Two-sided printing equipment for electronic paper

A double-sided printing and electronic paper technology, which is applied in the direction of cathode ray tube indicators, optics, instruments, etc., can solve problems such as the inability to digitize double-sided electronic paper, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

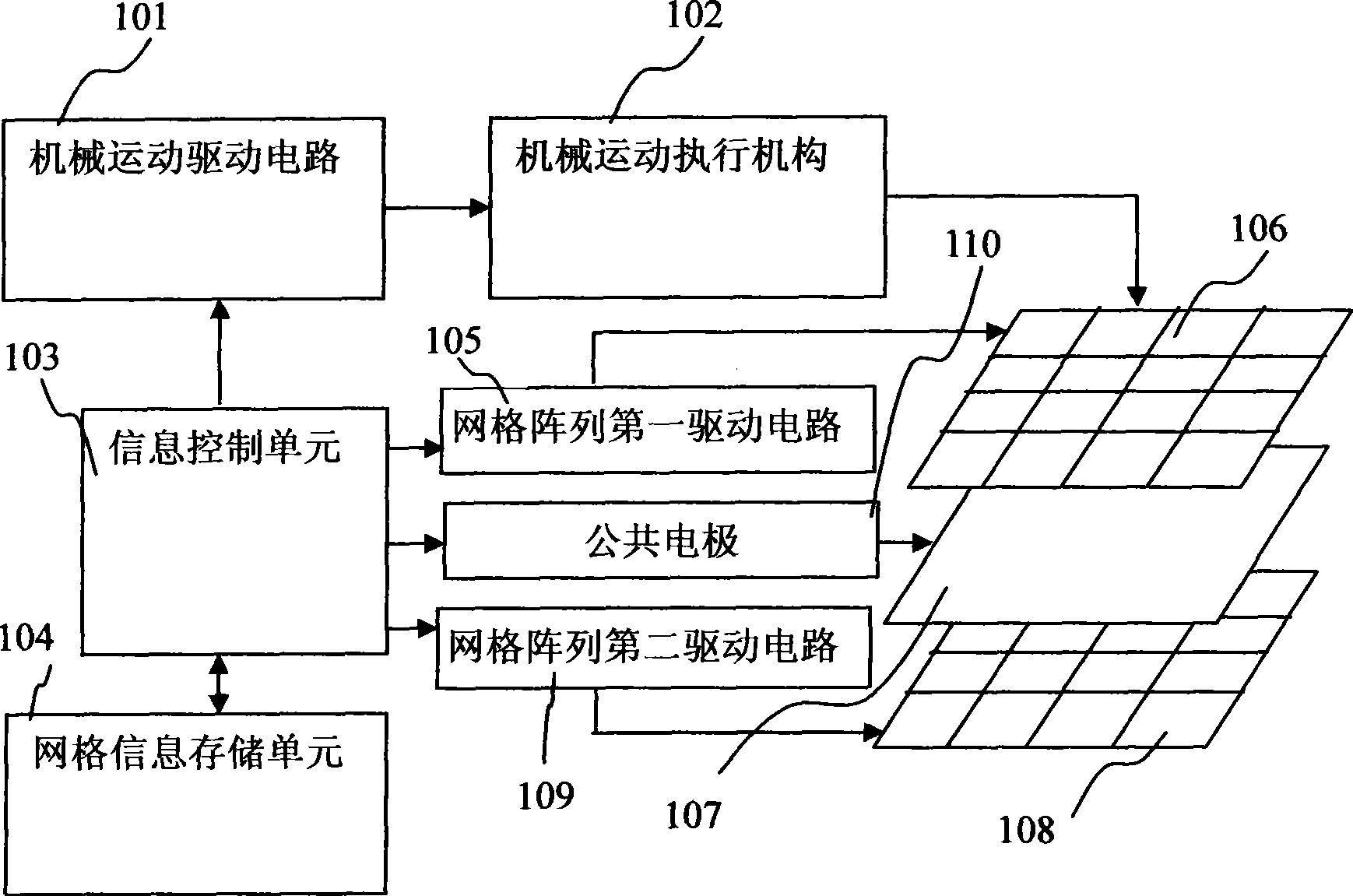

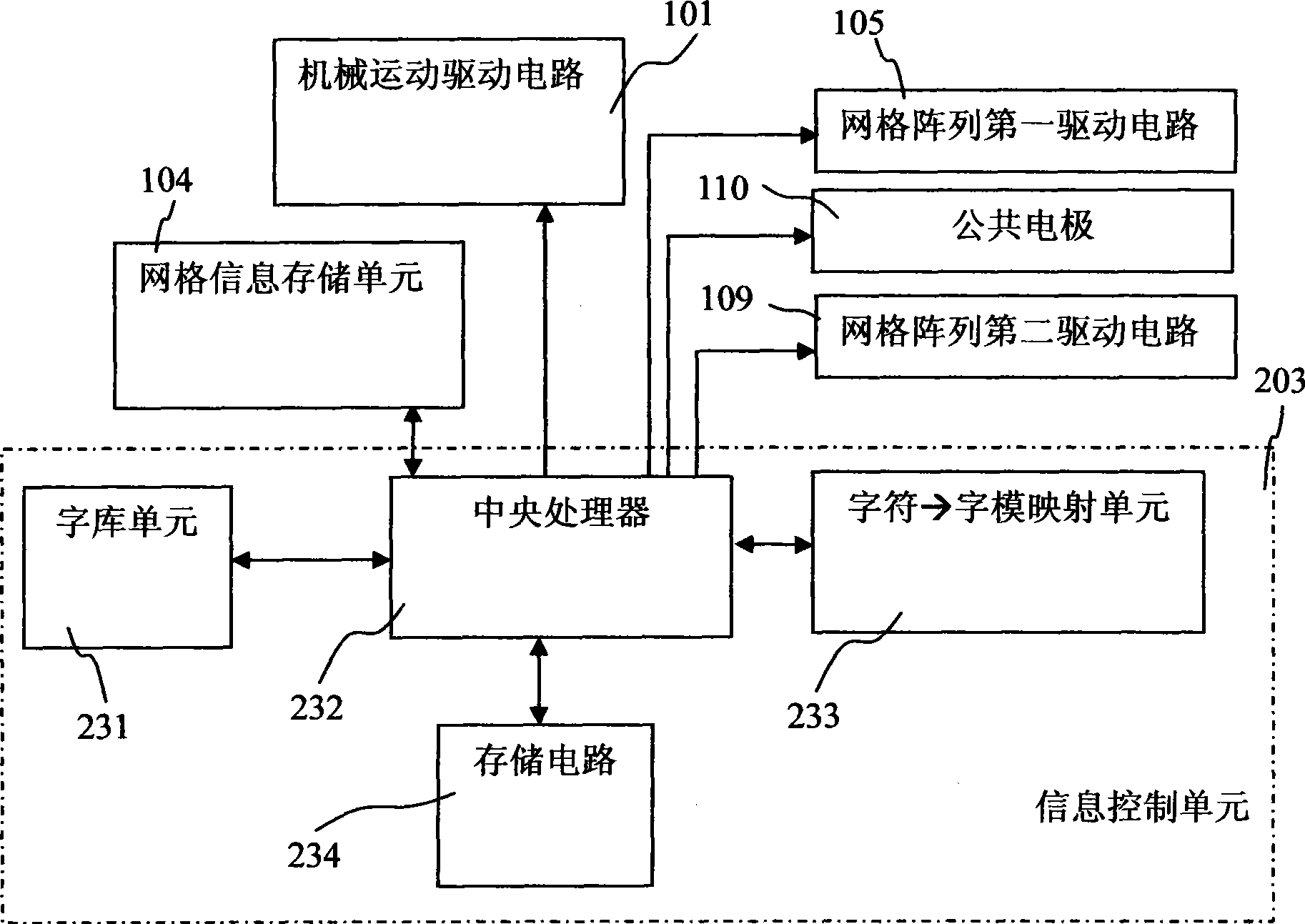

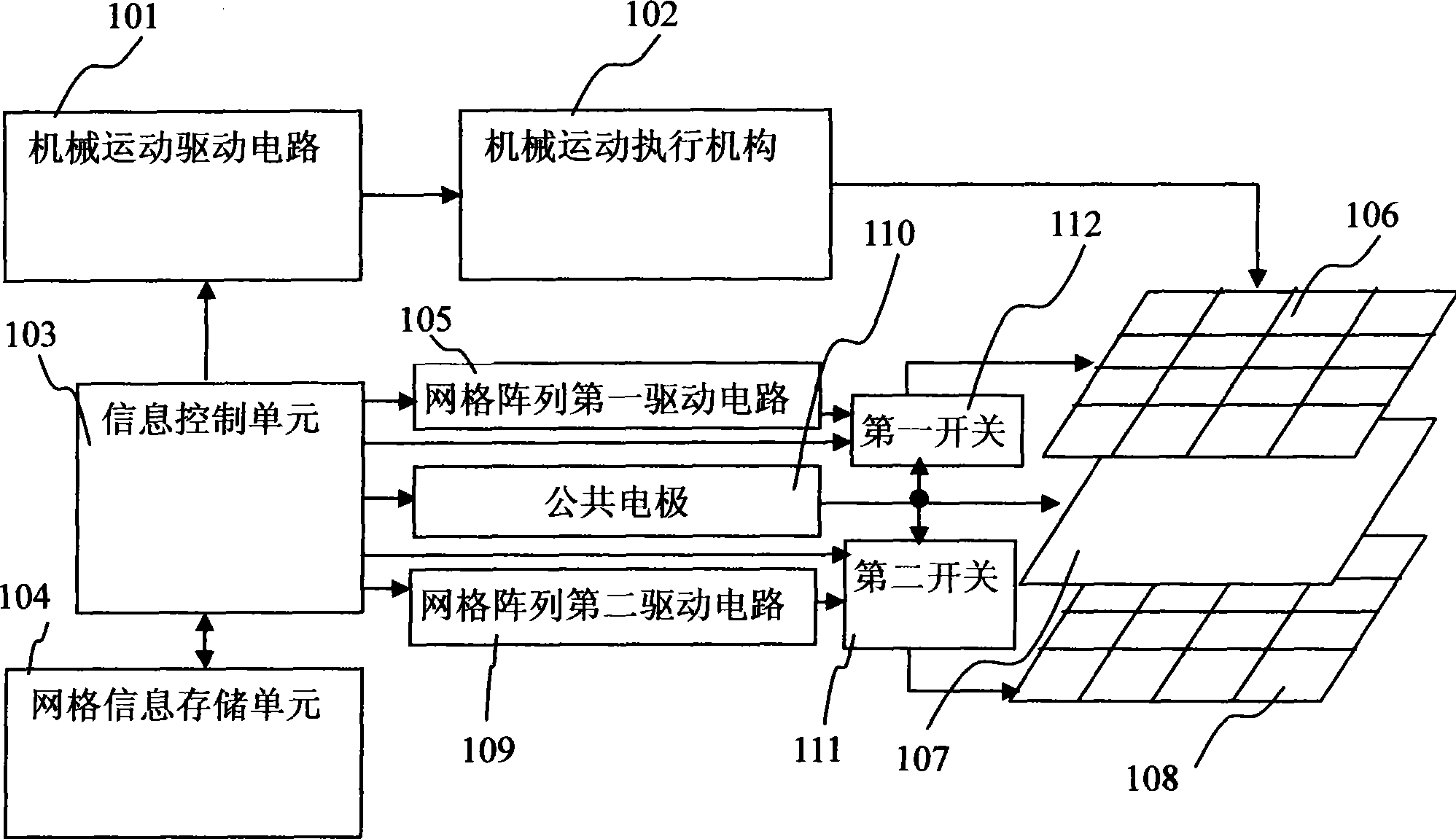

[0152] Electronic paper is a special paper coated with micro-units (also called pixel units) with electrophoretic or electrowetting properties. These micro-units have the characteristics of changing the optical state under the action of an external electric field, and the optical state After the change, even if the external electric field is removed, the optical state can still be maintained. Therefore, the printing of electronic paper is actually to control the size and direction of the external electric field applied to each micro-unit on the electronic paper, so that each micro-unit on the electronic paper presents the optical characteristics we need.

[0153] The electronic paper in the present invention does not have metal electrodes for printing or electronization to reduce the cost of the electronic paper. Instead, all the metal electrodes for printing or electronization are used as parts of the electronic paper printing device. Therefore, the printing and electronicization...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com