Efficient and energy-saving boiler barrel type fire tube steam boiler and using method thereof

A steam boiler, high-efficiency and energy-saving technology, which is applied in fire-tube steam boilers, steam boilers, steam generation, etc., can solve the problems of high risk of fuel oil transportation and storage, inability to use natural gas, and high initial investment costs, and achieves improved production. Assembly efficiency, reduced heat consumption, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

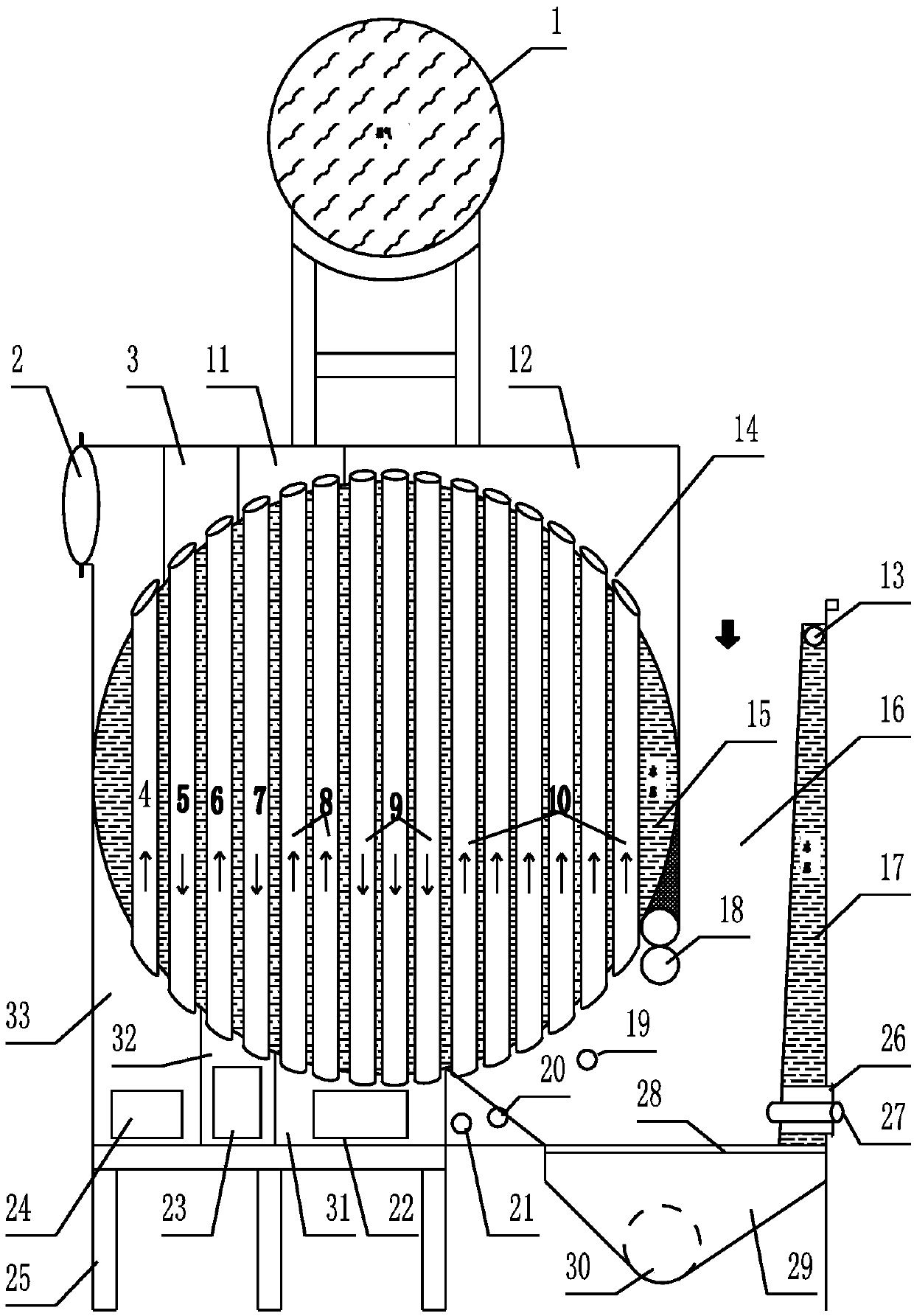

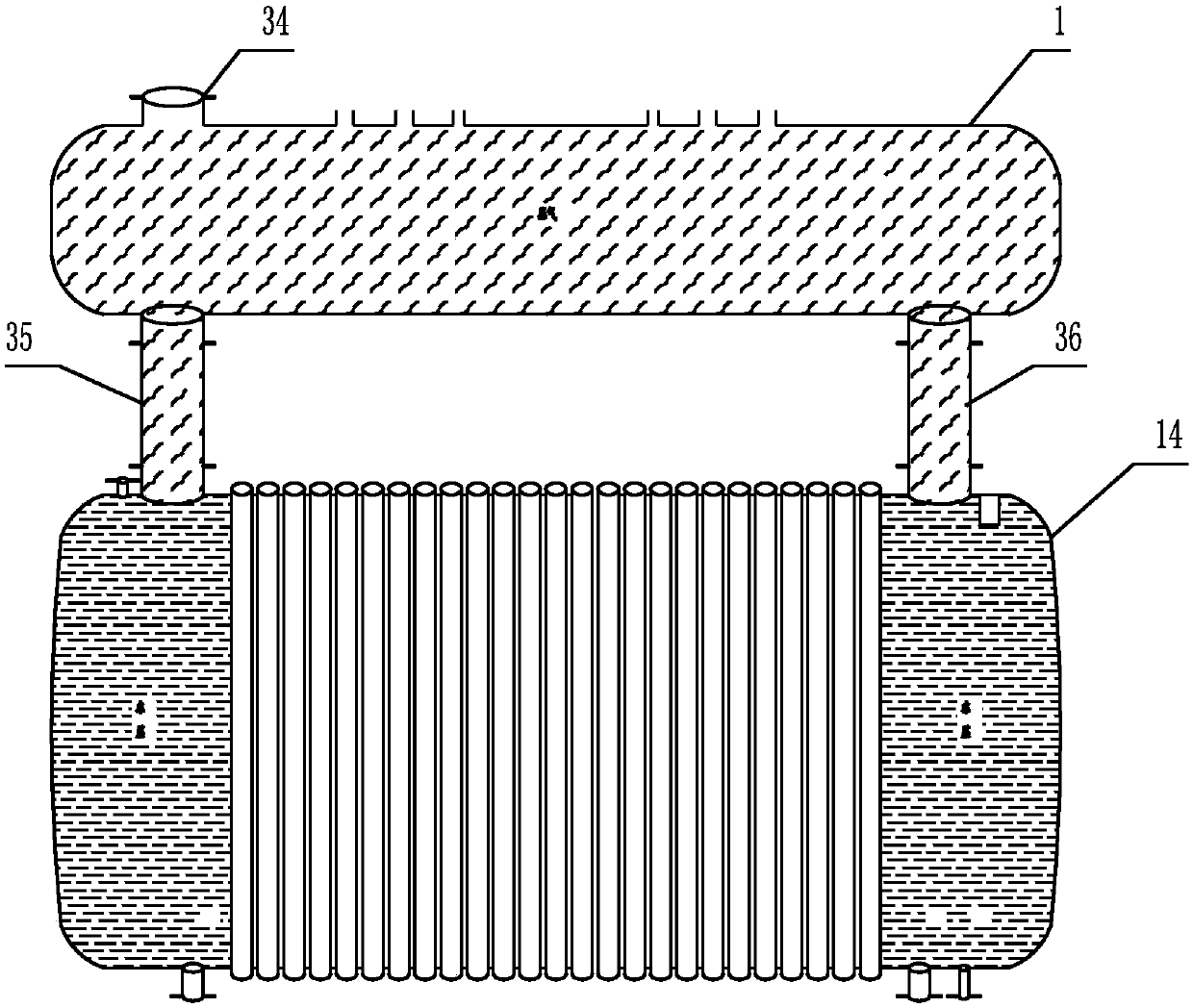

[0037] Embodiment 1: See the accompanying drawings: a high-efficiency and energy-saving drum-type fire-tube steam boiler is provided with a bracket 25, and a furnace body is arranged on the bracket; the furnace body is provided with a gasification combustion chamber and a drum-type heat exchange assembly The drum-type heat exchange assembly is arranged above the gasification combustion chamber, and is provided with an upper drum 1 and a lower drum 14. The upper drum is a sealed long cylinder with a length of 200 cm and a diameter of 80 cm. There is an insulating layer, and a steam outlet 34 is provided on its upper side; the lower drum is also a sealed long cylinder, 200 cm long and 150 cm in diameter, which is arranged below the upper drum, and steam delivery pipes 35, 36 It communicates with the upper drum; in the lower drum, there are vertically arranged multi-row tubular upper and lower fire passages 10, lower fire passages 9, upper flue passages 4, 6, 8 and lower flue pass...

Embodiment 2

[0045] Embodiment 2: A high-efficiency and energy-saving drum-type fire-tube steam boiler. The structure of the steam boiler in this embodiment is the same as that in the embodiment, and its use method is as follows:

[0046] 1) Add fuel to the fuel feeding bin, and then ignite and burn in the gasification combustion chamber;

[0047] 2) Turn on the automatic controller system, open the network connection between the automatic control system and the remote monitoring center, start the controller to run, automatically control the operation of the boiler, and set the on-duty personnel to deal with the alarm situation in time.

[0048] This embodiment has been tested by a factory and has achieved good results. With the same steam production capacity, the fire tube boiler of this embodiment saves 30% of fuel and 70% of labor, and has achieved good economic benefits. There was no accident for a month, and the evaluation of the environmental protection department also gave a favorab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com