Sealing structure of diesel low-voltage fuel metal oil conduit and mounting method thereof

A sealing structure and diesel engine technology, applied in the direction of charging system, mechanical equipment, engine components, etc., can solve the problems of metal pipes and oil pipes that are easy to break, anti-high temperature environment is easy to age, and it is difficult to take into account the forming design, so as to achieve good appearance quality and reliability Good performance and low fuel flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

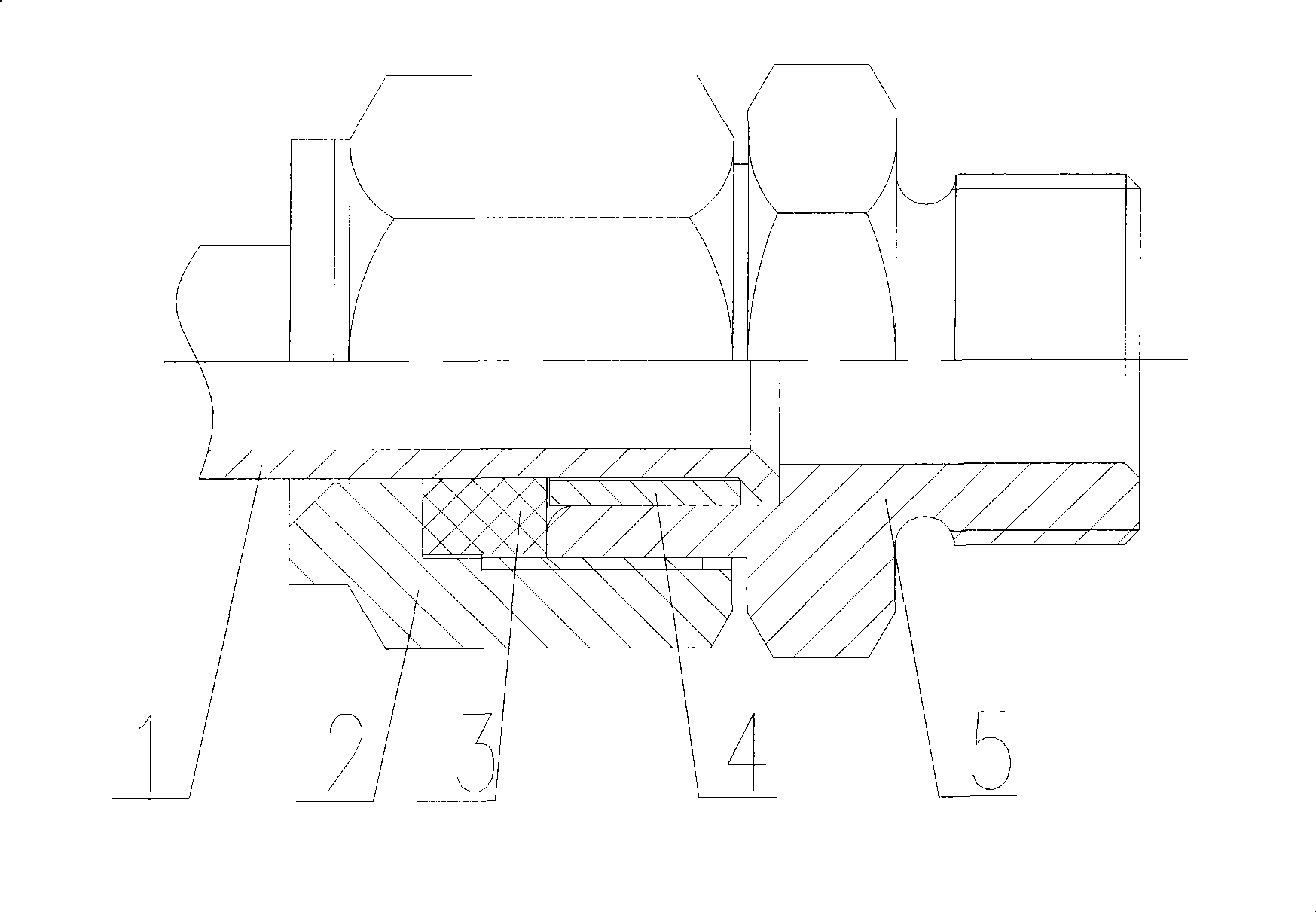

[0022] Such as figure 1 As shown, the sealing structure of the diesel engine low-pressure fuel oil metal oil pipe of the present invention includes a pipe nut 2, a joint 5 and a sealing rubber sleeve 3, the pipe nut 2 is installed on the diesel engine low-pressure fuel oil metal oil pipe 1, and the joint 5 is located at the end of the metal oil pipe 1 , The pipe nut 2 and the joint 5 form a sealed cavity on the outer wall of the metal oil pipe 1, and the sealing rubber sleeve 3 is arranged in the sealed cavity. A bushing 4 is provided between the outer wall of the metal oil pipe 1 and the inner hole wall of the joint 5 .

[0023] The tightness rate between the sealing rubber sleeve 3 and the outer circle of the metal oil pipe 1 is 95%-100%. The filling ratio of the sealing rubber sleeve 3 ranges from 80% to 95%, and the compression ratio is about 15% to 25%. The sealing rubber sleeve 3 is made of nitrile rubber, or acrylic rubber, or fluororubber. The pipe nut 2 and the joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com