Wireless tool control system and method for vehicle assembly and fabrication technique

A wireless tool and manufacturing technology technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of sequence product quality and quality affecting safe production, production operation uncertainty data security, errors and omissions, etc. The effect of ensuring operation quality and product quality, rapid deployment, and increasing the difficulty of malicious damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

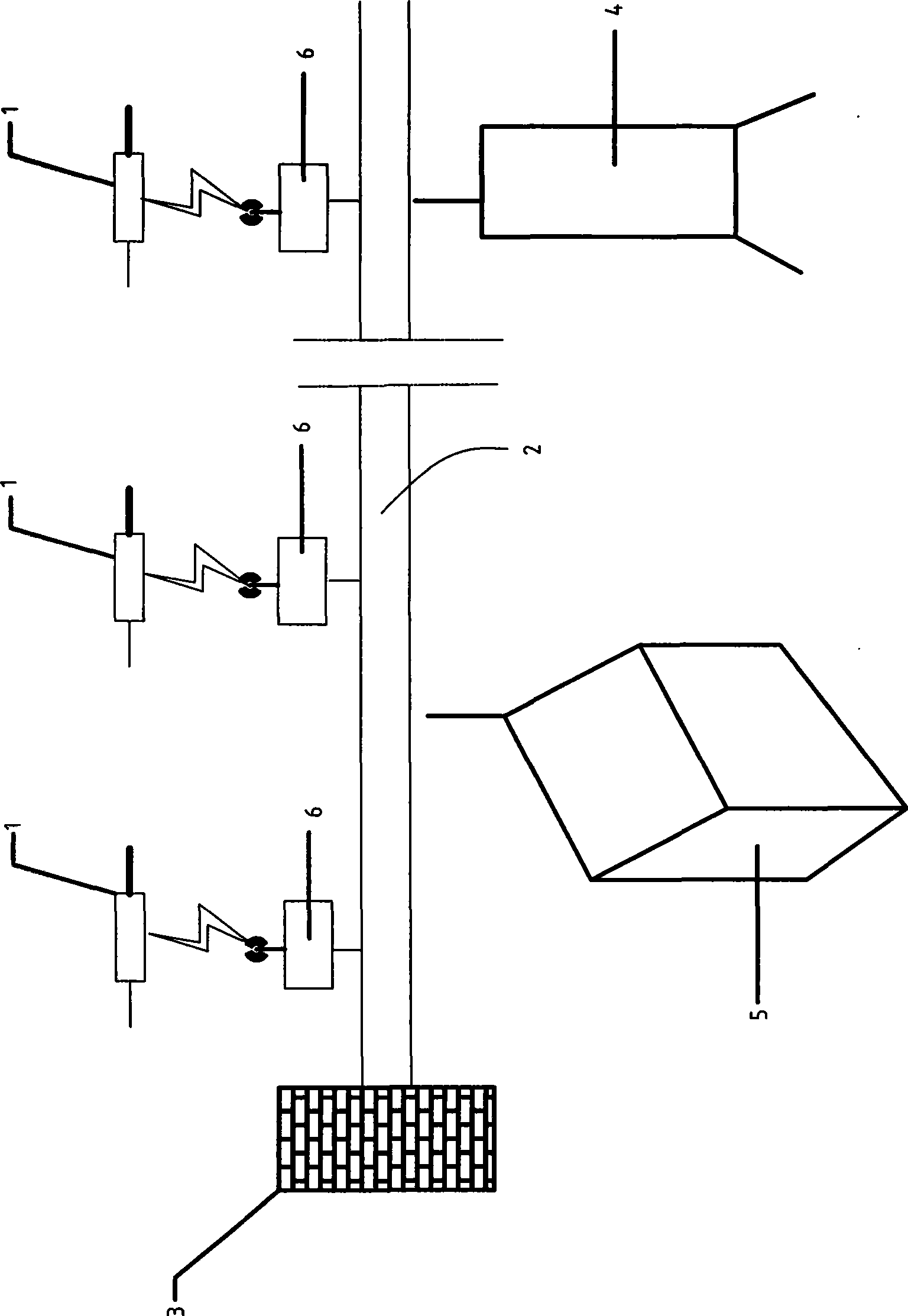

[0030] Such as figure 1 As shown, the wireless tool control system used in the automobile assembly manufacturing technology of the present invention includes more than one wireless tool 1, the automobile manufacturing production line Ethernet network 2, the enterprise firewall 3 embedded in the automobile manufacturing production line Ethernet network, and the automobile manufacturing production line Ethernet network. A production line monitoring center 4 connected to a network and equipped with a human-machine interface, a quality control service unit 5, more than one counting network instrument 6, and a safety certification system 7; wherein the wireless tool 1 includes a wireless torque wrench 1a and a wireless barcode scanner 1b; Among them, the quality control service unit 5 is an on-site operation computer or embedded system embedded in the wireless tool control system. The quality control service unit is provided with a data storage system 8, and the data storage system ...

Embodiment approach 2

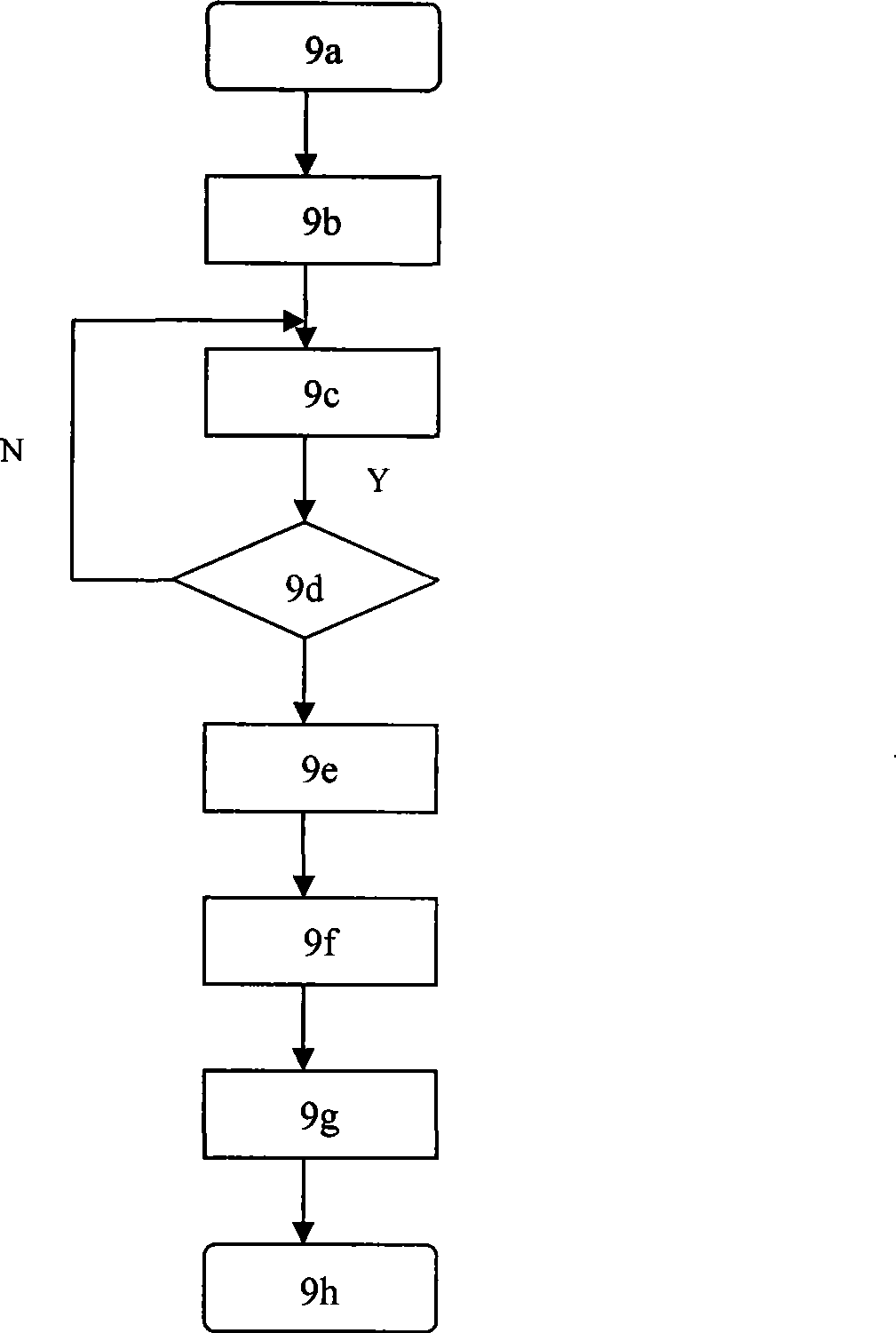

[0033] Such as figure 1 and figure 2As shown, the wireless tool control method used in the automobile assembly manufacturing technology of the present invention is: the first step 9a, setting the normal operating value range, control parameters and abnormal processing resources of the wireless tool 1 in the quality control service unit 5, and coexisting Enter the quality database of the quality control service unit; define the working logic of each wireless tool 1 in the quality control service unit 5, and store it in the quality database of the quality control service unit; the second step 9b, the quality control service unit Unit 5 assigns an identification certificate to each wireless tool 1, and writes the identification certificate into the wireless tool 1, the wireless tool 1 includes a wireless torque wrench 1a and a wireless barcode scanner 1b; the third step 9c, on the production line The wireless barcode scanner 1b assigned with the identification certificate reads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com