Radial double-flow turbine

A steam turbine and double-flow technology, applied in the field of steam turbines, can solve the problems of generating axial force and easily reducing efficiency, etc., and achieve the effects of small energy loss, significant energy saving effect, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

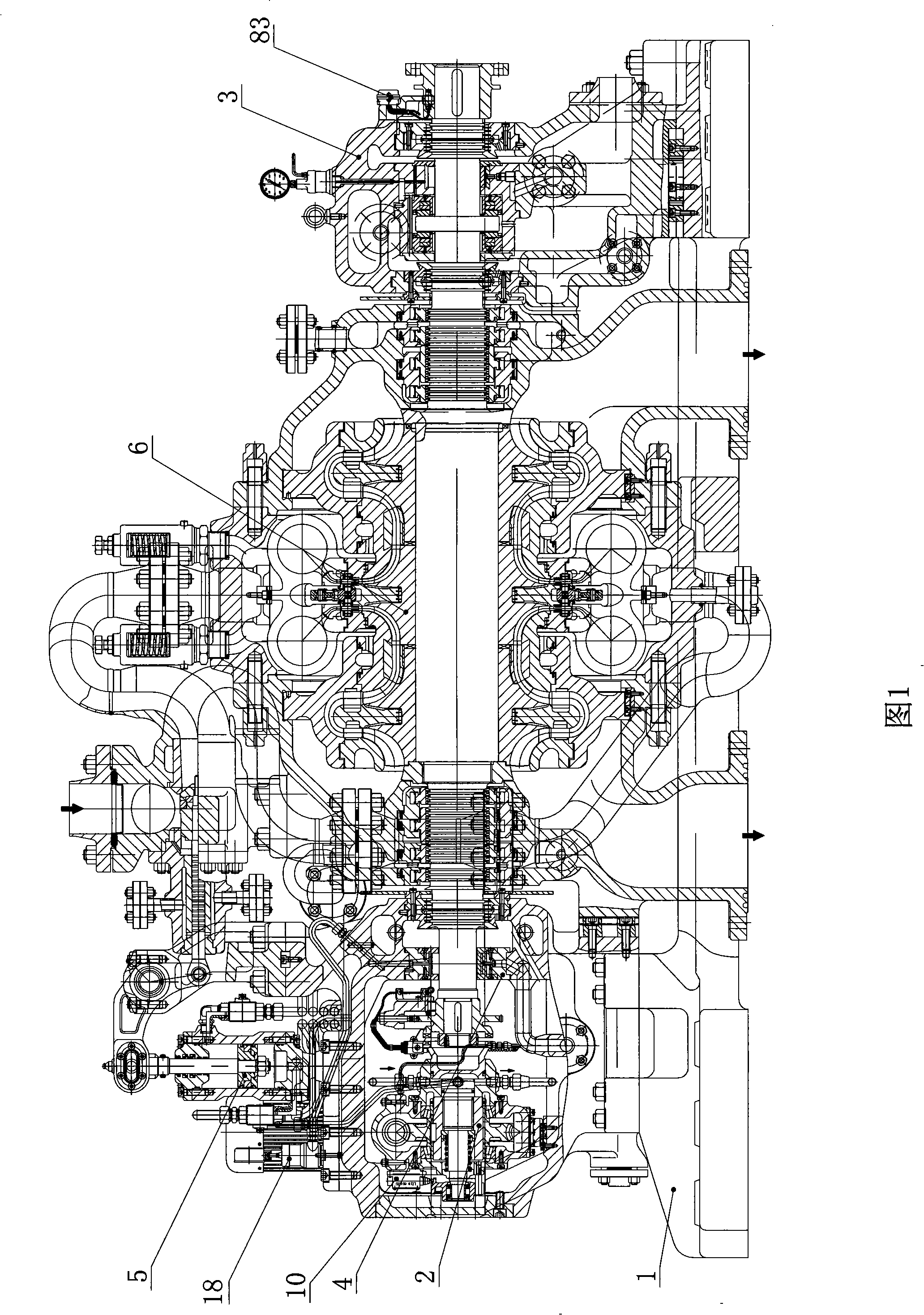

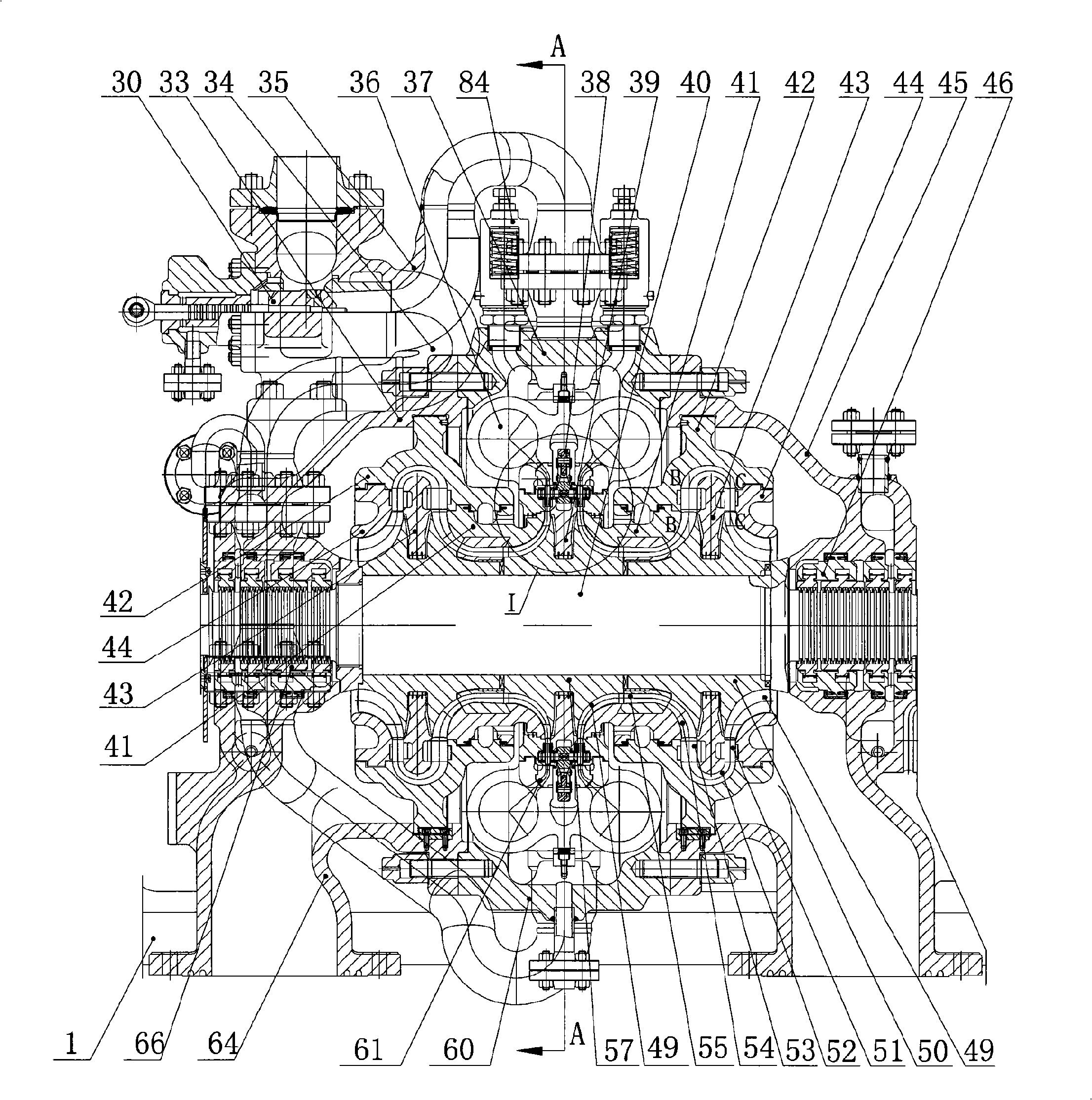

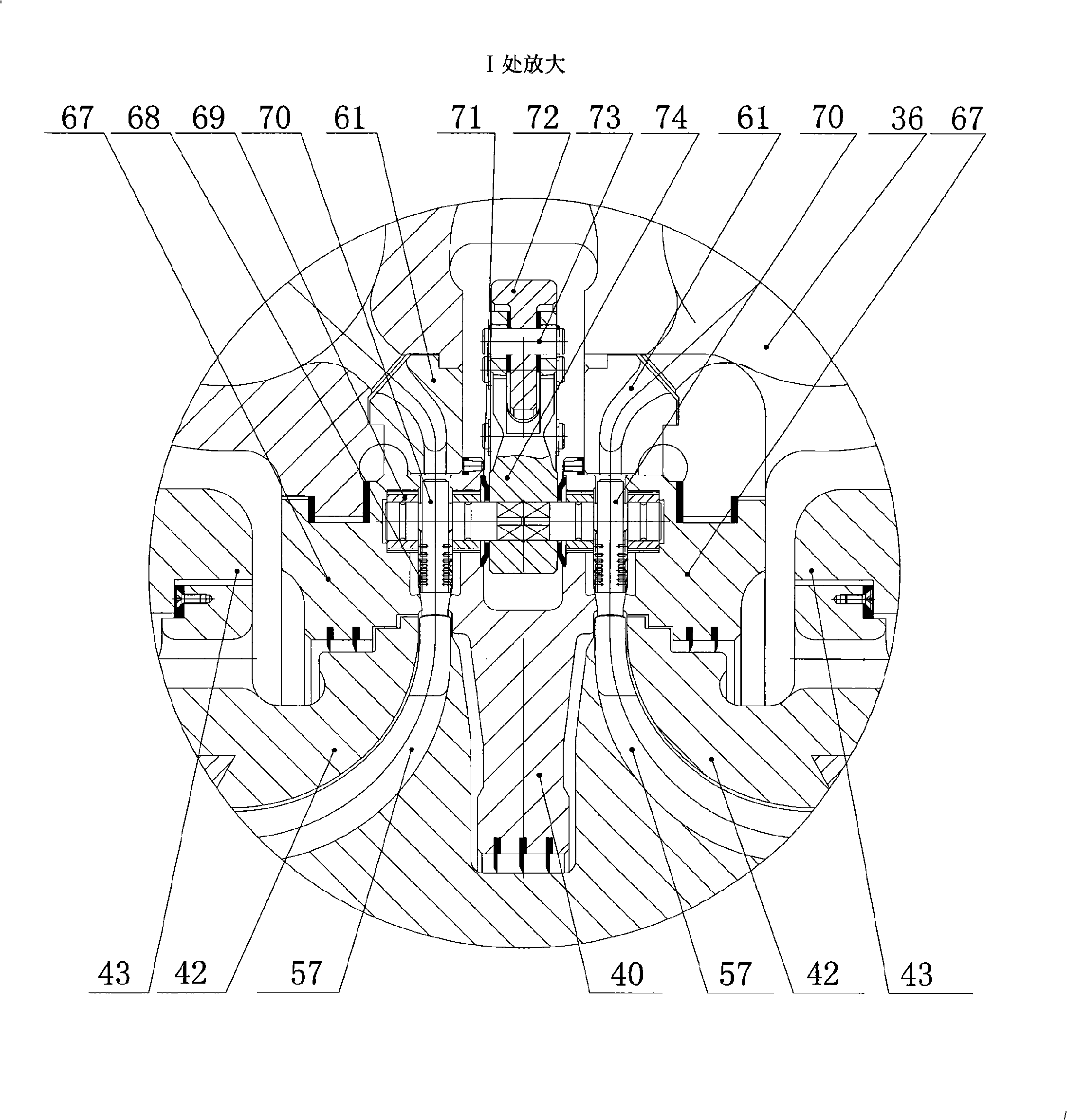

[0046] Embodiment: The radial double-flow steam turbine (see accompanying drawing 1) comprises a base 1, a front bearing housing 2 and a rear bearing housing 3 arranged on the base and an adjusting actuator 5 arranged on the front bearing housing, the front bearing housing and the rear bearing housing A steam turbine body 6 is arranged between the bearing boxes, and a main shaft 40 is arranged in the steam turbine body, and the main shaft communicates with the front bearing box and the rear bearing box. There is a centripetal integral impeller 50 on both sides of the impeller respectively, the main shaft and each integral impeller adopt an integral structure, and each integral impeller is arranged with equal diameters (see attached Figure 10 ).

[0047] Front bearing box (see attached Figure 18 attached Figure 19 ) consists of a set of overspeed protection device, a bevel gearbox, a reducer and a bearing box. End cover, limit switch 10, oil inlet pipe, lubricating oil pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com