Cover locking device

A technology for locking devices and locking components, which is applied to washing devices, building locks, locks operated by non-mechanical transmission, etc., can solve the problems of overcurrent flowing through the motor, abnormal heating, and failure to miniaturize the motor, so as to prevent resonance and reduce The effect of small drive loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

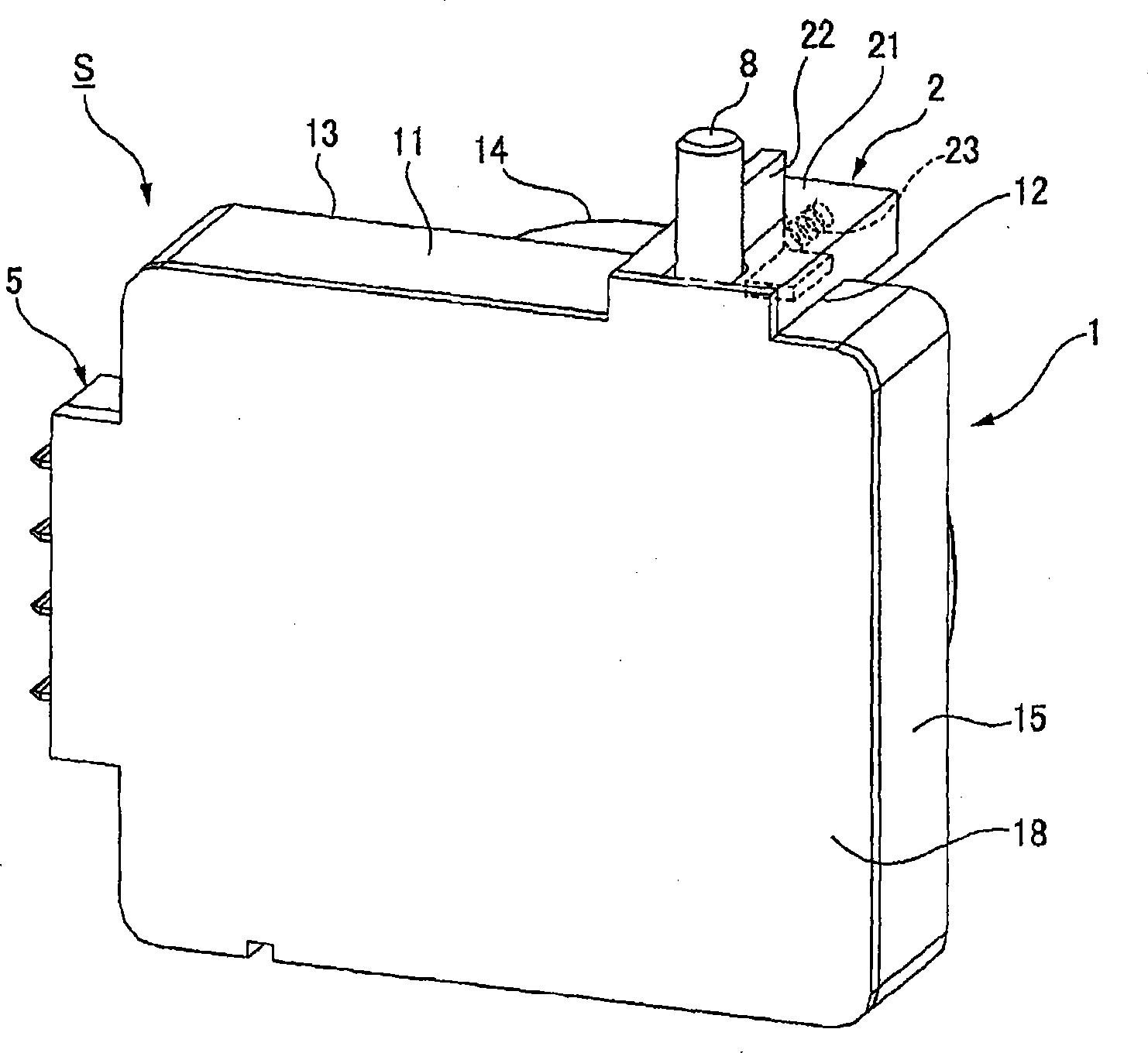

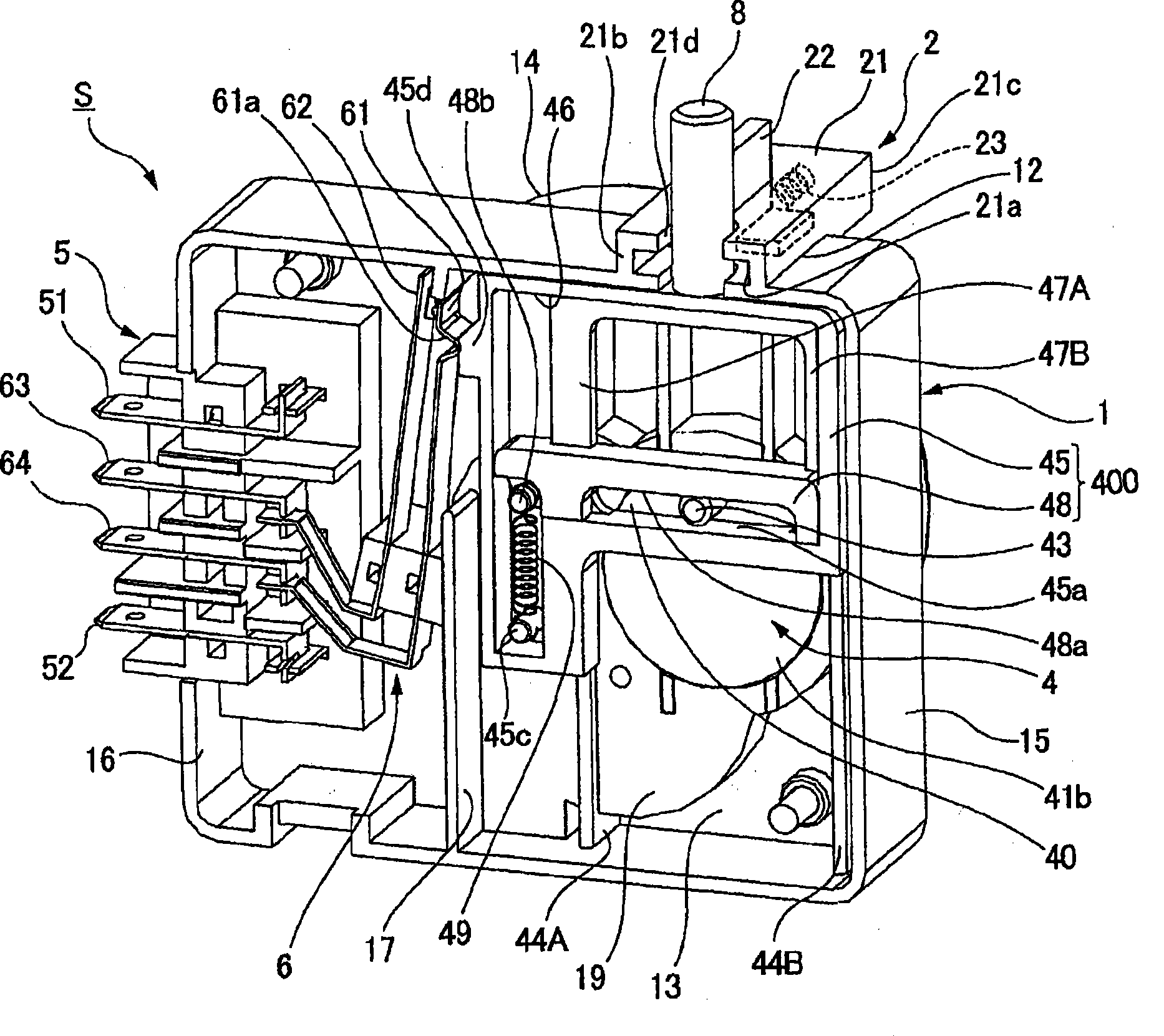

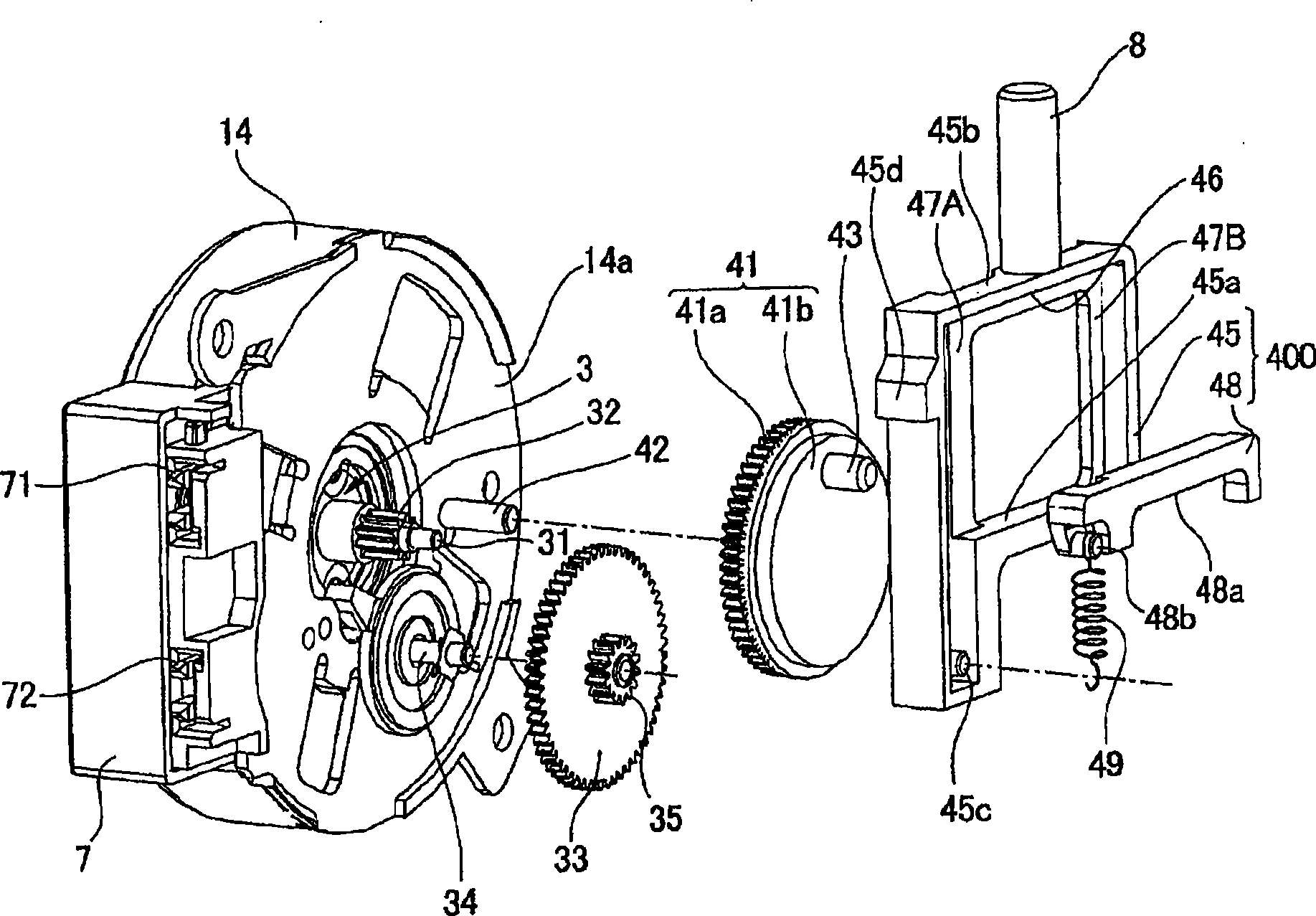

[0057] Next, an embodiment of the lid lock device to which the present invention is applied will be described with reference to the drawings.

[0058] figure 1 is a perspective view of the lid locking mechanism, figure 2 It is a perspective view of the cover locking device omitting the end plate of the case,

[0059] image 3 It is an exploded perspective view of the drive unit including the motor, Figure 4 It is an explanatory diagram of the operation of the cover locking device,

[0060] Figure 5 It is an explanatory diagram of a device with a cover lock installed.

[0061] (Structure of cover lock mechanism)

[0062] like figure 1 , figure 2 As shown, the lid locking device S includes a thin, substantially cuboid housing 1 . An opening 12 serving as a passage for a lock pin 8 , which is a lock member, is formed on a side surface (long side surface) 11 of the case 1 . The shutter mechanism 2 for opening or closing the passage of the lock pin 8 is provided in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com