Pressure dissolution type oxygenation device

An aeration device and pressure technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as low efficiency, high purchase and use costs, and high noise, and achieve aeration High efficiency, convenient maintenance, low cost of purchase and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

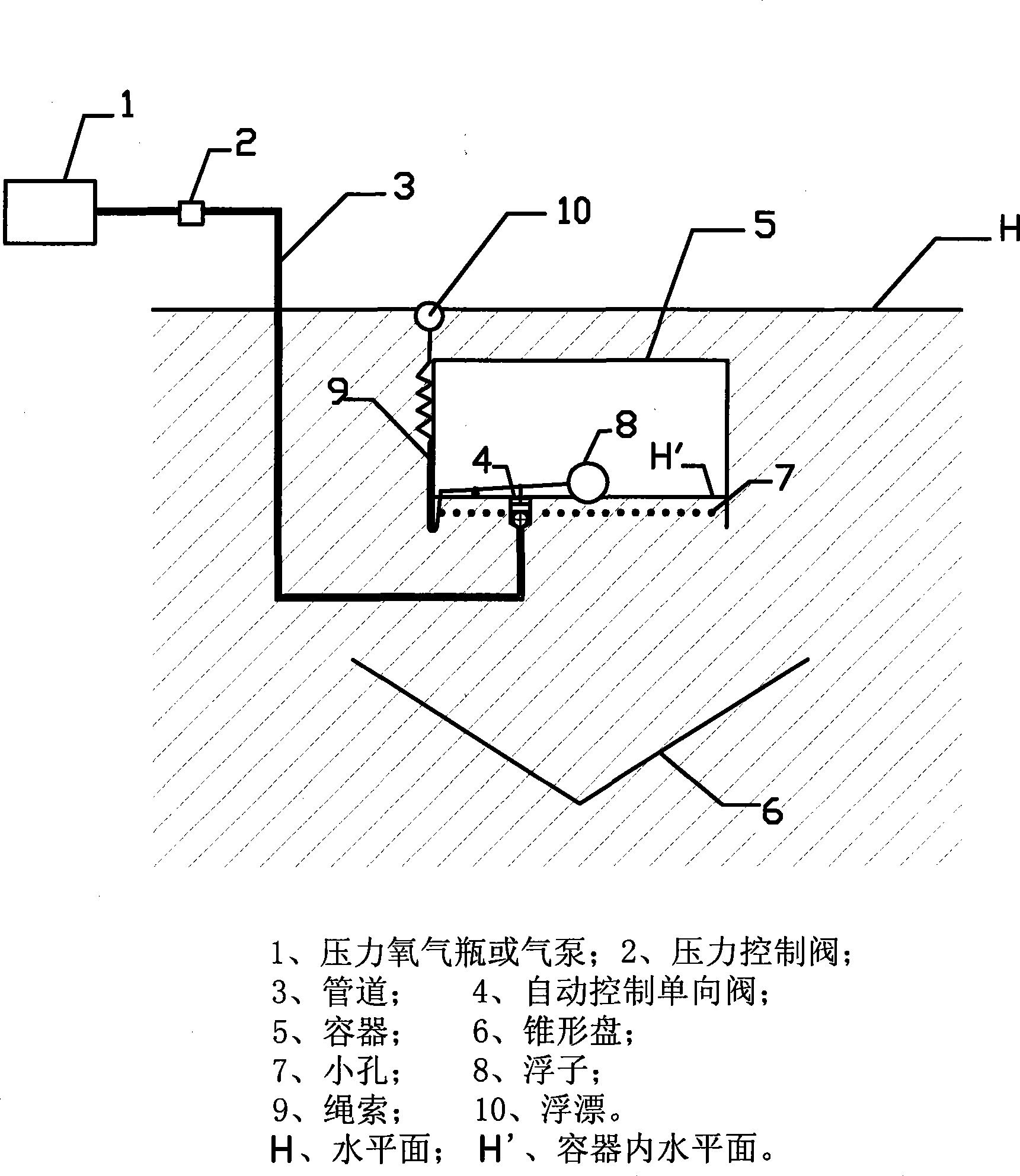

[0007] High-purity oxygen or higher-pressure air is provided by the pressure oxygen cylinder 1 (or air pump), etc., and the pressure is adjusted by the pressure-adjustable pressure-regulating valve 2 according to the need, and then the pressure-resistant tube 3 and the self-control check valve 4 are passed into the setting Below the open container 5 with a certain depth below the water surface, the bubbles that emerge are allowed to escape into the container 5. The pressure of the water surface height H'in the container 5 is equal to the pressure of the gas in the container, and it is also equal to H'and the water surface height. The pressure of the difference between H (H-H′) is in accordance with the formula P=ρg(H—H′), ρ (water density) gH (water surface height) is fixed, and the pressure P increases with the decrease of H′. The amount of oxygen also increases. A soft cable or a hard structure can be used below the container 5, and a conical disk 6 with a bottom area and geomet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com