Semiconductor miniature suspension structure and method of producing the same

A technology of suspension structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, microstructure technology, microstructure device and other directions, can solve the problems of metal pollution in etching machine cavity, reduction of etching rate, pollution of micro-electromechanical structure, etc. The effect of reducing micro-loading effects, reducing high-precision requirements, and avoiding metal contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

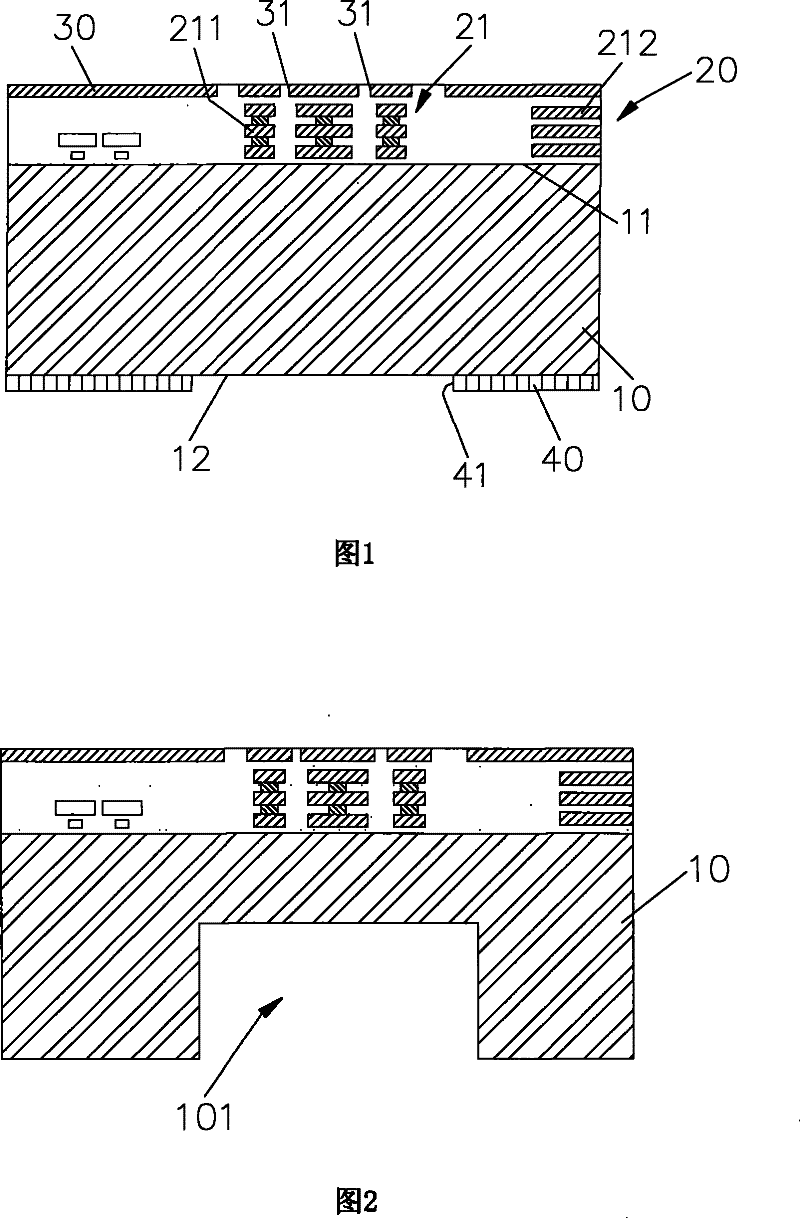

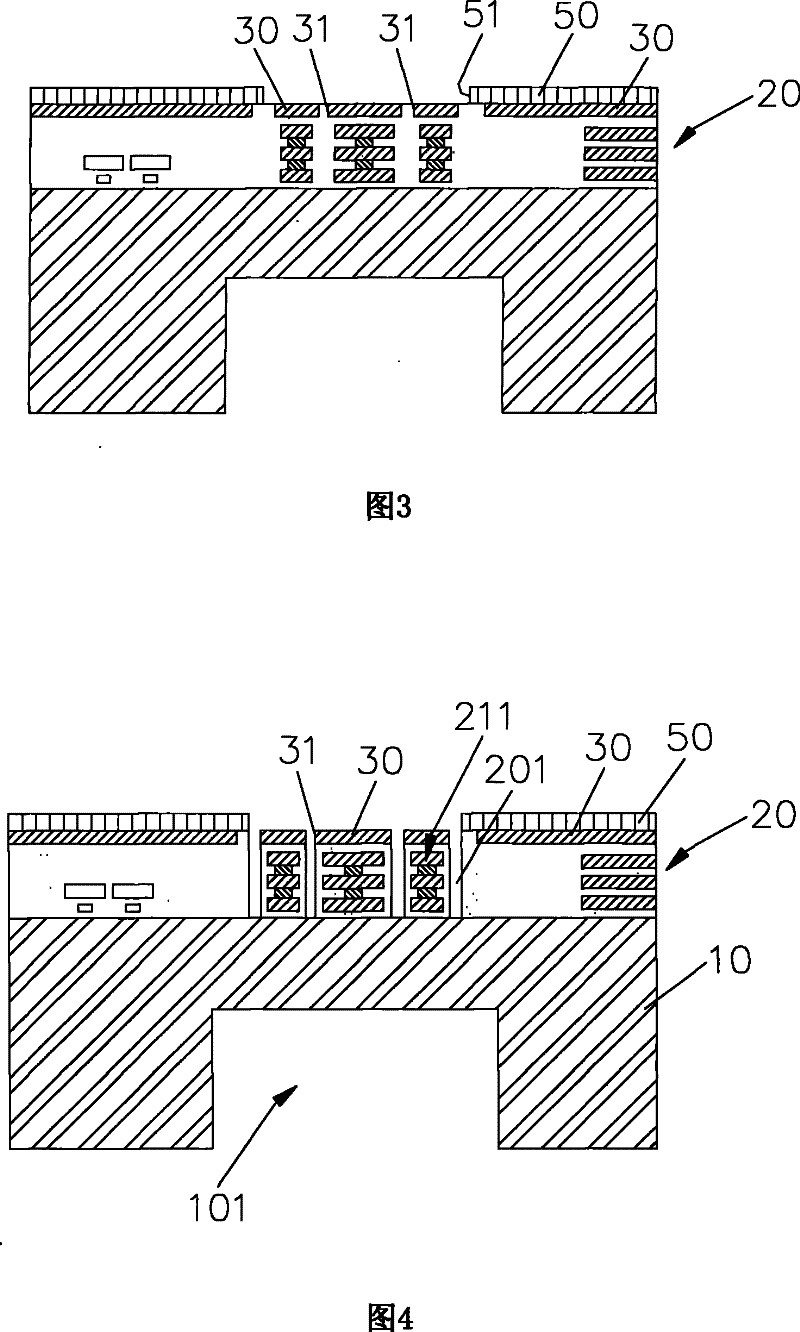

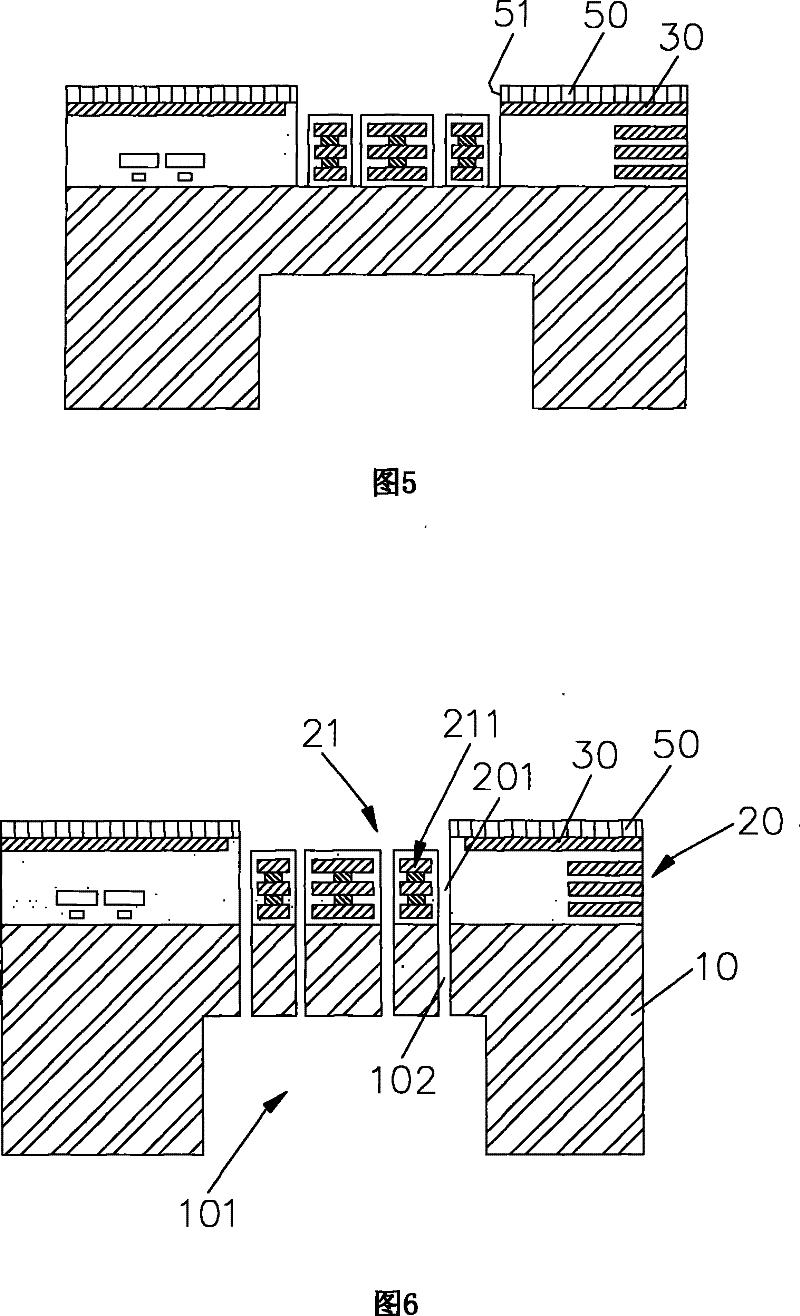

[0038] Figure 1 to Figure 7 As a specific embodiment of the present invention, the detailed description of the micro-suspension structure compatible with integrated circuits of the present invention and its manufacturing method is as follows:

[0039] (1) The structure of the present invention is as figure 1 As shown, first an insulating layer 20 with a microelectromechanical structure 21 is formed on the upper surface 11 of a silicon substrate 10. The microelectromechanical structure 21 includes at least one microstructure 211 and a plurality of metal circuits 212 that are independent of each other, and the microelectromechanical structure is in The surface of the insulating layer has an exposed portion 30, and the exposed portion 30 is provided with a through hole 31 corresponding to the expected etching space between the micro-electromechanical structure. The expected etching space only passes through the insulating layer 20 without contacting the micro-electro-mechanical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com