Machine tool horizontal lead screw oil lift device

A support device and hydraulic support technology, which is applied in the field of machine tools, can solve problems such as vibration, too long screw, large screw sagging deflection, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to facilitate understanding of the content of the present invention.

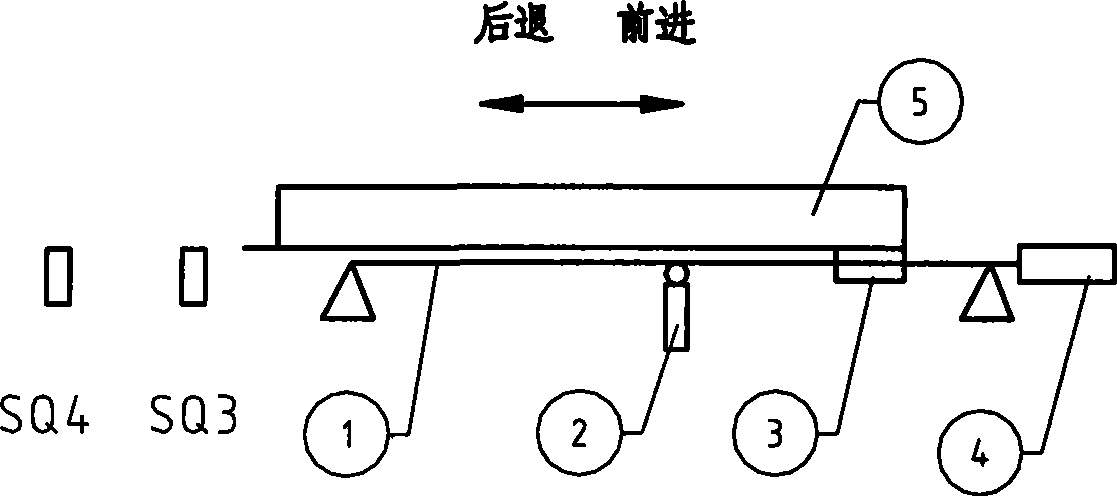

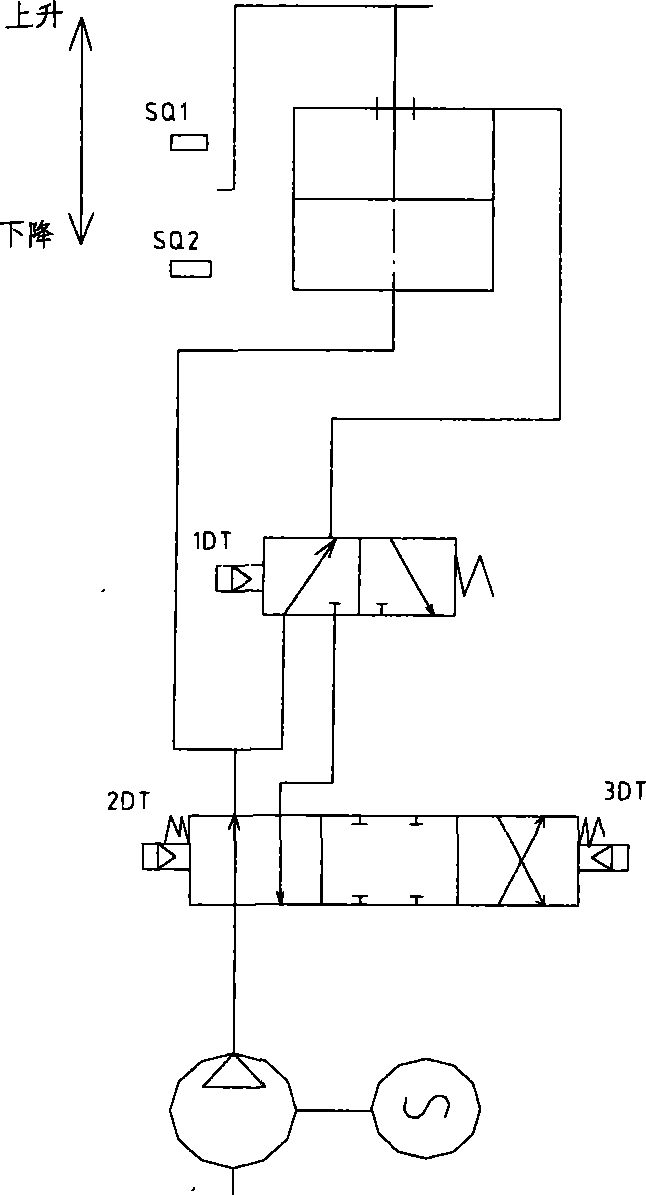

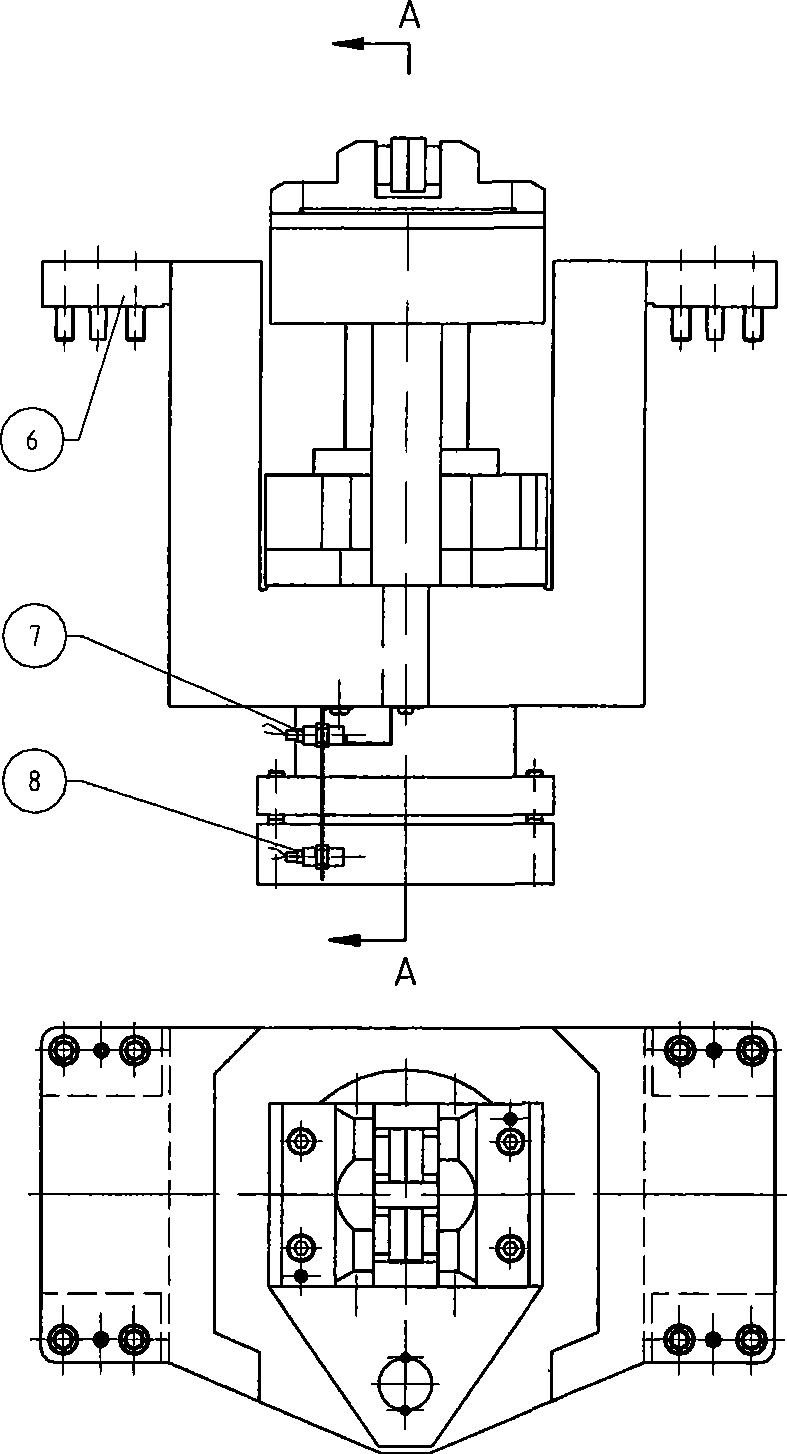

[0013] exist figure 1 , figure 2 , image 3 , Figure 4 During the process, the workbench 5 moves backward, the solenoid valve 1DT and the solenoid valve 2DT are energized, the solenoid valve 3DT is de-energized, the piston 18 and the piston rod 15 of the hydraulic support device 2 rise, and drive the supporting plate 12 and the bracket 10 to make the rollers 9 is in contact with the horizontal screw rod 1 (when the screw rod rotates, it drives the roller to rotate to avoid sliding friction), the lower part of the bracket 10 is equipped with an adjustment pad 11, the lower end of the supporting plate 12 is fixed with a guide rod 13, and the supporting plate 12 is fixed by the mounting bracket 6 , the lower end of the guide rod 13 is connected with the guide sleeve 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com