Loader and forklift simulation operation training system

A technology of simulation operation and training system, applied in the field of loader and forklift simulation operation training system, it can solve the problems of high talent consumption, inability of students to master excavator operation skills, skills, hidden dangers, etc., and achieve the effect of increasing training time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

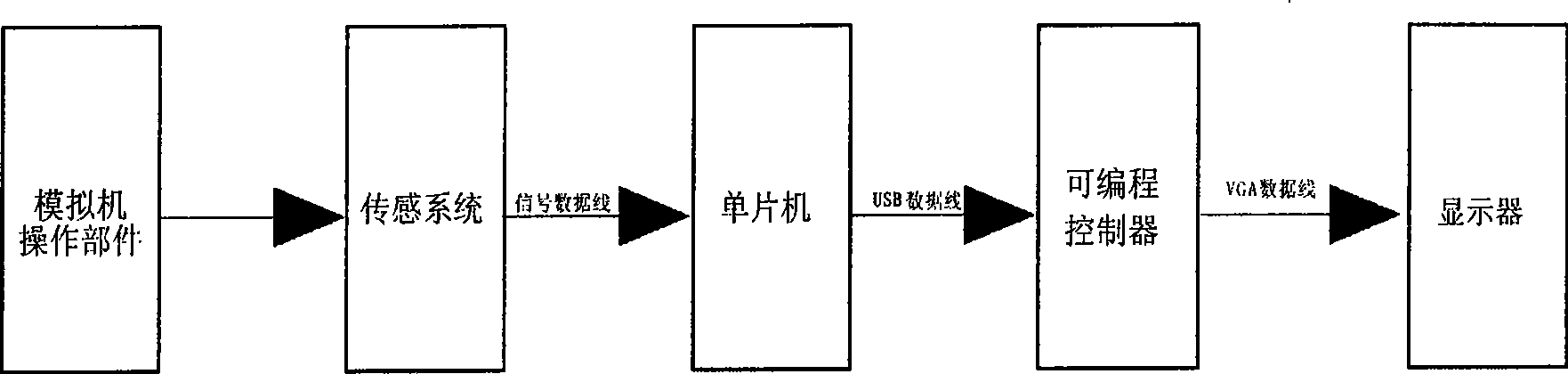

[0012] Such as figure 1 As shown, the system is composed of the operating parts of the analog machine, sensors, single-chip microcomputer, programmable controller (composed of the main board, the main board electrical processing unit, and the storage unit) and the display. The action of the operating table collects signals through the sensor, and transmits them to the single-chip microcomputer through the signal data line. After the single-chip microcomputer processes the data, it inputs the programmable controller through the USB data line. The programmable controller displays the operation action on the screen through the display after signal processing.

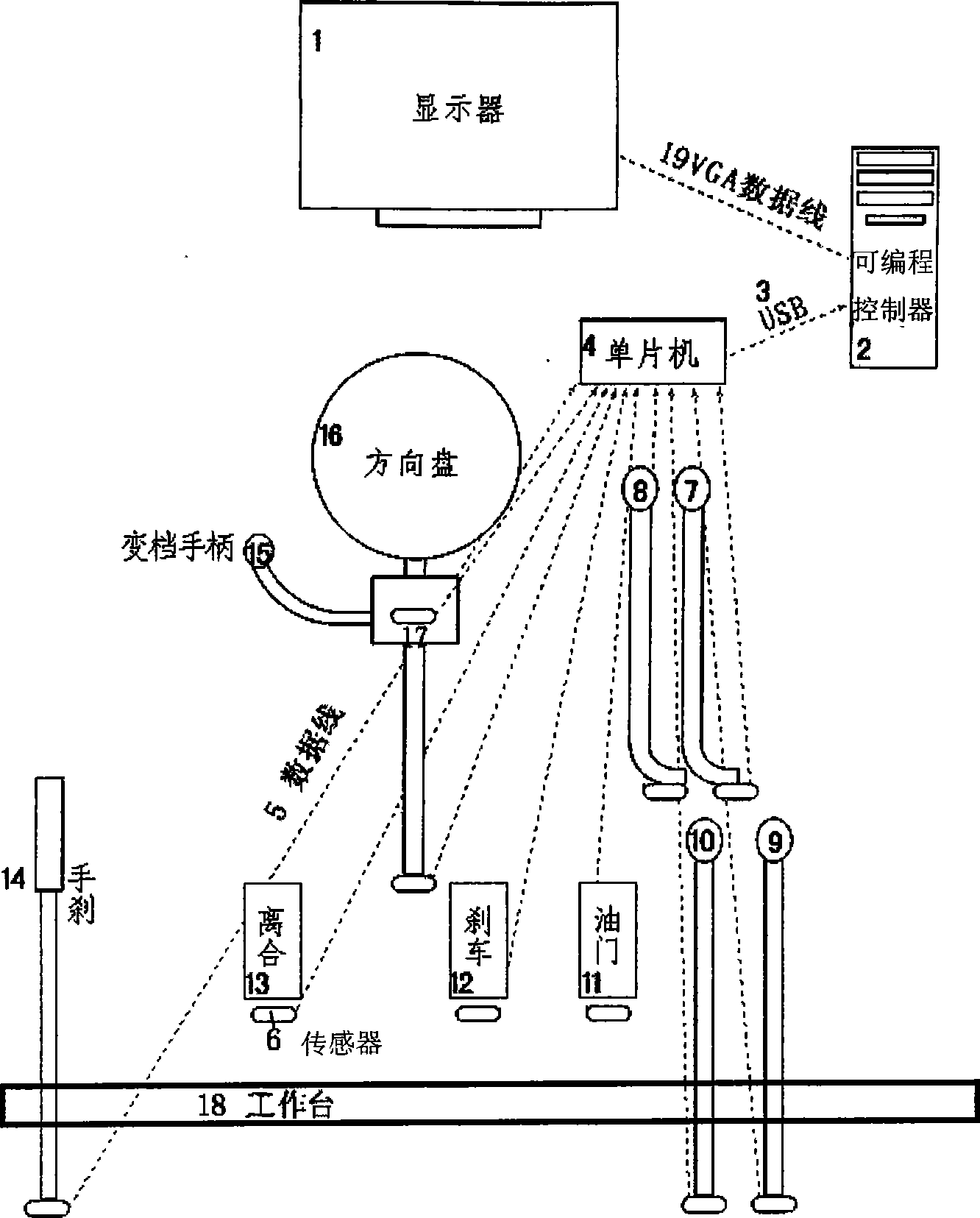

[0013] Such as figure 2 As shown, the operating platform includes a workbench 18, a boom / lift fork operating handle 10 installed on the working platform 18, a bucket / gantry operating handle 9, a steering wheel 16 and a connecting rod 17, a shift handle 15, a hand brake 14, Clutch 13, brake 12, throttle 11, the sensor sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com