Prefabricating common concrete outer plate recycled concrete core shear wall and processing method thereof

A technology of ordinary concrete and recycled concrete, applied in the direction of walls, building materials, building components, etc., can solve the problems of difficult disposal of waste concrete and deterioration of the ecological environment, and achieve the effect of ensuring sustainable development and protecting the living environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

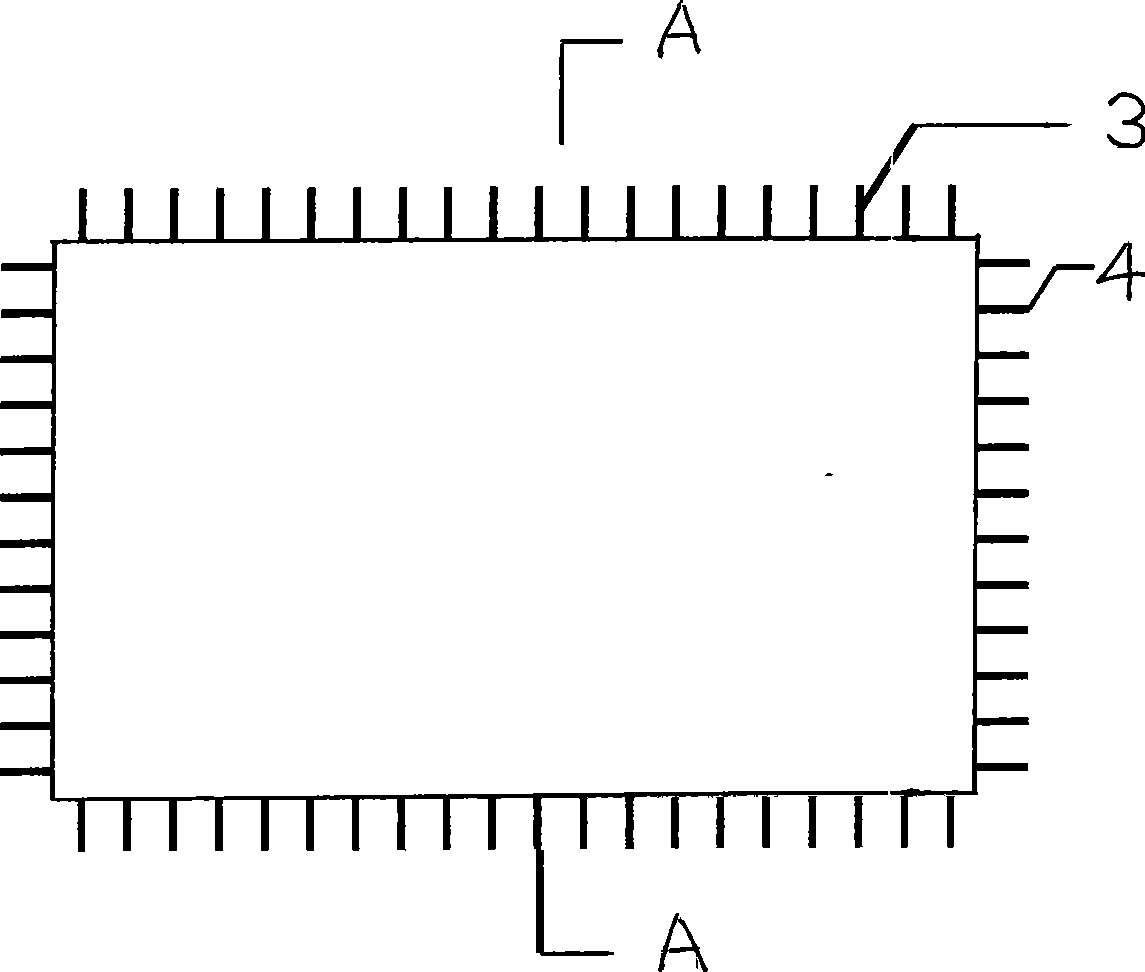

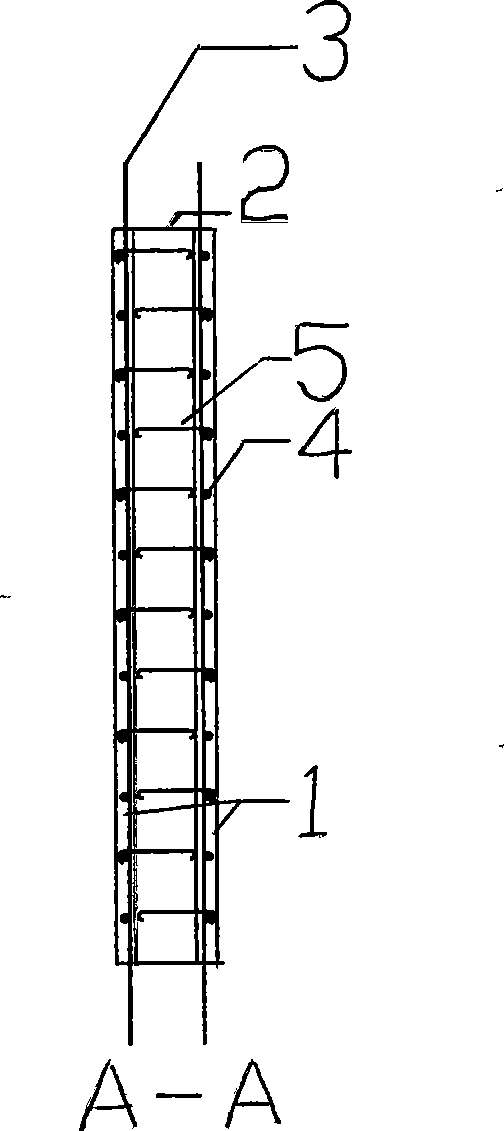

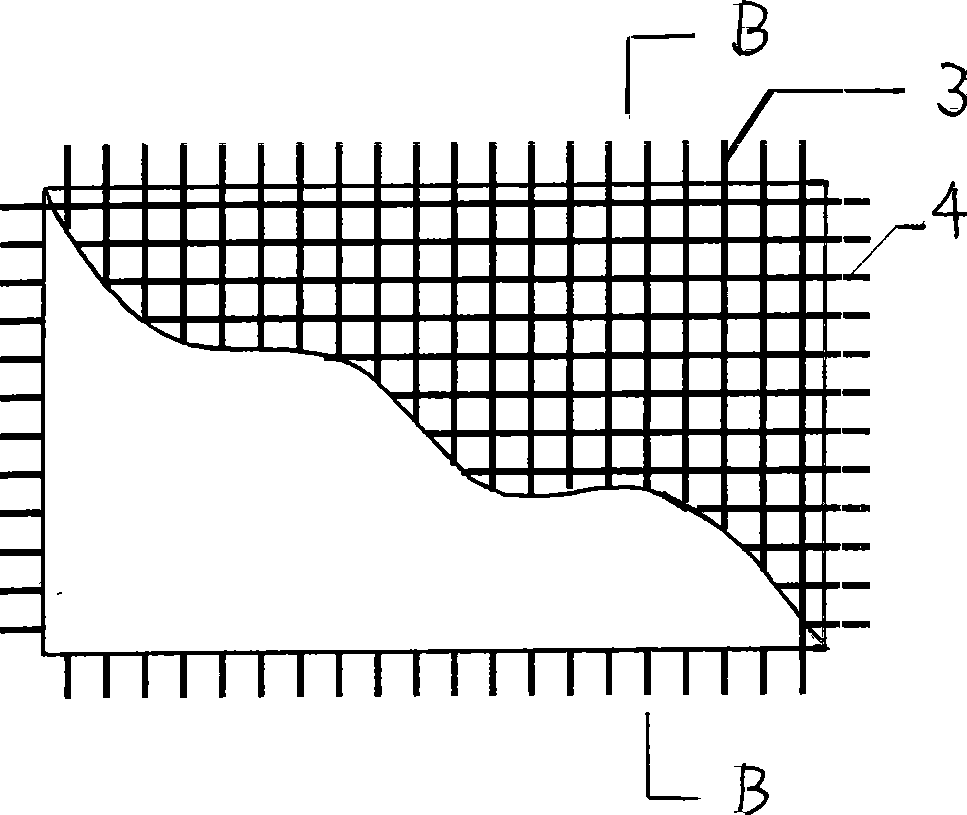

[0021] Embodiment: Prefabricated ordinary concrete outer slab recycled concrete core shear wall, which is superimposed by prefabricated ordinary concrete outer slab 1 and cast-in-place recycled concrete 2, and it prefabricated ordinary concrete outer slab 1 as a formwork for reinforced concrete components during construction, and the middle Cast-in-place recycled concrete 2, combined into one after the completion of the project.

[0022] 1) The ordinary concrete outer panel 1 is made with a steel mold, the thickness is not less than 50mm, and one side is roughened.

[0023] 2) Prepare horizontal 3, vertical steel bars 4 and tie bars 5 according to the current specifications, and the length of the horizontal and vertical bars protruding out of the slab is not less than the anchorage length of the steel bars stipulated in the current "Code for Design of Concrete Structures".

[0024] 3) One end of the tie bar is tied to the steel mesh, and the other end protrudes out of the roug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com