Chemico-mechanical polishing liquid

A chemical machinery, polishing liquid technology, applied in other chemical processes, chemical instruments and methods, polishing compositions containing abrasives, etc., to achieve the effects of low growth rate, long storage time, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

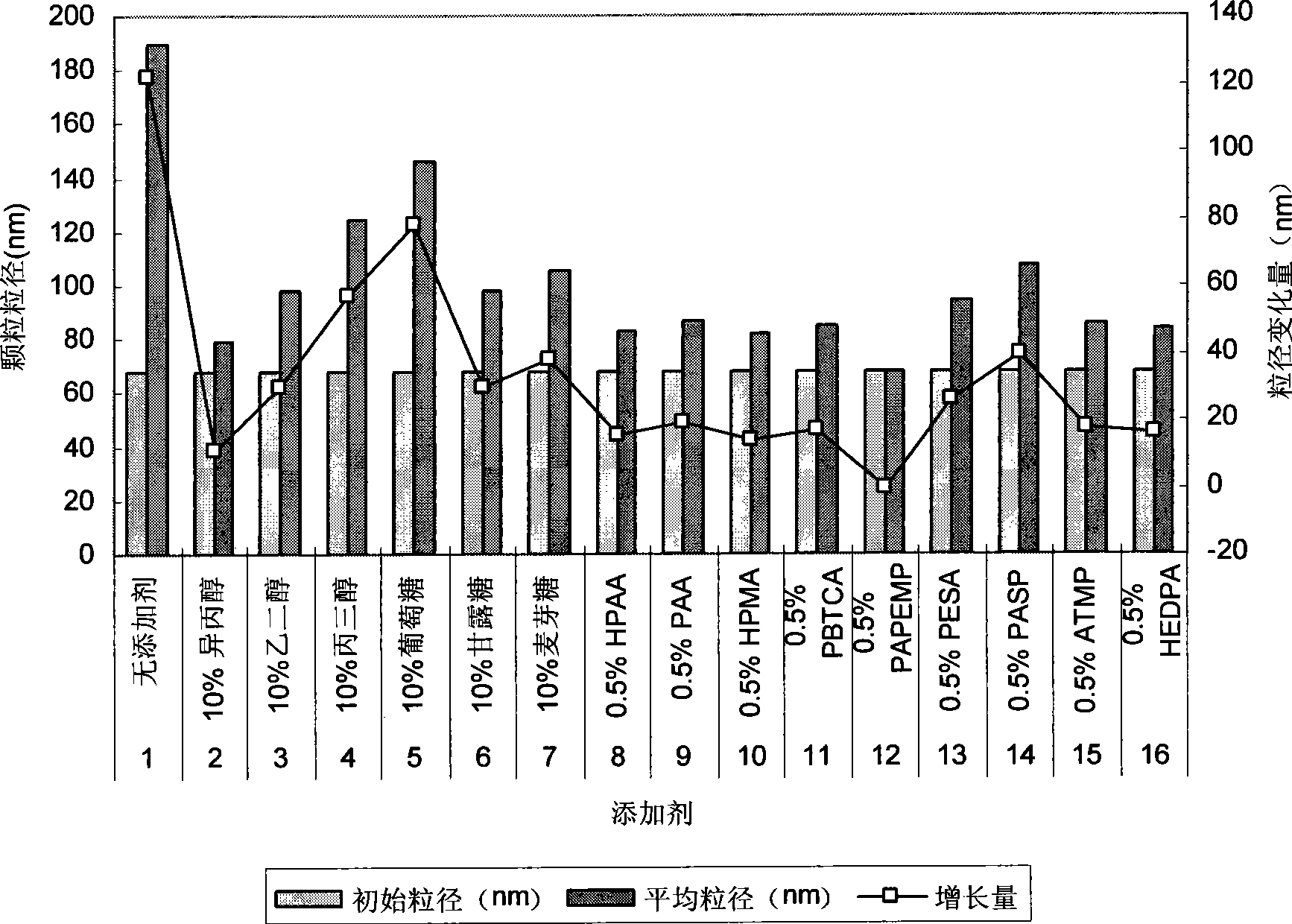

Image

Examples

Embodiment 1~36

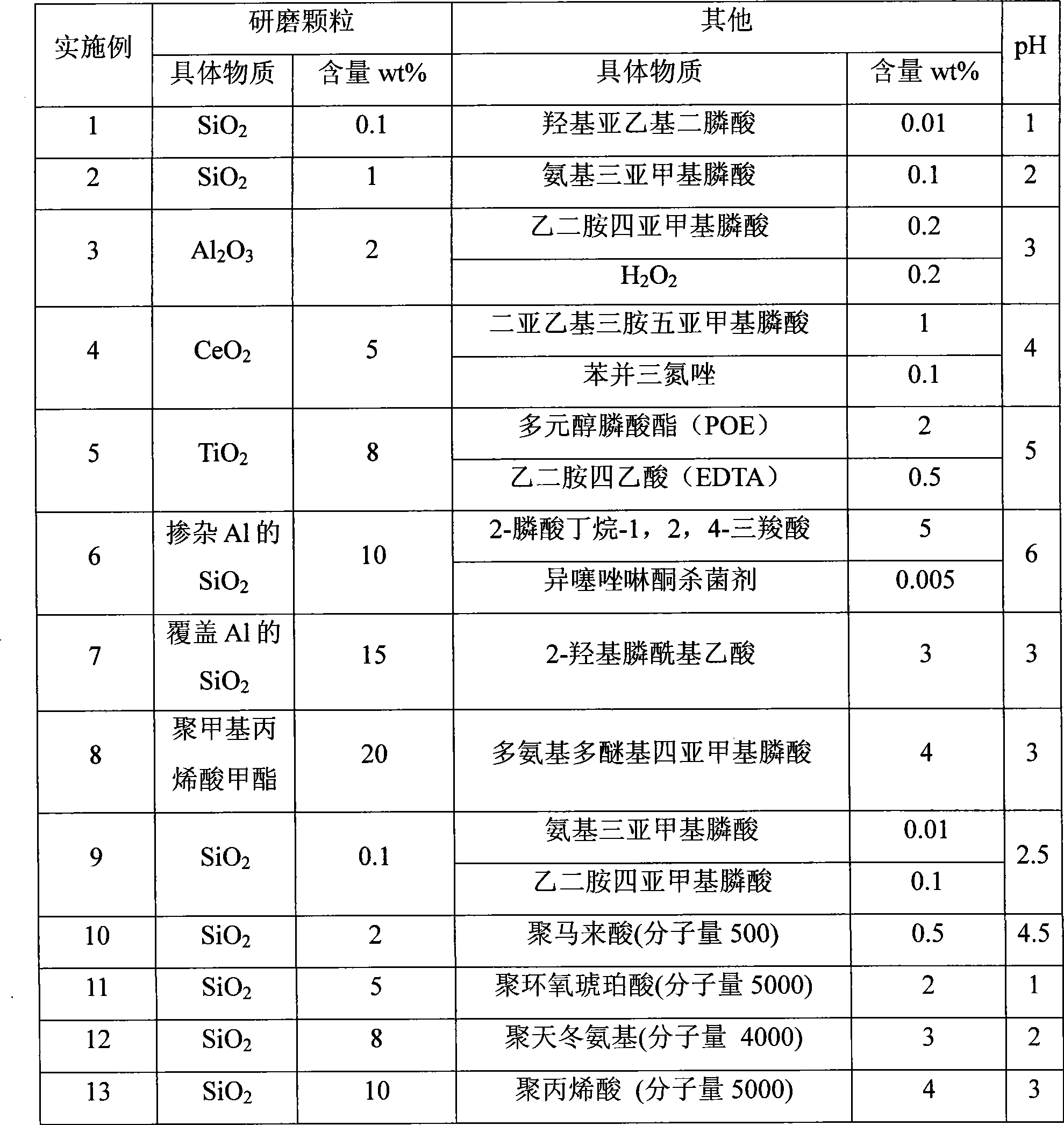

[0018] Table 1 provides the chemical mechanical polishing liquid embodiment 1~36 of the present invention, according to the formula in the table, each component is simply and evenly mixed, and the balance is water, and then adopts potassium hydroxide, ammonia water and nitric acid to adjust to a suitable pH value, The polishing liquid of each embodiment can be prepared.

[0019] Table 1 Chemical mechanical polishing liquid embodiment 1~36 of the present invention

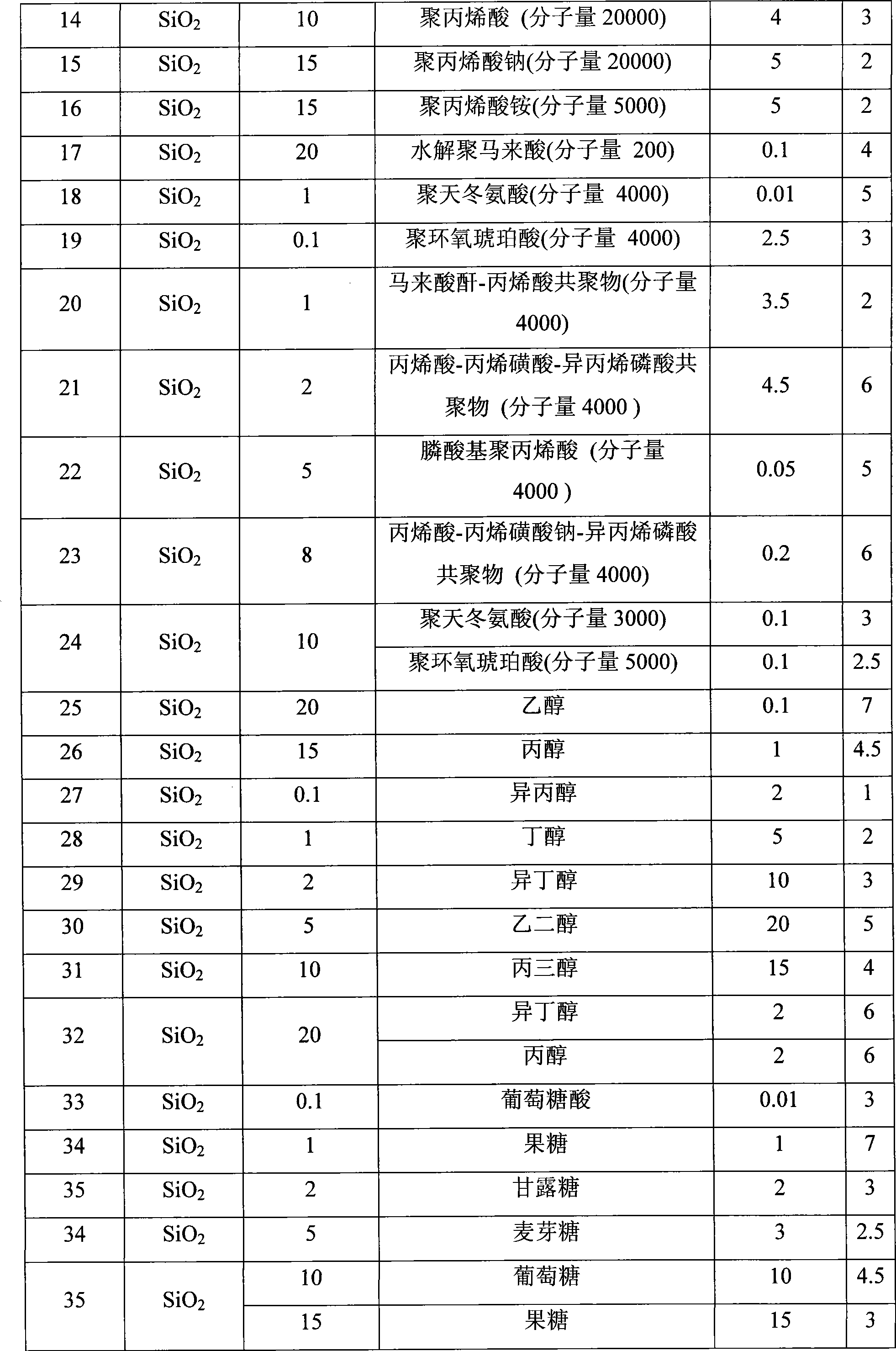

[0020]

[0021]

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com