Fan and stator holder thereof

A fixed seat and fan technology, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, pump devices, etc., can solve the problems of large noise, large vibration, shortening the service life of fans, etc. Damage to the structure, good joint effect, effect of increasing the strength of the base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

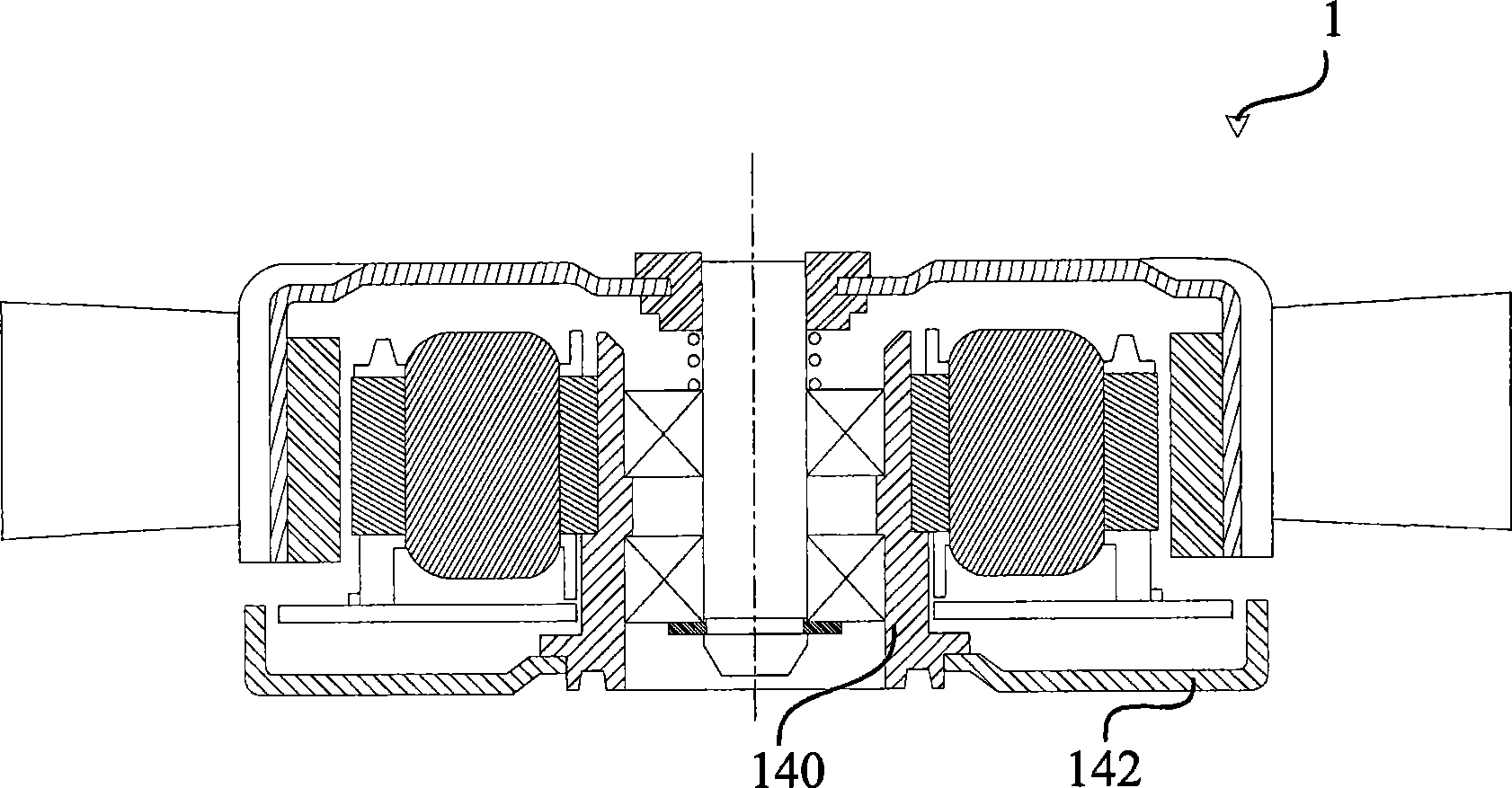

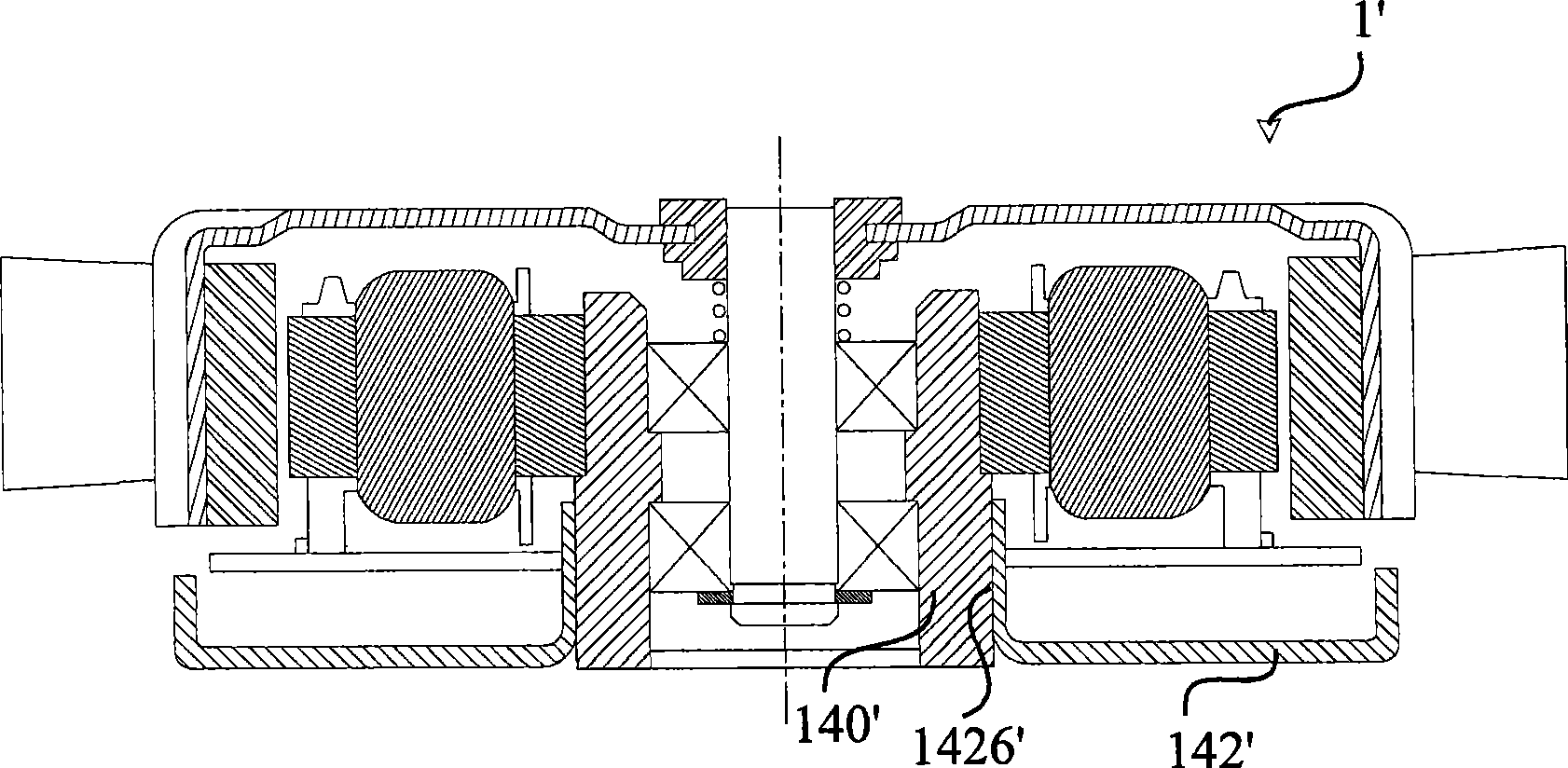

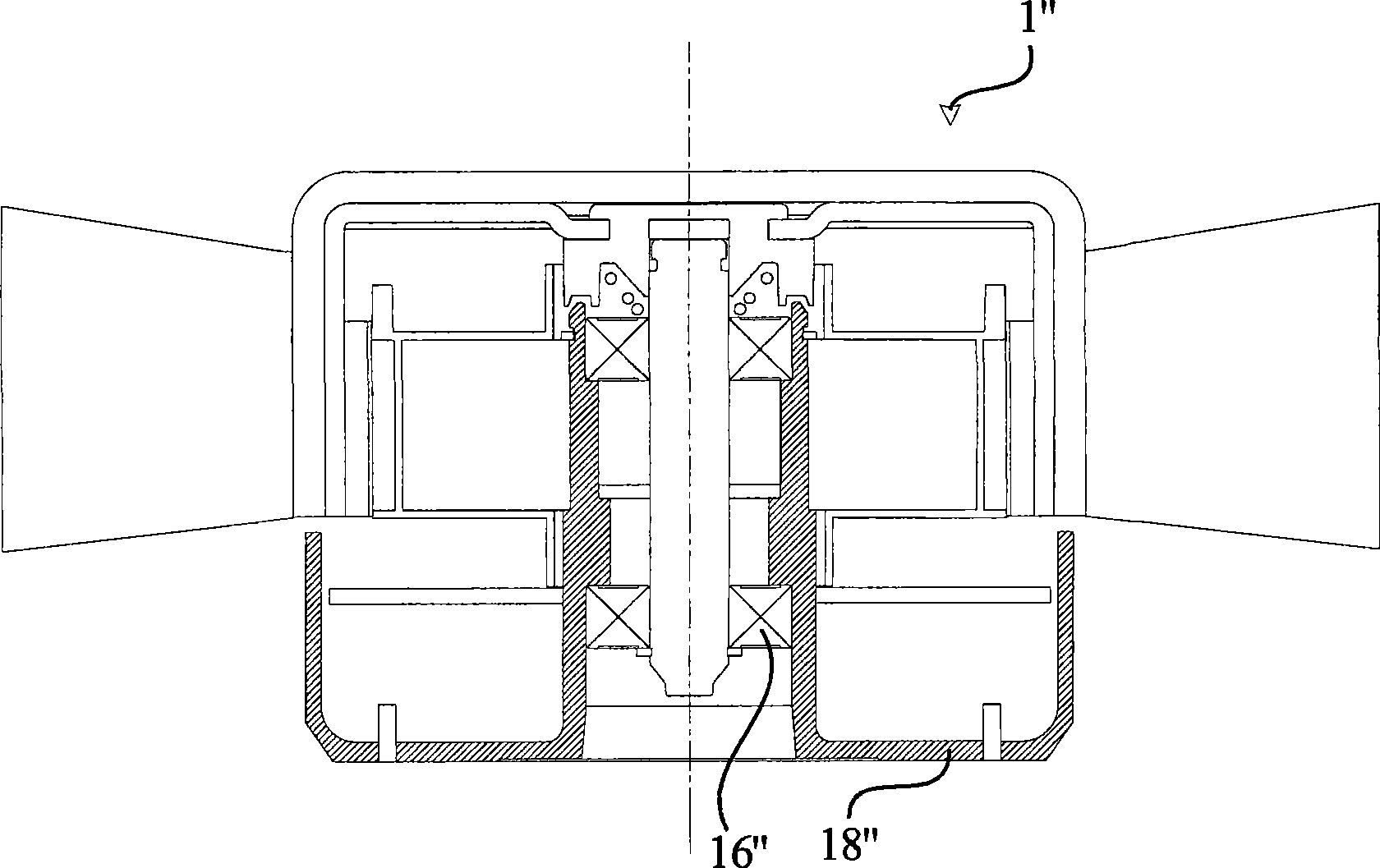

[0026] see Figure 2A , which is a sectional view of the fan 2 according to the first preferred embodiment of the present invention. The fan 2 includes an impeller 20 , a stator structure 22 , a stator fixing seat 24 and a bearing 26 . The stator structure 22 is arranged corresponding to the impeller 20 . The stator fixing seat 24 is used for supporting the stator structure 22 . The stator structure 22 includes an electromagnetic element 220 such as a coil and a driving circuit board 222 . The stator fixing seat 24 includes a plastic bearing sleeve 240 , a metal base 242 and an anti-vibration medium 244 . The bearing 26 is located between the stator fixing seat 24 and the rotating shaft 200 of the impeller 20 . In addition, the stator fixing seat 24 can be connected with devices 9 such as fan frame or system frame.

[0027] The metal base 242 has a connecting portion 2420 and a fixing portion 2422 . The connecting portion 2420 is engaged with the plastic bearing sleeve 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com