Traditional Chinese medicine cataplasm cross-feeding medicine-membrane forming device

A poultice and horizontal technology, which is applied in the field of traditional Chinese medicine poultice film forming devices, can solve the problems of uneven thickness of the drug film and difficult removal of air bubbles, and achieves the effect of reducing the height of the equipment, facilitating disassembly and assembly, and convenient and thorough cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

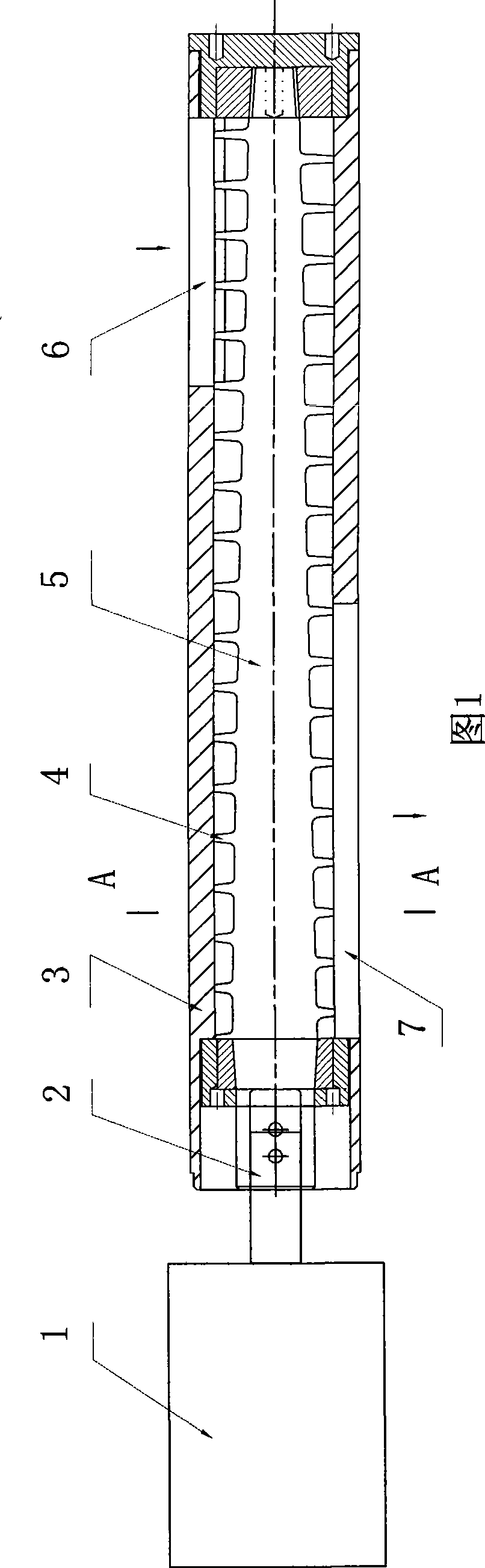

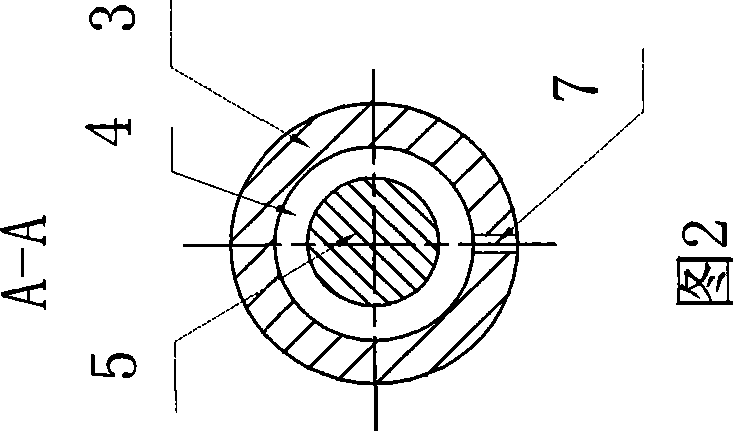

[0011] Description of main parts and details in the drug film forming device of the present invention: 1. Motor, 2. Main shaft, 3. Pump casing, 4. Spiral piece, 5. Pump shaft core, 6. Feed port, 7. Discharge mouth.

[0012] As shown in Fig. 1, the Chinese medicine cataplasm lateral feeding drug film forming device of the present invention comprises a cylindrical pump body shell 3, a main shaft 2 and a screw pump connected with the main shaft 2, and the pump body shell 3 is respectively provided with feeding Inlet 6 and discharge port 7, the pump shaft of the screw pump is set horizontally, and the pump shaft core 5 is provided with a helical piece 4, the pump shaft core 5 is conical, and the helical piece 4 runs through the entire pump shaft On the core 5, thereby forming multi-circle spiral pieces, the outer diameters of each circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com