Series parallel movement polisher with six freedom degrees

A degree of freedom, polishing machine technology, applied in the field of polishing machines, can solve the problems of expensive robots, low efficiency, harm to the human body, etc., to achieve the effect of unmanned operation and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

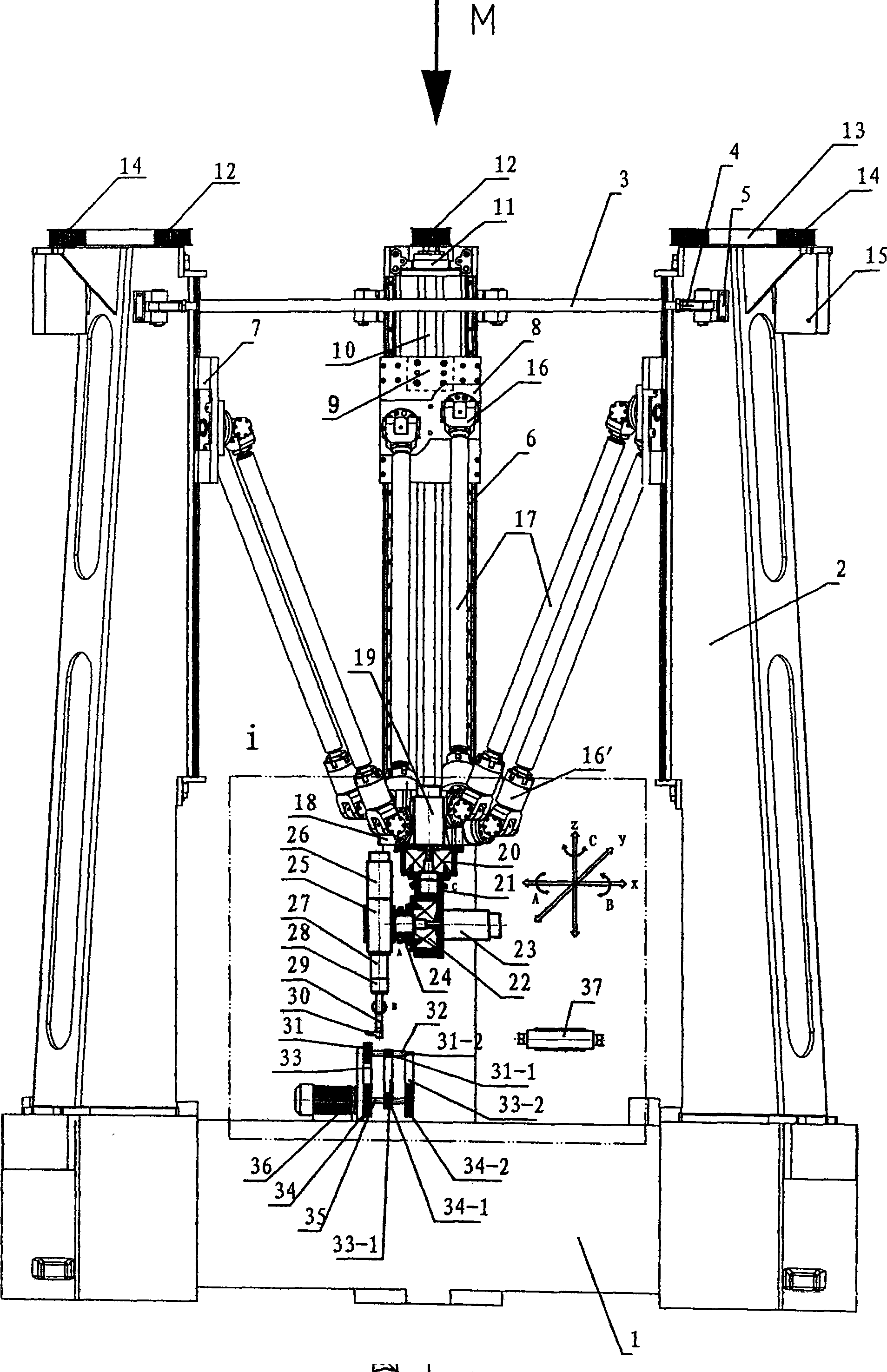

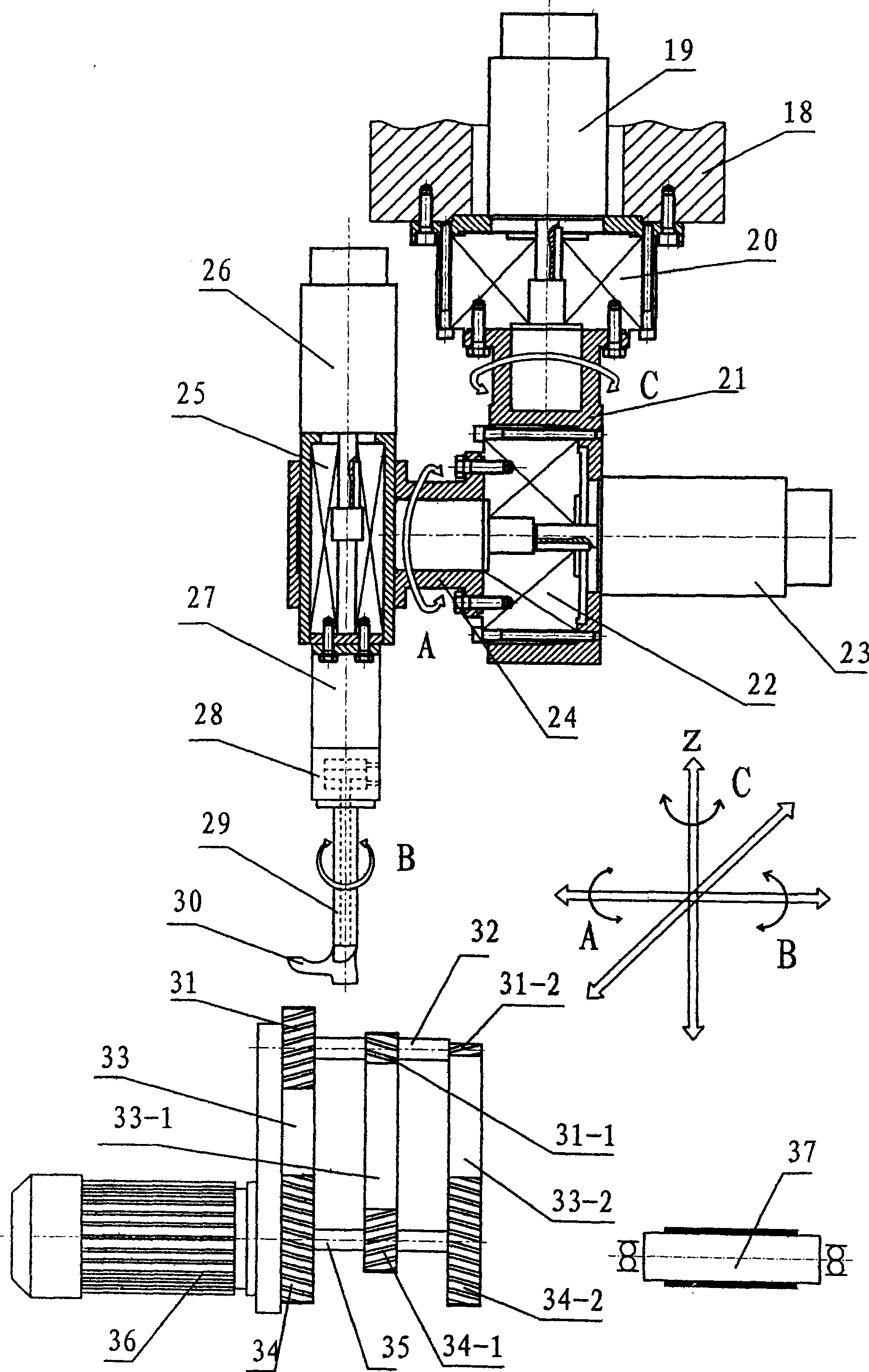

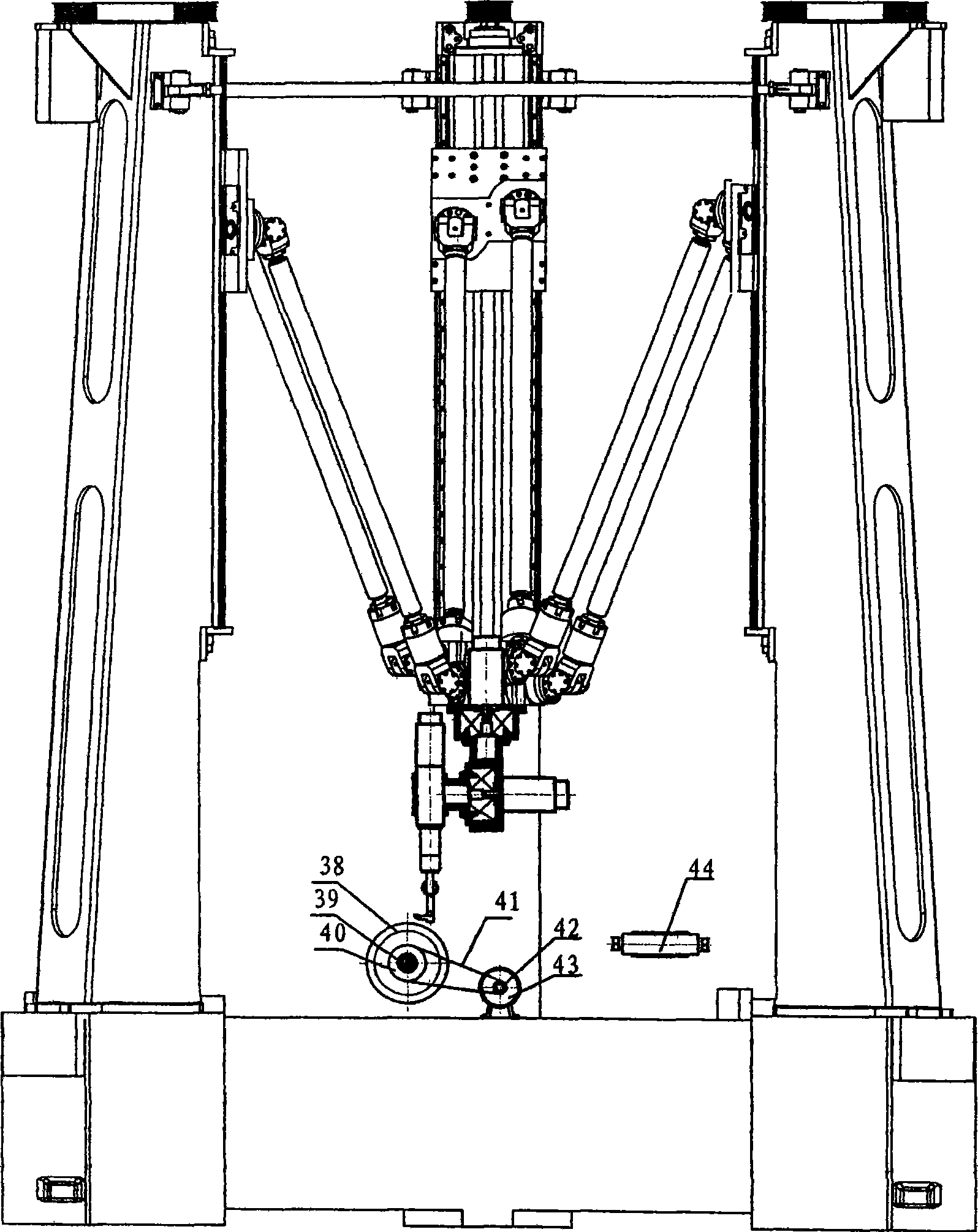

[0017] The present invention will be further described below in conjunction with the accompanying drawings, and the present invention is relatively clear to those skilled in the art.

[0018] See attached Figure 1-4 , the present invention is on the base 1 of the polishing machine, press Figure 4 A column 2 is respectively arranged at the apex of the equilateral triangle, and the lower end of each column 2 is fixed on the base 1 with screws, and the upper ends of the outer surfaces of the three columns 2 are connected with three horizontal tie rods by using a ball joint bearing 4 and a bearing seat 5. 3. Three pull rods 3 tighten the three uprights 2 in an equilateral triangle;

[0019] The inner surface of the column 2 is provided with two linear rolling guide rails 6 along the longitudinal direction, and one end surface of the four guide rail auxiliary sliders 7 is fixed on the slide plate 8 to form a rectangle, and the other ends of the four guide rail auxiliary sliders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com