Method for producing black glaze gold drip glaze and product thereof

A glaze, black glaze technology, applied in the field of ceramic technology, can solve the problems of difficult process, difficult selection of glaze, low yield, etc., and achieve the effect of three-dimensional visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

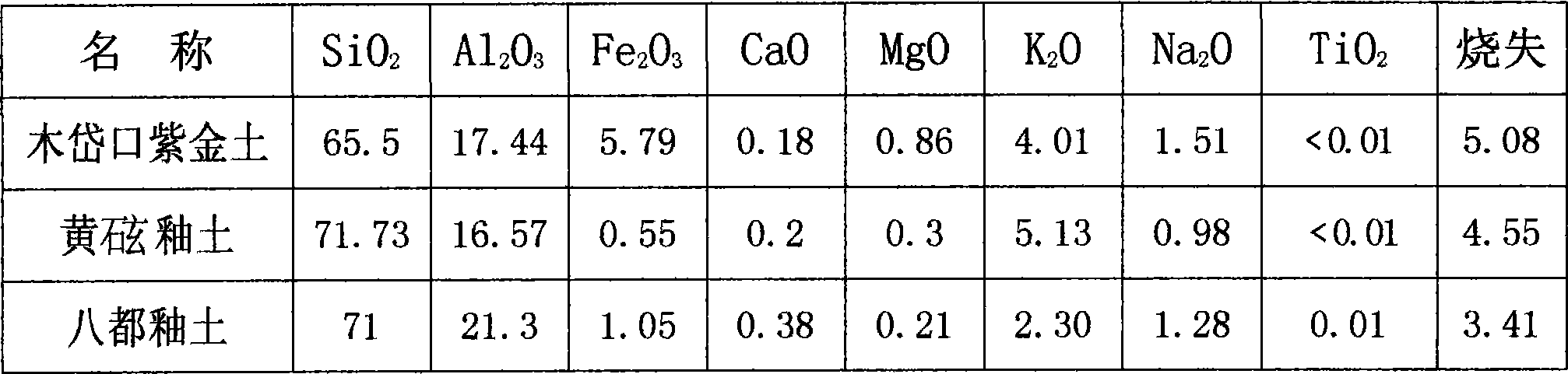

[0016] Embodiment Glaze batching weight percent composition: Mudaikou purple gold soil 12%, yellow Glazed soil 28%, Badu glazed soil 30%, talcum powder 5%, limestone 15%, ferric oxide 10%. All kinds of glazes are finely selected according to the formula requirements and mixed evenly, and then the ratio of ball stone: glaze: water is 1.5:1:0.8, and then put into the grinding equipment to grind into glaze slurry.

[0017] A black-bodied chicken heart bowl is molded from clay, dried and placed in a kiln for 8 hours, then fired slowly over a warm fire until the temperature reaches 830°C, and left to cool naturally for 15 hours before leaving the kiln. After the dust is removed from the biscuit, the glaze is divided into two processes: inner glaze and outer glaze. First, the glaze slurry is adjusted to a water content of 38%. At 1.8 mm; after the inner glaze of the biscuit is finished, the water in the biscuit should be drained, and then the outer glaze of the biscuit should be a...

Embodiment 2

[0020] Embodiment glaze batching weight percent composition: Mudaikou purple gold soil 18%, yellow Glazed soil 14%, Badu glazed soil 20%, talcum powder 8%, limestone 20%, ferric oxide 20%. All kinds of glazes are finely selected according to the formula requirements and mixed evenly, and then the ratio of ball stone: glaze: water is 1.5:1:0.8, and then put into the grinding equipment to grind into glaze slurry.

[0021] A black tire amphorae is molded from clay, dried and placed in a kiln. After 10 hours of biscuit firing, it is slowly fired at a warm fire until the temperature is 860°C, and it is cooled naturally for 20 hours before leaving the kiln. After the dust is removed from the bisque, the glazing of the biscuit is divided into two processes: inner glaze and outer glaze. After the inner glaze of the biscuit is finished, the water of the biscuit should be drained, and then the outer glaze of the biscuit should be applied by dipping the glaze method, and the thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com