Microwave thermal conversion material, carrier and preparation method of microwave thermal conversion material

A heat conversion and microwave technology, applied in combustion methods, lighting and heating equipment, electrical components, etc., can solve the problems of high cost, cumbersome processing links, difficult structural molding, etc., and achieve the effect of low cost, light weight and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A microwave heat conversion material is made of the following materials in weight ratio: 60% of graphite powder, 12% of ferrite powder, 20% of glass fiber, 5% of cold-setting pellet binder and 3% of activated carbon binder.

Embodiment 2

[0030] A microwave heat conversion material is made of the following materials in weight ratio: 55% of graphite powder, 15% of ferrite powder, 25% of glass fiber, 6.25% of cold-setting pellet binder and 3.75% of activated carbon binder.

Embodiment 3

[0032] A microwave heat conversion material is made of the following materials in weight ratio: 65% of graphite powder, 10% of ferrite powder, 15% of glass fiber, 3.75% of metallurgical pellet binder and 2.25% of active carbon binder.

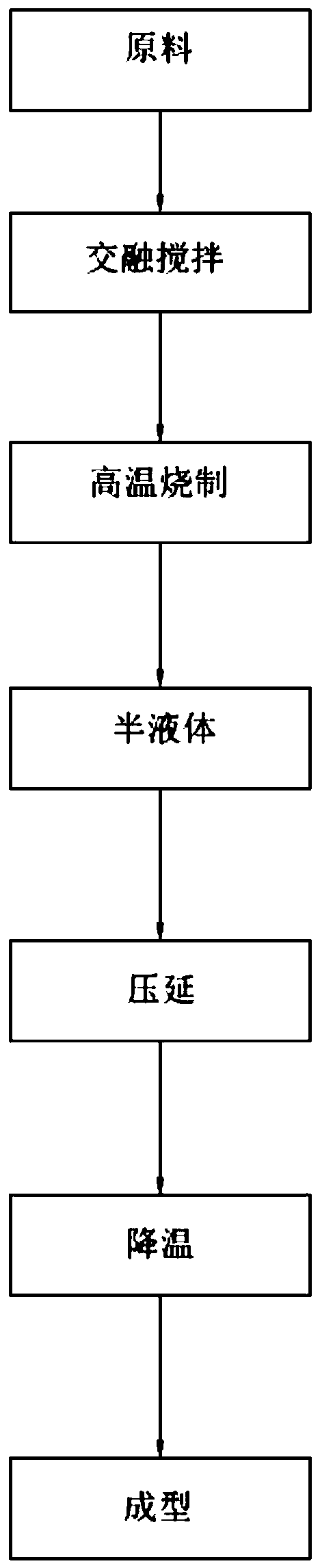

[0033] The preparation method of the microwave heat conversion material in the above-mentioned embodiment 1-embodiment 3, such as figure 1 As shown, it includes the following steps: take graphite powder, ferrite powder, glass fiber and binder in proportion, blend and stir evenly, and burn it at a high temperature of 1200-1350 degrees to form a semi-liquid, and the semi-liquid is processed by calendering equipment for multi-stage Roll forming, cooling 10-30 degrees, forming a flexible plate, that is.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com