Swivelling circuit board plug-in connector

A technology of printed circuit boards and plug connectors, applied in the structural connection of printed circuits, printed circuit components, circuits, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

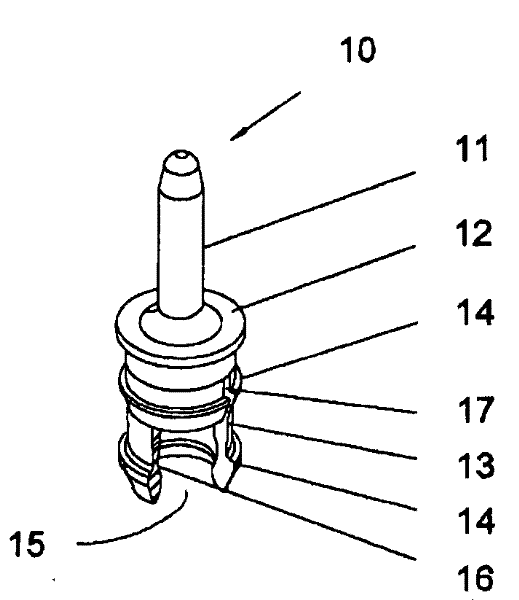

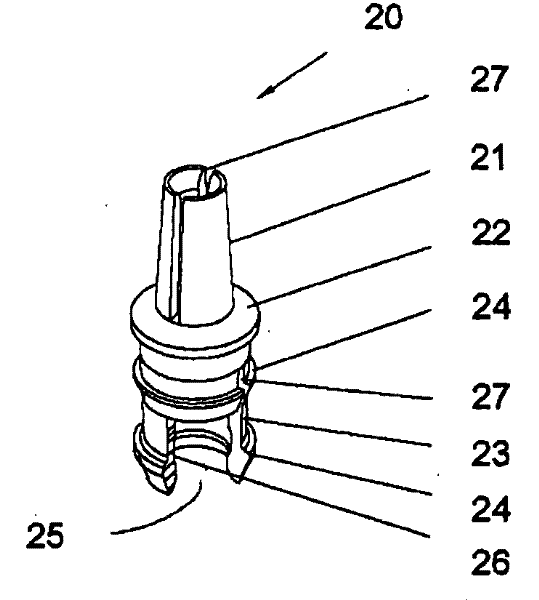

[0038] Figure 1a , 1b shows the inner contacts of a coaxial plug-in module designed as pin contacts and as sleeve contacts, which are constructed almost identically.

[0039] The only difference is that the plug-in side of the sleeve contact 20 has a slotted socket 21 , although in the form of a contact pin, whereas the pin contact 10 has a closed contact pin 11 .

[0040] The plug-in regions of the contact pins 11 and sockets 21 each terminate at a flange 12 , 22 , to which a slotted sleeve part 13 , 23 and radial projections 14 , 24 adjoin.

[0041] In the interior of the sleeve part 13 , 23 there is provided an axial bore 15 , 25 with a spherical recess 16 , 26 , into which a spherical formation 41 of a contact element 40 will subsequently engage during assembly.

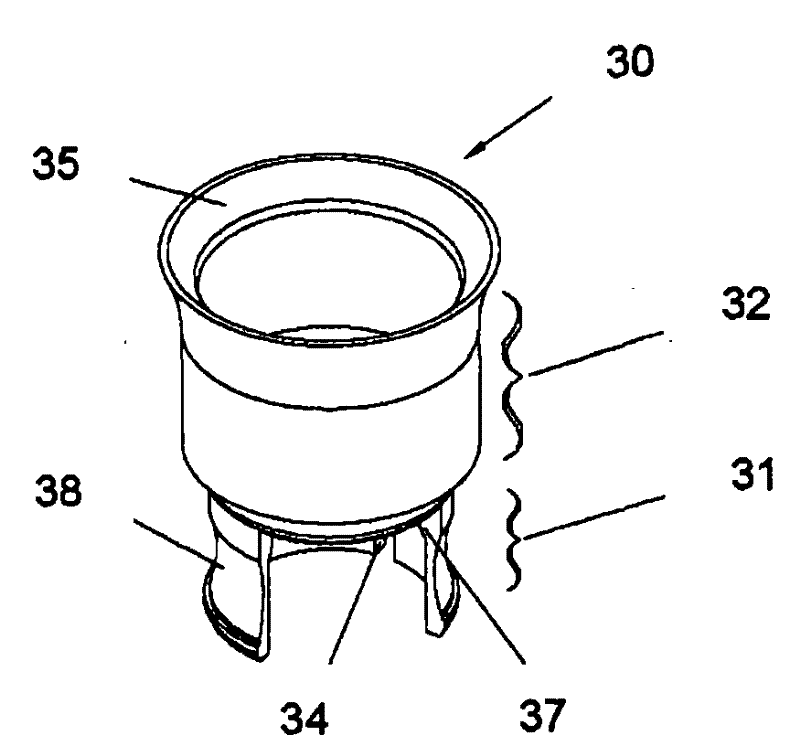

[0042] Figure 2a and Figure 2b Shown are the barrel contacts 30, 30' of the coaxially configured printed circuit board plug connector, which are the outer contacts of the plug-in module.

[0043] here, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com