Energy-saving method for middle storage type coal mill

A coal mill and warehouse-type technology, which is applied in the direction of combustion methods, block/powder fuel preparation, combustion equipment, etc., can solve problems such as large time lag, waste of electric energy, and automatic control systems that cannot be optimally controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

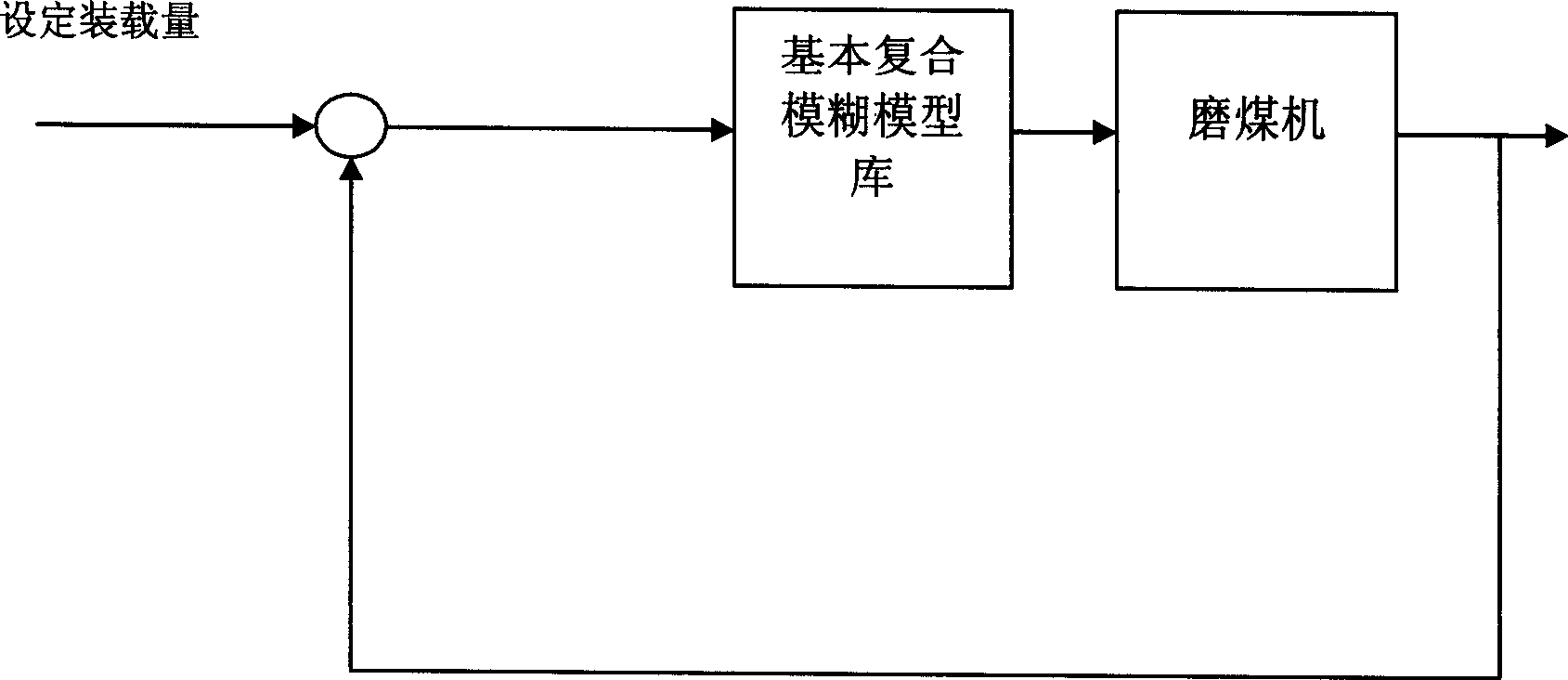

[0006] 1. The present invention uses an intelligent control method to optimize the optimal load of steel balls to achieve the optimal load of steel balls, thereby realizing the energy saving of the coal mill.

[0007] 2. The steel ball loading amount referred to in the present invention is the optimal loading amount, which is given by the fuzzy controller and realized by the real-time action of the actuator.

[0008] 3. The mechanical structure of the executive mechanism referred to in the present invention is the steel ball real-time loading and unloading channel provided by the coal mill.

[0009] 4. The control structure of the actuator referred to in the present invention is that the loading and unloading channel is provided with an excitation device and an excitation control device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com