Sewage settling pond

A sedimentation tank and sewage technology, applied in the sedimentation tank and other directions, can solve the problems of slow sedimentation and long cleaning cycle of natural sedimentation, and achieve the effect of easy cleaning, simple and convenient operation and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

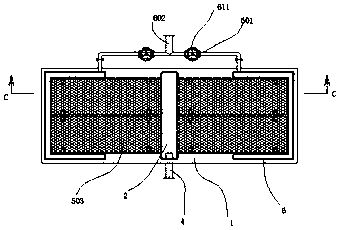

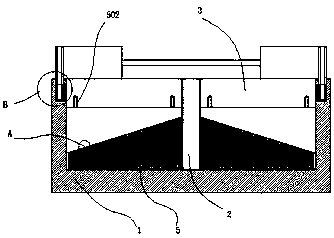

[0042] refer to Figure 1 to Figure 9 The shown sewage sedimentation tank includes a pool body 1 formed by pouring concrete, and a channel 2 is poured at the central position of the pool body 1, and the pool body 1 forms left and right sides under the separation of the channel 2. Two sedimentation chambers 3 that are not connected to each other are provided with overflow tanks 201 on the left and right sides of the channel 2. When the water level in the sedimentation tank 3 reaches the position of the overflow tank 201, it overflows into the channel 2. An outlet pipe 4 is embedded in the passage 2, and the outlet pipe 4 penetrates to the outside of the pool body 1. The height of the outlet pipe 4 is lower than the height of the overflow tank 201, and the overflow tank 201 V-shaped overflow outlets 211 are evenly distributed on the bottom of the tank, and more than one intercepting device 5 is arranged in each of the settling chambers 3;

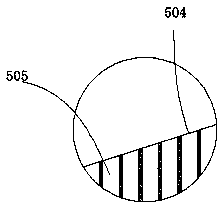

[0043] Interception device 5 comprise...

Embodiment 2

[0046] refer to Figure 10~12 As shown, an L-shaped baffle plate 212 is welded at the inner left and right end faces of the passage 2, and the front and rear ends of the baffle plate 212 are welded with the inner front and rear end faces of the passage 2 to form a seal. A transition cavity 213 is formed on the inner side of the overflow tank 201, and the sewage entering from the overflow tank 201 flows into the interior of the channel 2 after passing through the transition cavity 213. A connection between the two channels is welded at the rear end of the channel 2. The U-shaped pipe 214 of the transition cavity 213, the U-shaped pipe 214 passes through the pool body 1, and the first connecting pipe 215 is welded on the outside of the U-shaped pipe 214, and the first connecting pipe 215 is installed with a second A ball valve 216, a cleaning pipe 217 is welded at the rear end of the channel 2, the cleaning pipe 217 extends to the outside of the pool body 1, and an end cap 218 i...

Embodiment 3

[0048] refer to Figure 13 As shown, slots 301 are provided at the front and rear inner walls of the precipitation chamber 3, the slots 301 extend downwards into the base 501, and a partition 302 is inserted in the slots 301, After the partition 302 is inserted, there is a gap of 5 cm to 20 cm between the bottom of the partition 302 and the upper surface of the interception plate 503, the lower end of the slot 301 is closed, and the upper end penetrates the pool upwards. Body 1, after the partition 302 is inserted, the height of the upper end surface of the partition 302 is higher than the height of the bottom of the overflow tank 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com