Bearing temperature-monitoring device and bearing device with the same

A bearing temperature and monitoring device technology, which is applied to parts of thermometers, rotating bearings, bearings, etc., can solve the problems of reduced bearing load capacity, damage to the rotating shaft, and increased compression, so as to prevent deformation and excessive rise. High, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

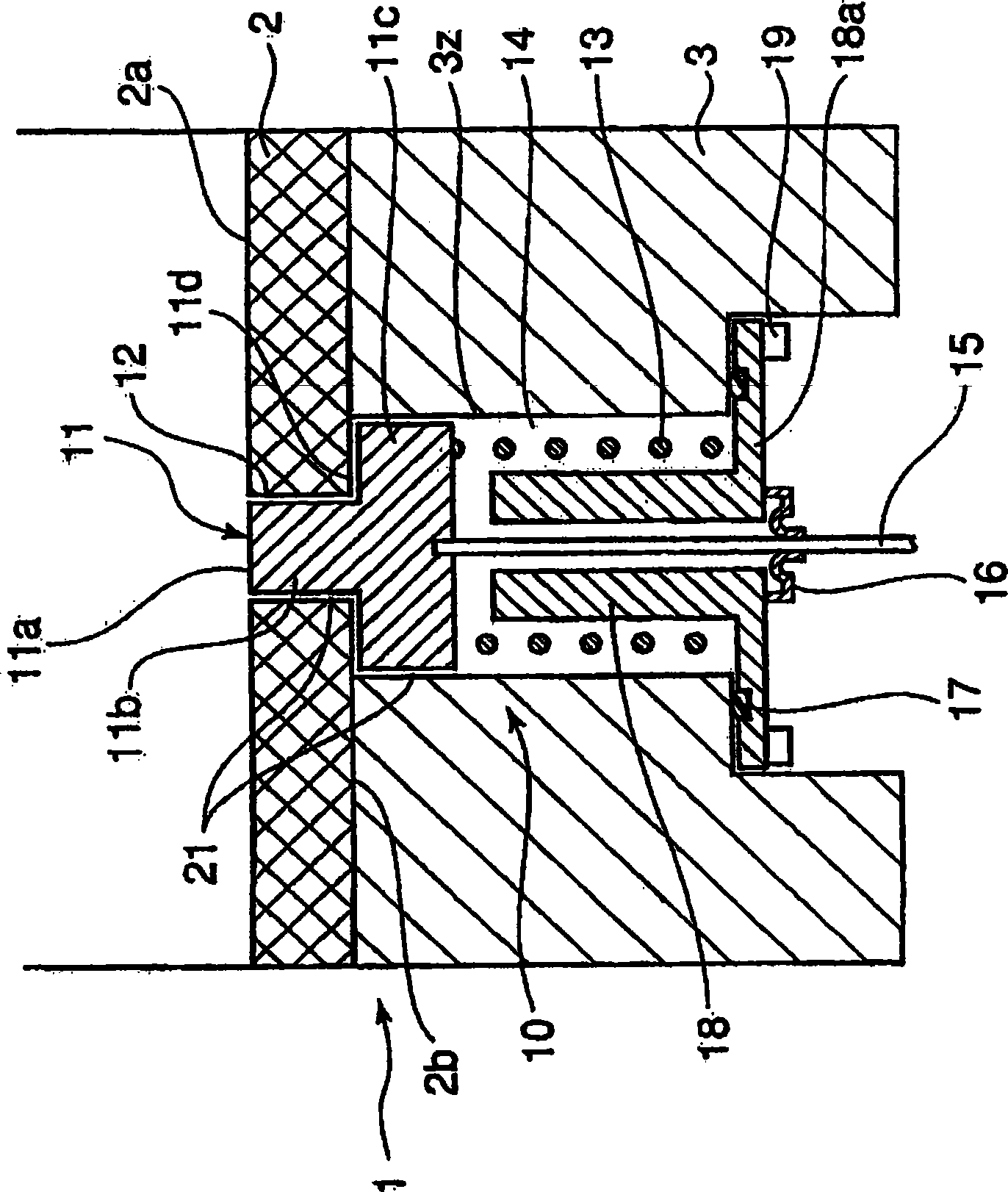

[0052] figure 1 It is a cross-sectional view of main parts along the axis line of the bearing temperature detection device of the bearing temperature monitoring device in the radial journal bearing according to the first embodiment of the present invention ( Figure 8 A-A line profile).

[0053] exist Figure 4 Among them, 3 is a metal backing made of steel, and 2 is a bearing member made of a resin material fixed inside the backing metal 3 . 12 is the installation hole of the front end portion 11b of the temperature sensing part 11 described later punched in such a way as to communicate with the inner surface 2a and the outer surface 2b of the bearing member 2, and 3z is the installation hole that communicates with the inner surface of the lining metal part 3. Mounting holes for the protruding amount limiting portion 11c of the temperature sensing member 11, the spring 13, etc., which are punched in the form of the surface and the outer surface will be described later.

...

Embodiment 2

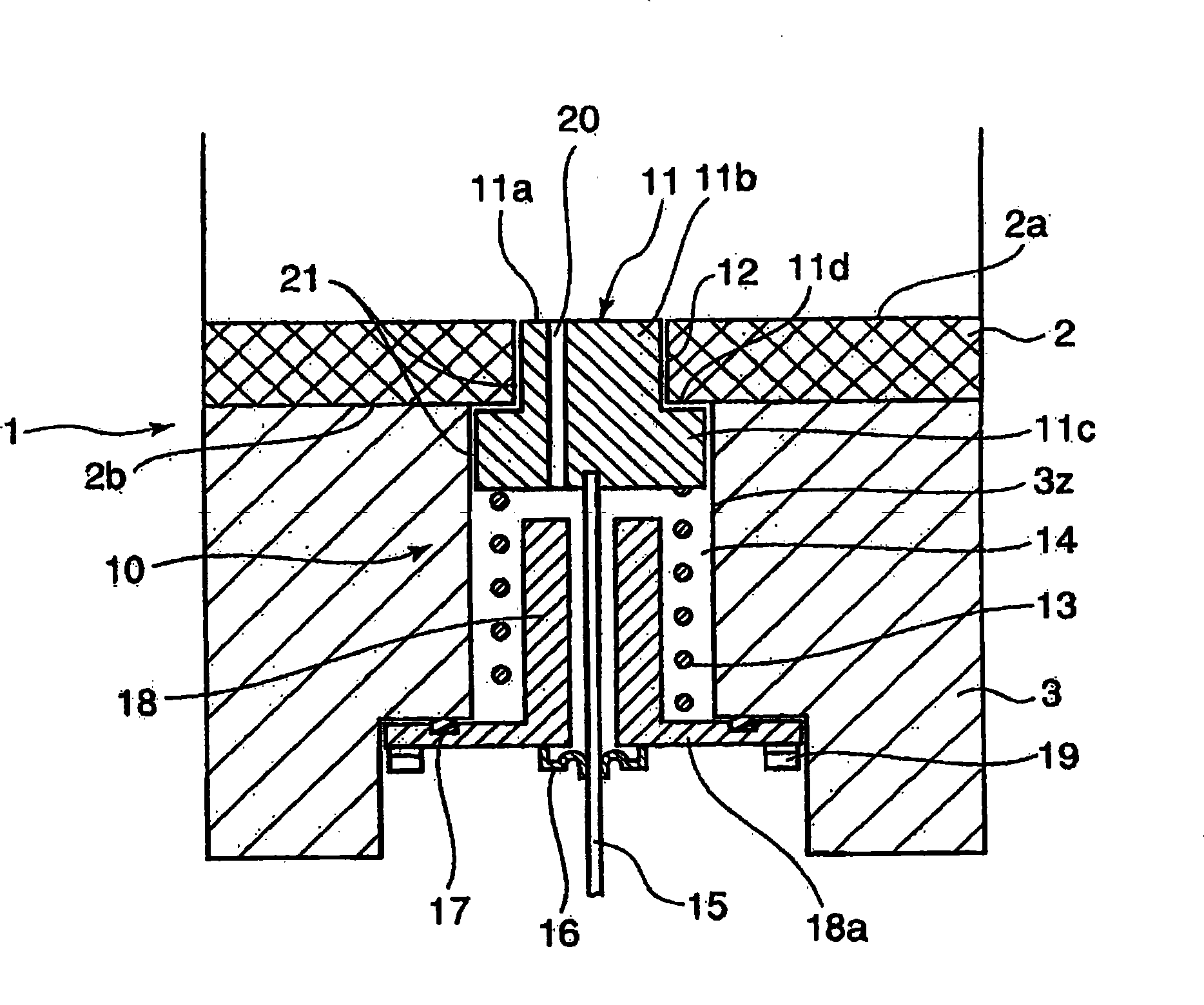

[0067] figure 2 is to represent the second embodiment of the present invention figure 1 Corresponding figure.

[0068] In the second embodiment, the temperature sensing part 11 is punched with a communication hole 20 for pressure balance that communicates the temperature detection end surface 11 a and the spring chamber 14 .

[0069] Other structures are the same as those of the first embodiment, and the same components are denoted by the same symbols.

[0070] According to the second embodiment, it can be seen that the oil on the inner surface 2a of the bearing member 2 can be easily guided to the back side of the temperature sensing member 11 through the communication hole 20, and the surface and back of the temperature sensing member 11 can be well maintained. The pressure is balanced, therefore, the gap between the temperature sensing part 11 and the bearing part 2 and the lining metal part 3 is easily adjusted without being affected by the oil film pressure of the bea...

Embodiment 3

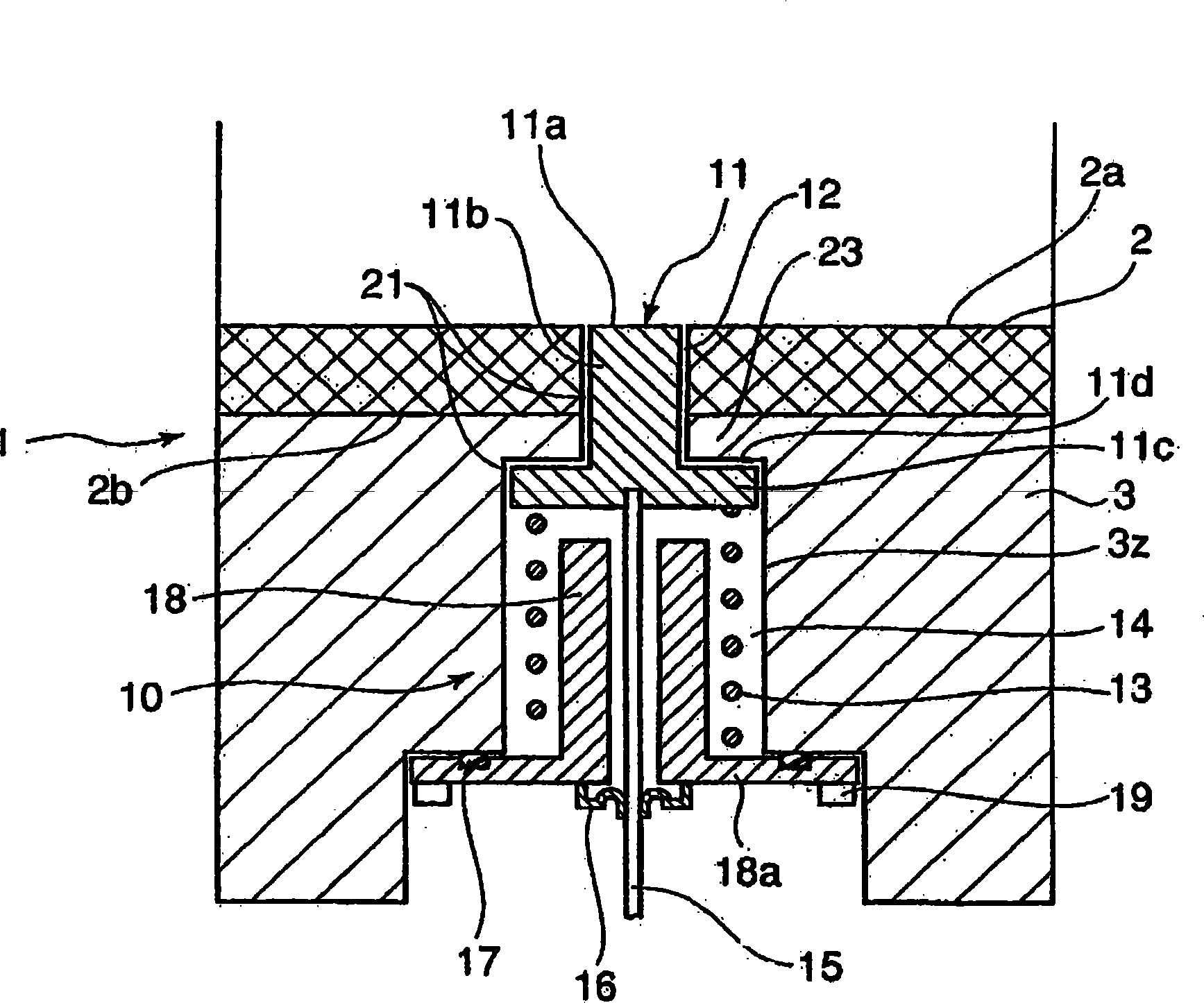

[0072] image 3 is a representation of the third embodiment of the present invention figure 1 Corresponding figure.

[0073] In this third embodiment, a protruding portion 23 is formed at the end portion of the lining metal member 3 on the side of the bearing member 2, and the protrusion amount limiting portion 11c of the temperature sensing member 11 is set by the mounting load of the spring 13 By abutting against the protruding portion 23 , the amount of protrusion of the temperature sensing member 11 toward the inner surface 2 a side of the bearing member 2 is restricted.

[0074] Other structures are the same as those of the first embodiment, and the same components are denoted by the same symbols.

[0075] According to the third embodiment, the temperature sensing member 11 is made to abut against the protruding portion 23 formed at the end portion of the backing metal fitting 3 on the bearing member 2 side. Supported by the lining metal member 3, the support rigidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com