Test device for turbulent flow gas-liquid blending flow field in transverse flow

A testing device and gas-liquid technology, which are applied in the field of turbulent gas-liquid mixing flow field testing devices in cross flow, can solve the problems of affecting PIV shooting and difficult shooting of flow field distribution, and achieve the effects of compact structure, easy operation and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with example and accompanying drawing, the present invention is further described.

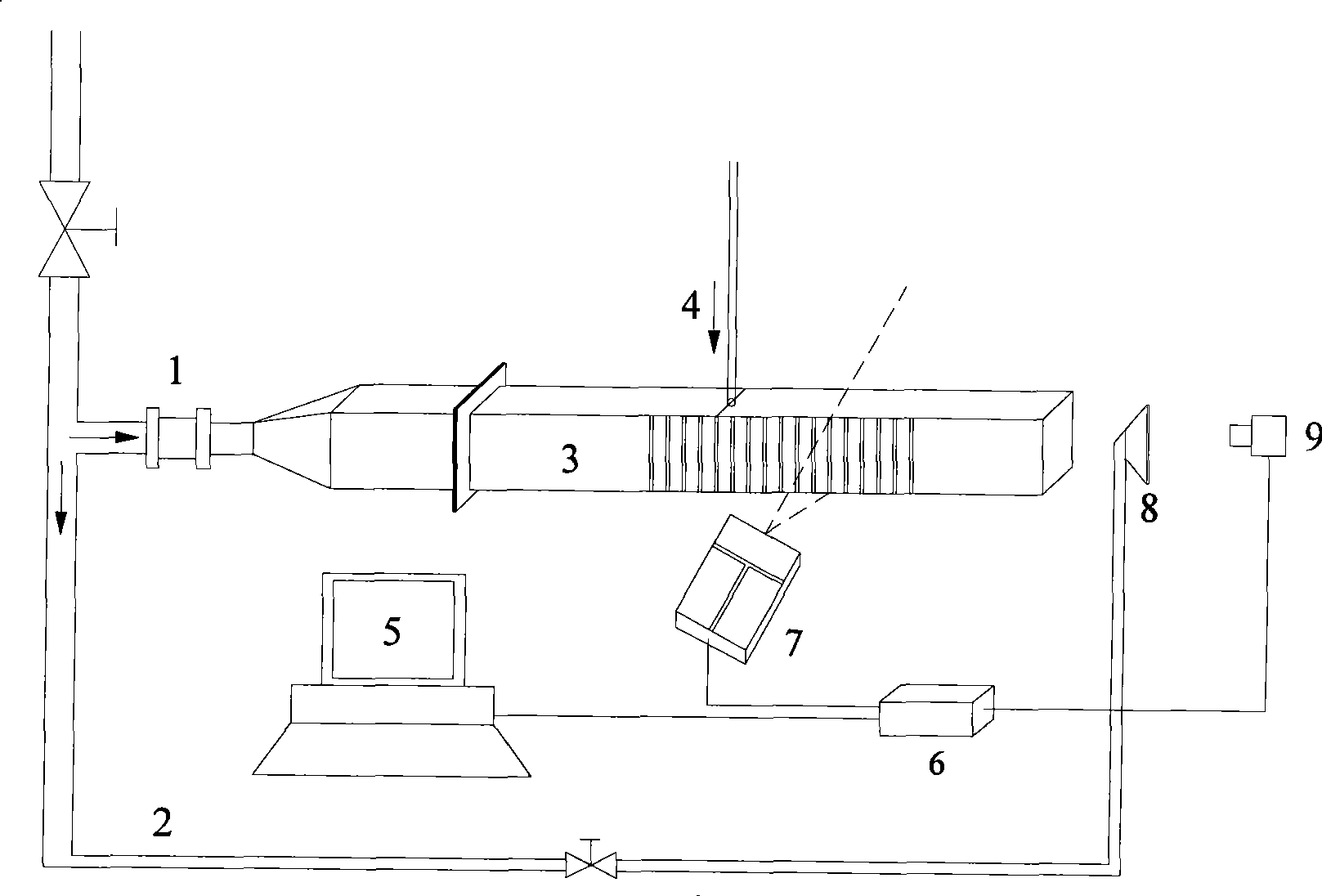

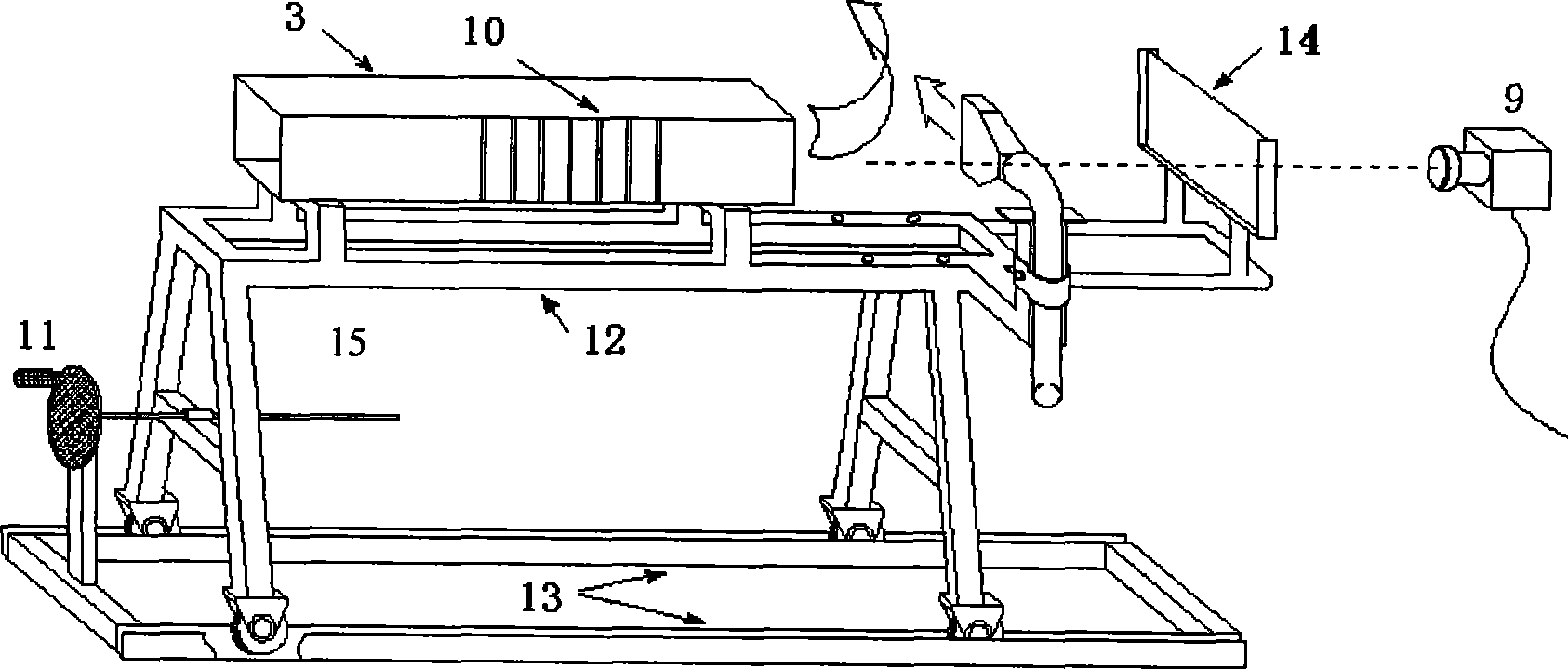

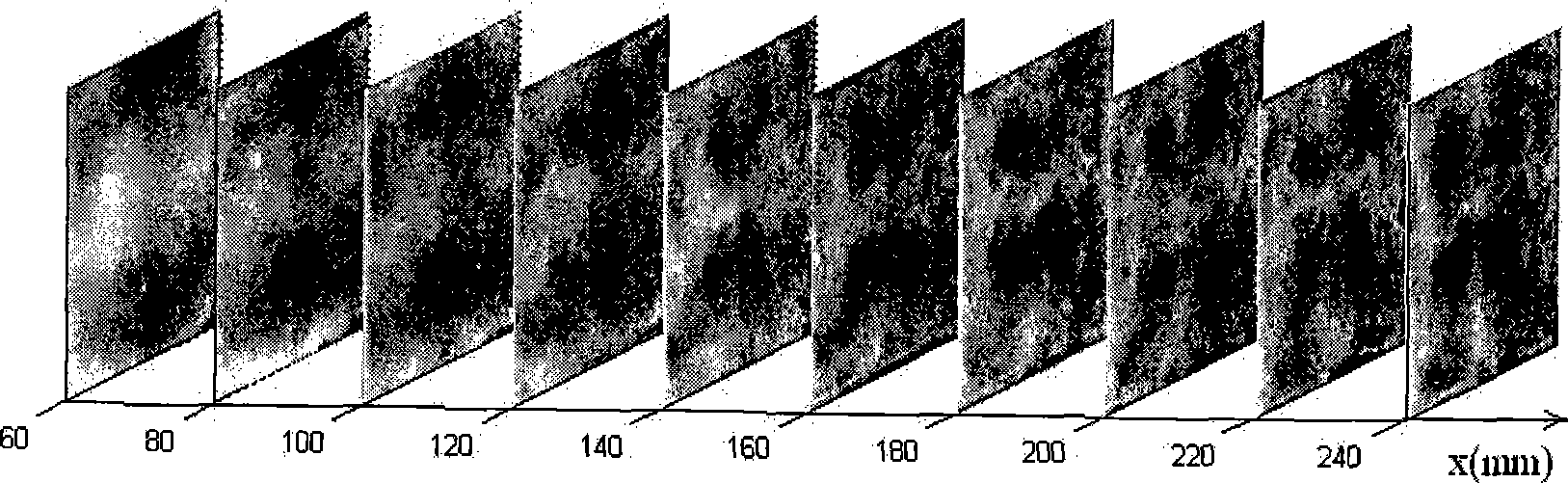

[0026] see figure 1 , 2, the present invention comprises experiment frame 12 and is arranged on experiment frame 12 and the mixing test section 3 that communicates with main air flow 1, is provided with the atomizing nozzle 4 that communicates with it on mixing test section 3, blends The inner wall of the test section 3 is uniformly coated with matte paint, and several slits 10 are opened on the side wall of the mixing test section 3, and a double pulse Nd: YAG laser 7, CCD camera 9 is arranged at the exit of mixing test section 3, said double-pulse Nd: YAG laser 7 and CCD camera 9 are respectively connected with computer 5 through PIV (Particle Image Velocimetry) synchronous controller 6. On the main air flow 1, also be connected with side air flow 2, the side air path outlet 8 of this side flow 2 is fixed on the test frame 12 and is positioned at the outlet of bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com