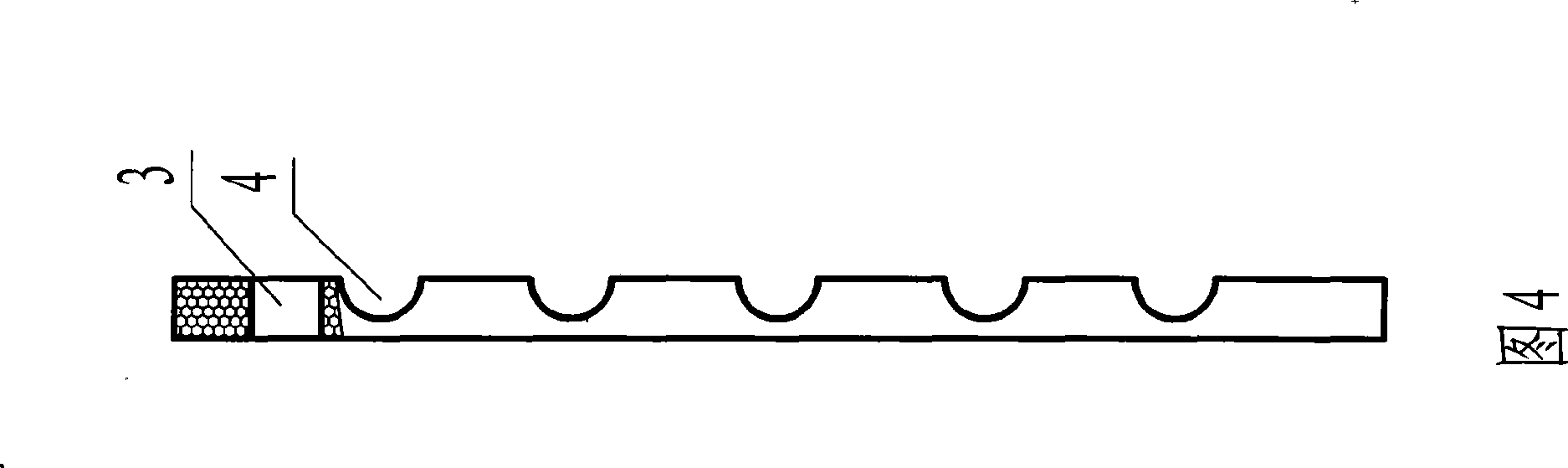

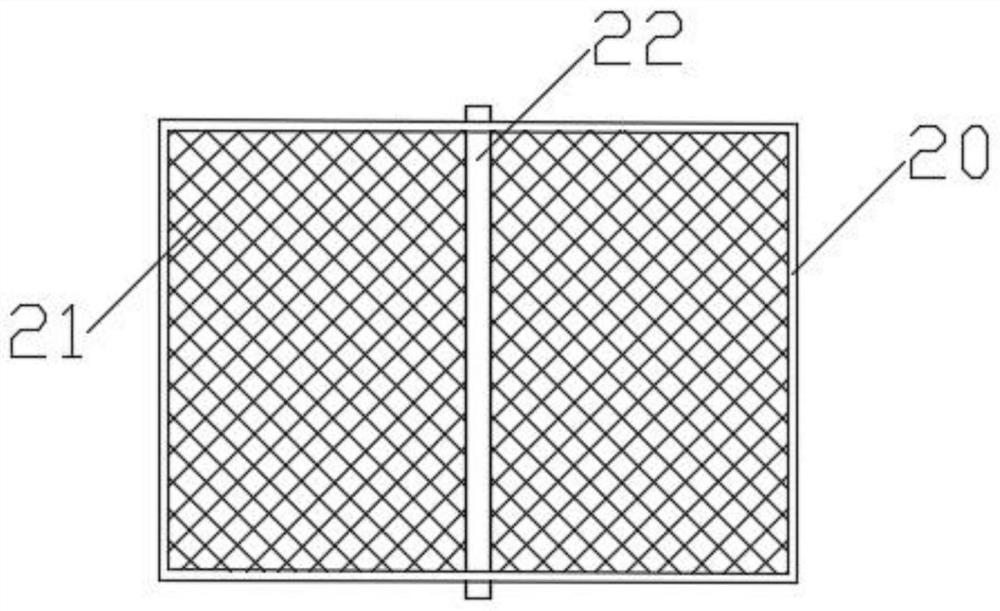

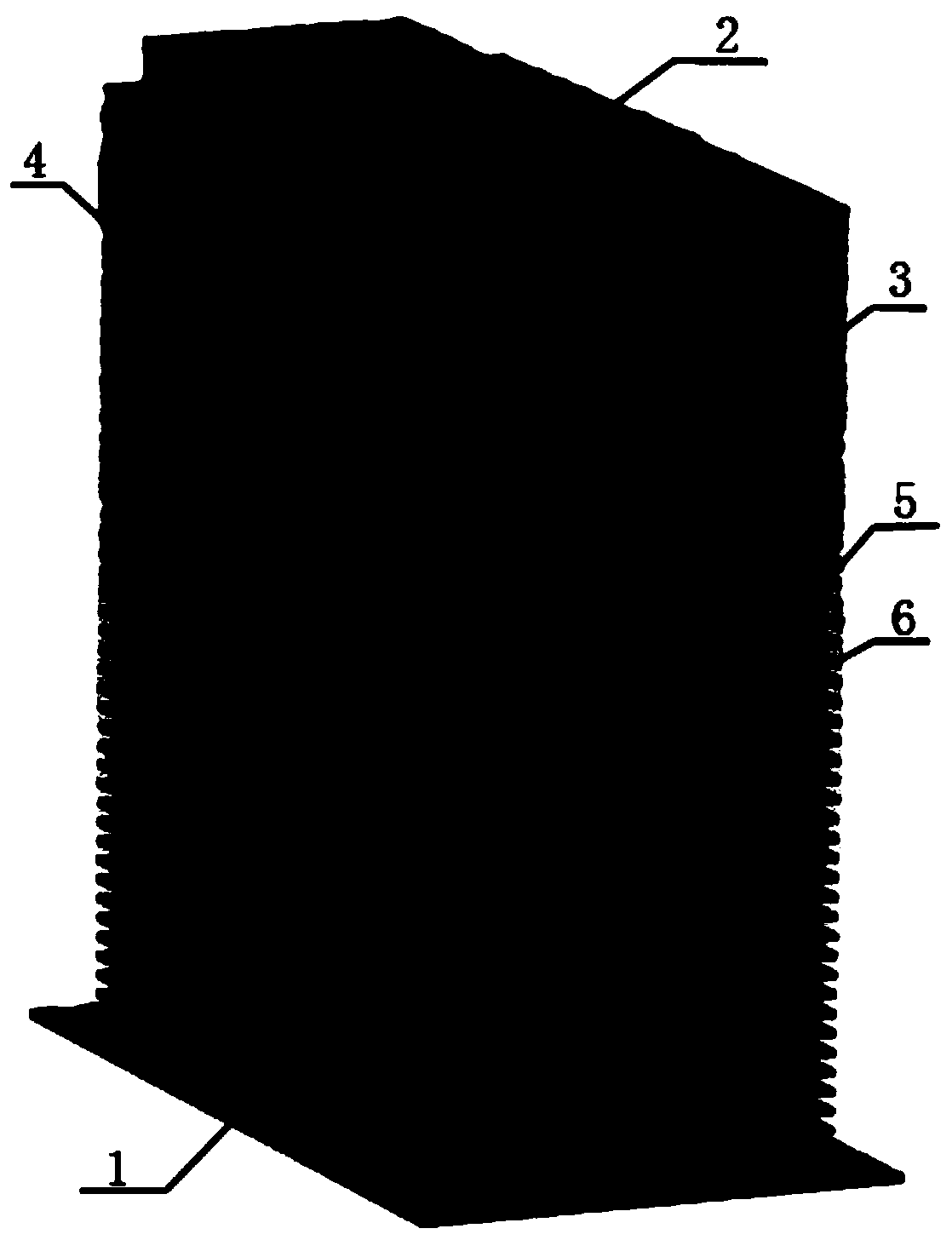

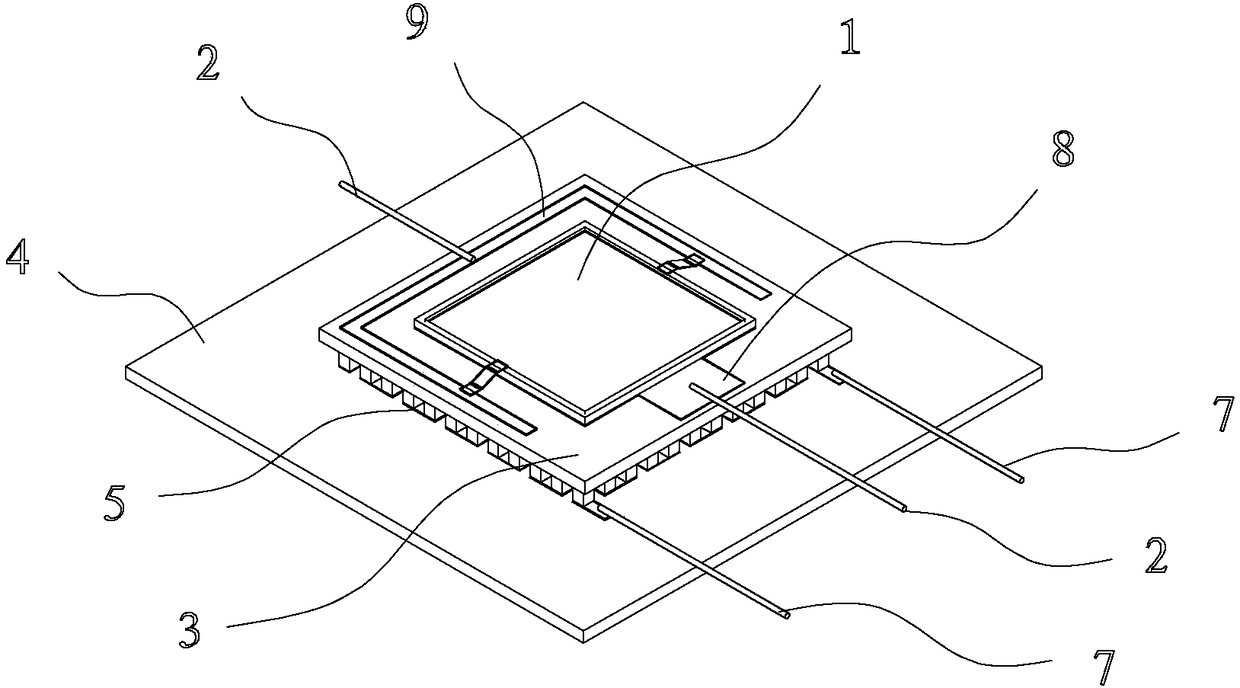

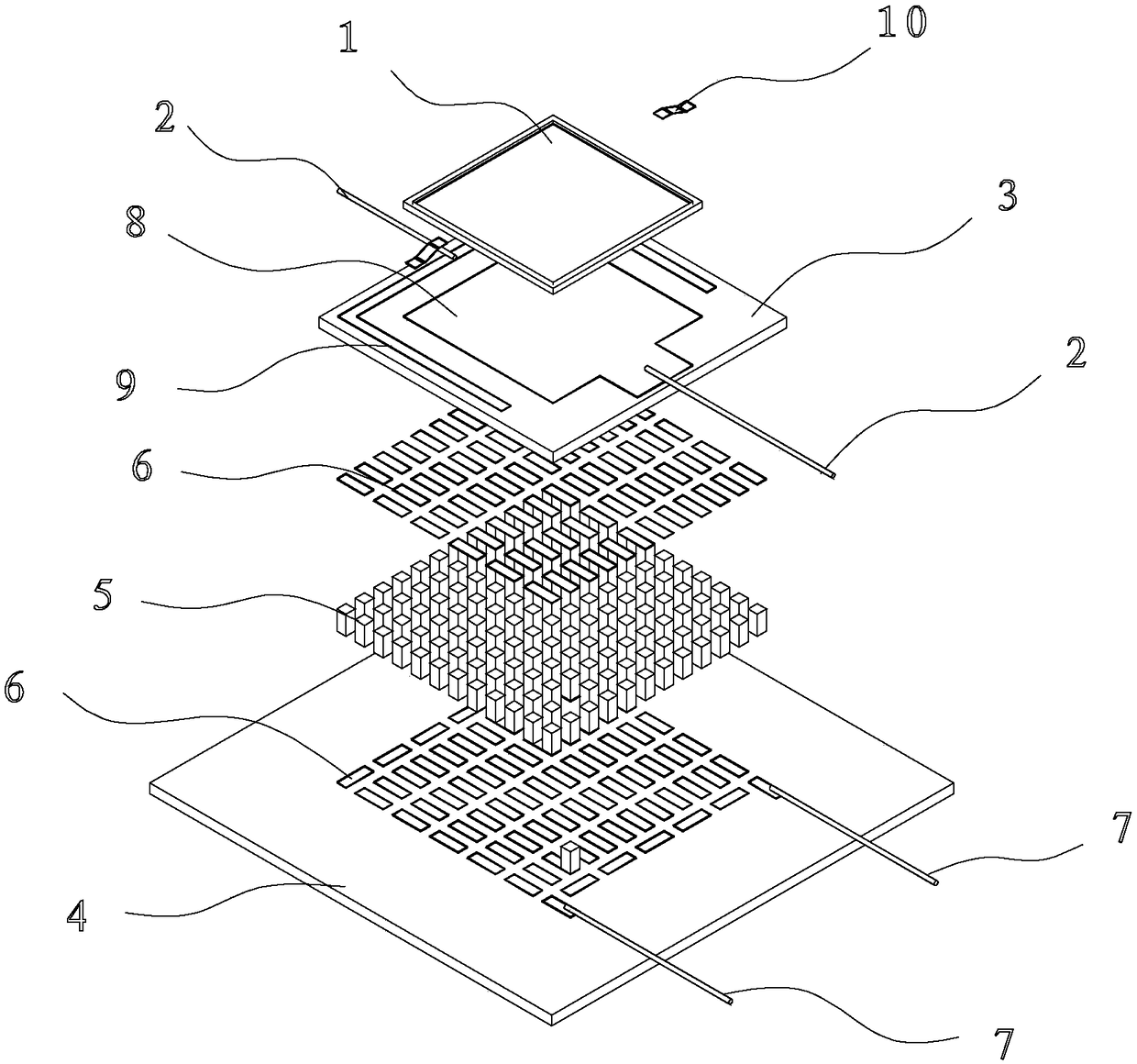

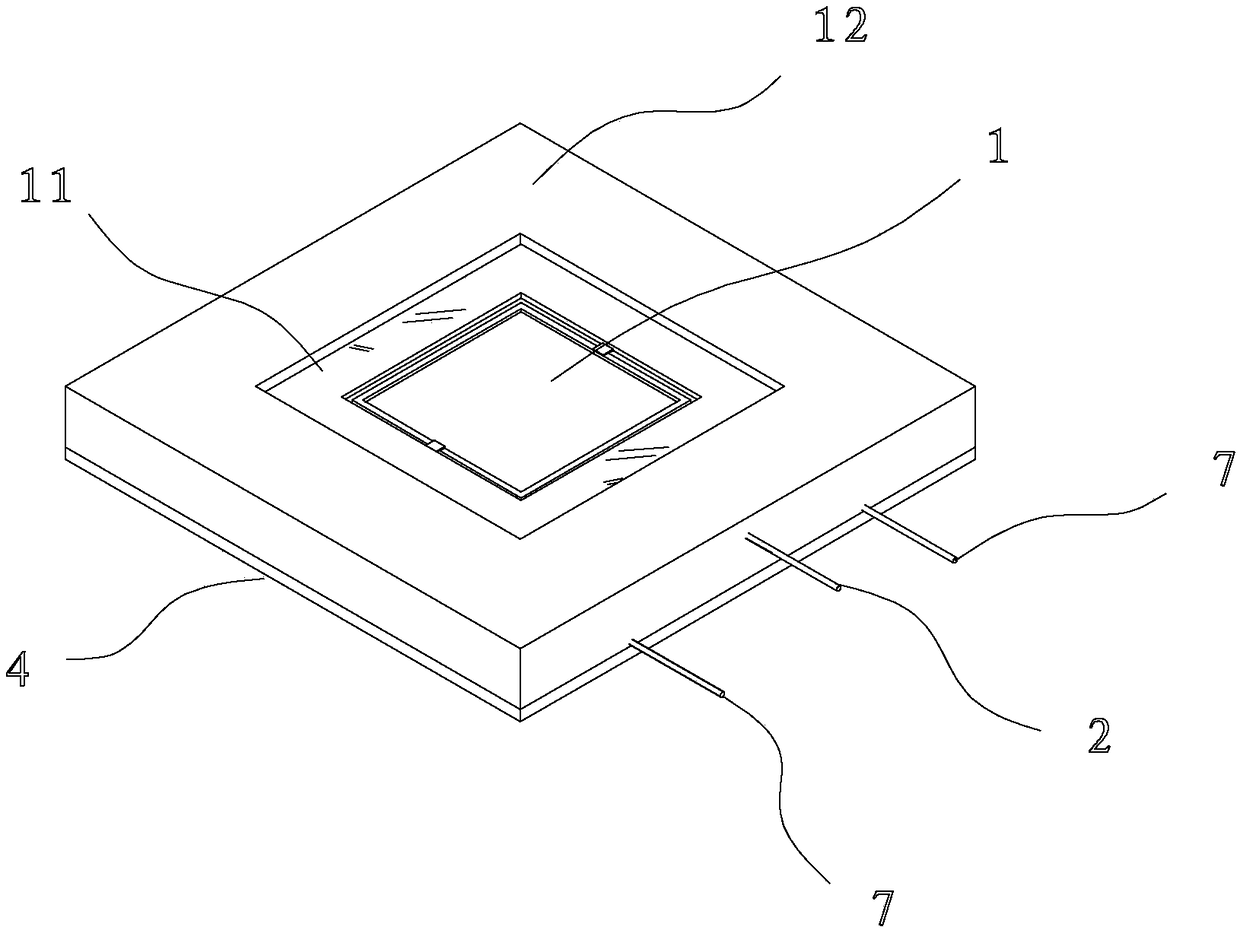

Assembled geothermal energy plate and assembling method

InactiveCN101457569AEvenly heatedGuaranteed smoothBuilding componentsFlooringGround temperatureThermal energy

An assembled terrestrial heat floor block and an assembling method thereof belong to the technical field of terrestrial heat. The assembled terrestrial heat floor block is formed by compounding upper layer assembled floor blocks and lower layer heated board parts, and has a flat plate structure; each of the heated board parts is provided with holes, and heat conduction grooves are arranged among the holes and provided with heating pipes; as a heating pipe disc is arranged inside the heat conduction groove, the heat can be conducted by air flow, and the ground temperature is uniform; the holes of the heated board parts are injected with cement mortar, concrete or benzene slab mastic cement to ensure the assembled floor blocks to be flat, and a complete geothermal heating floor is formed. The invention has simple structure and easy processing. The method for assembling the assembled terrestrial heat floor block has the advantages of rapid and convenient construction, good monodirectional heat transmission effect, high thermal energy conversion efficiency, simple construction and maintenance, low cost, etc.

Owner:陈星

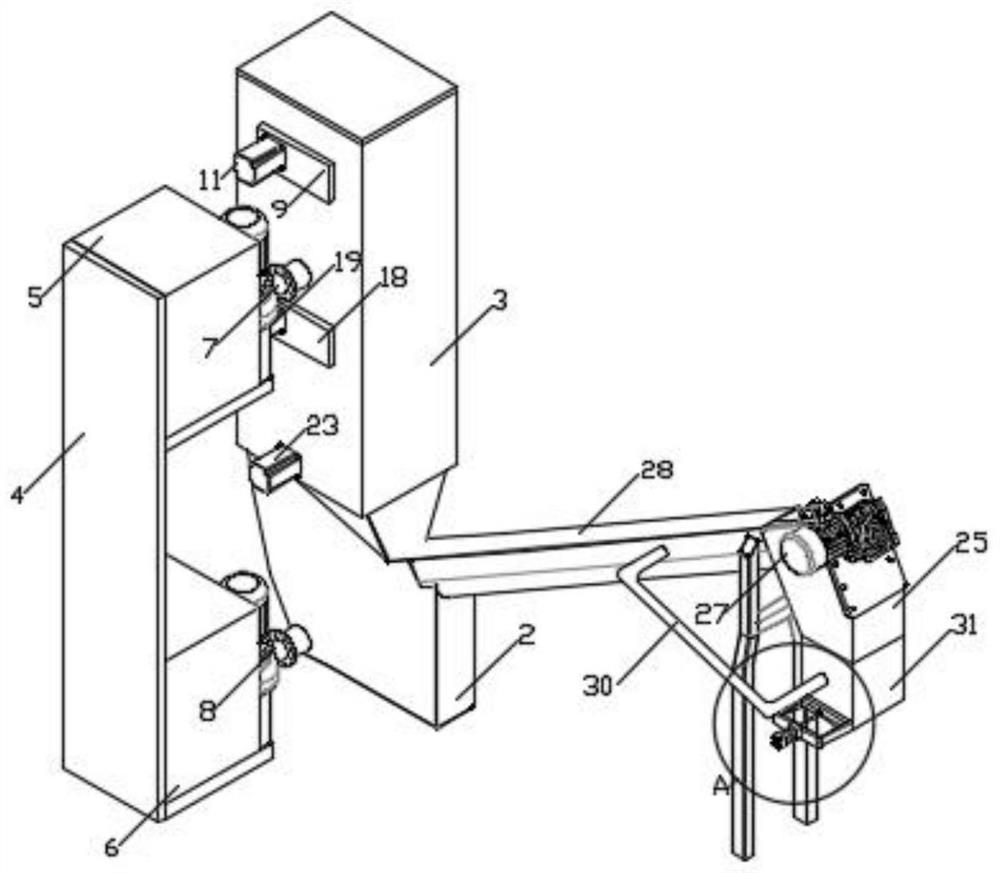

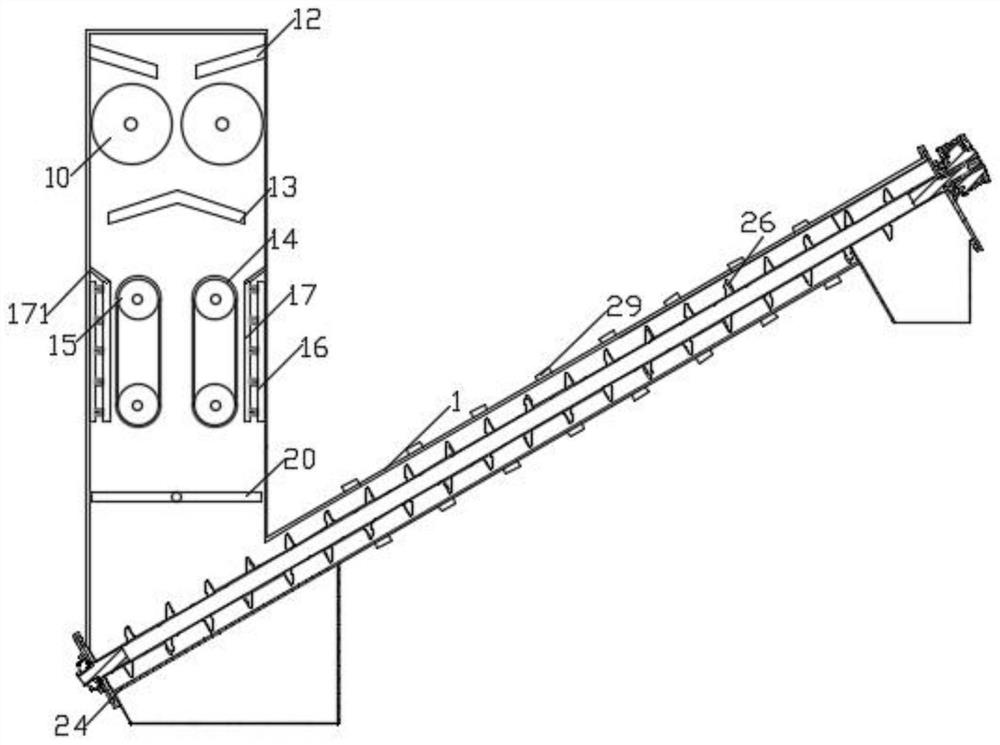

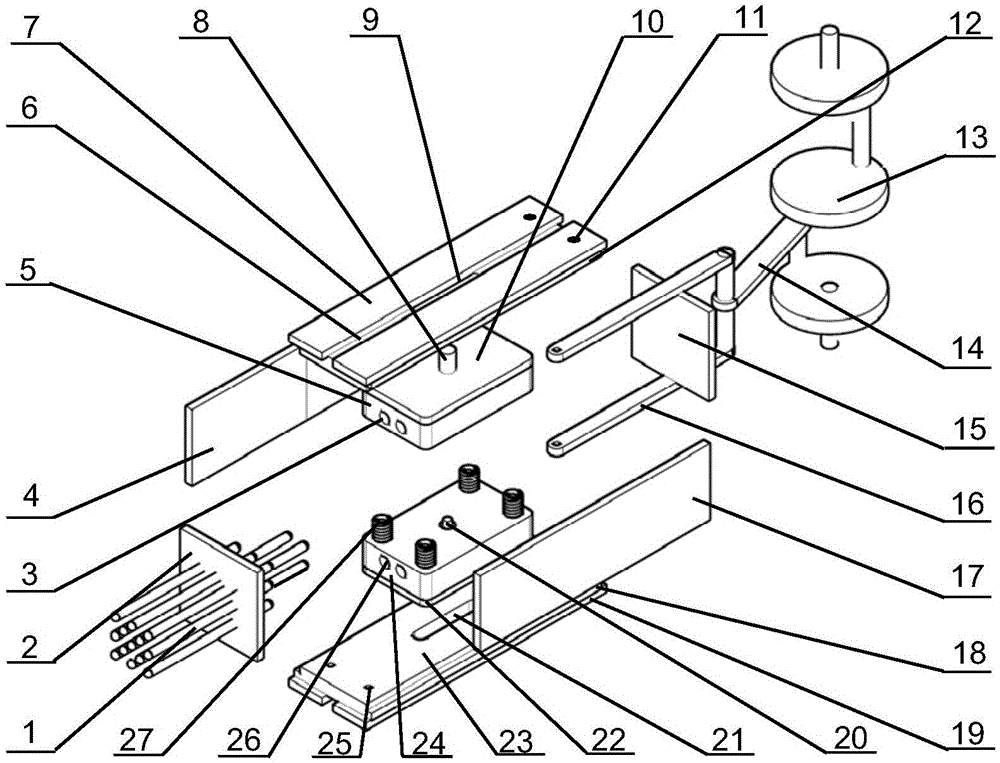

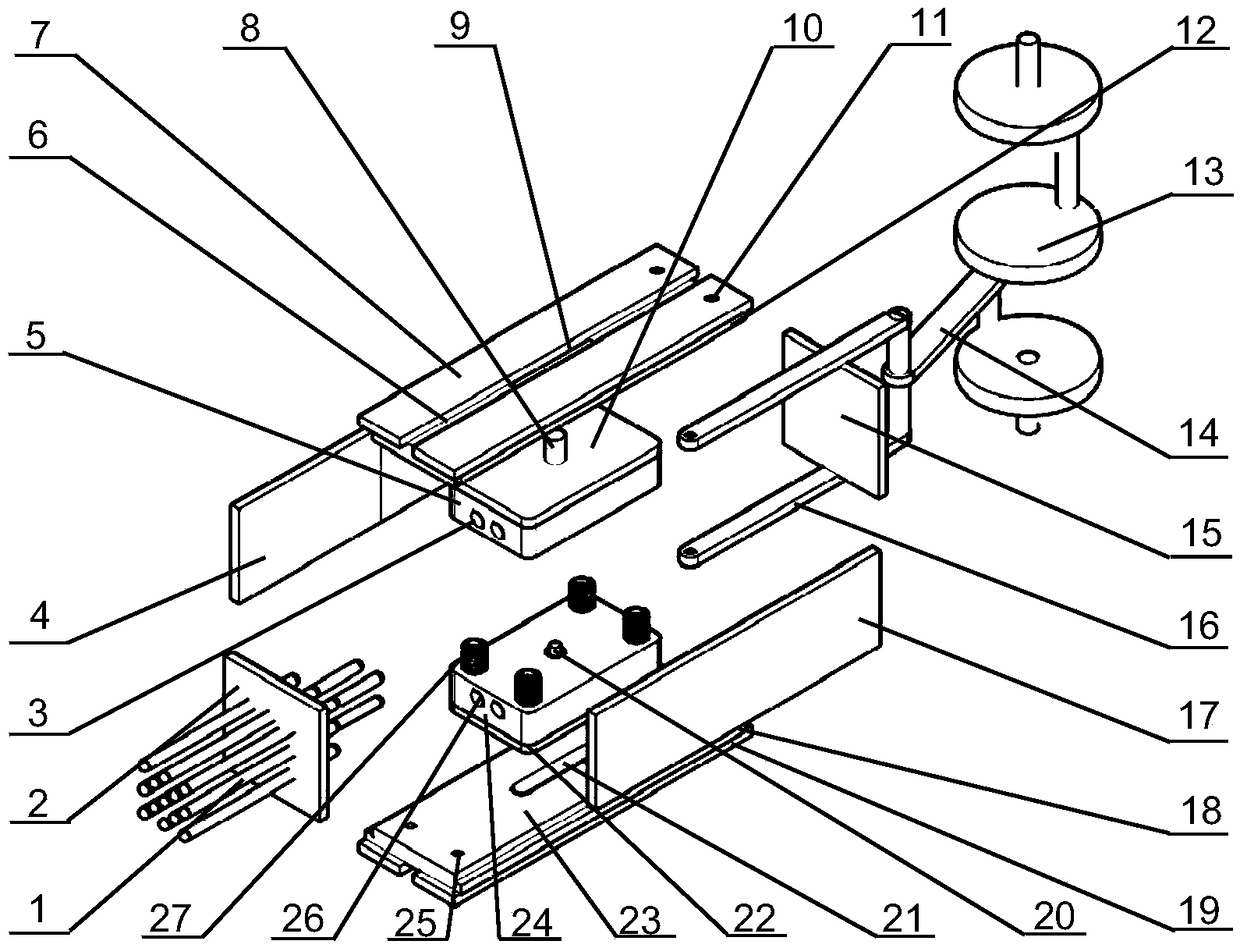

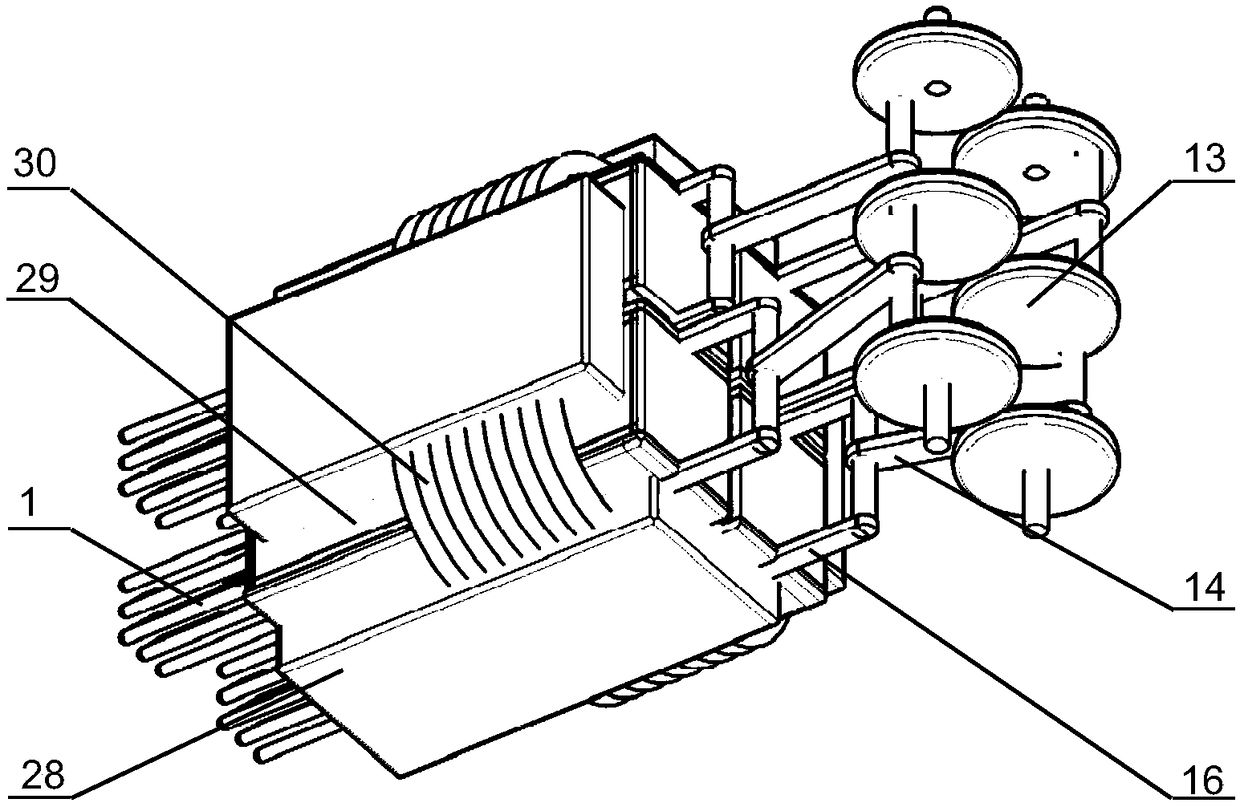

Feeding machine convenient to adjust for plastic processing

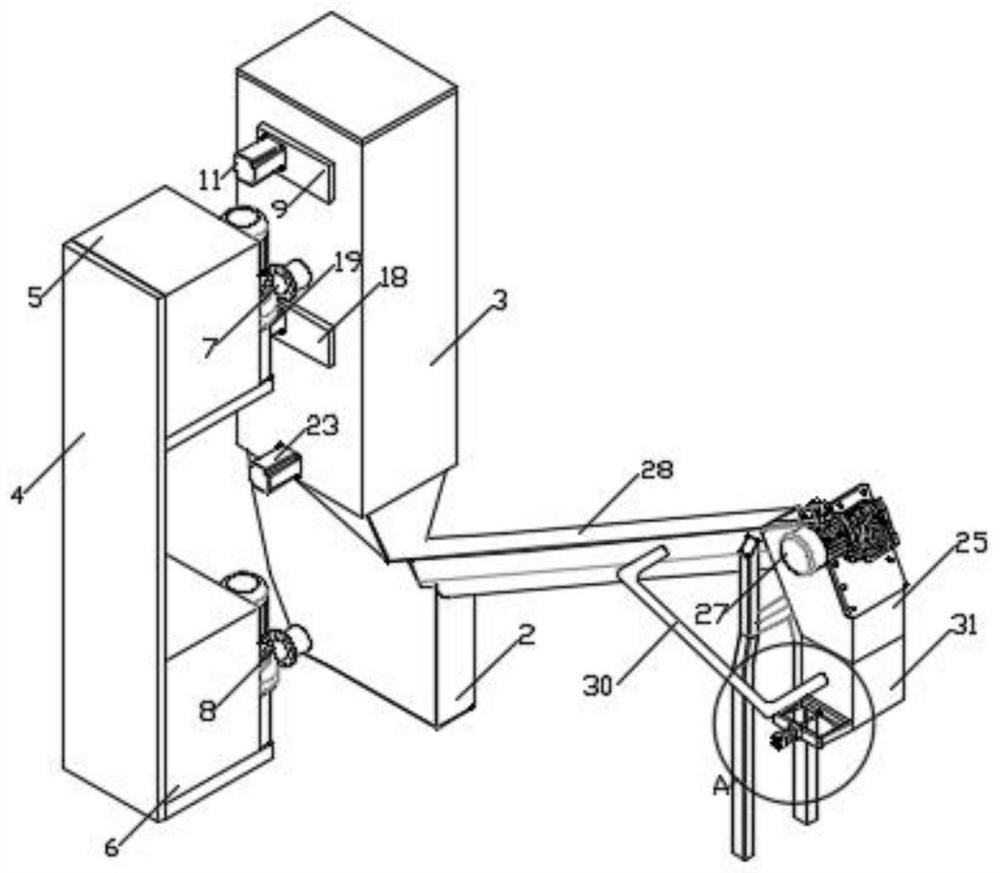

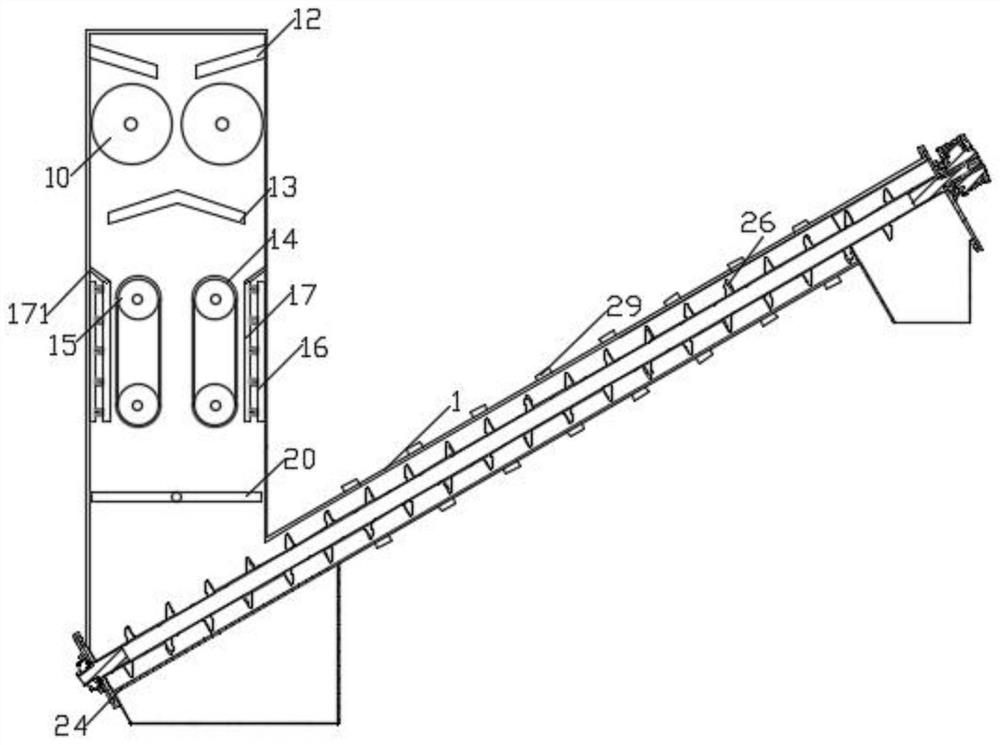

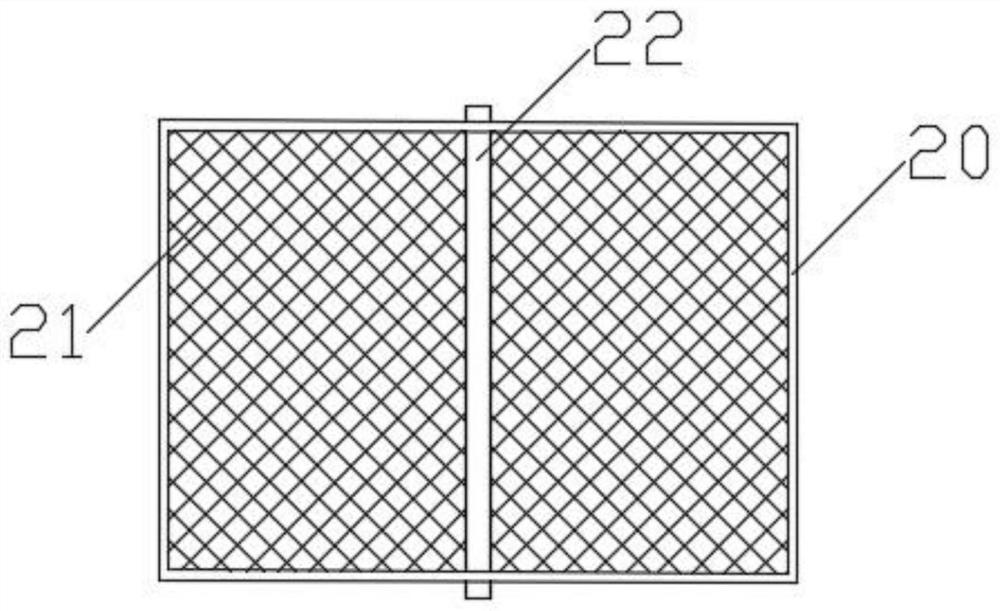

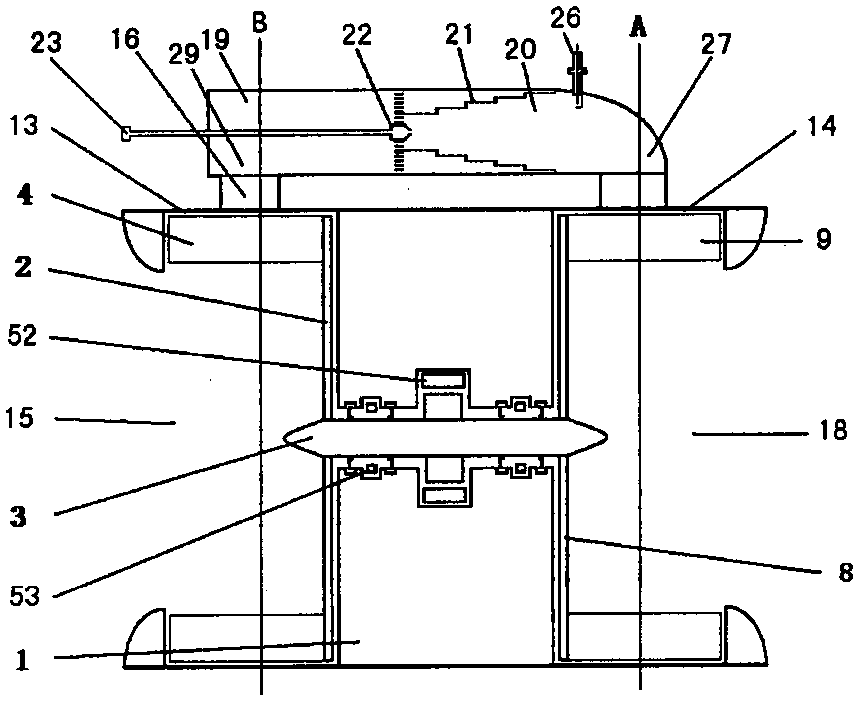

ActiveCN112045888AAvoid staying in the cavity of the feeding boxCircumstances affecting deliverySievingScreeningProcess engineeringHeat energy

The invention discloses a feeding machine convenient to adjust for plastic processing. Through the design of a filter belt and a sweeping plate and the design of springs, plastic raw materials of different sizes can penetrate through the space between the filter belt and the sweeping plate, dust on the surfaces of the plastic raw materials can be swept through the filter belt and the sweeping plate, meanwhile, transmission of the filter belt helps the plastic raw materials in conveying downwards, the situation that the plastic raw materials stay in an inner cavity of a feeding box is avoided,the feeding machine can effectively separate and recycle cleaned cleaning liquid and the plastic raw materials, the situation that conveying of the plastic raw materials is affected due to the fact that the cleaning liquid remains in a feeding screw rod is avoided, two times of drying are conducted in the plastic raw material conveying process, the efficiency of the two times of the drying is high, through the design of a heat exchange pipe, waste heat of the first time of the drying is conducted through the heat exchange pipe for conducting second time of the drying, the whole heat energy conversion efficiency is high, the drying effect is good, and the subsequent plastic raw material processing process is facilitated.

Owner:佛山市顺德区汝鸿塑料实业有限公司

High-temperature steam generation apparatus

InactiveCN101358727BReduce energy consumptionIncrease profitSteam generation heating methodsEngineeringOperation safety

The present invention relates to the technical field of the steam generation device, in particular relates to a high-temperature steam generation device that is used for the devices heating and cooking different foods, which comprises a high-temperature steam generator and an upper cover, wherein, the main body of the high-temperature steam generator is provided with a heating cavity; both ends of the heating cavity are communicated with a water inlet and a steam outlet, which are arranged on the main body; a heating pipe is arranged inside the main body of the high-temperature steam generator and the upper cover covers on the main body of the high-temperature steam generator; the heating pipe inside the high-temperature steam generation device is in a U shape; a plurality of projection elements that are arranged inside the heating cavity increase the contact area between the heating cavity of the water, so that the water can be better contacted with the heating cavity, so as to rapidly produce the steam; moreover, the heat energy conversion efficiency is high; in addition, the upper cover prevents the steam and the heat from leaking; the produced steam is exhausted from the steamoutlet, so that the steam is easy to be collected, and the steam utilization rate is high. The high-temperature steam generation device has simple and compact structure, and occupies less space, and is safe and reliable to be operated, and has high heat efficiency, and saves energy and protects the environment.

Owner:GUANGDONG LUBY ELECTRONICS

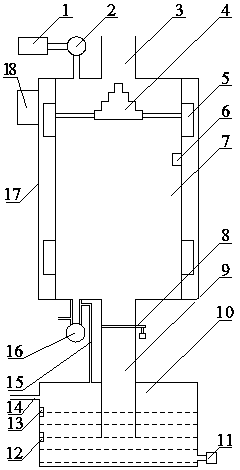

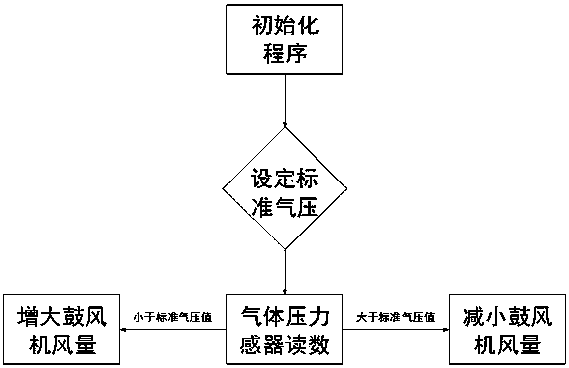

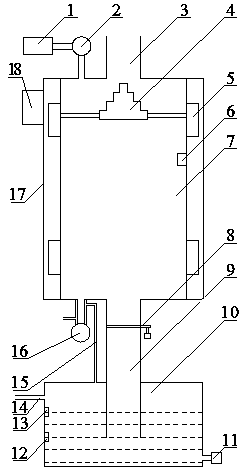

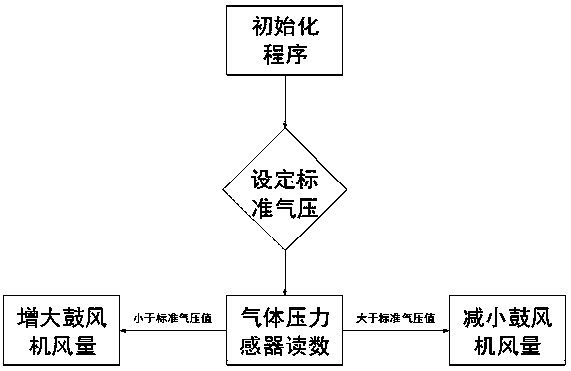

Heating furnace for conducting microwave treatment on ore and application method of heating furnace

ActiveCN106152785AAvoid damageExtend your lifeCharge composition/stateFurnace typesMicrowaveAir blower

The invention relates to a heating furnace for conducting microwave treatment on ore and an application method of the heating furnace. The heating furnace comprises a microwave treatment cavity 7. A feeding port 3 is fixedly connected with the top of the microwave treatment cavity 7. An exhaust fan 2 is fixedly connected with the top of the microwave treatment cavity 7 through a pipeline. A material distributor 4 is fixedly connected with the microwave treatment cavity 7 through a cross rod. The top end of the material distributor 4 coincides with the center line of an outlet of the feeding port 3. Microwave generators 5 are located on the periphery of the microwave treatment cavity 7. A gas pressure sensor 6 is located in the microwave treatment cavity 7 and fixedly connected with the microwave treatment cavity 7. An inlet of a discharging end 9 is fixedly connected with the bottom of the microwave treatment cavity 7. A discharging control device 8 is arranged at the middle portion of the discharging end 9. A cooling pond 10 is located at the lower portion of the discharging end 9. An air blower 16 is located at the bottom of the microwave treatment cavity 7 and fixedly connected with the microwave treatment cavity 7 through a pipeline. An air flow controller 18 is electrically connected with the exhaust fan 2 and the air blower 16. The heating furnace is simple in structure and safe and convenient to use; and by means of the method, high-temperature and rapid treatment of the ore can be achieved, the mineral can be efficiently dissociated, and the requirement for continuous operation is met.

Owner:WUHAN UNIV OF SCI & TECH

Efficient hot blast furnace for tobacco baking equipment

InactiveCN106931637AHigh thermal energy conversion efficiencyImprove conversion efficiencyTobacco preparationAir heatersThermal energyCooking & baking

Owner:陈伟峰

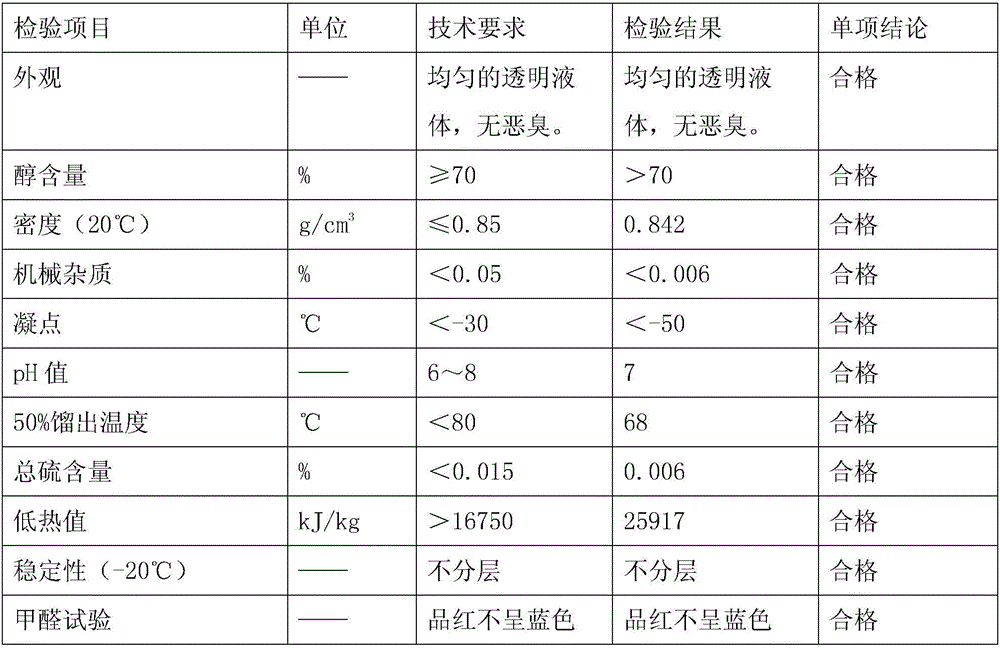

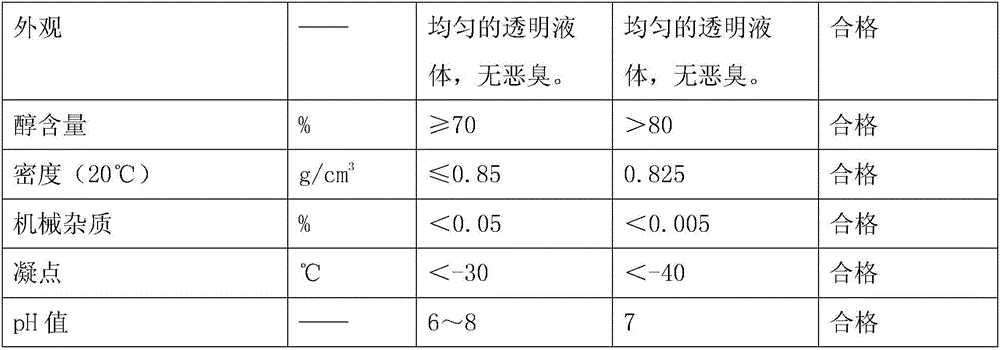

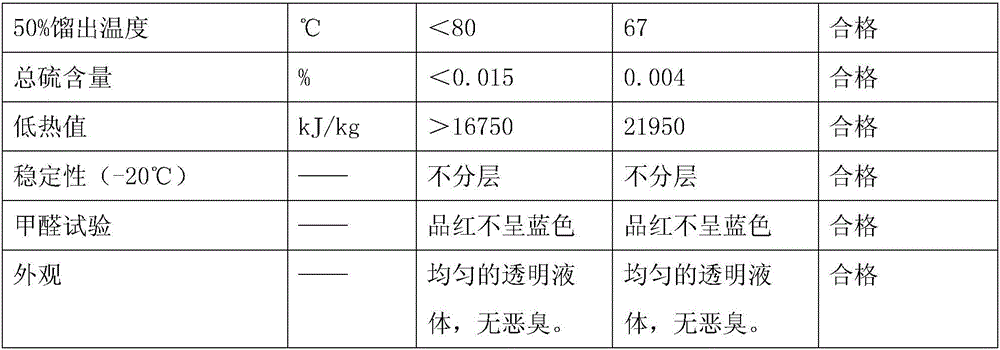

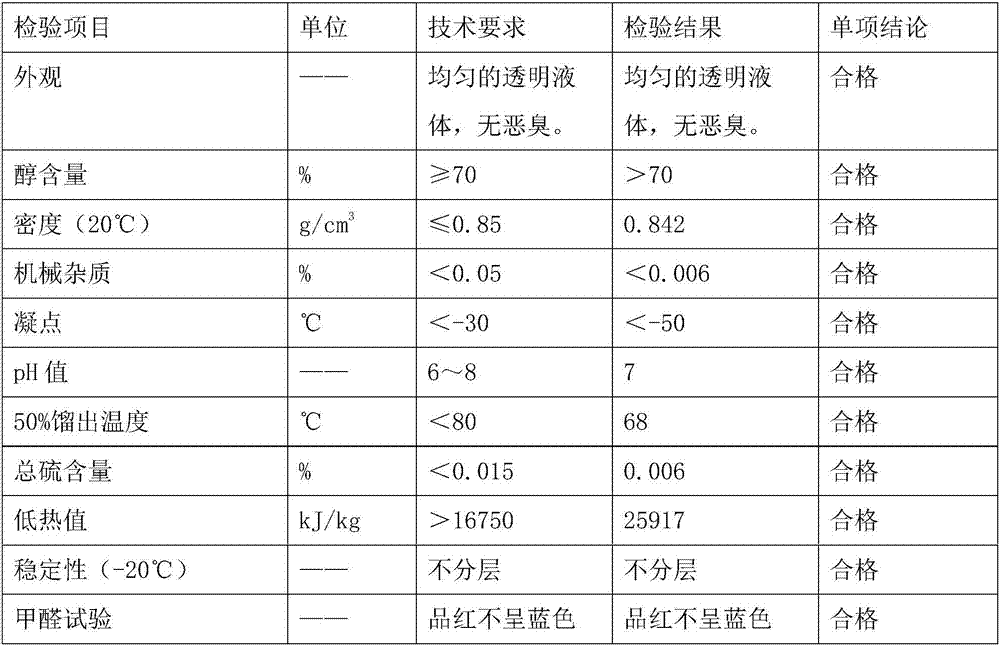

Novel alcohol-base liquid fuel and additive thereof

ActiveCN106350128ABurn completelyImproved vaporizationLiquid carbonaceous fuelsFuel additivesSocial benefitsThermal energy

The invention belongs to the field of domestic alcohol-base liquid fuels, and particularly relates to a novel alcohol-base liquid fuel and an additive thereof. In order to solve the problems of low quality, low combustion efficiency, potential safety hazards and the like in the existing alcohol-base liquid fuel, the invention provides a novel alcohol-base liquid fuel which comprises 70-90% of main combustion component, 5-23% of auxiliary combustion component and 5-7% of composite additive. The invention also provides an additive for the alcohol-base liquid fuel. Methanol used as the main combustion component of the alcohol-base liquid fuel has the advantages of thorough combustion and high thermal energy conversion efficiency. The particular auxiliary combustion component and composite additive are matched, so the matching components have abundant and economical sources and are convenient for storage and transportation. The novel alcohol-base liquid fuel has the advantages of low price, simple compounding process and mature technique, does not generate three wastes, and effectively protects the environment. The invention provides a clean environment-friendly alternative fuel having development potential, and has important economic benefits and social benefits.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

A kind of alcohol base liquid fuel and its additive

ActiveCN106350128BBurn completelyImproved vaporizationLiquid carbonaceous fuelsFuel additivesThermal energySocial benefits

The invention belongs to the field of domestic alcohol-base liquid fuels, and particularly relates to a novel alcohol-base liquid fuel and an additive thereof. In order to solve the problems of low quality, low combustion efficiency, potential safety hazards and the like in the existing alcohol-base liquid fuel, the invention provides a novel alcohol-base liquid fuel which comprises 70-90% of main combustion component, 5-23% of auxiliary combustion component and 5-7% of composite additive. The invention also provides an additive for the alcohol-base liquid fuel. Methanol used as the main combustion component of the alcohol-base liquid fuel has the advantages of thorough combustion and high thermal energy conversion efficiency. The particular auxiliary combustion component and composite additive are matched, so the matching components have abundant and economical sources and are convenient for storage and transportation. The novel alcohol-base liquid fuel has the advantages of low price, simple compounding process and mature technique, does not generate three wastes, and effectively protects the environment. The invention provides a clean environment-friendly alternative fuel having development potential, and has important economic benefits and social benefits.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE +2

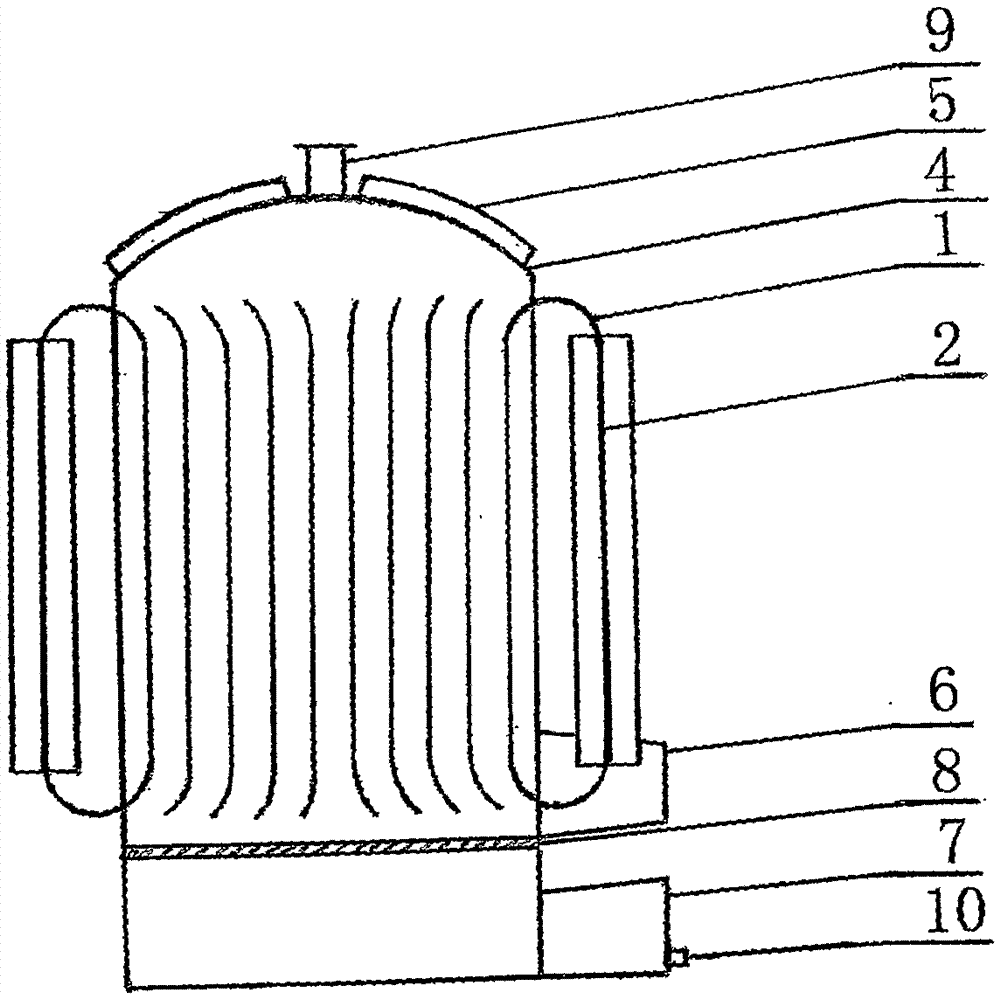

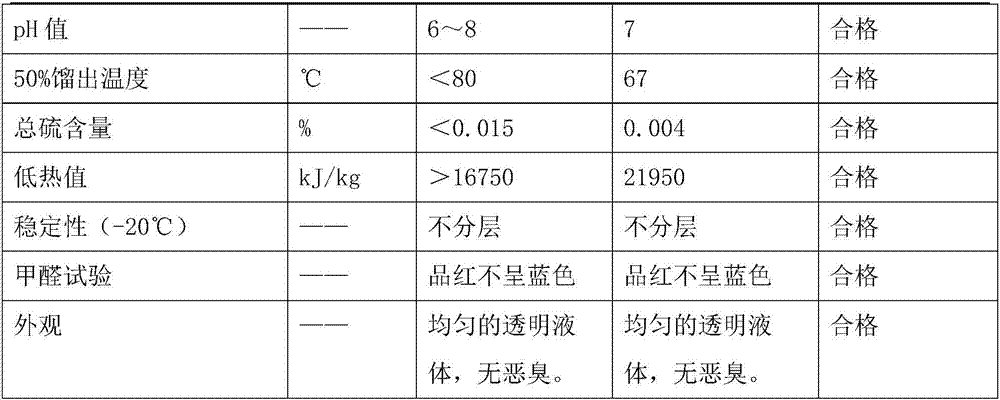

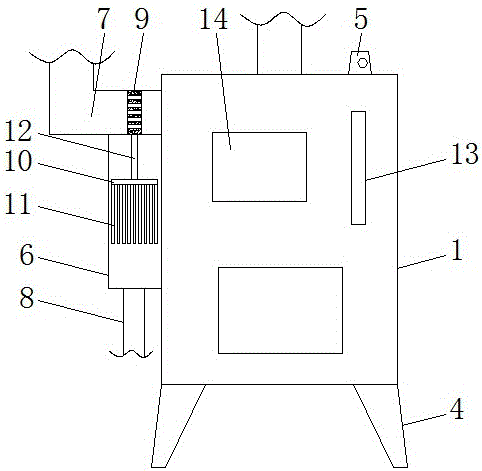

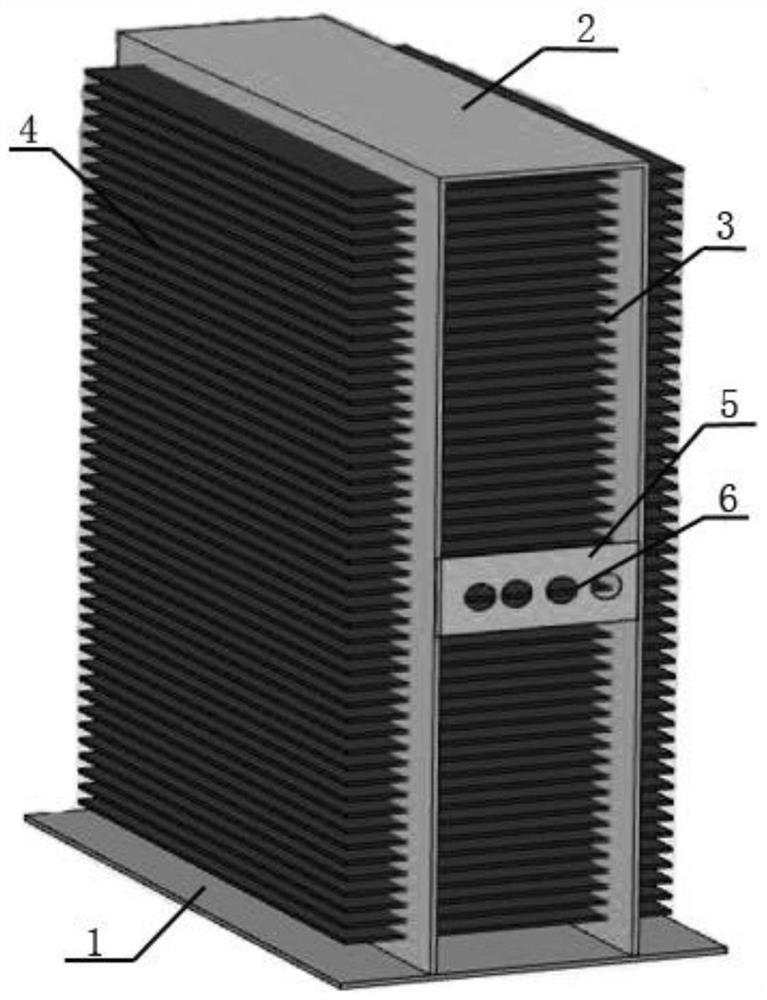

Energy-saving-type boiler

InactiveCN106123314AHigh thermal energy conversion efficiencyReduce usageWater heatersInsulation layerEconomic benefits

The invention discloses an energy-saving-type boiler. The energy-saving-type boiler comprises a furnace body, wherein the furnace body comprises a furnace wall; the furnace wall comprises an inner layer and an outer layer; a heat insulation layer is arranged in a clearance between the inner layer and the outer layer; four support legs which are uniformly distributed are arranged on the bottom of the furnace body; a pressure valve and a steam pipe are arranged on the top of the furnace body; a water tank and a smoke exhaust pipe are arranged on one side surface of the furnace body; a water inlet pipe is arranged on the bottom of the water tank; heat exchange sheets are arranged in the smoke exhaust pipe; a radiation plate is arranged in the water tank; radiation fins which are uniformly distributed are arranged on the radiation plate; a heat conduction sheet is arranged between the heat exchange sheets and the radiation plate; and the side surface, which is close to the water tank, of the furnace body is provided with a thermometer, a pressure gage and a material inlet. By adopting the energy-saving-type boiler, heat in the smoke exhaust pipe can be absorbed and utilized again; an energy-saving effect can be realized; the heat conversion efficiency of the boiler is improved; the use effect is better; the use amount of fuel coal is reduced; and economic benefit of an enterprise is improved.

Owner:无锡欧玛森远洋工程设备有限公司

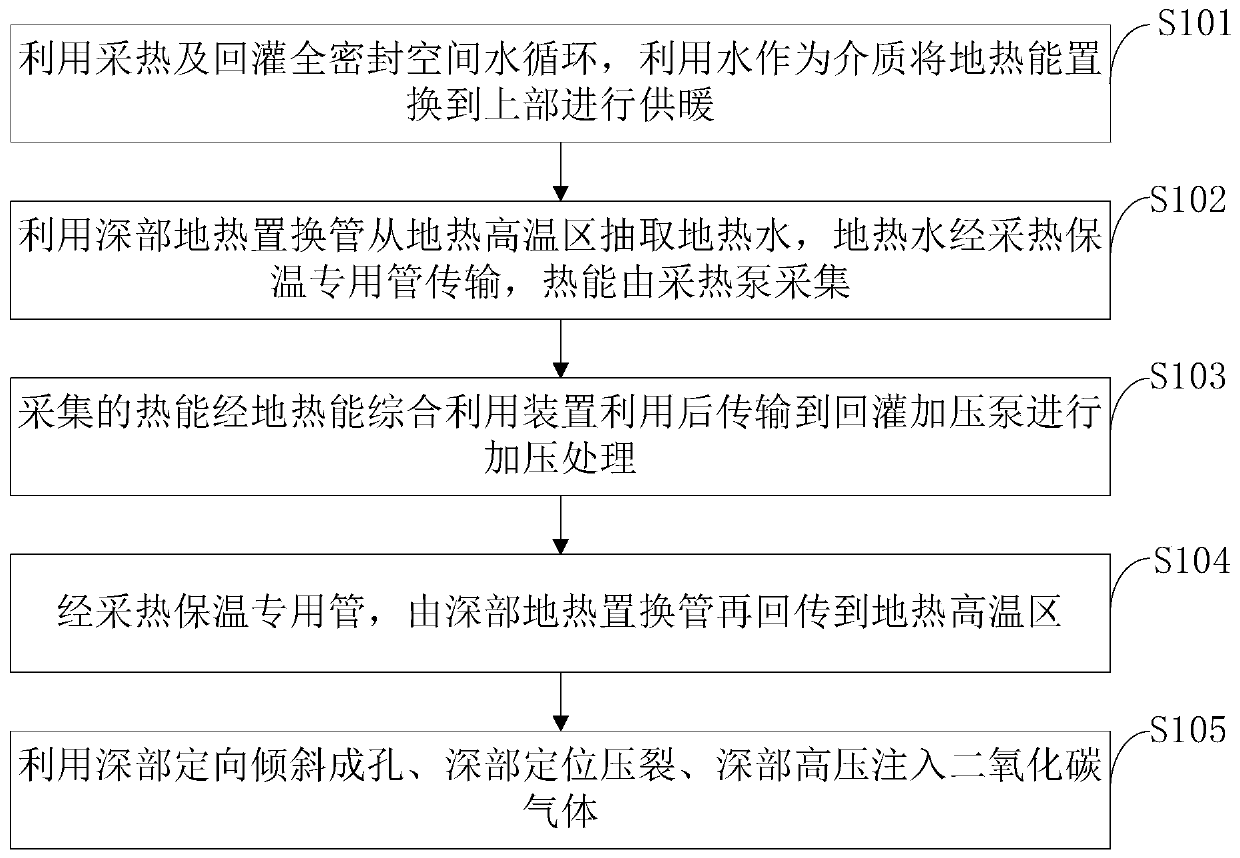

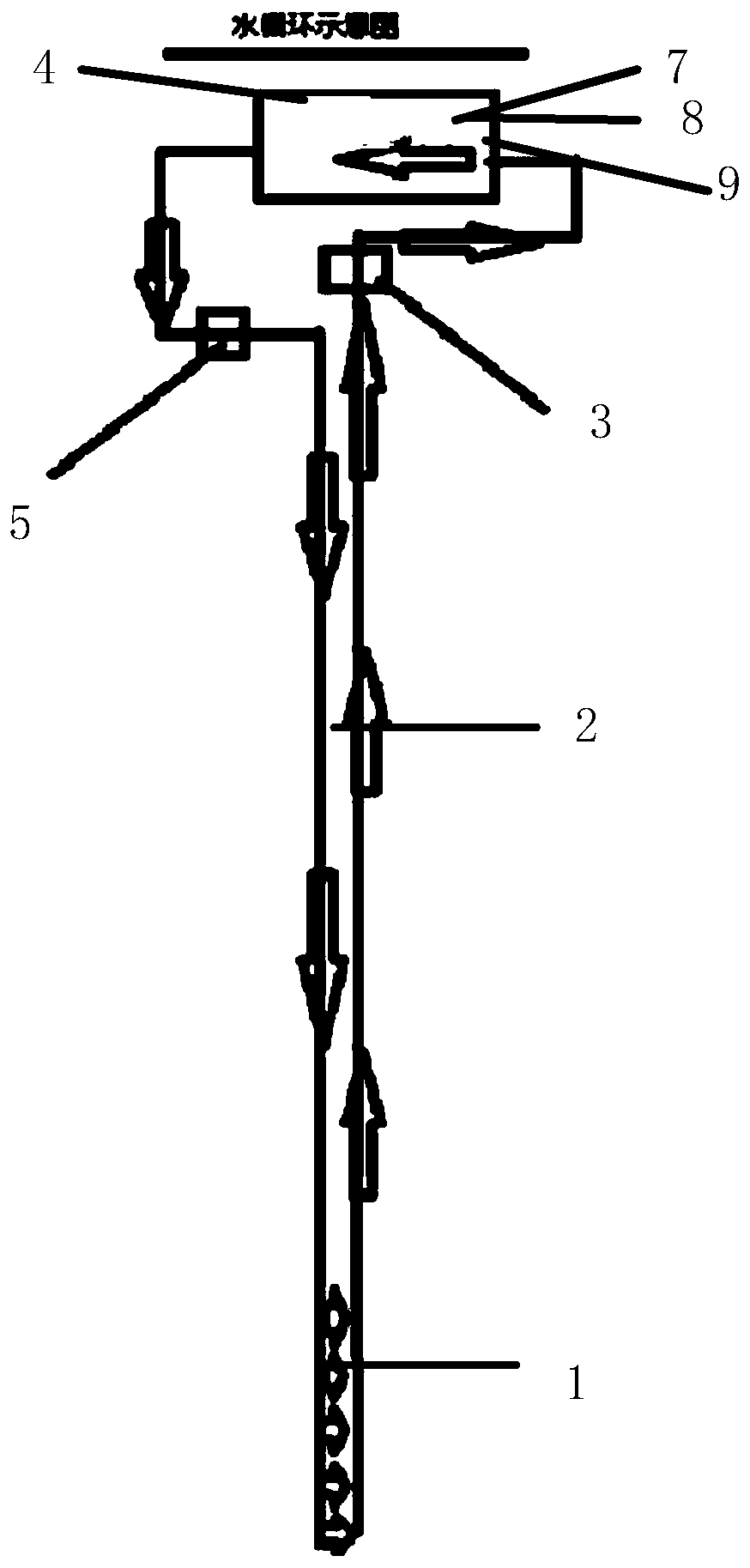

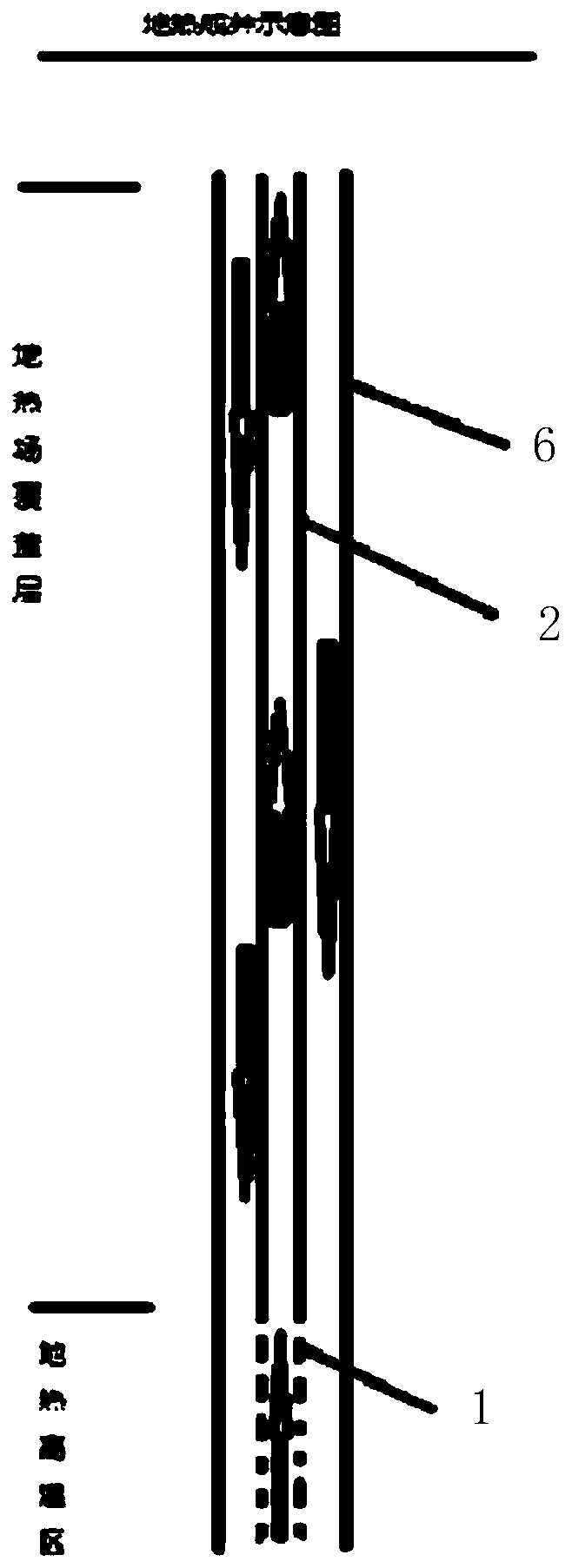

Integrated geothermal well single-hole extraction and charging heat exchange method and equipment

InactiveCN110285593AImprove heat recovery and heat exchange efficiencySave waterGeothermal energy generationCollector with underground water as fluidWater cyclingEngineering

The invention belongs to the technical field of application of geothermal wells, and discloses an integrated geothermal well single-hole extraction and charging heat exchange method and integrated geothermal well single-hole extraction and charging heat exchange equipment. The heat exchange method is characterized in that a deep geothermal replacement pipe, a special pipe for heat collection and heat preservation, a heat recovery pump, a geothermal energy comprehensive utilization device, a recharge pressurization pump, a geothermal well pipe, a water return supplement pump, a water pressure gauge, a water gas observation meter and other equipment instruments are adopted, deep geothermal wells are formed one by one, a heat collection and recharge full-sealed space water circulation is adopted used for replacing geothermal energy to the upper part for heating in winter, and a heat preservation measure is taken in the process of extracting the ground hot water; and the water circulation heat exchange is carried out by utilizing the characteristics that the deep heat is high, the space leakproofness is good, and the water resource consumption is small. According to the heat exchange method and equipment, the good effects that environment is protected, water resources are saved, the stratum application is wide, the heat energy conversion efficiency is high, and the well-forming workload is reduced are achieved, the method and the equipment can be used for energy development of a terrestrial heat site and hot dry rock, and the characteristics of energy conservation, environmental protection, low cost, good social benefit and good economic benefit are achieved.

Owner:SHANDONG LUNAN GEOLOGICAL ENG SURVEY INST

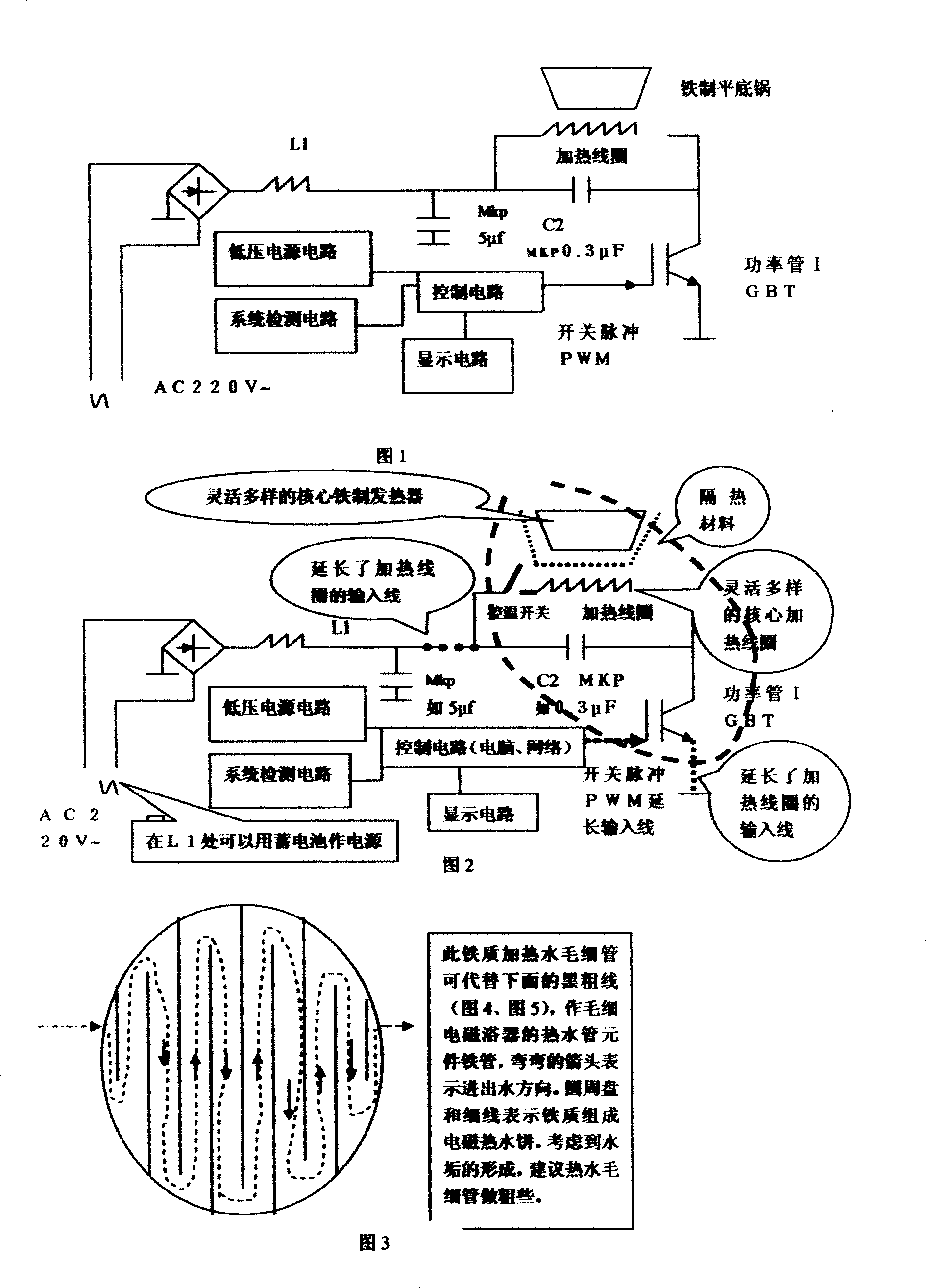

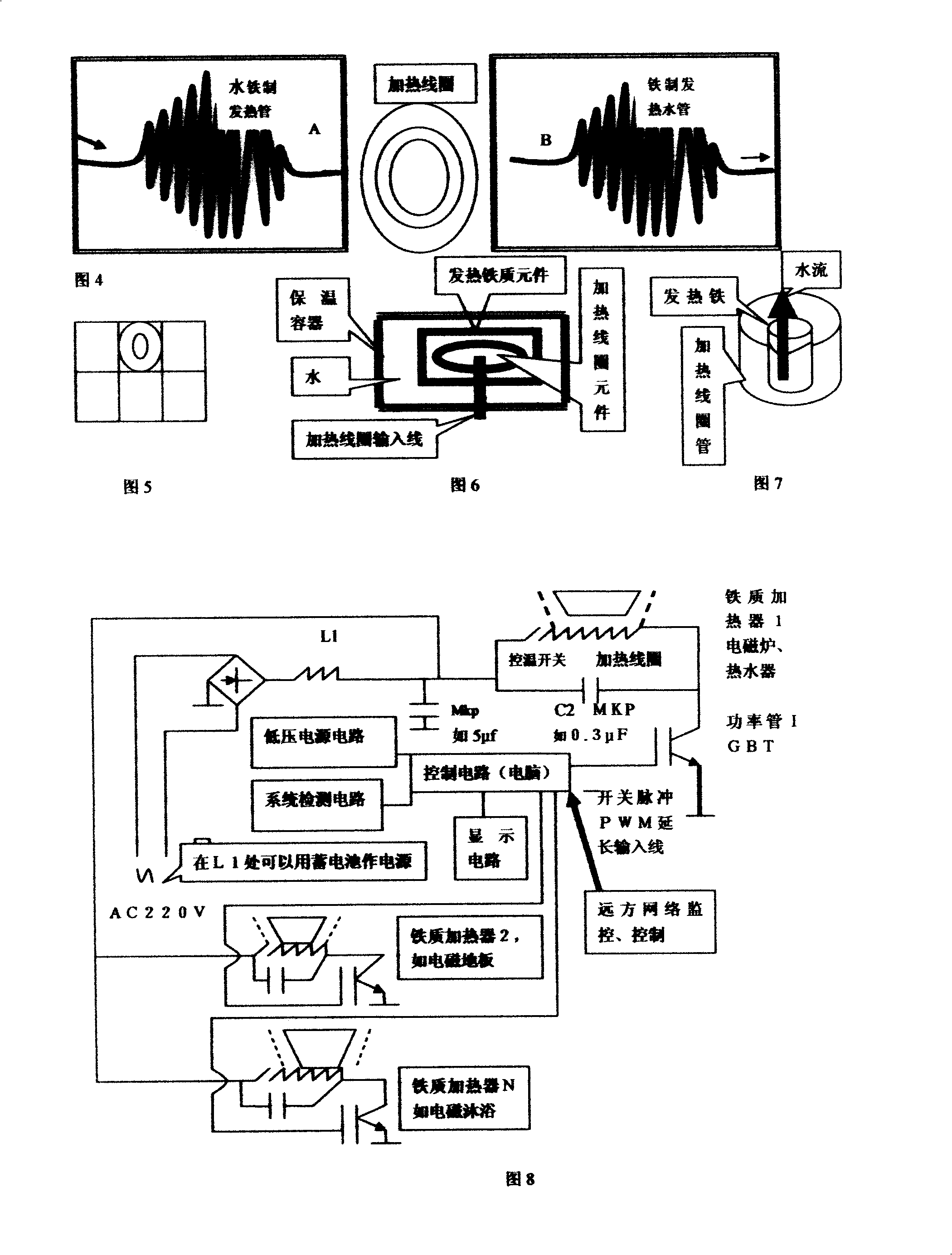

Network electromagnetic heater product series

InactiveCN101262719AHigh thermal energy conversion efficiencyEnergy efficient ICTCoil arrangementsThermal energyEngineering

Network electromagnetic heat device series products which are provided by the invention pertain to the technical field of network household electrical appliances. By adopting the products, 1. the problem of the existing mono-functional induction cooker with a unilateral heating element is solved and a multi-functional and bilateral (or multilateral) heating element is then developed not only to improve various uses and be extended to wired and wireless networks and remote controls, but also to be developed to multi-functional electromagnetic heat devices, such as electromagnetic heat shoes, electromagnetic heat floors, electromagnetic heat clothes, electromagnetic heat chairs, electromagnetic heat water pipes, electromagnetic heat cups, electromagnetic heat blankets, etc., thus the space is saved and the environment is clean to provide a high quality life;. 2. the problem that the existing electric cookers, heating devices, heaters, etc. adopt heating cords as heating elements to result in low thermal efficiency caused by the indirect conduction to the aim converting from electric energy to heat energy is solved and when only heat energy to the aim is adopted, the high thermal efficiency can be realized. Other applications can be the references for the technical field of integrated technique, such as the applications in non household electrical appliances and military affairs. The series products of the invention have essential uses: household electrical appliances (including network household electrical appliances), military affairs, hotels, etc.

Owner:林国刚

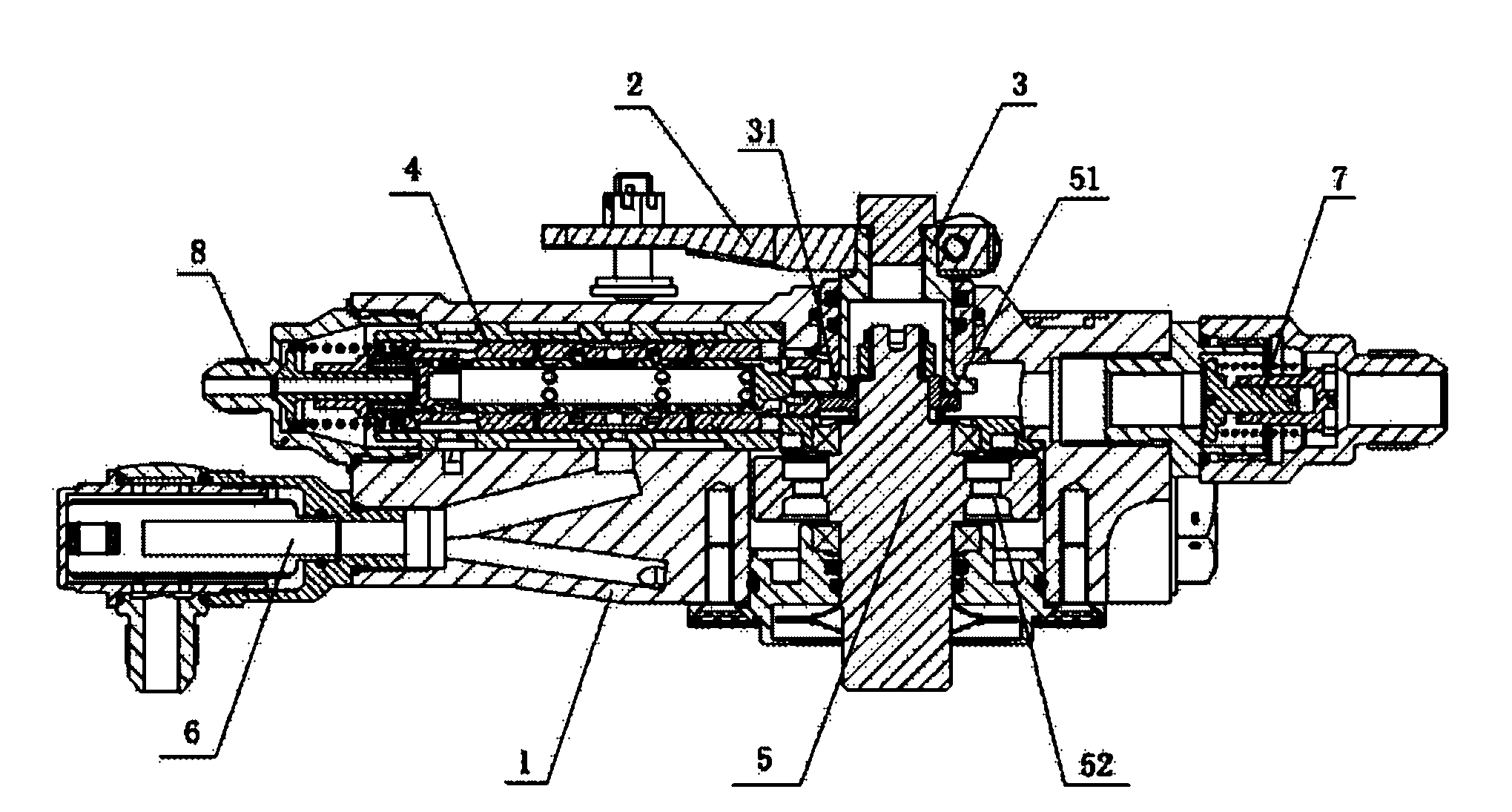

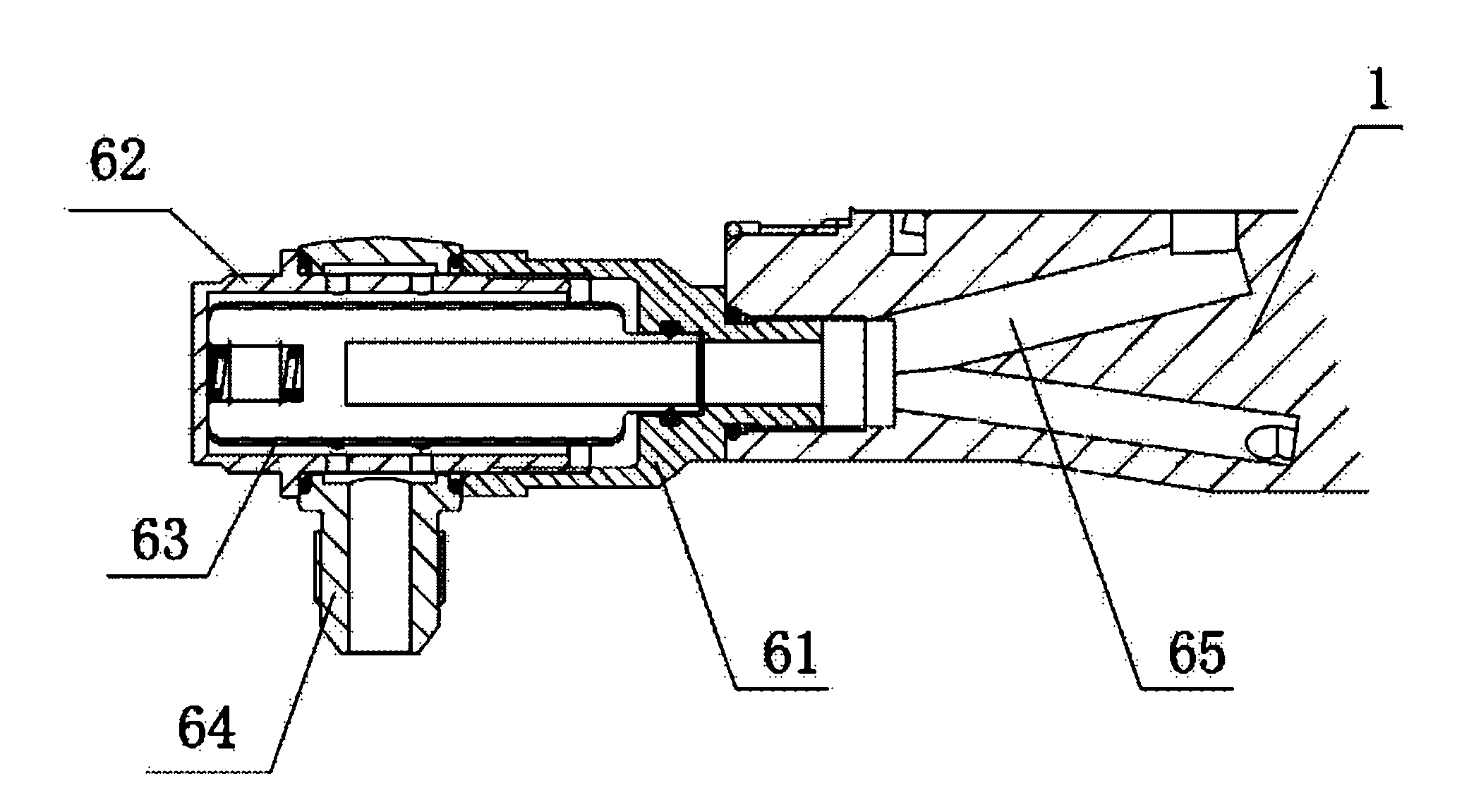

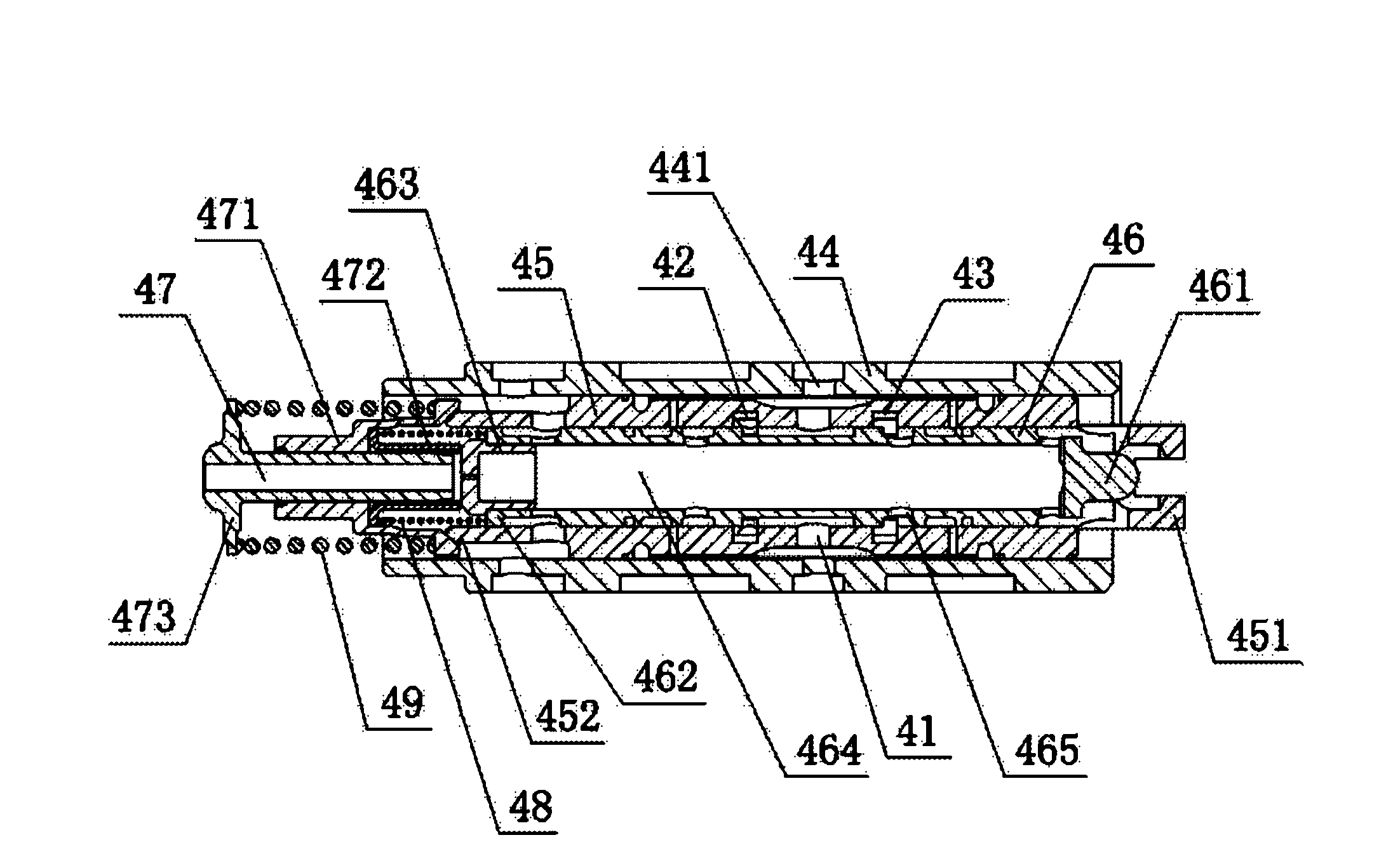

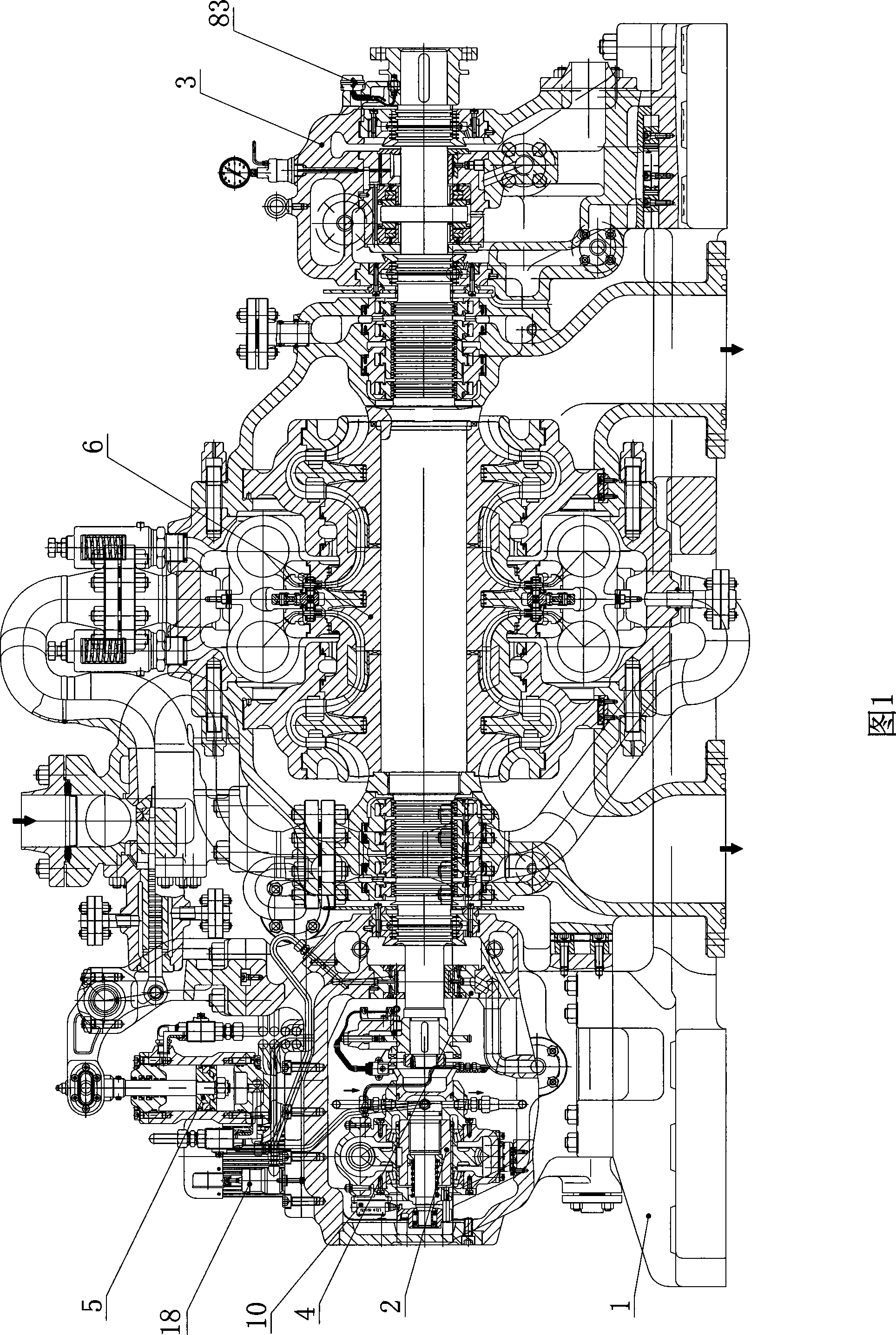

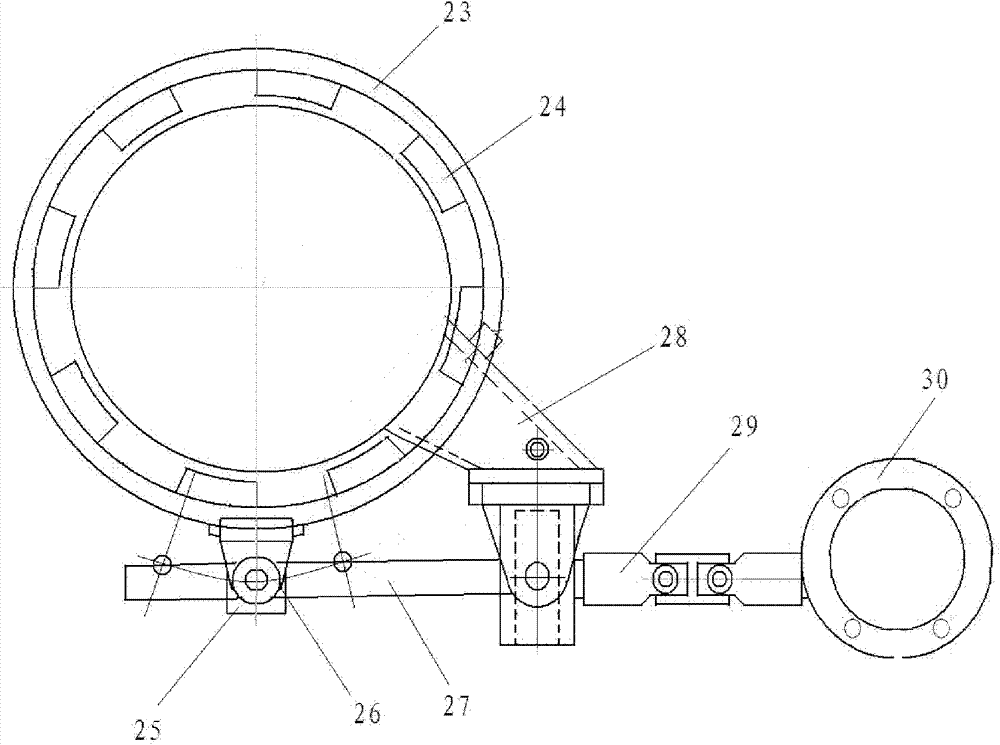

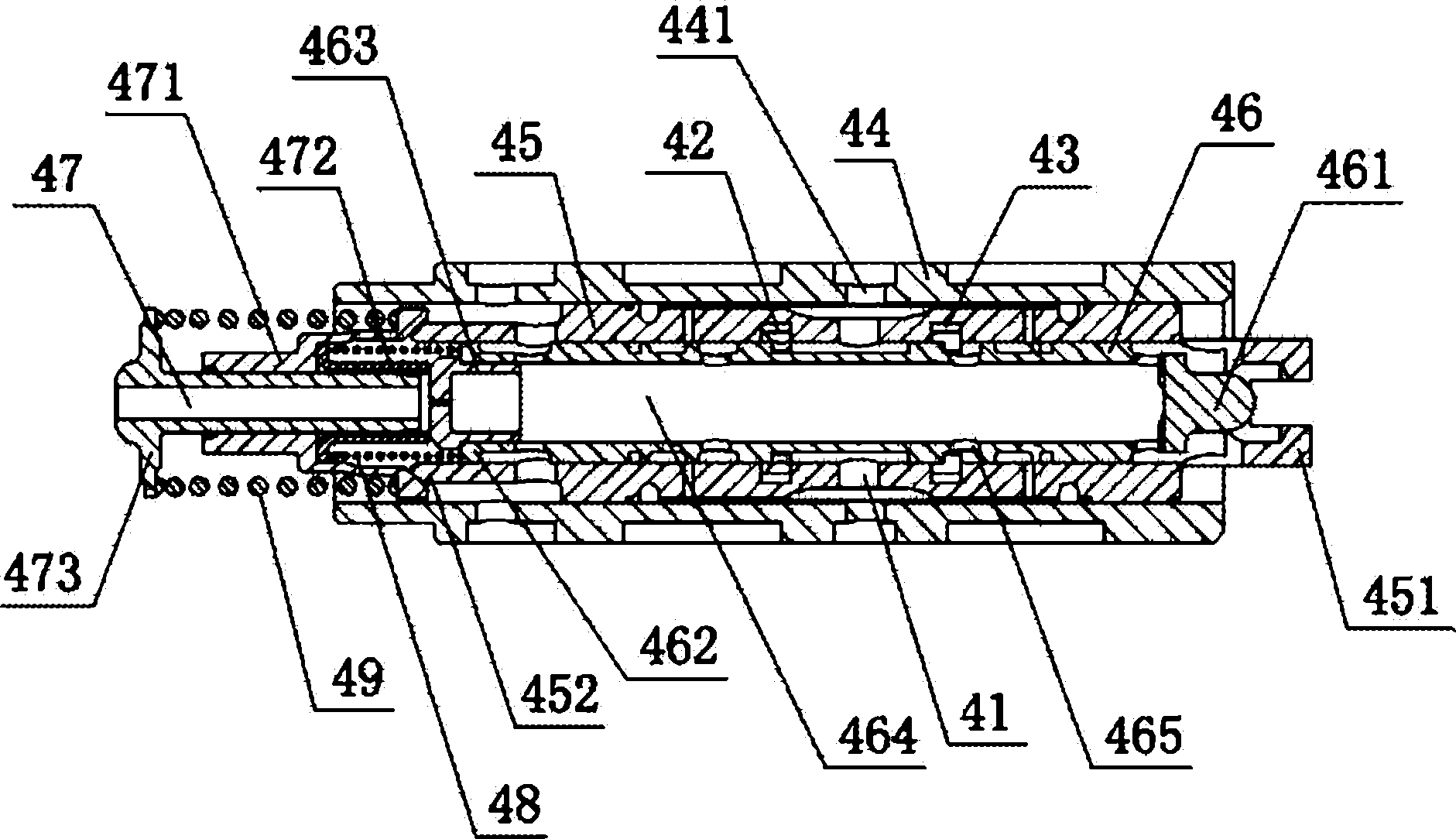

Turbine guide vane adjuster

ActiveCN102278146AHigh thermal energy conversion efficiencyStatorsMachines/enginesThermal energyTurbine blade

The invention provides a device for regulating a guide blade of a turbine, comprising a case (1), a regulating cam (3) arranged on the case (1) in a rotatable manner, as well as a follow-up valve (4) and an actuating mechanism (5) which are contained and arranged in the case (1), wherein the follow-up valve (4) and the actuating mechanism (5) interact to provide a rotating power for the guide blade. In the invention, the device for regulating the guide blade is hydraulically driven, and the angle of the guide blade can be continuously and steplessly regulated, thus the angle of the guide blade can be matched with the blade airflow air suction angle requirement at different rotating speeds and the thermal energy conversion efficiency of a turbine blade is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

A heating furnace for ore microwave treatment and its application method

ActiveCN106152785BAvoid damageExtend your lifeCharge composition/stateFurnace typesThermodynamicsAir volume

The invention relates to a heating furnace for microwave treatment of ore and a using method thereof. The heating furnace includes: a microwave processing cavity 7; the feed port 3 is fixedly connected to the top of the microwave processing cavity 7; the exhaust fan 2 is fixedly connected to the top of the microwave processing cavity 7 through a pipeline; the distributor 4 is connected to the microwave processing cavity through a cross bar. The cavity 7 is fixedly connected, and the top of the distributor 4 coincides with the center line of the outlet of the feed port 3; the microwave generator 5 is located around the microwave processing cavity 7; the gas pressure sensor 6 is located inside the microwave processing cavity 7 and is fixedly connected with the microwave processing cavity 7; The inlet of the material end 9 is fixedly connected with the bottom of the microwave processing chamber 7, and a discharge control device 8 is arranged in the middle of the discharge end 9; the cooling pool 10 is located at the bottom of the discharge end 9; the blower 16 is located at the bottom of the microwave processing chamber 7, and is connected to the 7 is fixedly connected through pipelines; the air volume controller 18 is electrically connected with the exhaust fan 2 and the blower 16. The device has a simple structure and is safe and convenient to use; the method can realize high-temperature rapid processing of ores, efficiently dissociate minerals, and meet continuous operation requirements.

Owner:WUHAN UNIV OF SCI & TECH

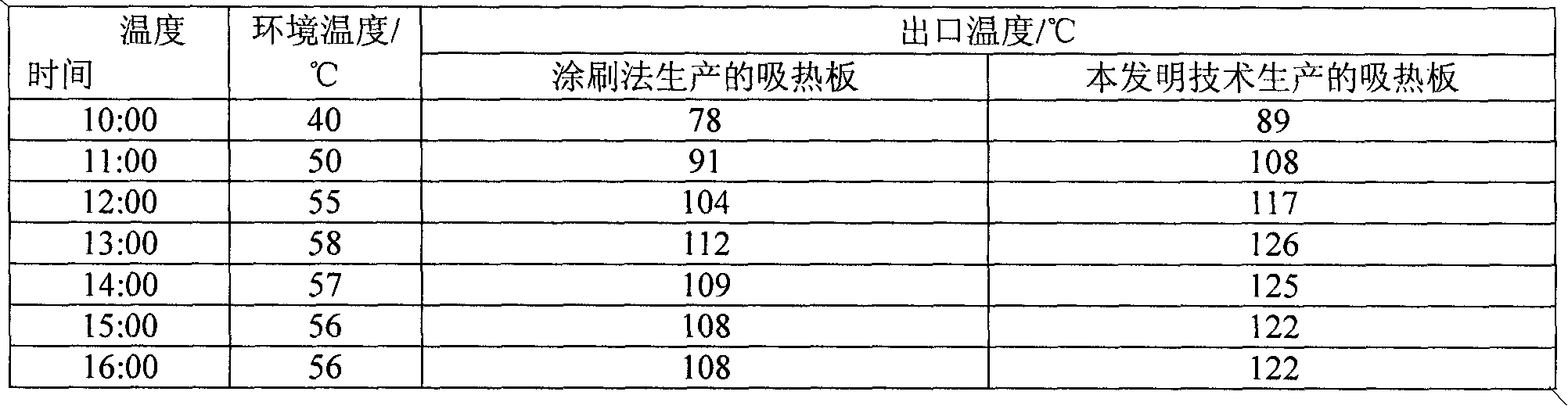

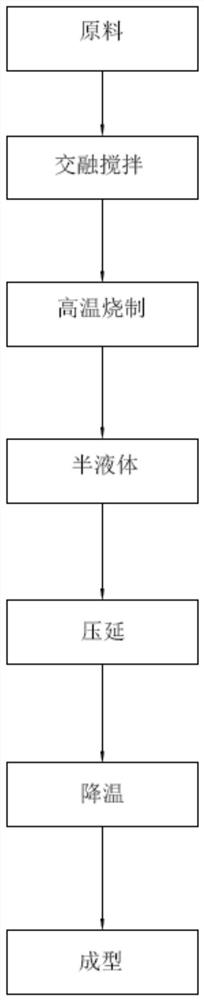

Production method of solar absorber plate

InactiveCN101818374AFast formingExtend the life cycleSurface reaction electrolytic coatingManganese sulphateSolar air collector

The invention discloses a production method of a solar absorber plate, which aims at solving the deficiency of the preparation process technology of the existing solar selective absorbing coating, difficult realization of preparation of large-area coating with the existing process technology, and high manufacturing cost. The production method comprises the following steps: taking a chrome-base alloy steel plate as a matrix material; pre-processing the plate such as de-oiling, polishing, activating, washing and the like; taking nitric acid, manganese sulphate, ammonium nitrate and the like as main coloring agents, and then coloring by chemical oxidation blackening; and finally performing chemical solidification and seal treatment to obtain the chrome-base alloy steel solar absorber plate with uniform bright-black conversion coating on the surface. The chrome-base alloy steel solar absorber plate has the characteristics of high thermal absorption rate and low emission rate, can be taken as the solar absorber plate for solar photo-thermal conversion, and can be widely applied to solar heat utilization equipment such as a flat-plate solar air collector, a solar water heater and the like.

Owner:GANSU JINSHI CHEM

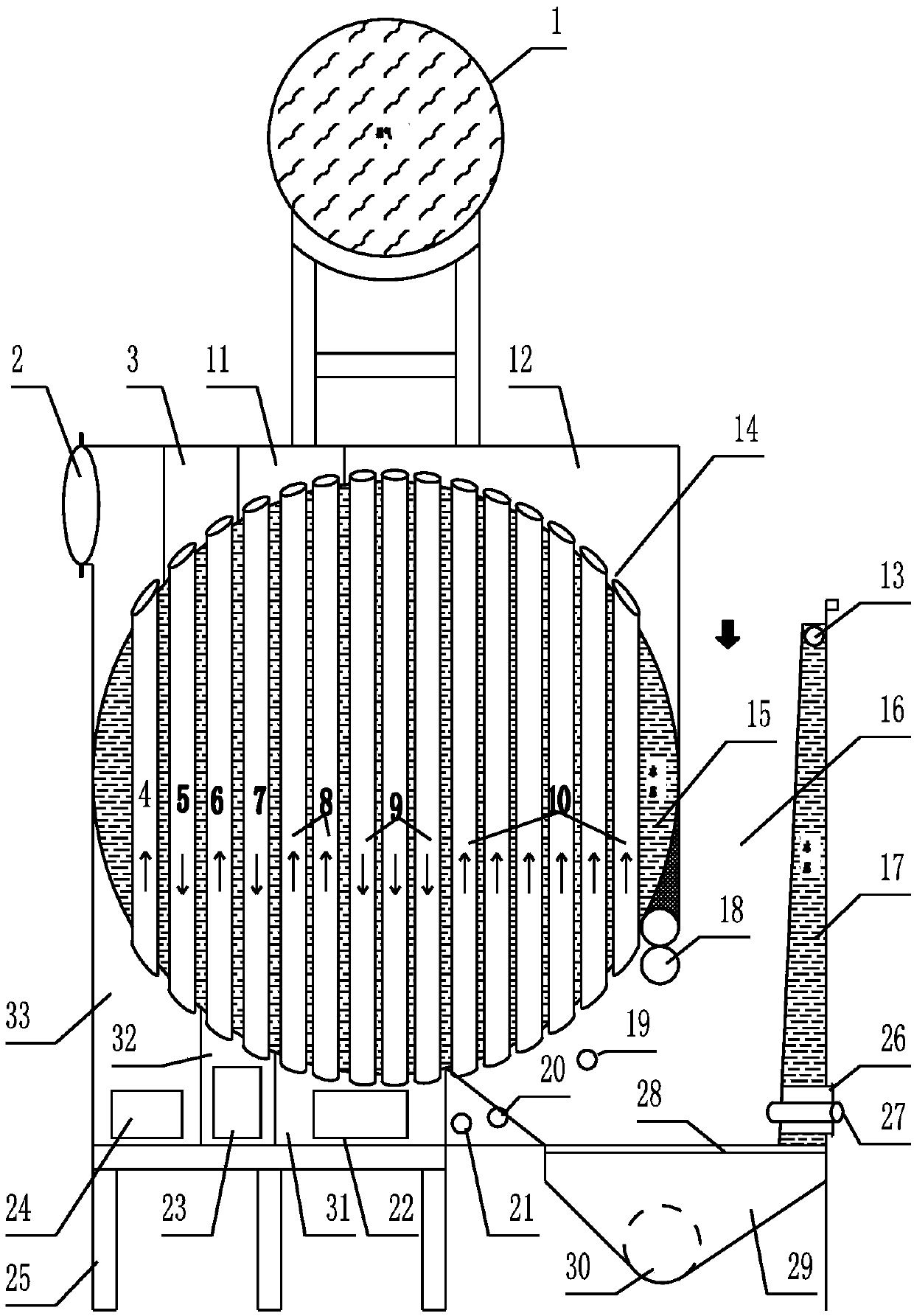

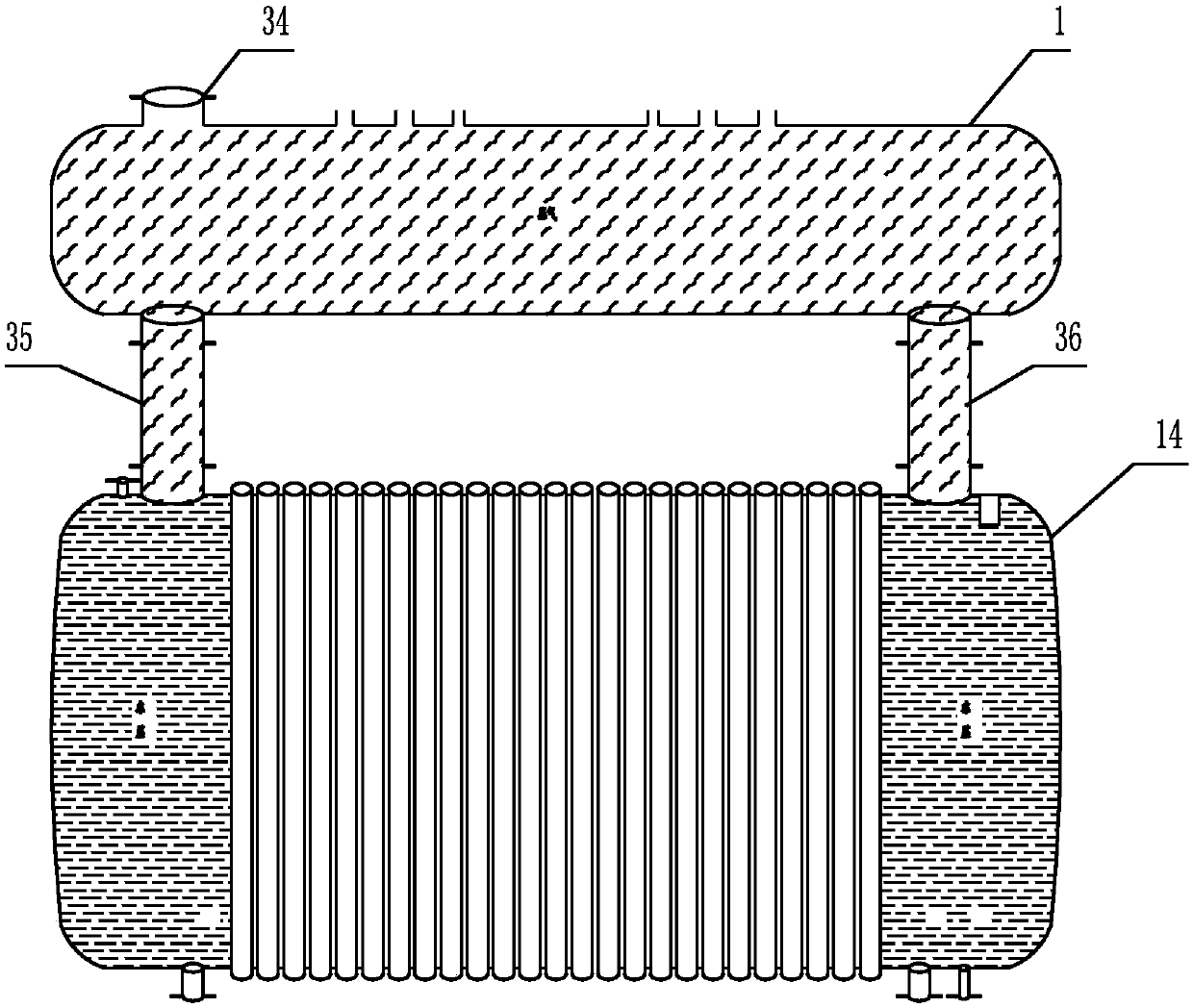

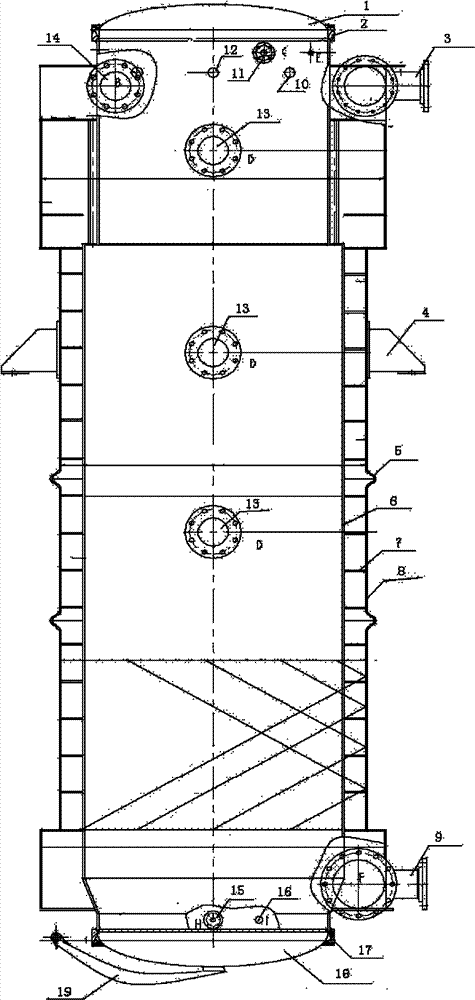

Efficient and energy-saving boiler barrel type fire tube steam boiler and using method thereof

The invention relates to an efficient and energy-saving boiler barrel type fire tube steam boiler and a using method thereof. The efficient and energy-saving boiler barrel type fire tube steam boileris provided with a support or a base and a boiler body, wherein the boiler body is provided with a gasification combustion chamber and a boiler barrel type heat exchange assembly; the boiler barrel type heat exchange assembly is provided with an upper boiler barrel and a lower boiler barrel; the upper boiler barrel is provided with a steam outlet; the lower boiler barrel communicates with the upper boiler barrel through a steam delivering tube; multiple rows of vertical tubular upper and lower fire paths with openings in the tops and the bottoms and vertical tubular upper and lower flues withopenings in the tops and the bottoms are arranged in the lower boiler barrel; the fire paths and the flues sequentially communicate with one another in the front-back direction through fire distributing boxes and smoke distributing boxes; the outlet of the upper flue at the tail end is provided with a tail gas discharge opening, an induced draft fan and a dust collector; the lower opening of the upper fire path at the foremost end communicates with the gasification combustion chamber; fire circulates in tubes of the fire paths and the flues; an internal water system is arranged on the outsidesof the tubes; a water layer is arranged in the outer wall of the gasification combustion chamber; and the water layer and water layers on the outsides of the fire distributing boxes and the smoke distributing boxes form an external water system. The steam boiler has the advantages of simple structure, small occupation area, high degree of automation, safe and reliable running, convenience in operation and use, low production and maintenance cost, energy conservation and environmental protection, capability of being popularized and used extensively and the like.

Owner:余生明 +1

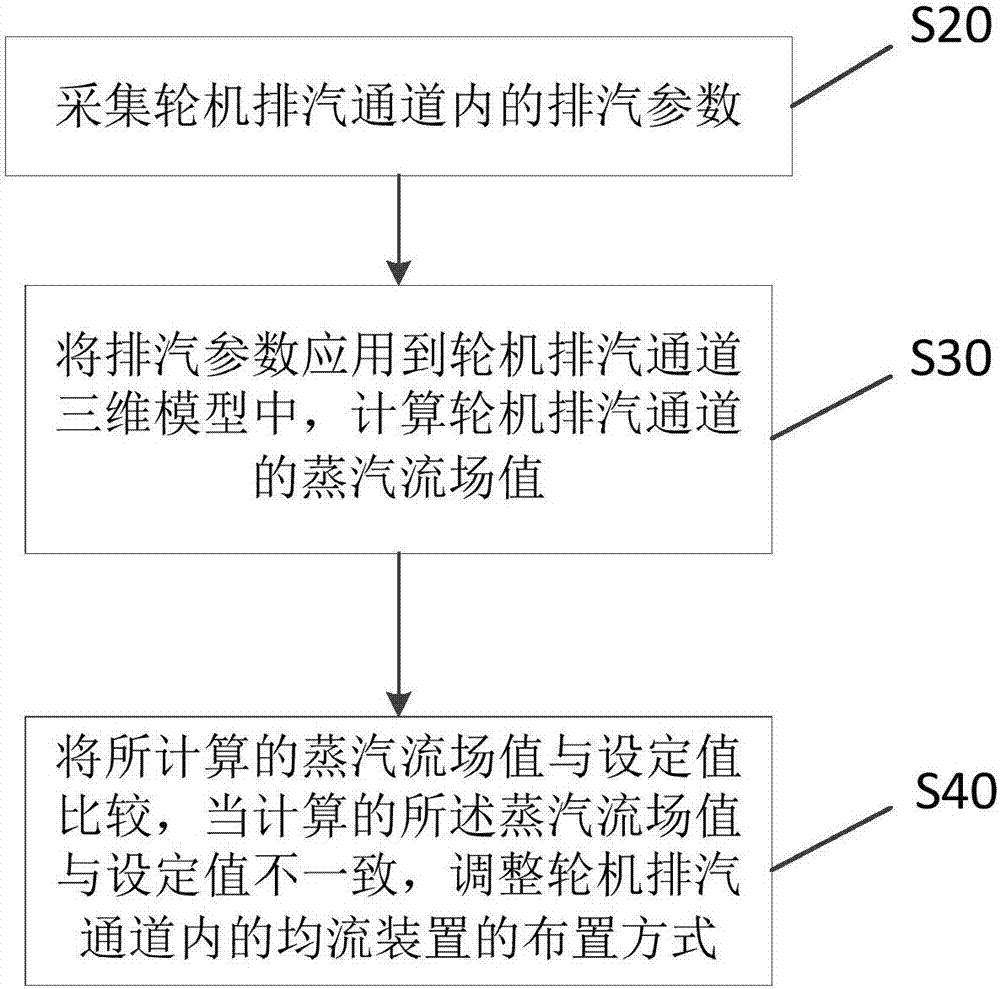

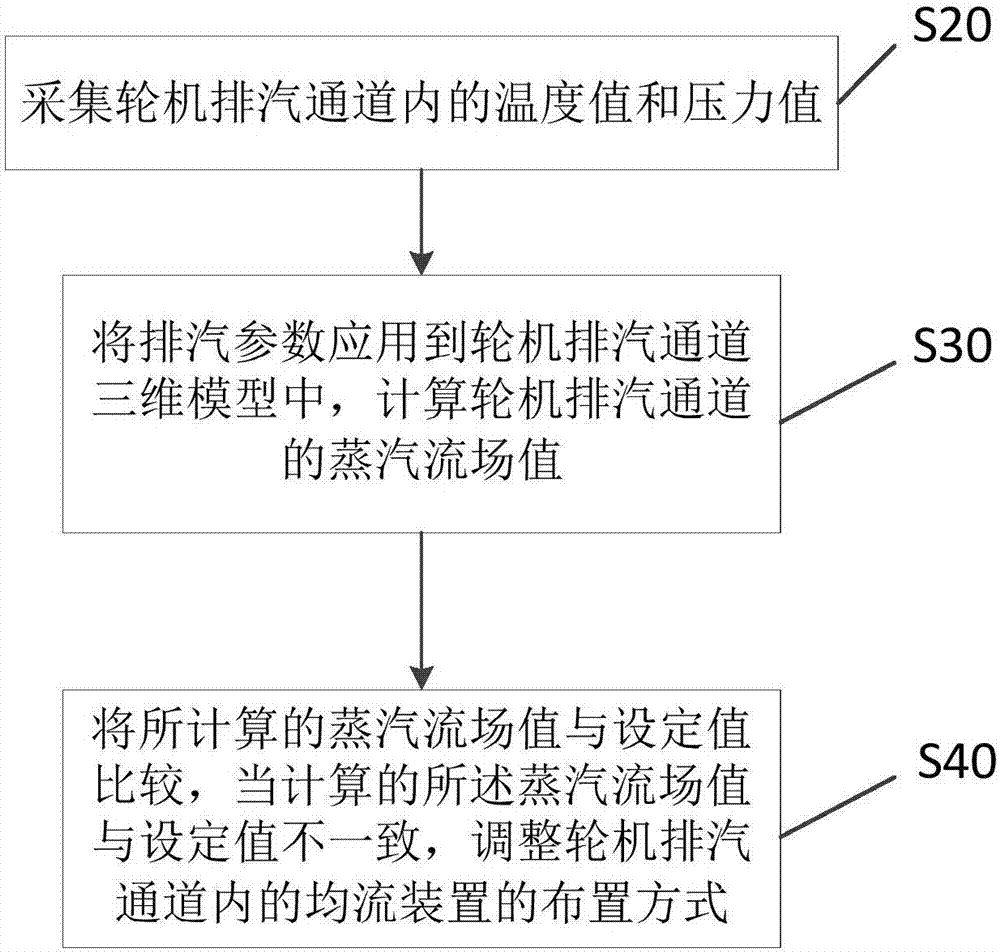

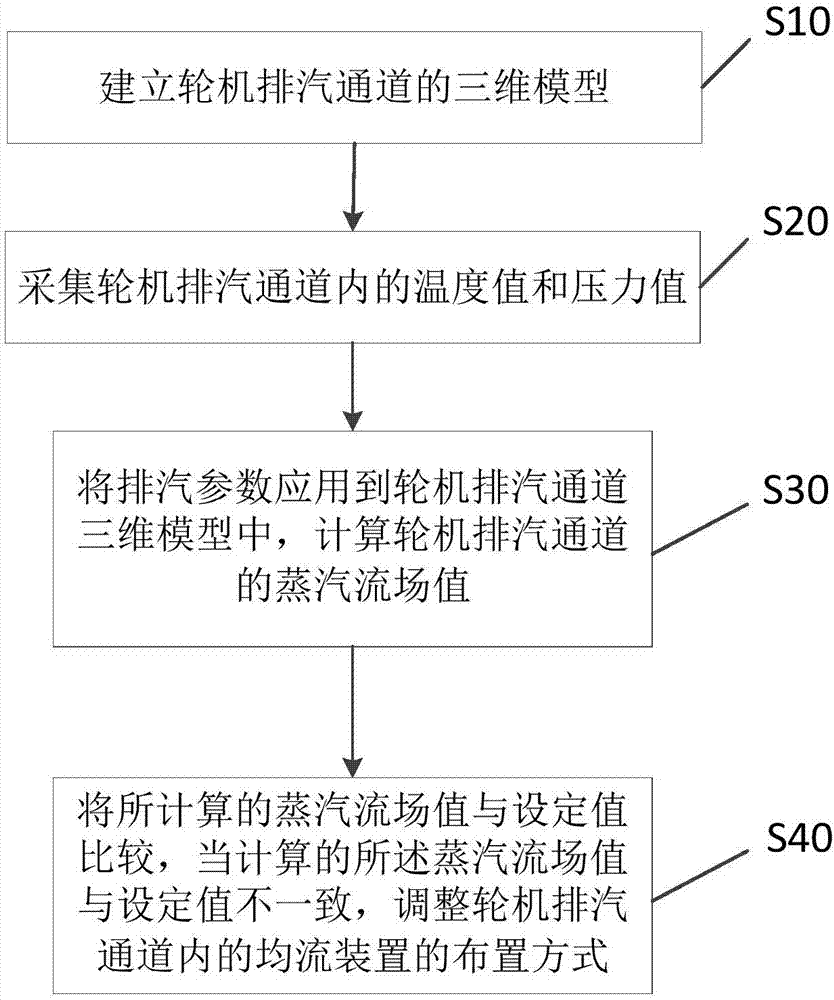

Exhaust passage optimization method and system used for turbine

InactiveCN107092762AImprove flow uniformityUniform gas fieldGeometric CADMachines/enginesEngineeringTurbine

The invention relates to the technical field of turbines and discloses an exhaust passage optimization method and system used for a turbine. The method comprises the steps of collecting exhaust parameters in an exhaust passage of the turbine; applying the exhaust parameters to a three-dimensional model of the exhaust passage of the turbine, and calculating a steam flow field value of the exhaust passage of the turbine; and comparing the calculated steam flow field value with a set value, and when the calculated steam flow field value is inconsistent with the set value, adjusting an arrangement mode of a flow-equalizing apparatus in the exhaust passage of the turbine. According to the method, the steam flow field value of the exhaust passage of the turbine is adjusted to reach the set value, so that the exhaust eddy is reduced, the exhaust velocity is uniformized, the structures such as the exhaust passage, a turbine low-pressure cylinder connected with the exhaust passage, and the like are more reasonable, and the product life and the heat exchange capability are prolonged and improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

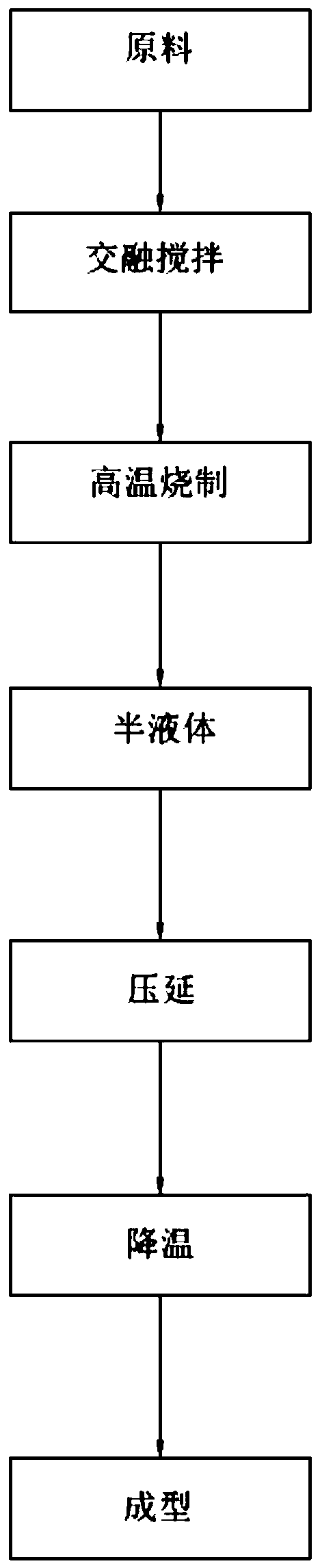

Microwave thermal conversion material, carrier and preparation method of microwave thermal conversion material

ActiveCN110049666AThe structure is convenient and simpleSimple mold structureMagnetic/electric field screeningIncinerator apparatusThermal energyThermal insulation

The invention belongs to the technical field of microwave thermal conversion, and particularly relates to a microwave thermal conversion material, a carrier and a preparation method of the microwave thermal conversion material. The microwave thermal conversion material is made of the materials, in weight percentage, as follows: 55-65% of graphite powder, 10-15% of ferrite powder, 15-25% of glass fiber and 5-10% of a binder. The structure is convenient and simple to form, the weight is light, and the insulating property, the acid resistance, the alkali resistance, the pressure resistance and the stripping property are good, physical and chemical properties are stable, high temperature resistance and high thermal insulation are realized, the resistant high temperature can reach 1350 DEG C, compared with an existing thermal conversion material, the thermal energy conversion efficiency of microwave absorption thermal energy conversion can be improved by 30%, the microwave thermal conversion material can be efficiently applied to microwave waste gas combustion equipment at a high speed, energy can be saved by 50% or above compared with an existing RTO combustor, consumable materials cannot be generated, and the microwave thermal conversion material is simple in preparation process, convenient to operate, easy to form and low in cost.

Owner:义乌韦陀环保科技有限公司

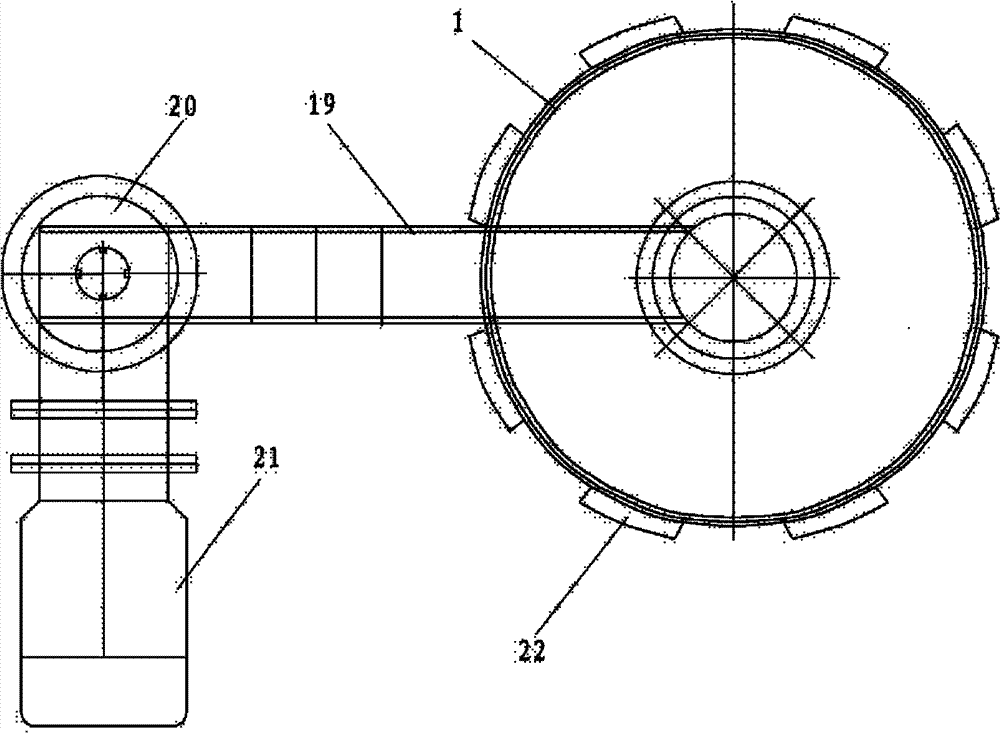

Axial-wearing-free rectangular cylinder Stirling engine

ActiveCN106224123AGuaranteed lubrication effectGuaranteed tightnessHot gas positive displacement engine plantsNew energyExternal combustion engine

A Stirling engine is a unique external combustion engine, as the theoretical efficiency is nearly equal to the maximum theoretical efficiency, the efficiency is called as carnot cycle efficiency, an external combustion engine cylinder in use is filled with a gas working medium of a certain volume and pressure; to ensure high-speed piston straight-line push-pull movement, a medium / high-pressure gas in the cylinder is prevented from leakage for a long time, and a transmission shaft which is connected with an external transmission mechanism is in high-density sealing lubrication and is free of axial mechanical wearing, and therefore, relatively high requirement is provided for structure materials and processes, and further the cost of an engine can be increased and popularization can be affected. The invention discloses an axial-wearing-free rectangular cylinder Stirling engine which is made of a high-performance ceramic material. Due to a planar super-low friction coefficient between ceramics, the lubrication performance approximate to that of an ice surface, and the high temperature resistance, the abrasion resistance, the wearing resistance and the good sealing performance of ceramic, a rectangular piston and a rectangular cylinder are adopted to form planar sealing lubrication, and an axial-wearing-free structure with double-axis lateral planar windowing power output can be formed. The development neck of a conventional Stirling engine shaft to high technical requirements is effectively broken, an external combustion engine with excellent performance can be relatively high in efficiency and relatively long in service life, and can be relatively rapidly popularized and applied in multiple fields of environment-friendly energy and the like.

Owner:LUOYANG WENSEN TECH CO LTD

Bainite Quenching Process of Steel Tape

InactiveCN109402336BReduce stressReduce unit energy consumptionFurnace typesIncreasing energy efficiencyTemperingHardness

The invention provides a bainite quenching process of a steel tape. The process comprises the following steps of (1) heating: making the tape pass through a heating device at the constant speed to beheated in the heating device to 880-900 DEG C; (2) cooling: making the tape pass through a cooling device at the temperature of 310-330 DEG C at the constant speed to be cooled in the cooling device after heating in the step (1), and then blowing the tape with inert gas to the room temperature to obtain the tape with a bainite structure; (3) cleaning: making the tape pass through a cleaning deviceat the constant speed, and then blowing off a cleaning medium on the surface of the tape with the inert gas. The quenching process has excellent wear resistance, maintains high hardness while maintaining good toughness, does not require a tempering process, simplifies the process, reduces costs, and improves production efficiency.

Owner:HENAN POLYTECHNIC UNIV

An easy-to-adjust feeder for plastic processing

ActiveCN112045888BAvoid staying in the cavity of the feeding boxCircumstances affecting deliverySievingScreeningPlastic materialsProcess engineering

Owner:佛山市顺德区汝鸿塑料实业有限公司

Novel turbine engine

PendingCN112901347ASave energyEnergy reduction flow rate reductionTurbine/propulsion fuel flow conduitsPump componentsAir compressionImpeller

The invention provides a novel turbine engine. According to the technical scheme, the novel turbine engine is mainly composed of an engine body, an air compression rotor, an acting rotor, a fuel gas generating device and the like, the air compression rotor and the acting rotor are installed on the same axis in the engine body, the air compression rotor is provided with an air inlet and an air outlet, the acting rotor is provided with an air inlet and an air outlet, the fuel gas generating device is composed of a combustion chamber, a fuel injector, a fuel supply device and an igniter, a gas outlet of the air compression rotor communicates with a gas inlet of the combustion chamber, a gas nozzle of the combustion chamber communicates with a gas inlet of an acting impeller, and the air inlet of the air compression rotor and the air outlet of the acting rotor communicate with the atmosphere.

Owner:于洁

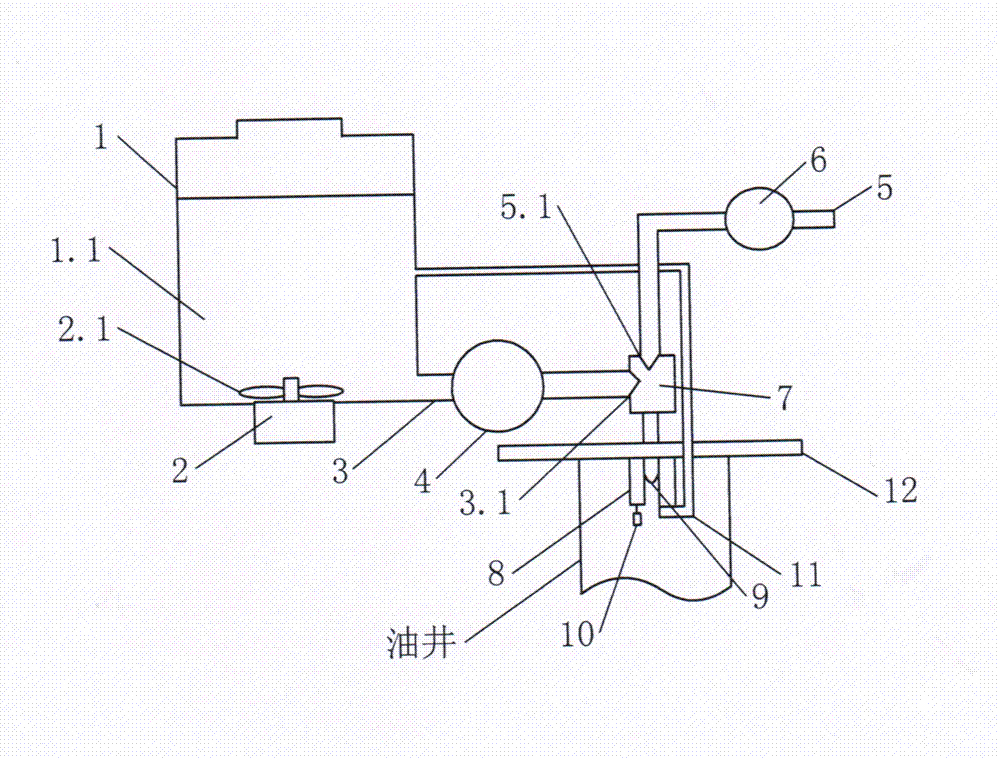

Method for generating combustion resonance steam from emulsified crude oil for heating oil wells

The invention provides a method for generating combustion resonance steam from emulsified crude oil for heating oil wells. The method includes emulsifying crude oil; generating the resonance steam; heating a crude oil emulsifying tank; and sealing the oil wells. By the method, the crude oil and water are emulsified at first, are mixed by an oil-air mixer to obtain mixtures, and the mixtures are ignited and are sprayed out of a steam jet provided with a resonator, so that a resonance steam flow is formed, and the oil wells can be heated. The method has the advantages of convenience in implementation, easiness in equipment manufacture, portability, flexibility in control, high heat conversion efficiency, good oil layer heating effect and capability of stopping pollution. The method is suitable for implementing steam heating for the oil wells.

Owner:RUISHI PETROLEUM TECH CO LTD

A Rectangular Cylinder Stirling Engine Without Axial Wear

ActiveCN106224123BLow costSolution to short lifeHot gas positive displacement engine plantsExternal combustion enginePush pull

A Stirling engine is a unique external combustion engine, as the theoretical efficiency is nearly equal to the maximum theoretical efficiency, the efficiency is called as carnot cycle efficiency, an external combustion engine cylinder in use is filled with a gas working medium of a certain volume and pressure; to ensure high-speed piston straight-line push-pull movement, a medium / high-pressure gas in the cylinder is prevented from leakage for a long time, and a transmission shaft which is connected with an external transmission mechanism is in high-density sealing lubrication and is free of axial mechanical wearing, and therefore, relatively high requirement is provided for structure materials and processes, and further the cost of an engine can be increased and popularization can be affected. The invention discloses an axial-wearing-free rectangular cylinder Stirling engine which is made of a high-performance ceramic material. Due to a planar super-low friction coefficient between ceramics, the lubrication performance approximate to that of an ice surface, and the high temperature resistance, the abrasion resistance, the wearing resistance and the good sealing performance of ceramic, a rectangular piston and a rectangular cylinder are adopted to form planar sealing lubrication, and an axial-wearing-free structure with double-axis lateral planar windowing power output can be formed. The development neck of a conventional Stirling engine shaft to high technical requirements is effectively broken, an external combustion engine with excellent performance can be relatively high in efficiency and relatively long in service life, and can be relatively rapidly popularized and applied in multiple fields of environment-friendly energy and the like.

Owner:LUOYANG WENSEN TECH CO LTD

A microwave heat conversion material, carrier and preparation method thereof

ActiveCN110049666BThe structure is convenient and simpleSimple mold structureMagnetic/electric field screeningIncinerator apparatusPhysical chemistryFerrite powder

The invention belongs to the technical field of microwave heat conversion, and specifically relates to a microwave heat conversion material, a carrier and a preparation method thereof. The microwave heat conversion material is made of materials with the following weight ratio: graphite powder 55-65%, ferrite powder 10‑15%, glass fiber 15‑25% and binder 5‑10%. The structure of the present invention is convenient and simple to form, light in weight, has good insulation, acid and alkali resistance, pressure resistance and peeling properties, stable physical and chemical properties, high temperature and heat resistance, strong heat insulation, and high temperature resistance up to 1350 degrees Celsius Compared with the existing heat conversion materials, the wave-absorbing heat energy conversion can increase the heat energy conversion efficiency by 30%, and can be used in microwave waste gas combustion equipment efficiently and at high speed. Compared with the previous RTO burner, the energy saving can reach more than 50% and will not produce Consumables, the preparation process is simple, easy to operate, easy to shape, and low cost.

Owner:义乌韦陀环保科技有限公司

Radial double-flow turbine

The invention relates to a steam turbine, in particular to a radial direction double flow type steam turbine which can effectively reduce axial force and use steam flow energy as much as possible. Double rows of centripetal integral impellers are arranged at the center of a live spindle, centrifugal integral impellers are arranged at two sides. The integral impellers do work when steam flow carries out centripetal movement to push the spindle to rotate, and do work again in the centrifugal stage to push the spindle to rotate after the angular transformation, and enter the next circulation. The structure can counteract the generated axial force, reduce the structure, use the centrifugal energy, and improve the efficiency.

Owner:程建平 +1

High-temperature feeding and deslagging cracker for waste rubber and waste plastic

ActiveCN102304235BHigh thermal energy conversion efficiencyAutomatic opening and closingPlastic recyclingPhysical hard workPhysical work

The invention discloses a high-temperature feeding and deslagging cracker for waste rubber and waste plastic, belonging to the field of waste recycle. The device comprises a vertical kettle body, wherein the upper end opening of the kettle body is a feeding hole; the lower end opening of the kettle body is a discharging hole; the upper end opening and the lower end opening of the kettle body are respectively provided with an upper cover and a lower cover; the surrounding wall of the kettle body is provided with an oil gas outlet, a vent and a wind inlet; the kettle body comprises an inner barrel and an outer barrel which are concentric; a jacket is arranged between the inner barrel and the outer barrel; a plurality of fin plates are arranged in the jacket; and an upper cover and a lower cover are quickly and automatically closed and opened with the kettle body by a driving mechanism. According to the device disclosed by the invention, the whole waste tyre and massive waste rubber and waste plastic can be directly put into the kettle. Because the materials do not need to be smashed or sliced, a tyre cutting machine can be omitted, and thus the investment of sets of equipment is reduced; and therefore, dust and solid particle pollution in the slicing process is omitted, and heavy physical work in the working procedures of power consumption and cutting in the slicing process can be saved. According to the high-temperature feeding and deslagging cracker, the environmentally-friendly performance is improved, energy consumption is saved, labor force is saved, and working efficiency is improved.

Owner:深圳市华镛环境工程有限公司

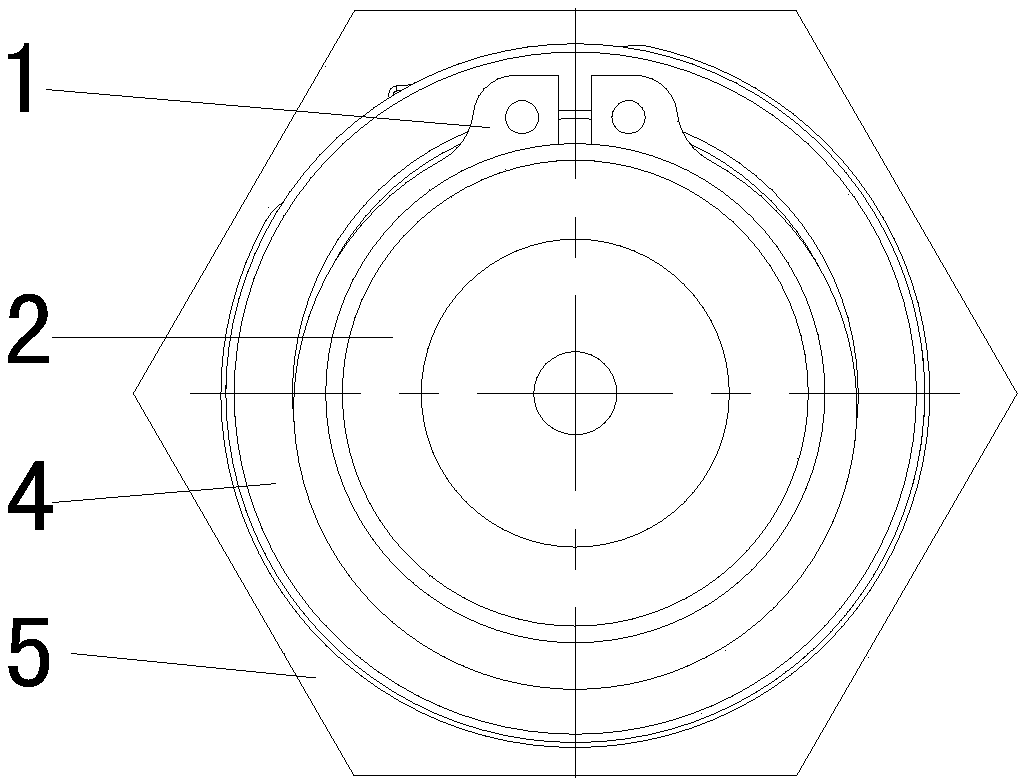

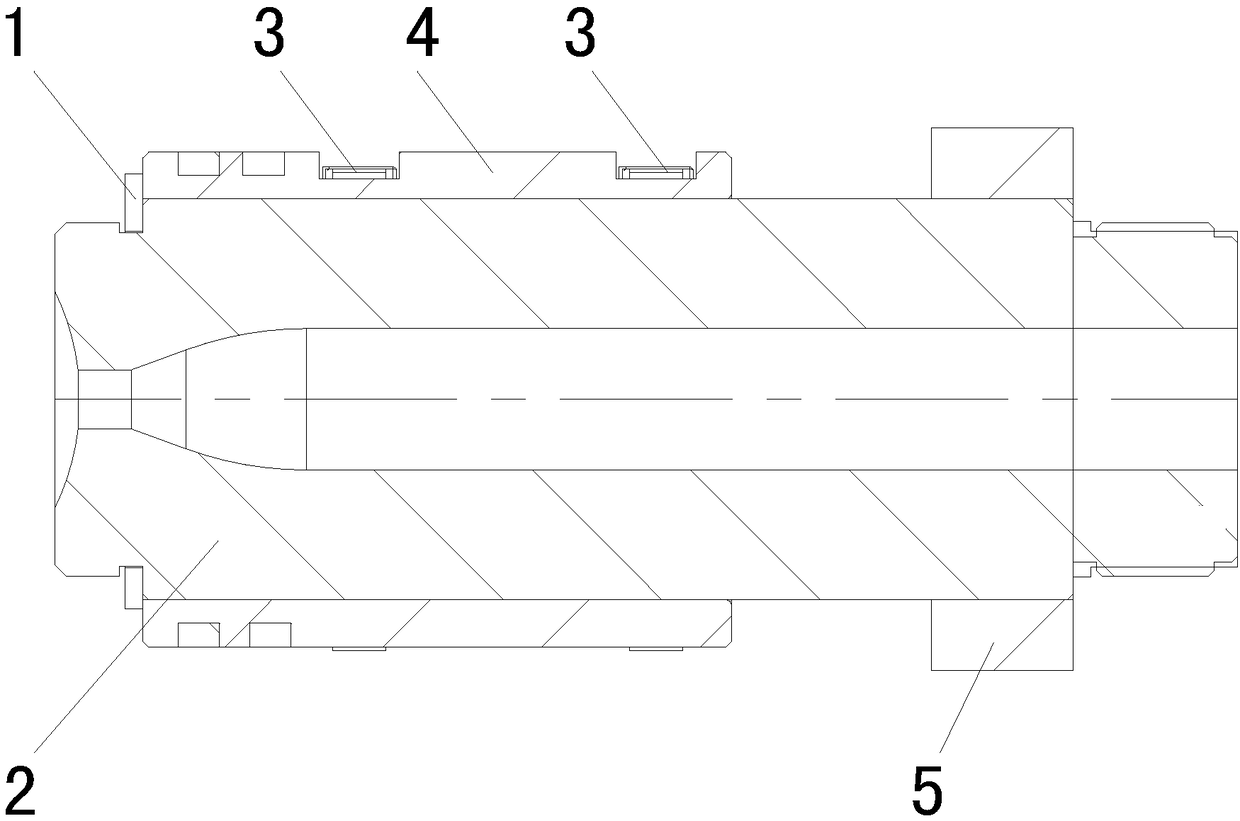

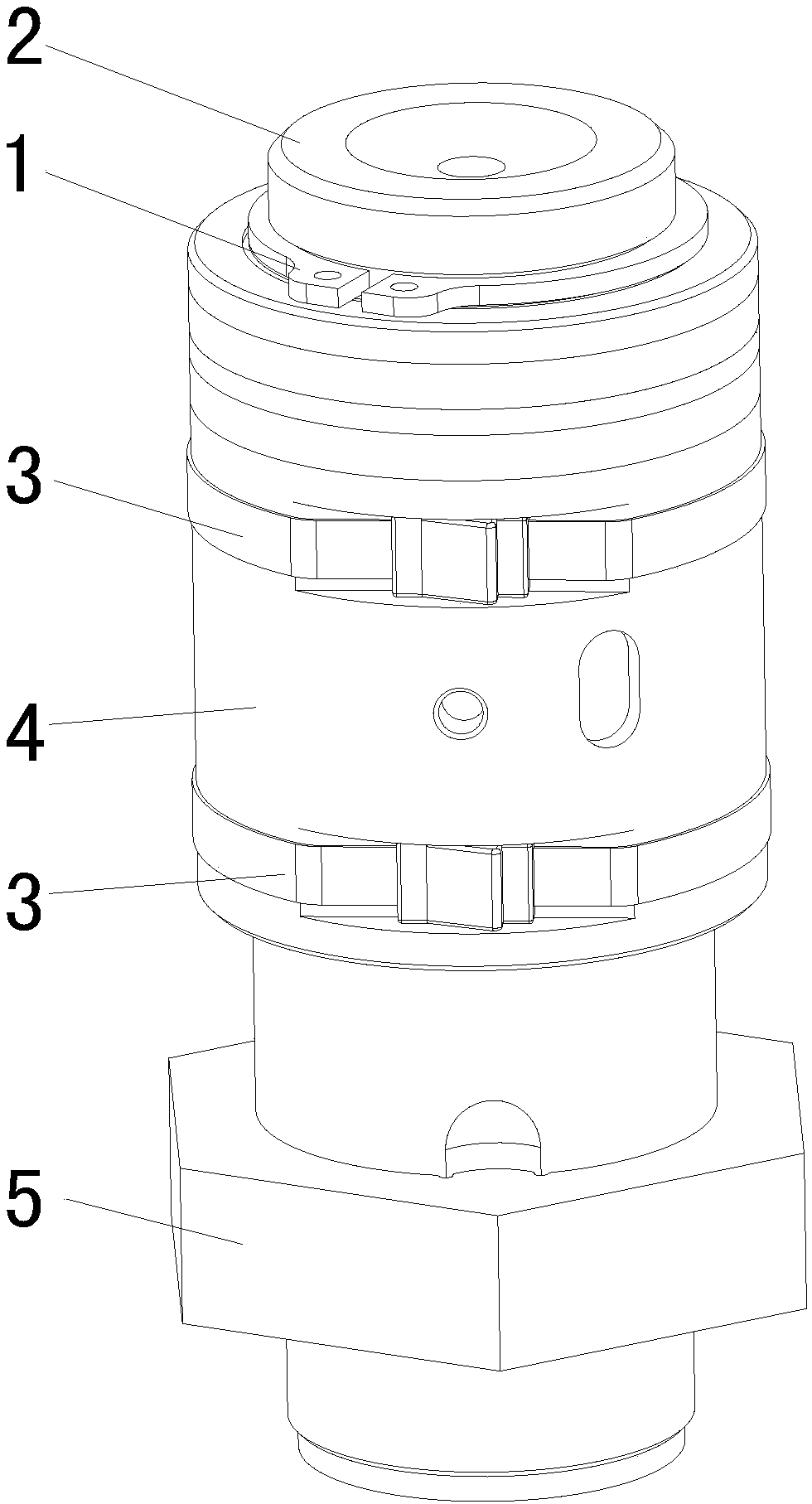

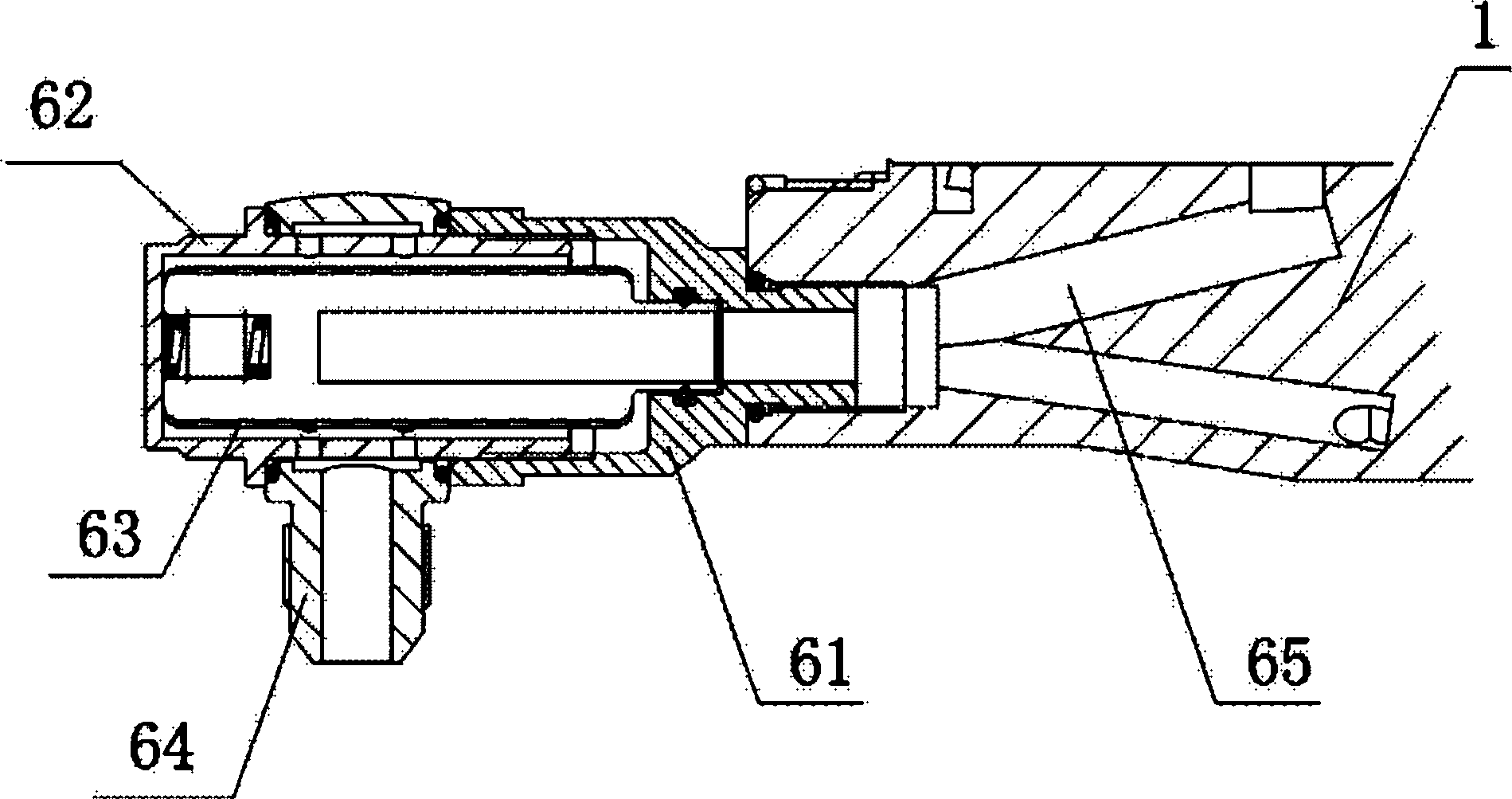

Injection nozzle assembly

The invention discloses an injection nozzle assembly, which comprises an injection nozzle main body, wherein the injection nozzle main body is arranged in a cylindrical shape, a through hole is arranged inside the injection nozzle main body, a heating steel sleeve is sleeved on the outer circumference of the injection nozzle main body, and is fixed on the injection nozzle main body by a metal snapping hoop, the outer circumference of the injection nozzle end of the injection nozzle main body is provided with a snapping spring for snapping the end portion of the heating steel sleeve, and the outer circumference of the other end of the injection nozzle main body is provided with a fastening hexagon nut. According to the present invention, the injection nozzle assembly has characteristics ofrapid heating, high heat energy conversion efficiency, balanced heating, energy saving, environmental protection, long service life and low cost.

Owner:SUZHOU HTS MOLD

Device for regulating guide blade of turbine

ActiveCN102278146BHigh thermal energy conversion efficiencyStatorsMachines/enginesThermal energyTurbine blade

The invention provides a device for regulating a guide blade of a turbine, comprising a case (1), a regulating cam (3) arranged on the case (1) in a rotatable manner, as well as a follow-up valve (4) and an actuating mechanism (5) which are contained and arranged in the case (1), wherein the follow-up valve (4) and the actuating mechanism (5) interact to provide a rotating power for the guide blade. In the invention, the device for regulating the guide blade is hydraulically driven, and the angle of the guide blade can be continuously and steplessly regulated, thus the angle of the guide blade can be matched with the blade airflow air suction angle requirement at different rotating speeds and the thermal energy conversion efficiency of a turbine blade is greatly improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

A semiconductor module for dual power generation

ActiveCN106784106BImprove conversion efficiencyWith the function of double power generationPhotovoltaic energy generationSemiconductor devicesLight energyEngineering

Owner:HANGZHOU DAHE THERMO MAGNETICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com