Image sensor and method for manufacturing the sensor

An image sensor, conductive type technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of output image sensitivity drop, image error, dark current saturation and sensitivity, etc., to minimize saturation decrease in accuracy and sensitivity, maximize fill factor, and minimize charge-sharing effects

Inactive Publication Date: 2010-12-01

DONGBU HITEK CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the charge sharing phenomenon occurs, the sensitivity of the output image decreases and image errors occur

Also, because photocharges may not move easily between the photodiode and the readout circuitry, dark currents can be generated and / or saturation and sensitivity degraded

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

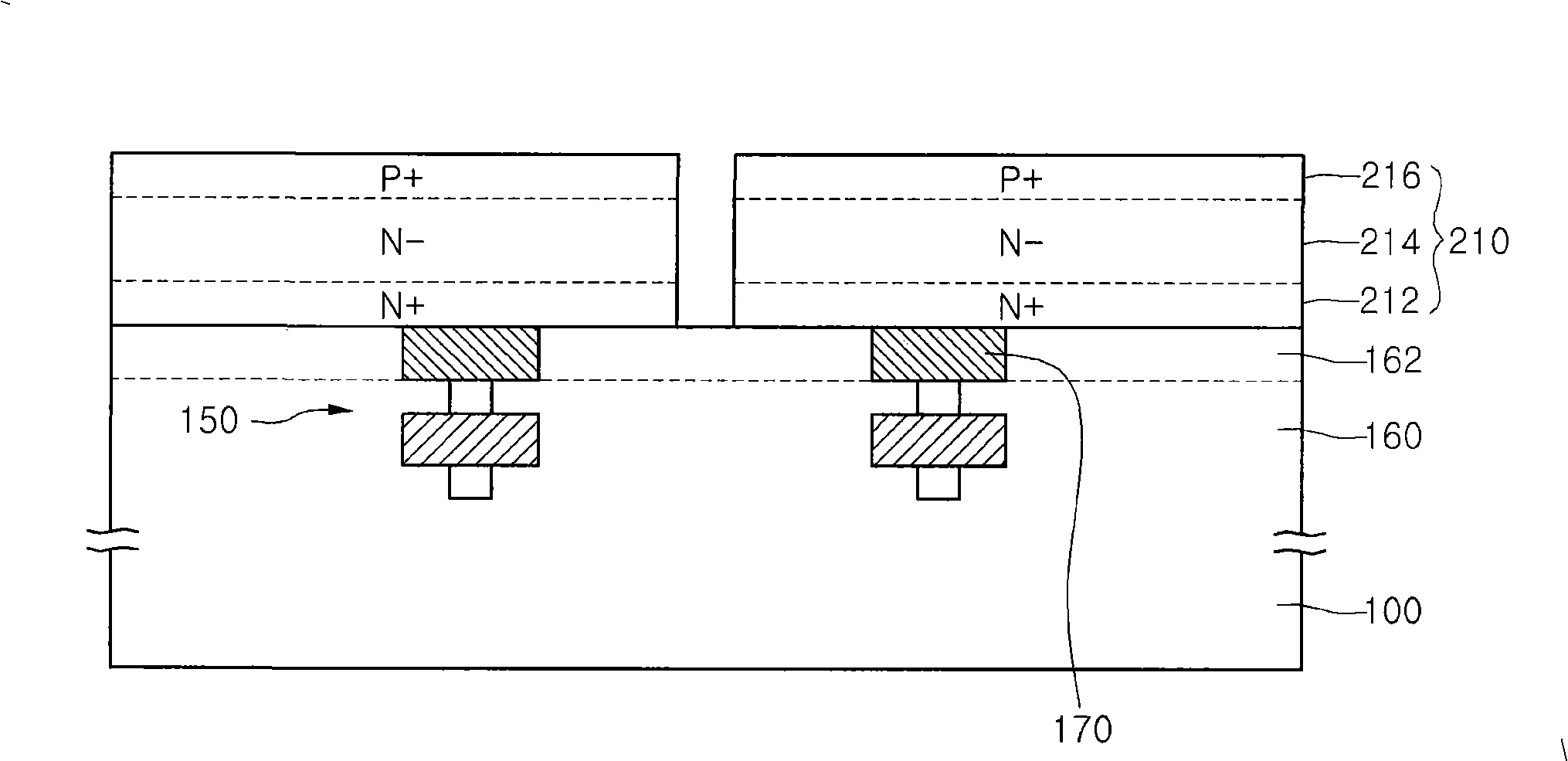

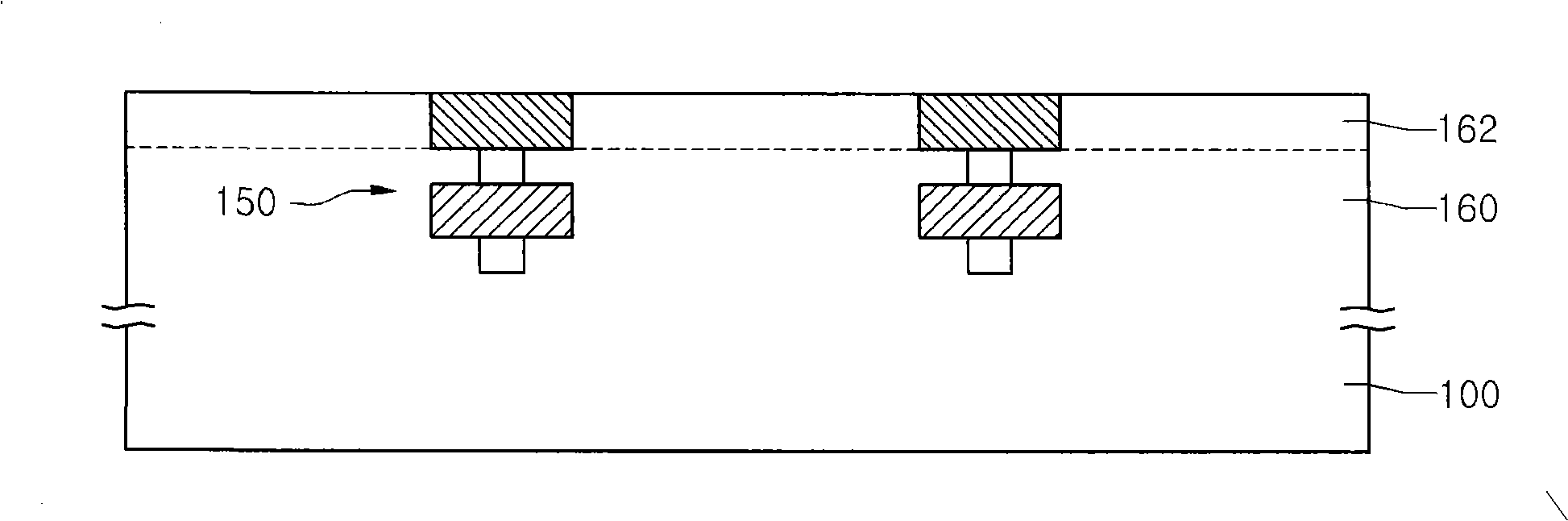

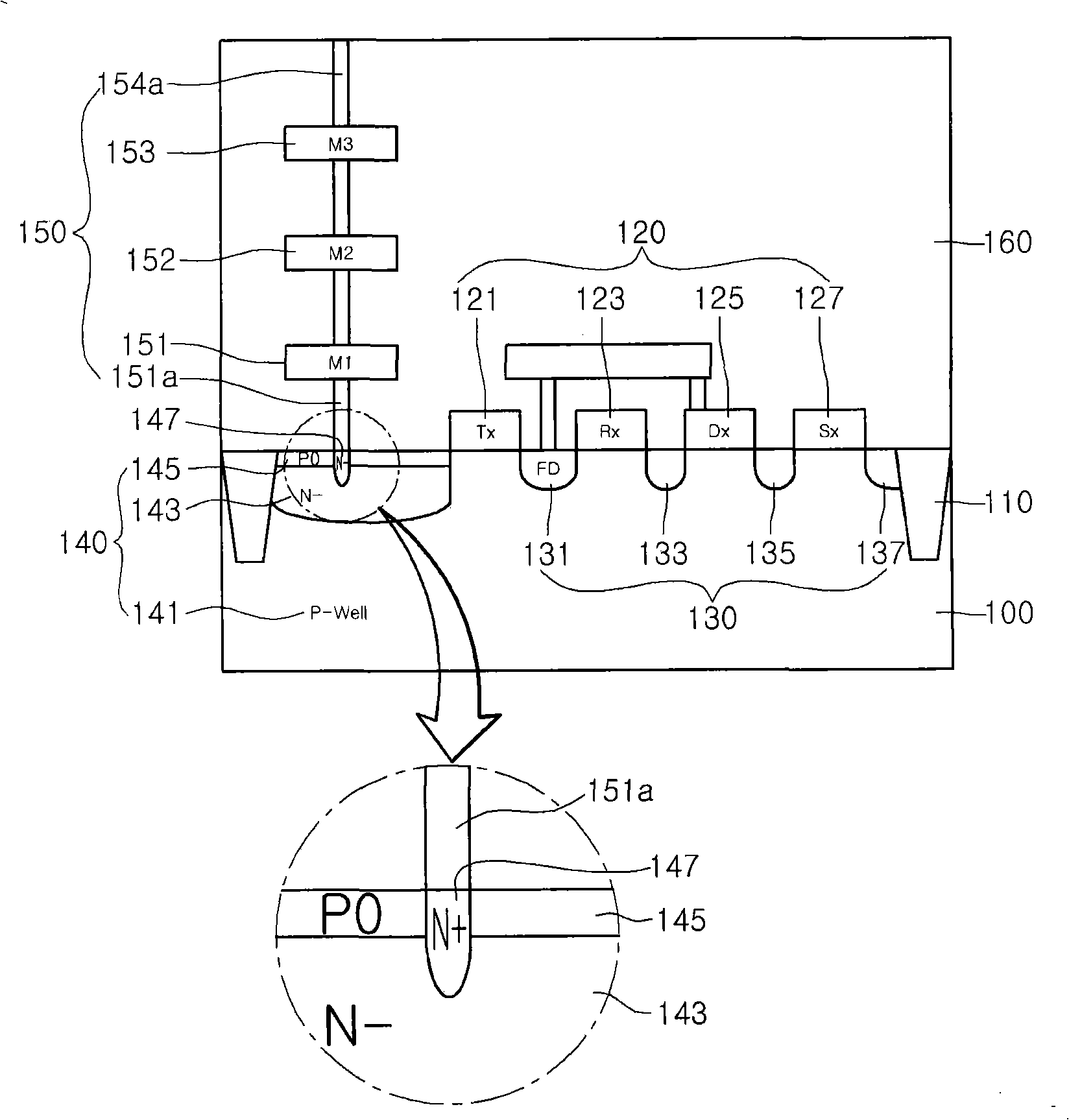

An image sensor includes a readout circuitry, a first substrate, a first interlayer dielectric, a metal interconnection, a top metal, and an image sensing device. The readout circuitry is formed on and / or over the first substrate and the first interlayer dielectric is formed on and / or over the first substrate. The metal interconnection is formed in the interlayer dielectric and electrically connected to the readout circuitry. The top metal is formed on and / or over the metal interconnection and the image sensing device is formed on and / or over the top metal. The disclosed manufacturing method of the image sensor can maximize a physical and electrical bonding force between an image sensing device and a metal interconnection, minimize the occurrence of charge sharing while maximizing a fill factor, and minimize a dark current source and minimize reduction in saturation and sensitivity.

Description

Image sensor and manufacturing method thereof technical field The invention relates to an image sensor and a manufacturing method thereof. Background technique An image sensor is a semiconductor device that converts an optical image into an electrical signal. Image sensors may generally be classified as Charge Coupled Device (CCD) image sensors or Complementary Metal Oxide Semiconductor (CMOS) image sensors (CIS). During the fabrication of image sensors, ion implantation may be used to form photodiodes in the substrate. In order to increase the number of pixels without increasing the size of the chip, the size of the photodiode has been continuously reduced, thereby also reducing the area of the light receiving portion, resulting in a decrease in image quality. However, since the stack height is not reduced to the extent that the light receiving part is reduced, photons incident on the light receiving part due to light diffraction (known as "ariydisk") amount will de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L27/146H01L23/522H01L21/822H01L21/768

CPCH01L27/14612H01L27/14632H01L27/14634H01L27/14636H01L27/14687

Inventor 张贞烈玄祐硕

Owner DONGBU HITEK CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com