A Rectangular Cylinder Stirling Engine Without Axial Wear

A technology of Stirling engine and axial wear, which is applied in the direction of machines/engines, hot gas variable displacement engine devices, mechanical equipment, etc., can solve the problems of not being widely used and the increase of engine cost, and solve the problems of axial wear and tear. The effect of developing bottlenecks to high-tech requirements, improving thermal energy conversion efficiency, and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

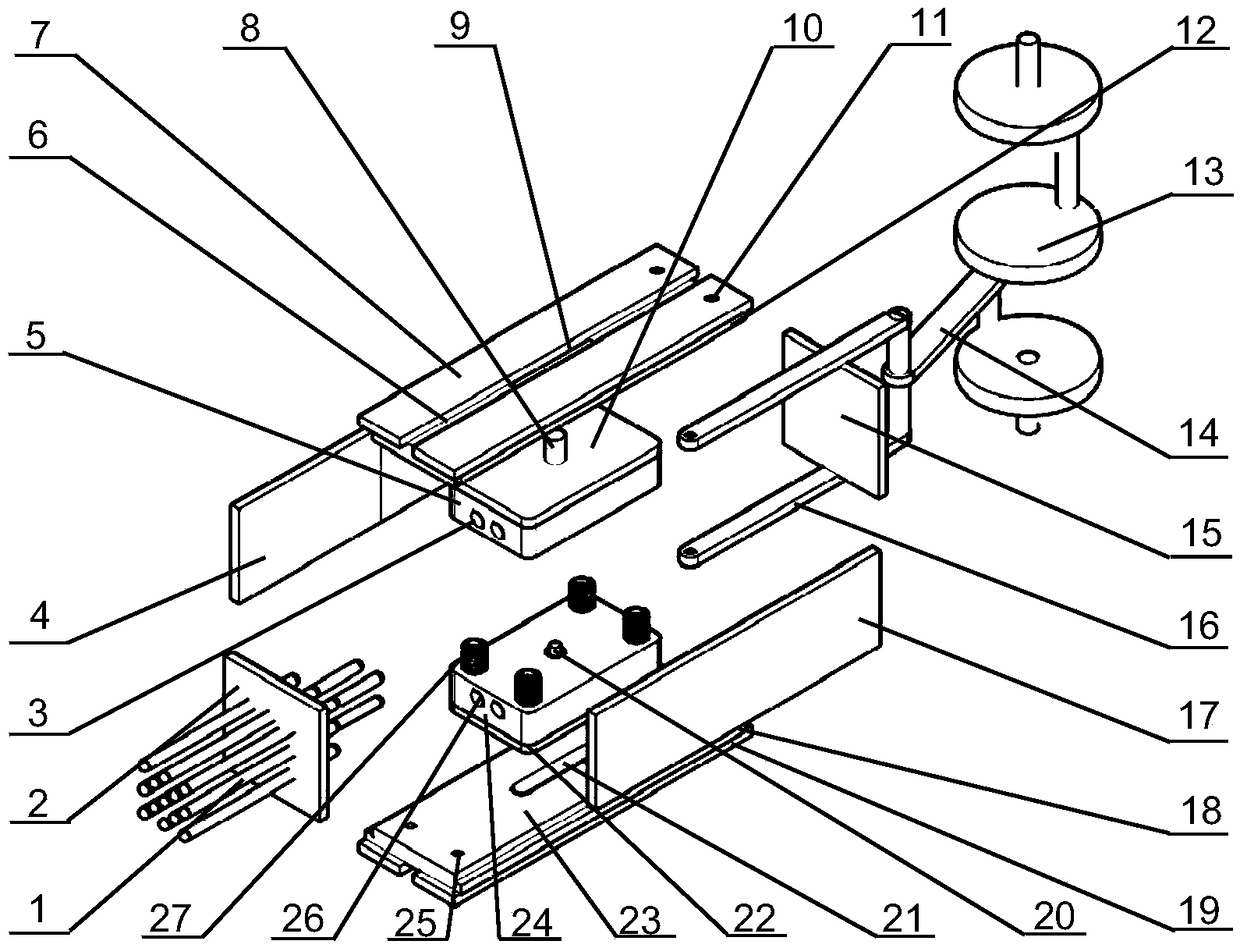

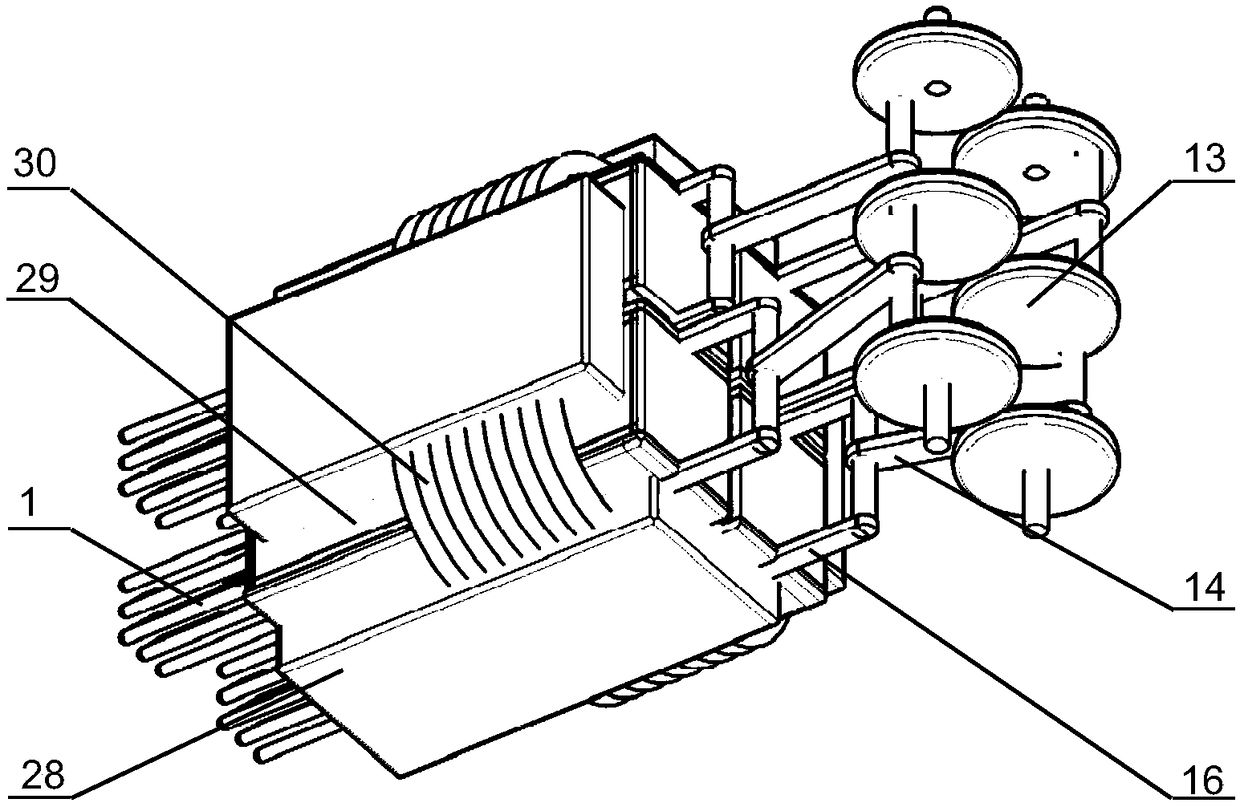

[0022] combined with figure 1 The structure of the present invention is illustrated:

[0023] The non-axial wear rectangular cylinder Stirling engine adopts the alloy steel layer with the closest expansion coefficient to the ceramic, and sinters the nano-scale high-performance ceramic material layer under high temperature and high pressure to form a flat composite body, forming two upper and lower layers , the rectangular piston facing outwards from the ceramics forms a rectangular cylinder 29 with the ceramics facing the inner cylinder wall, the rectangular piston moves back and forth in the cold and hot cylinder areas of the cylinder in the form of ceramic plane friction, the upper cylinder wall friction surface and the lower cylinder wall friction surface middle part have a Sliding windows 9, 21, the transmission shaft 8 in the middle of the upper piston, and the transmission shaft 20 in the middle of the lower piston are vertically installed, and the kinetic energy of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com