Automatic lubrication apparatus

A paper shredder and machine core technology, applied in mechanical equipment, transmission parts, components with teeth, etc., to achieve the effect of easy operation and prevention of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

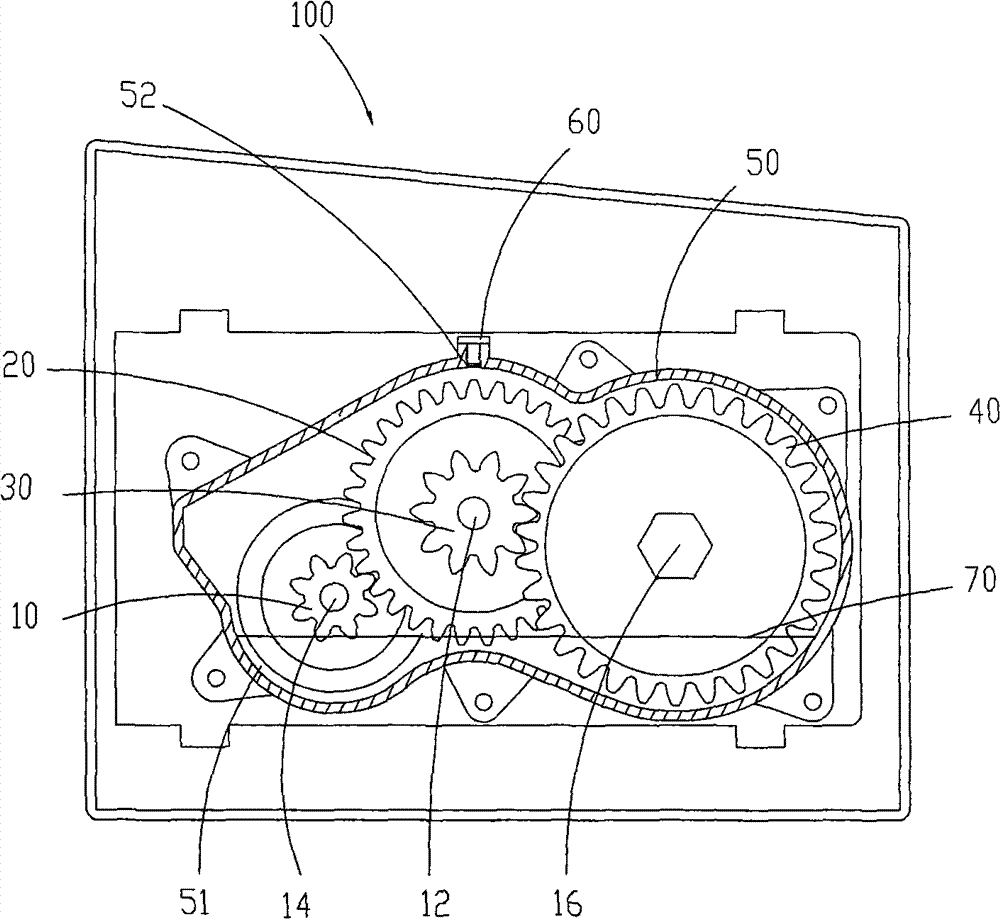

[0012] Such as figure 1 As shown, as an embodiment of the paper shredder of the present invention, the paper shredder 100 includes a first gear 10 , a second gear 20 , a third gear 30 and a fourth gear 40 . The automatic lubricating device includes a gear box body 50 and a sealing member 60 .

[0013] The first gear 10 is meshed with the second gear 20, the third gear 30 is meshed with the fourth gear 40, the second gear 20 and the third gear 30 are arranged on the same rotating shaft 12, the first gear 10 is connected to a motor (not shown), The second gear 20 and the fourth gear 40 are respectively connected with two sets of blades (not shown) in the paper shredder 100 .

[0014] The gear case 50 is a hollow case with an oil tank 51 formed at the bottom thereof, and the first gear 10 , the second gear 20 , the third gear 30 and the fourth gear 40 are all arranged in the gear case 50 . The outer casing of the gear case 50 is also provided with a filler port 52, which is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com