Three-arm buttjunction module flat lattice type self-reorganization robot

A docking module and self-reconfiguration technology, applied in the direction of claw arms, joints, manipulators, etc., can solve the problems of high power consumption, no invention, and high cost of memory alloys, and achieve a compact internal structure, easy to implement, and convenient and firm docking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

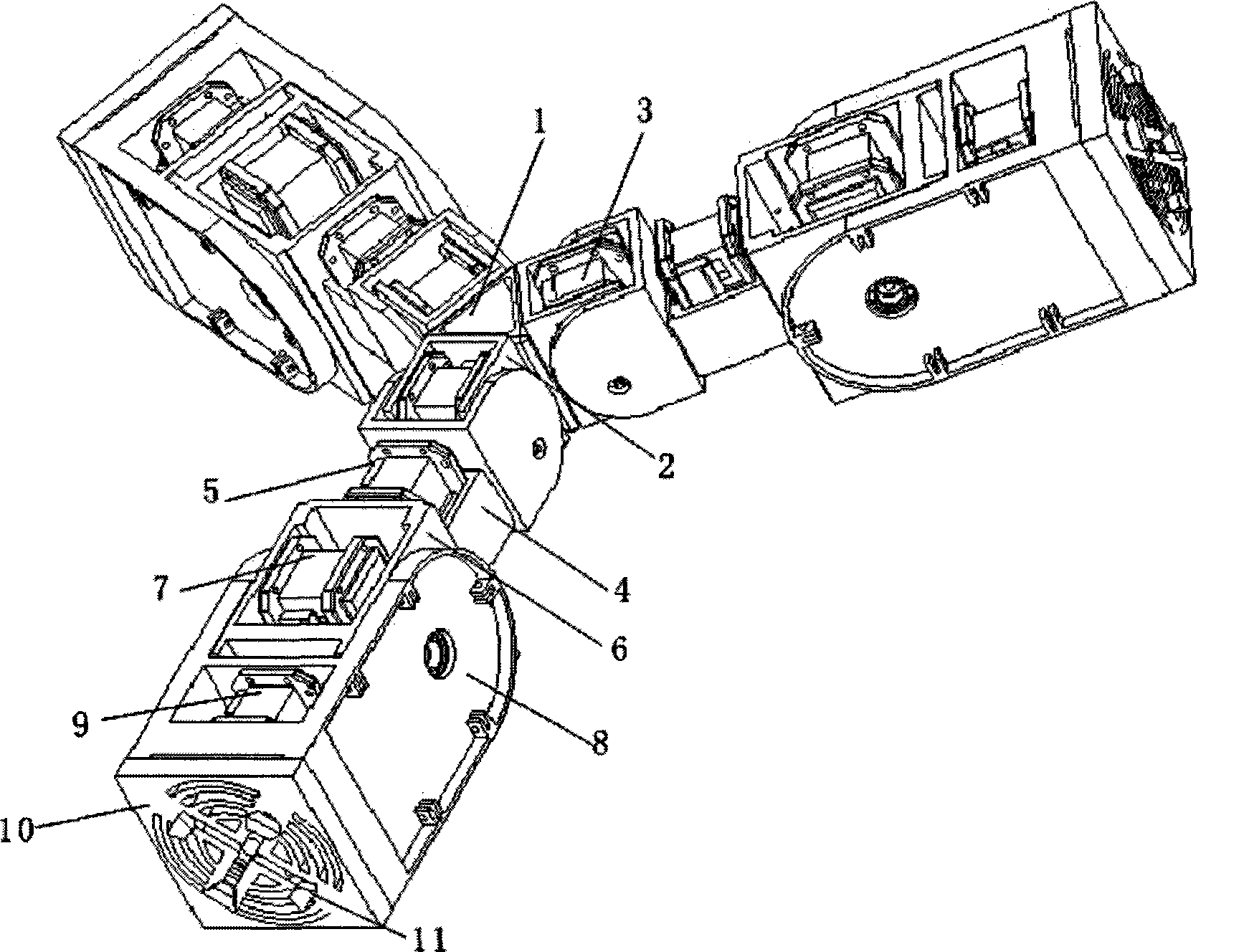

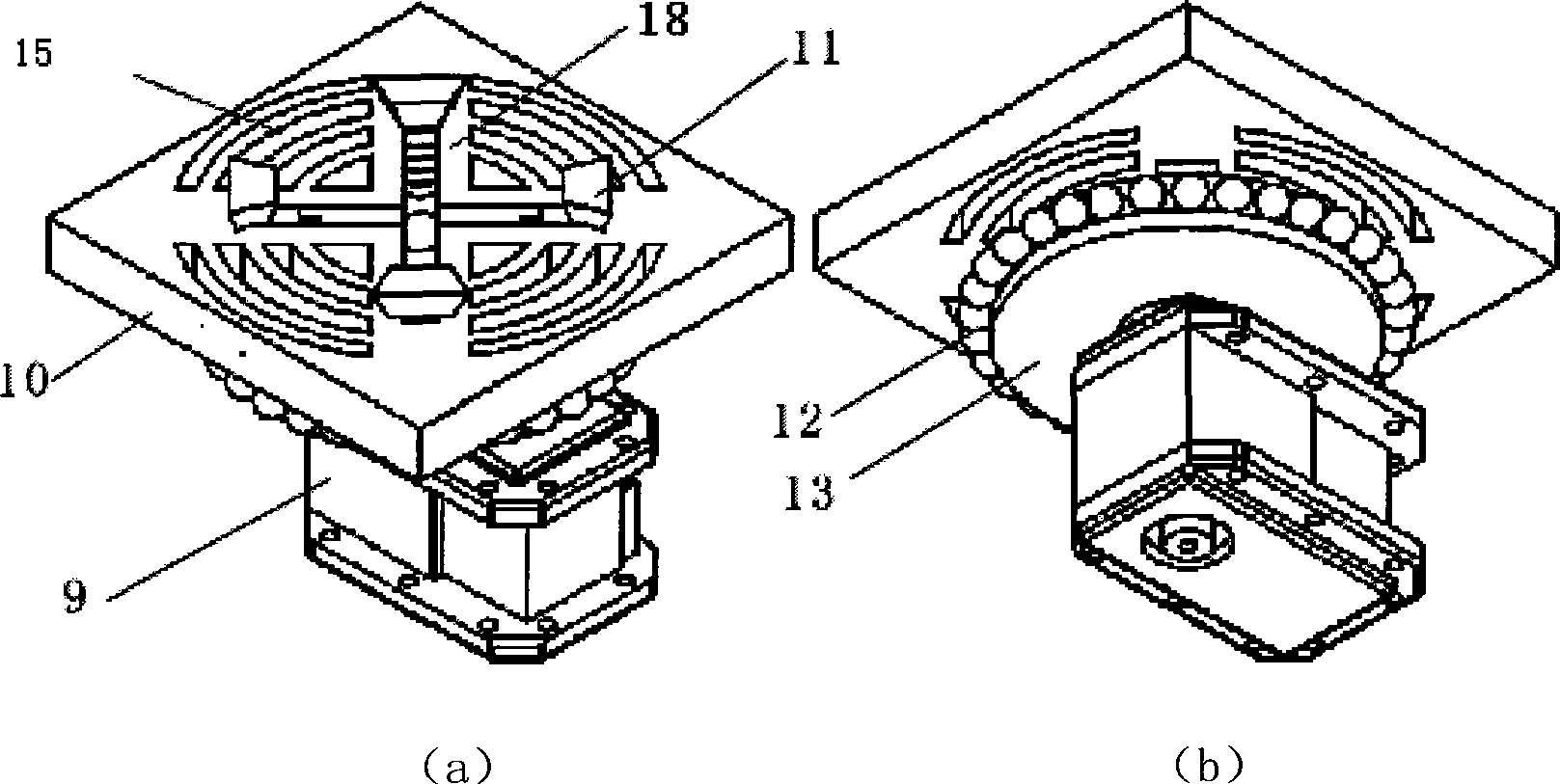

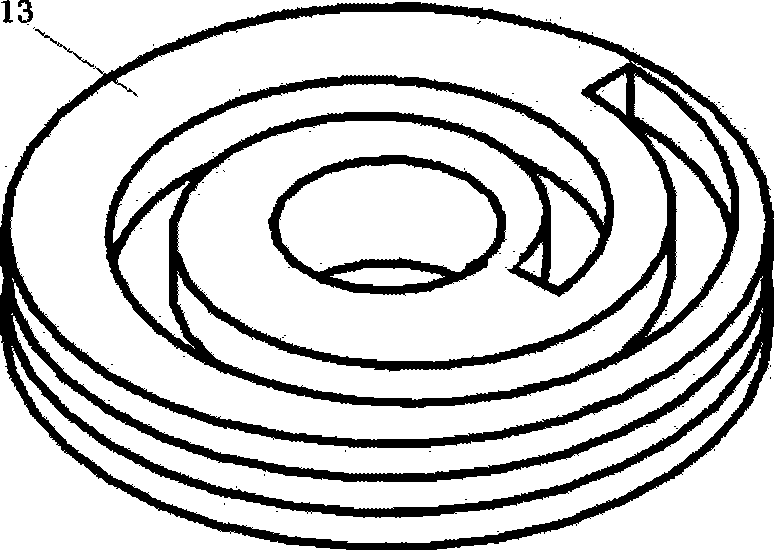

[0025] Such as figure 1 , 2As shown, this embodiment includes: a central frame body 1 and several docking single arms, wherein the central frame body 1 is an equilateral triangular prism, each side of the equilateral triangular prism is fixedly connected with a docking single arm respectively, and each The docking single arm includes: the first inner frame 2, the first turning motor 3, the middle frame 4, the rotating motor 5, the second inner frame 6, the second turning motor 7, the outer frame 8, the docking surface device, the first inner frame The frame 2 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com