Method for manufacturing large-sized high purity 12Cr% low-ilicon low-aluminum electroslag remelting steel ingot

A technology for electroslag remelting steel and a manufacturing method, which is applied in the field of steel ingot manufacturing, can solve the problems of technical realization difficulty and huge investment, and achieves the effect of reducing oxygen content, small investment and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

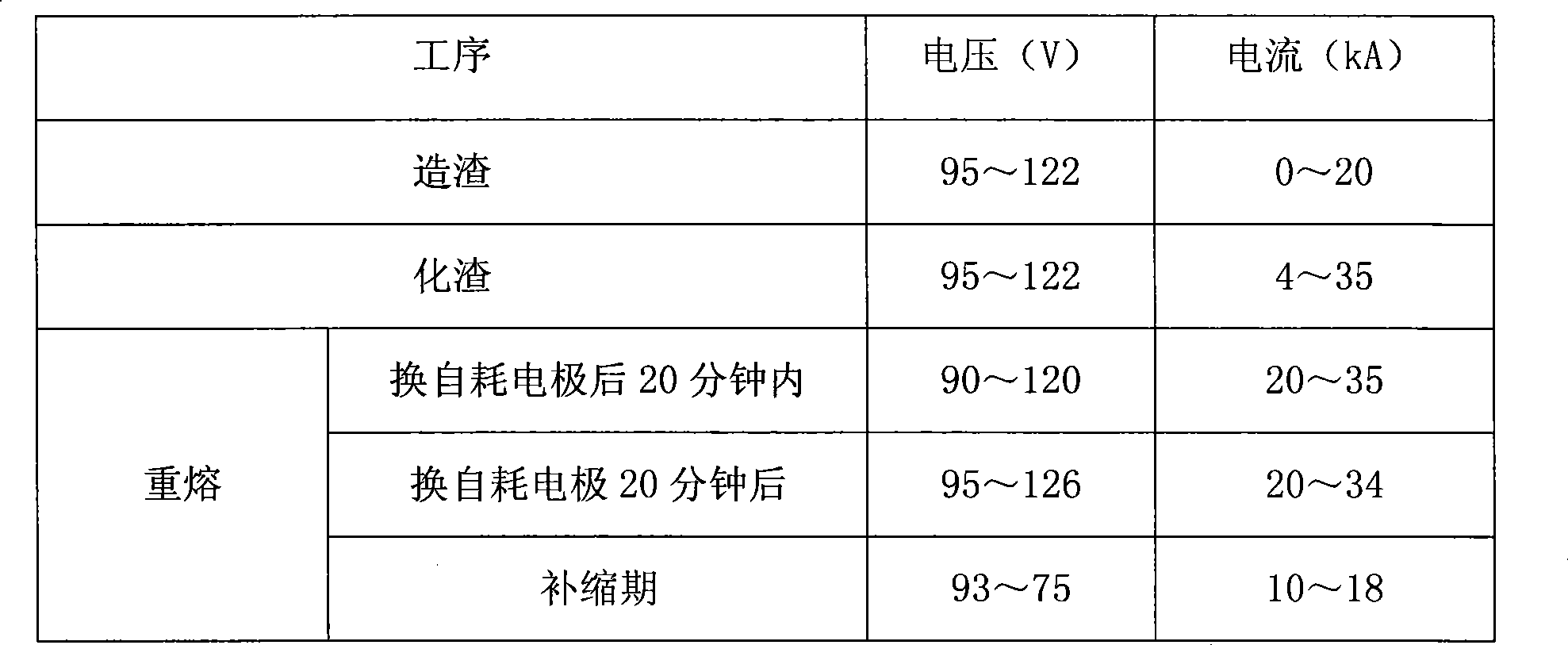

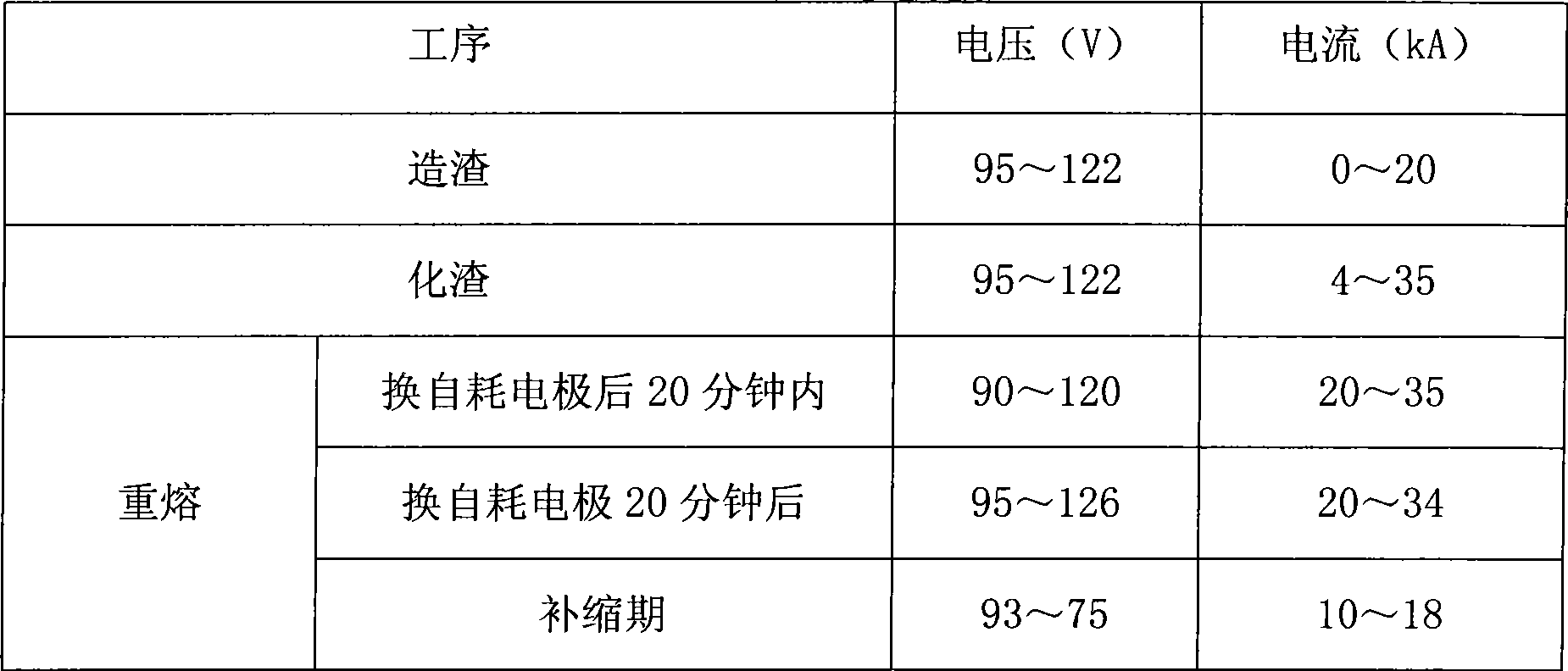

[0034] The method for manufacturing large-scale high-purity 12Cr%-like low-silicon and low-aluminum electroslag remelting steel ingots of the present invention adopts the nitrogen-protected electroslag remelting method to manufacture large-scale high-purity 12Cr%-like low-silicon and low-aluminum steel ingots for high-pressure rotors of ultra-supercritical steam turbines Electroslag remelting steel ingots, the specific steps are as follows:

[0035] 1. Electroslag remelting preparation

[0036] 1.1. Use single-phase bipolar series electroslag remelting furnace or three-phase bipolar series electroslag remelting furnace.

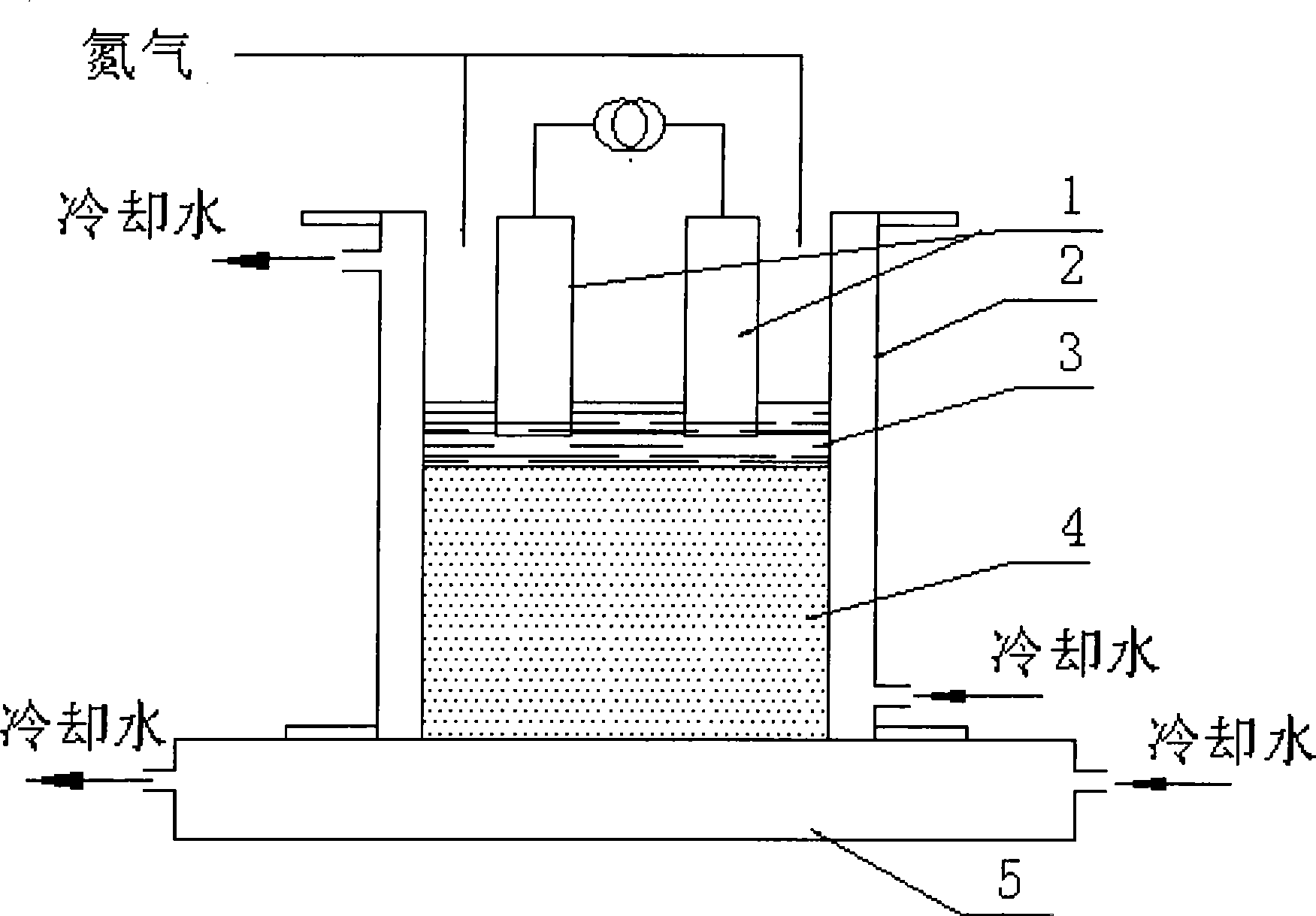

[0037] 1.2. Copper wall water-cooled crystallizer 2 is adopted. The specifications of crystallizer 2 are Φ1760 / Φ1720×3700, that is, the diameter of the upper bottom is 1760mm, the diameter of the lower bottom is 1720mm, and the height is 3700mm. The bottom of the crystallizer 2 is provided with a water-cooled bottom plate 5, such as figure 1 shown.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com