Method for checkinkg temp. sensor and device for controlling transfer torque in motor-driven vehicle

A temperature sensor, motor vehicle technology, applied in the direction of control devices, transportation and packaging, couplings, etc., can solve the problems of pressure loss that cannot be compensated by the return spring, functional failure, etc., and achieve the effect of high clutch operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

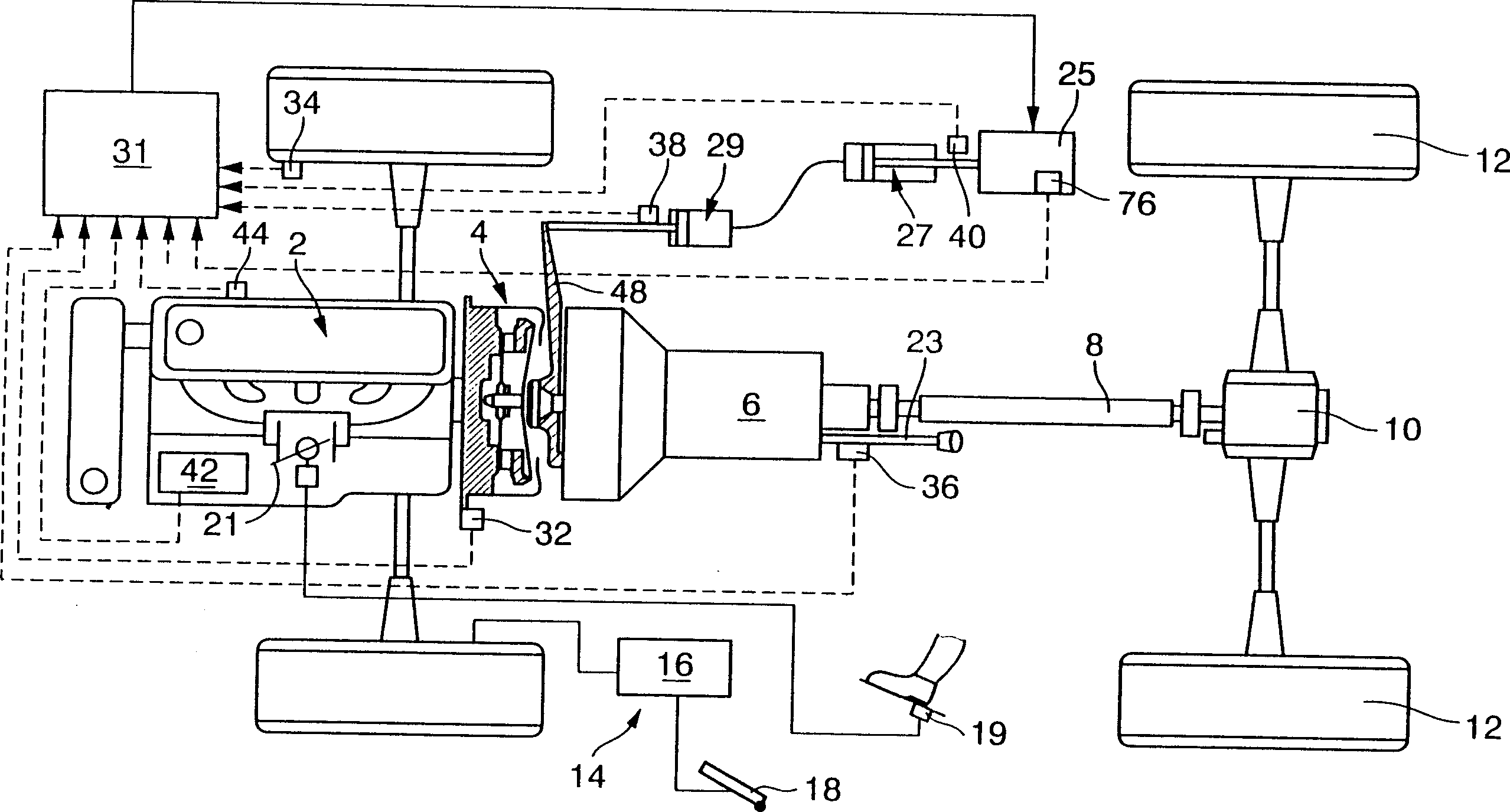

[0027] according to figure 1 , a motor vehicle has an engine, such as an internal combustion engine 2, which is connected via a clutch 4 to a transmission, such as a shift gearbox 6, which drives the rear wheels 12 via a cardan shaft 8 and a differential 10. For braking the motor vehicle, a brake device 14 is provided with a brake mechanism 16 which is actuated via a brake pedal 18 . Only the connection from the brake mechanism 16 to the left front wheel has been described here. It can be understood that the braking mechanism 16 cooperates with all the wheels of the motor vehicle.

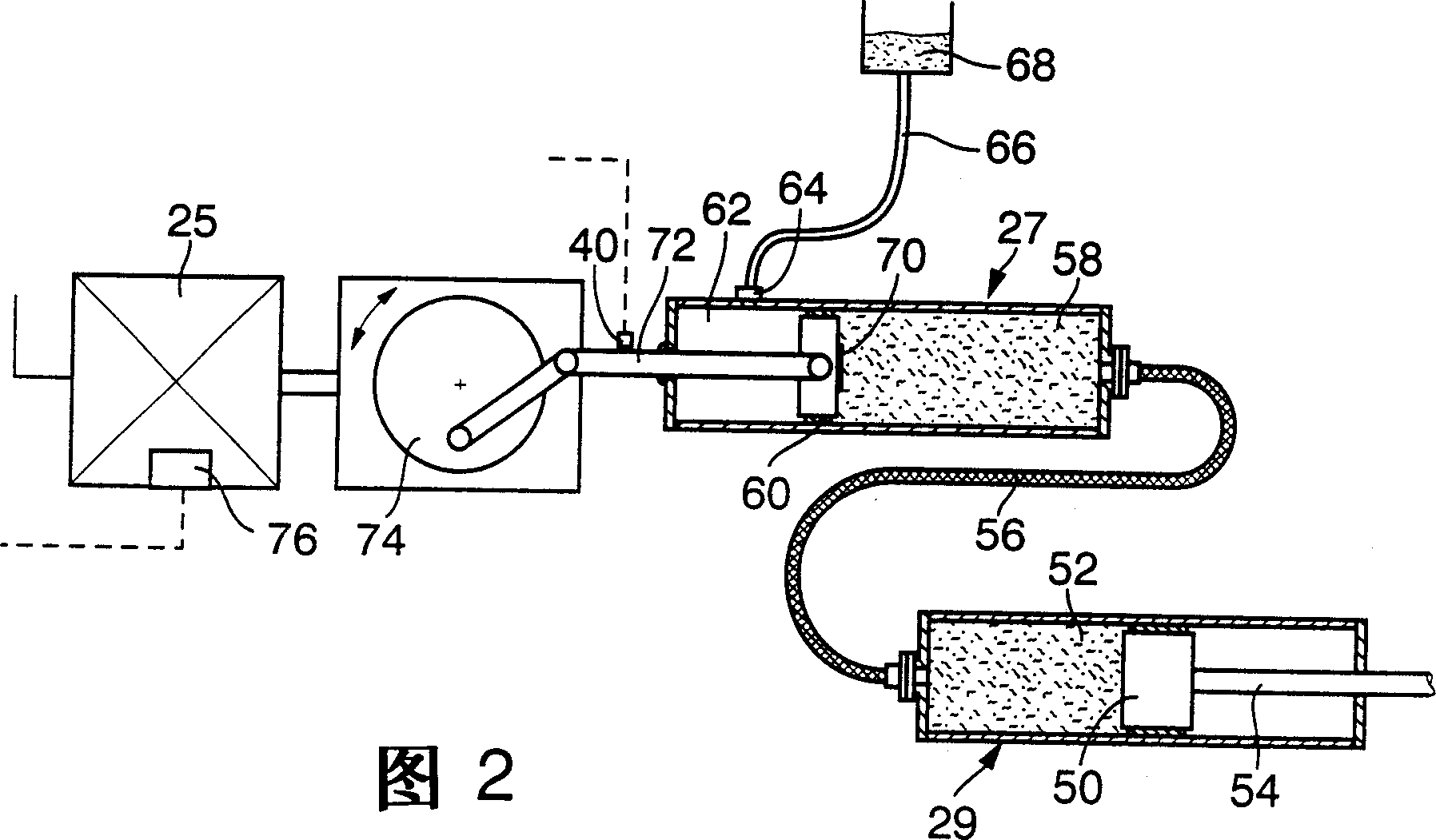

[0028]To control the load on internal combustion engine 2 , a driver pedal 19 is provided, which actuates a throttle valve 21 . The gearbox 6 is shifted by means of a selector lever 23 . The clutch 4 is set automatically and is actuated by an operating unit such as a reactor 25 via a sending cylinder 27 and a receiving cylinder 29 . The reactor 25 is controlled by a control unit such as an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com