Device for production of nanofibres through electrostatic spinning of polymer solutions

A polymer solution, electrospinning technology, used in nanotechnology, nanotechnology, fiber processing, etc. for materials and surface science, which can solve the problem of liquid level solidification, inability to maintain a constant height, and inability to uniformly disperse polymer solutions Open and other problems to achieve the effect of preventing the solution from drying out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

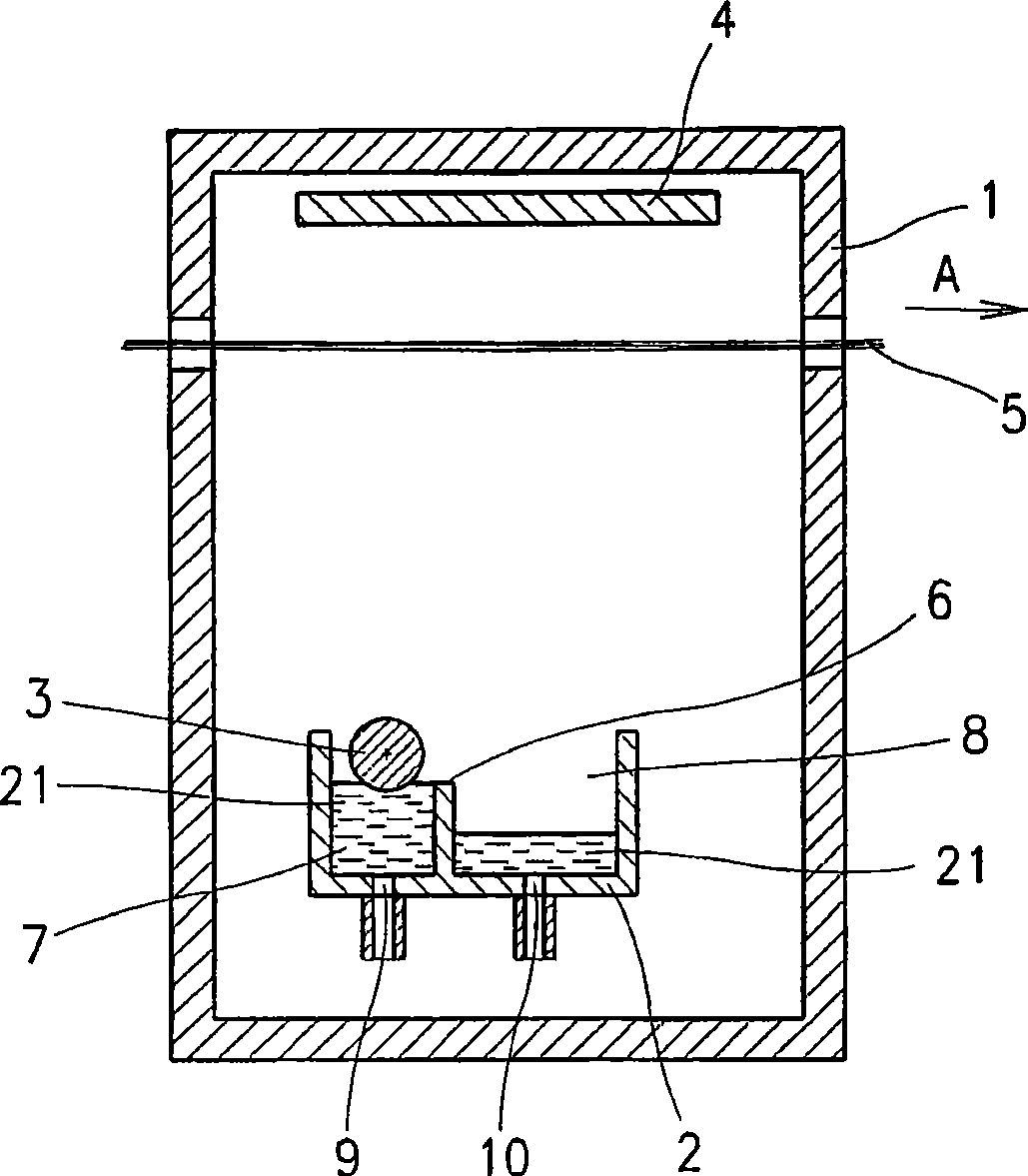

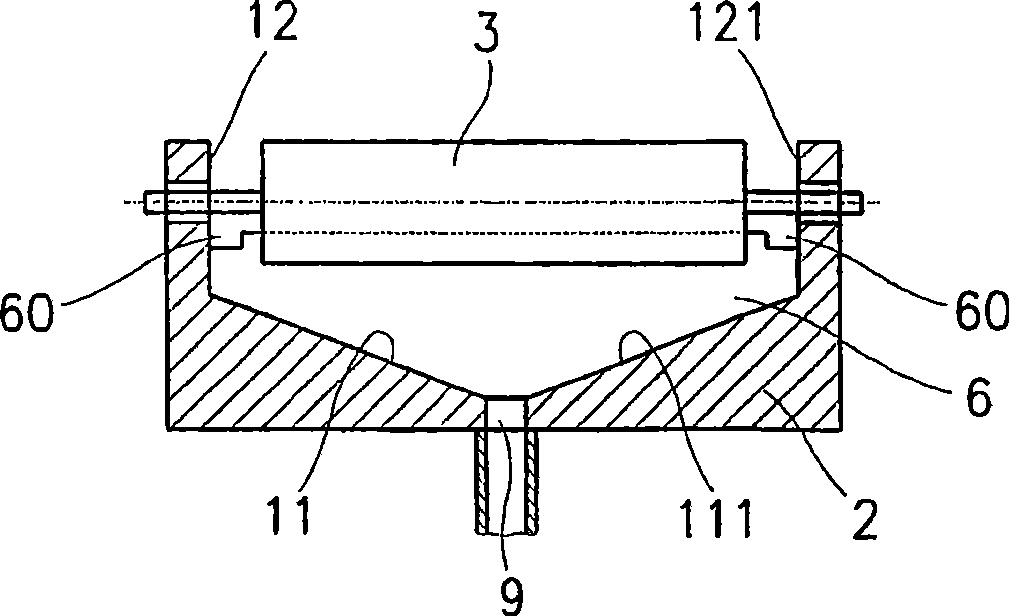

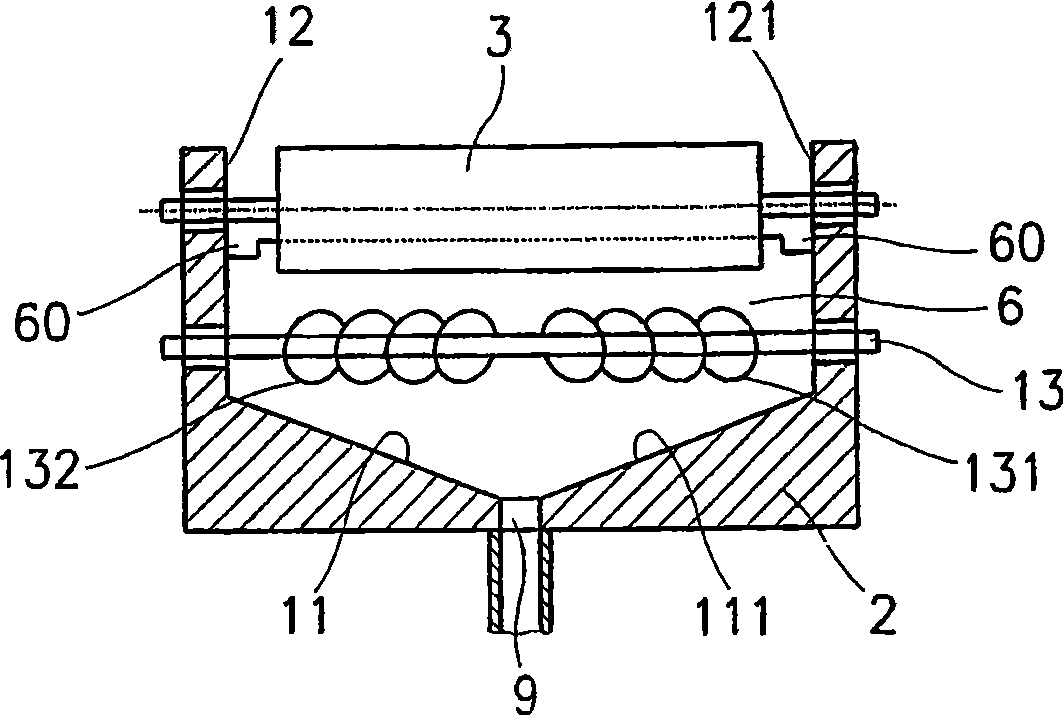

[0020] Below will be in figure 1 In a schematically illustrated embodiment the device according to the invention is described for the production of nanofibers by electrospinning of polymer solutions in an electric field between at least one spinning electrode and a collecting electrode, wherein the at least a spinning electrode is rotatably mounted and is elongate in shape, a portion of the perimeter of the spinning electrode extends into the polymer solution in the polymer solution container, and said collector electrode is positioned against the spinning electrode, Wherein, in the lower part of the spinning chamber 1 of the device for producing nanofibers by electrospinning, there is provided a container 2 containing a polymer solution 21, and a spinning electrode 3 of elongated shape is rotatably mounted in the container 2, part of the surface of the spinning electrode extends into the polymer solution 21 contained in said container 2. The spinning electrode 3 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com